Introduction: Navigating the Global Market for irrigation valve box sizes

In the complex landscape of global irrigation systems, sourcing the right irrigation valve box sizes presents a significant challenge for B2B buyers. Selecting an appropriate valve box is crucial, as it safeguards essential components, ensuring efficient maintenance and operation. This guide delves into the diverse types and applications of irrigation valve boxes, offering insights into supplier vetting, cost considerations, and best practices for installation. By equipping international buyers from regions such as Africa, South America, the Middle East, and Europe—particularly in countries like Germany and Nigeria—with comprehensive information, we aim to streamline the purchasing process.

Understanding the nuances of valve box sizes is vital for optimizing irrigation systems. A poorly sized valve box can lead to operational inefficiencies, increased maintenance costs, and potential damage to your irrigation infrastructure. This guide empowers buyers to make informed decisions by highlighting key factors that influence valve box selection, including material durability, design configurations, and compatibility with various valve types. Additionally, it addresses common challenges faced in different markets, providing actionable strategies to mitigate risks and enhance system performance. By the end of this guide, B2B buyers will be well-equipped to navigate the global market, ensuring that their irrigation systems are both effective and sustainable.

Understanding irrigation valve box sizes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Valve Box | Rectangular shape, typically 12″ x 18″, removable lid | Residential and small commercial setups | Pros: Cost-effective, easy to install. Cons: Limited space for multiple valves. |

| Jumbo Valve Box | Larger dimensions (e.g., 26″ x 20″), extra depth | Larger commercial systems | Pros: Ample space for multiple valves, enhanced accessibility. Cons: Higher cost and may require more excavation. |

| Super Jumbo Valve Box | Extra-large size (e.g., 33″ x 24″), dual locks | Large-scale agricultural applications | Pros: Maximum capacity, secure access. Cons: Bulkiness may complicate installation. |

| Round Valve Box | Circular design, typically 10″ or 12″ diameter | Tight spaces or retrofitting projects | Pros: Space-efficient, versatile. Cons: Limited valve capacity compared to rectangular options. |

| Anti-Siphon Valve Box | Built-in backflow prevention, often smaller | Areas with contamination risks | Pros: Protects water supply, compact design. Cons: May have limited access for multiple valves. |

What Are the Characteristics of Standard Valve Boxes?

Standard valve boxes are the most commonly used type for residential and small commercial irrigation systems. Typically measuring 12″ x 18″, they feature a removable lid for easy access to valves. Their compact size makes them a cost-effective choice, but buyers should consider that they may not accommodate multiple valves comfortably. B2B buyers often choose standard boxes for smaller projects where budget constraints are a priority.

Why Choose Jumbo Valve Boxes for Larger Applications?

Jumbo valve boxes offer larger dimensions, such as 26″ x 20″, providing ample space for multiple valves and enhanced accessibility for maintenance. These boxes are ideal for larger commercial irrigation systems where multiple valves need to be housed together. While they come at a higher cost than standard boxes, their benefits in terms of maintenance efficiency and reduced excavation time make them a valuable investment for B2B buyers managing extensive irrigation setups.

What Are the Advantages of Super Jumbo Valve Boxes?

Super jumbo valve boxes are designed for large-scale agricultural applications, featuring dimensions like 33″ x 24″ and dual locks for added security. They provide the maximum capacity for housing multiple valves, making them suitable for complex irrigation systems. However, their bulkiness can complicate installation, and they may require more excavation. B2B buyers in agriculture will find these boxes beneficial for maintaining extensive irrigation networks efficiently.

How Do Round Valve Boxes Fit into Irrigation Systems?

Round valve boxes, often available in sizes like 10″ or 12″ in diameter, are ideal for tight spaces or retrofitting existing systems. Their circular design allows for space-efficient installations, making them versatile for various applications. However, they typically have a lower capacity for multiple valves compared to rectangular designs. B2B buyers should consider round boxes when working in constrained environments where maximizing space is crucial.

When Should You Use Anti-Siphon Valve Boxes?

Anti-siphon valve boxes incorporate built-in backflow prevention, making them essential for areas prone to contamination risks. These boxes are often smaller, designed to protect a single valve while ensuring safe water supply. While their compact design is advantageous, they may not provide sufficient access for multiple valves. B2B buyers in regions with stringent water quality regulations should prioritize anti-siphon valve boxes to ensure compliance and safeguard their irrigation systems.

Key Industrial Applications of irrigation valve box sizes

| Industry/Sector | Specific Application of irrigation valve box sizes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Protecting irrigation systems in large-scale farming | Ensures operational efficiency and reduces repair costs | Need for durable materials to withstand environmental conditions |

| Landscaping | Housing valves in commercial landscaping projects | Facilitates easy maintenance and prolongs valve lifespan | Sizing must accommodate multiple valves for extensive projects |

| Municipal Water Management | Enclosures for valves in municipal irrigation networks | Enhances system reliability and minimizes water loss | Compliance with local regulations and standards for public infrastructure |

| Golf Course Management | Protecting irrigation valves in golf courses | Maintains aesthetic quality and operational efficiency | Requires larger valve boxes for complex irrigation systems |

| Sports Facilities | Housing irrigation valves in stadiums and sports complexes | Ensures consistent maintenance and efficient water usage | Consideration for high traffic areas and accessibility for repairs |

How Are Irrigation Valve Box Sizes Utilized in Agriculture?

In the agriculture sector, irrigation valve boxes are crucial for safeguarding the valves that control water flow in extensive farming operations. These boxes protect delicate equipment from soil erosion and environmental damage, ensuring that farmers can maintain optimal irrigation without frequent interruptions. International buyers from regions such as Africa and South America must consider the durability of materials due to varying climate conditions, ensuring that the boxes can withstand extreme weather while providing easy access for maintenance.

What Role Do Valve Boxes Play in Landscaping Projects?

In commercial landscaping, proper housing of irrigation valves is essential for both functionality and aesthetics. Valve boxes allow for organized maintenance access, reducing the need for extensive digging during repairs. Buyers should look for larger valve boxes that can accommodate multiple valves, particularly in expansive landscaping projects typical in urban developments across Europe and the Middle East. The choice of size and material affects long-term maintenance costs and system efficiency.

How Do Municipal Water Management Systems Benefit from Valve Boxes?

Municipal irrigation systems rely on robust valve boxes to protect vital components from damage, ensuring a reliable water supply for public parks and green spaces. These boxes help prevent water loss and system failures, which can lead to costly repairs. International buyers in this sector should prioritize compliance with local regulations, especially in Europe, where standards for public infrastructure are stringent. The selection of appropriate box sizes is critical to accommodate various valve types and configurations.

Why Are Valve Boxes Important for Golf Course Management?

In golf course management, irrigation valve boxes play a pivotal role in maintaining the lush landscapes that attract players and visitors. These boxes protect the valves from damage while providing easy access for regular maintenance, which is essential for efficient water management. Buyers should consider the specific requirements for larger valve boxes due to the complex irrigation systems used in golf courses, particularly in regions with high foot traffic, ensuring that maintenance can be performed without disrupting the play environment.

How Do Sports Facilities Utilize Irrigation Valve Boxes?

Sports facilities require effective irrigation systems to maintain the quality of their playing fields. Valve boxes are essential for housing and protecting the irrigation valves that ensure consistent watering schedules. The need for easy access for repairs and maintenance is critical, especially during peak usage times. Buyers must consider the size of the valve boxes to accommodate the specific irrigation setups used in these facilities, which may vary significantly based on the type of sport and the facility’s location.

3 Common User Pain Points for ‘irrigation valve box sizes’ & Their Solutions

Scenario 1: Choosing the Right Size for Multiple Valves

The Problem: B2B buyers often face the challenge of selecting an appropriate irrigation valve box size when accommodating multiple valves. A common mistake is underestimating the space required, leading to cramped conditions that complicate maintenance and repair tasks. This can result in having to dig up the valve box, wasting time and resources, and potentially damaging the valves themselves in the process. Such scenarios can lead to frustration, increased labor costs, and interruptions in service, impacting overall operational efficiency.

The Solution: To avoid this issue, buyers should perform a thorough assessment of the number of valves and their specific sizes before purchasing a valve box. It’s essential to opt for a valve box that is not only large enough to house all the valves but also provides sufficient room for maneuverability during maintenance. When sourcing valve boxes, consider options that come with adjustable pipe slots and removable tops, as these features can facilitate easy access and accommodate future expansions. Additionally, consulting with suppliers who offer expert guidance on sizing can help ensure that the chosen box meets current and future needs, minimizing the risk of costly replacements or adjustments down the line.

Scenario 2: Dealing with Leakage Issues in Valve Boxes

The Problem: Another prevalent issue among B2B buyers is the occurrence of water accumulation inside valve boxes, often due to leaking valves. This can create a challenging environment for maintaining the irrigation system, as wet conditions can lead to corrosion, electrical failures, and even damage to the surrounding landscape. The presence of water in the box can also complicate routine inspections and repairs, causing significant downtime and potential financial losses.

The Solution: To mitigate leakage issues, buyers should proactively inspect valves for wear and tear and replace any faulty components before they lead to leaks. Investing in high-quality valve boxes with proper drainage features can also be beneficial. When selecting a valve box, look for models designed with drainage holes or channels that allow any excess water to escape, thus maintaining a dry environment for the valves. Regular maintenance schedules should be established, where the valves are checked for leaks and the valve box is cleaned to prevent debris buildup. This not only prolongs the lifespan of the irrigation system but also enhances its efficiency.

Scenario 3: Ensuring Accessibility for Maintenance

The Problem: Accessibility is a critical pain point for B2B buyers when it comes to irrigation valve boxes. Many buyers fail to consider how deep the valve box should be buried, often opting for shallow installations that can lead to accessibility issues during maintenance. When valves are not easily reachable, repairs can require significant excavation, which is labor-intensive and time-consuming, ultimately leading to higher operational costs.

The Solution: To ensure easy access, buyers should install valve boxes at a depth that keeps them flush with the ground while still protecting the valves from damage. It’s advisable to follow manufacturer guidelines regarding installation depth and to consider local soil conditions that may affect the valve box’s integrity over time. Additionally, using larger valve boxes can help provide more room for tools and hands, making maintenance less cumbersome. Regular training for maintenance staff on best practices for accessing and servicing valves can further enhance efficiency and reduce the time spent on repairs. Implementing these strategies can lead to smoother operations and improved reliability of the irrigation system.

Strategic Material Selection Guide for irrigation valve box sizes

What Are the Key Materials for Irrigation Valve Box Sizes?

When selecting irrigation valve boxes, understanding the material composition is crucial for ensuring optimal performance, longevity, and compliance with regional standards. Here, we analyze four common materials used in irrigation valve box manufacturing: Polyethylene, PVC, Fiberglass, and Metal.

How Does Polyethylene Perform in Irrigation Valve Boxes?

Polyethylene (PE) is a thermoplastic polymer known for its excellent chemical resistance and durability. It can withstand a temperature range of -40°F to 140°F (-40°C to 60°C) and is resistant to corrosion, making it suitable for various soil conditions and weather patterns.

Pros: Polyethylene is lightweight and cost-effective, making it a popular choice for many irrigation systems. Its flexibility allows for easy installation, and it can endure impacts without cracking.

Cons: While PE is durable, it may not withstand extreme temperatures over long periods, leading to potential degradation. Additionally, it may not provide the same level of structural integrity as heavier materials.

Impact on Application: PE is compatible with most irrigation media, including water and fertilizers, but may not be suitable for high-pressure applications.

Considerations for International Buyers: Compliance with standards like ASTM F405 is essential, particularly in regions like Europe and North America. In markets such as Nigeria and South America, buyers should ensure that the material meets local environmental regulations.

What Advantages Does PVC Offer for Valve Boxes?

Polyvinyl Chloride (PVC) is another widely used material in irrigation valve boxes. It has a temperature rating of up to 140°F (60°C) and offers good resistance to corrosion and chemical exposure.

Pros: PVC is known for its rigidity and strength, providing excellent protection for valves. It is also lightweight and easy to work with, making installation straightforward.

Cons: The rigidity of PVC can be a disadvantage in areas with expansive soils, as it may crack under pressure. Additionally, it may not be as impact-resistant as other materials.

Impact on Application: PVC is suitable for most irrigation systems, but care should be taken in high-pressure scenarios. It is generally compatible with water and many chemicals used in irrigation.

Considerations for International Buyers: PVC products should comply with standards such as DIN 8061 in Europe. Buyers in the Middle East and Africa should check for local certifications to ensure quality and safety.

How Does Fiberglass Compare for Durability in Valve Boxes?

Fiberglass is a composite material that combines glass fibers with resin, offering exceptional strength and durability. It can withstand a wide temperature range and is resistant to corrosion, making it ideal for harsh environments.

Pros: Fiberglass is highly durable and can last for many years with minimal maintenance. Its resistance to UV rays and chemicals makes it suitable for outdoor applications.

Cons: The manufacturing process for fiberglass can be more complex and costly compared to other materials. Additionally, it may be heavier, complicating installation.

Impact on Application: Fiberglass valve boxes are suitable for high-pressure applications and can handle various media without degrading.

Considerations for International Buyers: Compliance with ASTM D3299 is essential for fiberglass products. Buyers in Europe and South America should verify that the products meet local regulations for construction materials.

Is Metal a Viable Option for Irrigation Valve Boxes?

Metal, particularly galvanized steel or aluminum, is another option for irrigation valve boxes. These materials have high strength and can withstand significant pressure and impact.

Pros: Metal valve boxes offer superior durability and can handle extreme conditions. They are also resistant to UV degradation and can be used in high-pressure applications.

Cons: The primary downside is the potential for corrosion, especially in moist environments. Regular maintenance may be required to prevent rust.

Impact on Application: Metal is suitable for applications where high strength is needed, but care must be taken to ensure that the metal is treated or coated to resist corrosion.

Considerations for International Buyers: Compliance with standards such as ASTM A123 for galvanized steel is crucial. Buyers in regions like Germany and Nigeria should ensure that the material meets local corrosion resistance standards.

Summary Table of Material Properties for Irrigation Valve Boxes

| Material | Typical Use Case for irrigation valve box sizes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene | Residential and light commercial irrigation systems | Lightweight and cost-effective | Limited temperature resistance | Low |

| PVC | General irrigation applications | Rigid and strong | Prone to cracking under pressure | Medium |

| Fiberglass | High-pressure and harsh environment applications | Exceptional durability | Higher manufacturing cost | High |

| Metal | Heavy-duty industrial irrigation setups | Superior strength and impact resistance | Susceptible to corrosion | Medium to High |

This strategic material selection guide aims to provide B2B buyers with actionable insights to make informed decisions when sourcing irrigation valve boxes, ensuring they choose the right materials for their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for irrigation valve box sizes

What Are the Key Stages in the Manufacturing Process of Irrigation Valve Boxes?

The manufacturing of irrigation valve boxes is a systematic process that involves several critical stages: material preparation, forming, assembly, and finishing. Understanding these stages can help B2B buyers make informed decisions when sourcing these products.

How Is Material Prepared for Irrigation Valve Boxes?

The first step in manufacturing irrigation valve boxes is material selection and preparation. Common materials include high-density polyethylene (HDPE), polypropylene, and other durable plastics known for their resistance to corrosion and weathering. Suppliers often utilize advanced techniques to ensure the materials are free from contaminants and meet industry standards. This may involve cleaning, granulation, and sometimes pre-conditioning the materials to enhance their performance characteristics.

What Techniques Are Used in Forming Irrigation Valve Boxes?

Forming is a critical stage where the prepared materials are shaped into the desired form. Techniques such as injection molding and rotational molding are commonly employed.

Injection Molding: This method involves injecting molten material into a mold to create the valve box. It allows for high precision and the ability to produce complex shapes, making it ideal for custom designs.

Rotational Molding: This technique is used for larger valve boxes. It involves heating the material in a mold that is rotated on multiple axes, ensuring an even coating and robust structure.

Both methods ensure that the valve boxes are durable and capable of withstanding the rigors of outdoor environments.

How Are Irrigation Valve Boxes Assembled?

After forming, the next step is assembly. This typically involves integrating components such as lids, sealing gaskets, and pipe slots. The assembly process is crucial for ensuring that all parts fit correctly and function as intended. Some manufacturers may use automated assembly lines for efficiency, while others may rely on skilled labor for intricate designs.

Quality checks during assembly ensure that any defects are caught early, reducing the risk of future failures and enhancing overall product reliability.

What Finishing Techniques Are Applied to Irrigation Valve Boxes?

Finishing is the final stage of manufacturing, where valve boxes undergo treatments to enhance their durability and aesthetics. This may include UV stabilization to prevent degradation from sunlight, surface treatments to improve scratch resistance, and coloring to meet branding or design specifications.

Effective finishing not only improves the product’s lifespan but also contributes to its visual appeal, which can be an important factor for B2B buyers who may consider aesthetic factors in their purchasing decisions.

What Are the Quality Assurance Measures for Irrigation Valve Boxes?

Quality assurance (QA) is vital in ensuring that irrigation valve boxes meet international standards and are suitable for various market demands. B2B buyers should be aware of the following QA measures and standards.

Which International Standards Apply to Irrigation Valve Box Manufacturing?

Manufacturers of irrigation valve boxes often adhere to international quality standards such as ISO 9001, which focuses on quality management systems. Compliance with ISO standards indicates that a manufacturer has processes in place to ensure consistent quality and customer satisfaction.

In addition to ISO standards, industry-specific certifications such as CE marking (in Europe) and API (American Petroleum Institute) certifications may apply, particularly for products used in critical applications.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are crucial in the manufacturing process to ensure that products meet specified standards. Key checkpoints typically include:

Incoming Quality Control (IQC): This involves inspecting raw materials before they enter the production line. Ensuring the quality of materials is fundamental to the final product’s integrity.

In-Process Quality Control (IPQC): During manufacturing, samples are taken at various stages to ensure that processes are functioning correctly and that products meet design specifications.

Final Quality Control (FQC): After assembly and finishing, a comprehensive inspection is conducted to verify that the final product meets all quality standards and specifications before shipping.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive measures to verify the QC practices of potential suppliers. This can include:

Conducting Audits: On-site audits allow buyers to assess manufacturing processes, quality control measures, and overall operational standards directly.

Requesting Quality Reports: Suppliers should be willing to provide detailed reports on their QC processes, including test results and compliance with relevant standards.

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices, adding an additional layer of assurance for buyers.

What Are the QC and Certification Nuances for International Buyers?

For international buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is essential. Different markets may have varying requirements regarding certifications, and compliance with local regulations is crucial.

How Can International B2B Buyers Navigate Certification Challenges?

B2B buyers should familiarize themselves with the specific certifications required in their respective markets. For example, while CE marking is essential for products sold in Europe, buyers in Africa may need to consider local standards such as SABS (South African Bureau of Standards) for South Africa or other regional certifications.

Establishing strong communication with suppliers regarding these requirements can ensure that the products meet local standards and avoid potential compliance issues.

What Role Does Supplier Reputation Play in Quality Assurance?

Finally, the reputation of a supplier can significantly influence the perceived quality of their products. Buyers should research potential suppliers, including their history in the industry, customer reviews, and any certifications they hold. A reputable supplier is more likely to have robust quality assurance processes in place, providing additional confidence to B2B buyers in their purchasing decisions.

By understanding the manufacturing processes and quality assurance measures for irrigation valve boxes, B2B buyers can make informed choices that align with their operational needs and market requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘irrigation valve box sizes’

Introduction

When procuring irrigation valve boxes, especially for diverse international markets, it’s essential to follow a structured approach. This checklist aims to guide B2B buyers through the critical steps of sourcing the right valve box sizes, ensuring optimal performance and maintenance of irrigation systems.

Step 1: Assess Your Project Requirements

Begin by clearly defining the specific requirements of your irrigation project. Consider factors such as the number of valves to be housed, the type of irrigation system, and environmental conditions.

- Why It Matters: An accurate assessment prevents costly mistakes and ensures that the selected valve box meets the operational demands of your system.

- What to Look For: Identify the dimensions and capacity needed, including whether you require a standard or jumbo-sized valve box.

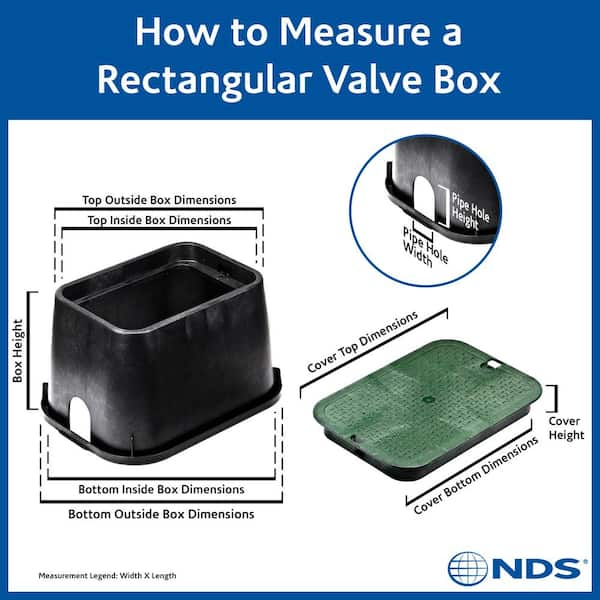

Step 2: Research Available Valve Box Sizes

Investigate the various sizes and shapes of valve boxes available in the market. Common options include round and rectangular designs with varying depths and widths.

- Why It Matters: Understanding the range of options helps you select a valve box that accommodates your specific valve configurations and maintenance needs.

- What to Look For: Evaluate the internal space and access features, such as removable tops and pipe slots, to facilitate easy installation and maintenance.

Step 3: Verify Material Durability and Quality

Evaluate the materials used in the valve boxes. Common materials include high-density polyethylene and fiberglass, known for their durability and resistance to environmental stressors.

- Why It Matters: High-quality materials prolong the lifespan of the valve boxes and protect your irrigation components from damage.

- What to Look For: Check for UV resistance, impact strength, and the ability to withstand extreme weather conditions prevalent in your region.

Step 4: Confirm Compatibility with Existing Systems

Ensure that the valve boxes you are considering are compatible with your existing irrigation system. This includes checking the fittings and valve types you currently use.

- Why It Matters: Compatibility issues can lead to installation challenges and increased costs for modifications.

- What to Look For: Review product specifications and consult with suppliers to ensure seamless integration with your current setup.

Step 5: Evaluate Supplier Reputation and Reliability

Research potential suppliers and assess their reputation in the market. Look for suppliers with a proven track record in providing high-quality irrigation components.

- Why It Matters: A reliable supplier can provide not only quality products but also customer support and warranties.

- What to Look For: Seek out customer reviews, case studies, and industry certifications to gauge the supplier’s credibility and service level.

Step 6: Request Samples and Technical Documentation

Before finalizing your purchase, request samples of the valve boxes along with technical documentation. This includes installation guidelines and maintenance instructions.

- Why It Matters: Samples allow you to physically assess the product quality and suitability for your needs.

- What to Look For: Ensure the documentation is comprehensive and easy to understand, facilitating a smooth installation process.

Step 7: Compare Pricing and Terms of Service

Finally, compare pricing from different suppliers, but don’t base your decision solely on cost. Consider terms of service, including warranties, return policies, and shipping options.

- Why It Matters: The lowest price may not always equate to the best value, especially if it compromises quality or service.

- What to Look For: Assess the total cost of ownership, including potential long-term savings from durable products and reliable service.

By following this checklist, B2B buyers can make informed decisions when sourcing irrigation valve boxes, ensuring efficient and effective irrigation systems tailored to their specific needs.

Comprehensive Cost and Pricing Analysis for irrigation valve box sizes Sourcing

What Are the Key Cost Components for Sourcing Irrigation Valve Boxes?

When assessing the costs associated with irrigation valve boxes, several critical components come into play. Materials are the primary expense, often comprising durable plastics or composites that can withstand environmental stressors. The labor cost includes wages for workers involved in manufacturing, assembly, and packaging. Additionally, manufacturing overhead encompasses utilities, facility costs, and equipment maintenance, which can vary significantly based on the location of production. Tooling costs are also relevant, especially for custom designs or sizes, while quality control (QC) processes ensure that products meet safety and performance standards. Finally, logistics costs, including shipping and handling, must be factored in, especially for international transactions, where tariffs and customs can add to the overall expense.

How Do Price Influencers Impact the Cost of Irrigation Valve Boxes?

Several factors influence the pricing of irrigation valve boxes. Volume and Minimum Order Quantity (MOQ) play a significant role; bulk purchases typically yield lower per-unit prices due to economies of scale. Specifications and customization can also drive prices up; unique dimensions or features often require specialized tooling and additional labor. The quality of materials and available certifications (like ISO or ASTM standards) can further affect pricing, as higher-quality materials often come at a premium. Supplier factors such as brand reputation and reliability can influence costs, with established brands generally commanding higher prices due to perceived value. Lastly, Incoterms define the responsibilities of buyers and sellers in international transactions, affecting logistics costs and overall pricing.

What Negotiation Tips Can Help Buyers Optimize Costs?

For B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe, negotiation is essential for cost optimization. Begin by researching market prices to establish a benchmark. Engage in discussions about Total Cost of Ownership (TCO), which includes not just the purchase price but also installation, maintenance, and potential downtime costs. Consider proposing long-term contracts to secure lower pricing through guaranteed volume. Additionally, leverage competition among suppliers by requesting quotes from multiple sources, which can foster a more favorable price. Be prepared to discuss payment terms and delivery schedules, as flexibility in these areas can sometimes lead to cost savings.

What Are the Pricing Nuances for International Buyers?

International B2B buyers face unique pricing nuances when sourcing irrigation valve boxes. Currency fluctuations can significantly impact costs; therefore, negotiating fixed prices in a stable currency may mitigate risks. Understand the logistics implications—shipping costs can vary dramatically based on the destination, so exploring various shipping options and Incoterms is vital. Moreover, consider local regulations and import duties that may apply, as these can add unforeseen expenses. For buyers in regions like Nigeria or Germany, ensuring compliance with local standards and certifications is crucial to avoid additional costs or delays.

Conclusion: Why Is It Important to Consider These Factors When Sourcing?

In conclusion, a comprehensive understanding of the cost structure, price influencers, and negotiation strategies is essential for B2B buyers sourcing irrigation valve boxes. By considering materials, labor, logistics, and more, buyers can make informed decisions that enhance cost efficiency and ensure the longevity of their irrigation systems. Keeping these factors in mind not only aids in budget planning but also fosters stronger supplier relationships, ultimately leading to better service and product quality. Always remember that prices can vary widely, so it is advisable to consult multiple suppliers for a more accurate cost analysis.

Alternatives Analysis: Comparing irrigation valve box sizes With Other Solutions

Exploring Alternatives to Irrigation Valve Box Sizes

When it comes to irrigation systems, selecting the appropriate method for managing valves is crucial for ensuring optimal performance and maintenance efficiency. While irrigation valve boxes are a popular solution, there are alternative technologies and methods that may suit specific requirements, particularly for international buyers in diverse markets. This section evaluates the merits of irrigation valve box sizes against two viable alternatives: above-ground valve covers and smart irrigation controllers.

| Comparison Aspect | Irrigation Valve Box Sizes | Above-Ground Valve Covers | Smart Irrigation Controllers |

|---|---|---|---|

| Performance | Excellent protection for underground valves; prevents soil and debris infiltration. | Provides easy access and visibility; however, may expose valves to weather. | Enables precise control of irrigation schedules and water usage; integrates with weather data. |

| Cost | Moderate initial investment; long-term savings on maintenance. | Generally lower cost; less durable than valve boxes. | Higher upfront cost; potential for significant water savings and efficiency gains. |

| Ease of Implementation | Requires excavation; installation can be labor-intensive. | Simple installation; no excavation needed. | Installation may require technical expertise; integration with existing systems can be complex. |

| Maintenance | Accessible for repairs; protects valves from damage. | Easy access for inspections; less protection against elements. | Requires regular software updates; remote monitoring capabilities simplify maintenance. |

| Best Use Case | Ideal for permanent installations in areas with high soil disturbance. | Suitable for temporary or less critical installations where visibility is prioritized. | Best for sophisticated systems needing automation and data-driven irrigation management. |

In-Depth Analysis of Alternative Solutions

Above-Ground Valve Covers

Above-ground valve covers serve as a practical alternative to underground valve boxes, especially in situations where quick access to valves is necessary. These covers protect valves from physical damage and allow for easy inspection. However, they may not shield against environmental factors like rain or extreme temperatures, leading to potential wear and tear. Additionally, while they are typically less expensive to purchase and install, their durability may not match that of traditional valve boxes, which could result in higher long-term costs due to repairs or replacements.

Smart Irrigation Controllers

Smart irrigation controllers represent a cutting-edge alternative that moves beyond physical housing solutions for valves. These devices utilize advanced technology to optimize watering schedules based on real-time weather data and soil conditions. The performance of smart controllers can significantly enhance water efficiency and reduce waste. However, they come with a higher initial investment and may require technical expertise for installation and integration with existing systems. For operations in regions where water conservation is critical, such as arid climates in Africa or South America, the long-term savings on water bills can justify the upfront costs.

Making the Right Choice for Your Irrigation Needs

When evaluating irrigation valve box sizes against these alternatives, B2B buyers should consider their specific operational needs, budget constraints, and the environmental conditions of their installation sites. If long-term protection and durability are priorities, investing in robust irrigation valve boxes may be the best choice. Conversely, for those seeking flexible, modern solutions that enhance water efficiency, above-ground valve covers or smart irrigation controllers might be more suitable. Ultimately, the decision should align with the overarching goals of the irrigation system, whether that be maintenance ease, cost-effectiveness, or advanced water management.

Essential Technical Properties and Trade Terminology for irrigation valve box sizes

What Are the Key Technical Properties of Irrigation Valve Box Sizes?

When selecting irrigation valve boxes, understanding specific technical properties is essential for ensuring optimal performance and longevity of your irrigation system. Here are some critical specifications to consider:

Material Grade

– Definition: The material grade refers to the quality and type of material used to manufacture the valve box, commonly high-density polyethylene (HDPE) or polypropylene.

– B2B Importance: High-quality materials resist environmental factors like UV exposure and corrosion, which is crucial in diverse climates, particularly in regions like Africa and the Middle East. Choosing durable materials minimizes replacement frequency and maintenance costs.Dimensions and Volume

– Definition: The dimensions (length, width, height) and volume capacity of the valve box dictate how many valves and related components it can accommodate.

– B2B Importance: Proper sizing ensures that maintenance is straightforward and that there’s adequate space for valve operation and repair. An appropriately sized box reduces the risk of damaging valves, which can lead to costly repairs.Load Capacity

– Definition: This specification indicates the maximum weight the valve box can support without deforming or breaking.

– B2B Importance: Understanding load capacity is vital for ensuring that the valve box can withstand the pressures from soil and vehicular traffic, particularly in agricultural or landscaped areas. It helps in preventing premature failure.Access Features

– Definition: Access features include removable lids, built-in pipe slots, and customizable configurations.

– B2B Importance: Easy access to valves for maintenance and repairs is critical to minimizing downtime in irrigation systems. Features that facilitate quick access can save labor costs and improve system efficiency.Weather Resistance

– Definition: This property refers to the ability of the valve box to withstand various weather conditions, including extreme temperatures, moisture, and UV radiation.

– B2B Importance: In regions with harsh climates, selecting weather-resistant boxes ensures that the irrigation system remains functional and reliable over time, reducing the need for replacements.Installation Depth

– Definition: This specification indicates how deep the valve box should be installed underground.

– B2B Importance: Proper installation depth protects the valves from environmental damage while ensuring easy access for maintenance. This is especially important in areas prone to flooding or soil erosion.

What Are Common Trade Terms in the Irrigation Valve Box Industry?

Familiarity with industry terminology can enhance communication and decision-making for B2B buyers. Here are some commonly used terms:

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts and equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships can help buyers identify reliable suppliers and ensure compatibility with existing irrigation systems.MOQ (Minimum Order Quantity)

– Definition: The MOQ is the smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers in planning their purchases effectively, particularly for large-scale projects in regions with varying demand.RFQ (Request for Quotation)

– Definition: An RFQ is a document that solicits price quotes from suppliers for specific products or services.

– Importance: Submitting an RFQ can lead to competitive pricing and ensure that buyers receive the best value for their investment.Incoterms (International Commercial Terms)

– Definition: Incoterms are a set of predefined international trade terms used to clarify the responsibilities of buyers and sellers.

– Importance: Familiarity with Incoterms helps buyers understand shipping responsibilities, costs, and risks, which is essential for international transactions.Lead Time

– Definition: Lead time is the period between the initiation of an order and its completion.

– Importance: Understanding lead times is critical for project planning, particularly in regions where delays can significantly impact agricultural cycles.Warranty

– Definition: A warranty is a guarantee provided by the manufacturer regarding the condition of the product and the commitment to repair or replace it if necessary.

– Importance: A robust warranty reflects the manufacturer’s confidence in their product and provides assurance to buyers regarding long-term investment security.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions when selecting irrigation valve boxes, ensuring that they meet the specific requirements of their irrigation systems.

Navigating Market Dynamics and Sourcing Trends in the irrigation valve box sizes Sector

What Are the Current Market Dynamics Influencing Irrigation Valve Box Sizes?

The global market for irrigation valve boxes is experiencing significant growth, driven by the increasing demand for efficient agricultural practices and sustainable water management. As regions in Africa, South America, the Middle East, and Europe face varying climatic challenges, the need for robust irrigation systems becomes critical. Key trends include the rise of smart irrigation technologies that integrate IoT devices, enabling real-time monitoring and control of water usage. This evolution is pushing manufacturers to innovate valve box designs that accommodate advanced features while ensuring ease of access for maintenance.

International B2B buyers are increasingly looking for suppliers that can provide customized solutions tailored to specific agricultural needs. The demand for larger valve boxes is also on the rise, as they allow for multiple valve installations, thus streamlining maintenance and enhancing system efficiency. Furthermore, with the shift towards localized sourcing, buyers are seeking suppliers who can offer competitive pricing without compromising on quality. This trend is particularly relevant in emerging markets where budget constraints are prevalent, yet the need for reliable irrigation solutions remains high.

How Does Sustainability and Ethical Sourcing Impact the Irrigation Valve Box Sector?

Sustainability has become a cornerstone of purchasing decisions in the irrigation valve box sector. B2B buyers are increasingly aware of the environmental impact of their sourcing choices, leading to a preference for suppliers that prioritize eco-friendly materials and manufacturing processes. The use of recycled plastics and other sustainable materials in valve box production not only minimizes waste but also enhances the overall durability and lifespan of the products.

Ethical supply chains are equally important, as buyers seek to ensure that their procurement practices do not contribute to social or environmental harm. Certifications such as ISO 14001 for environmental management systems and other ‘green’ certifications are becoming crucial in supplier selection processes. Buyers in regions like Europe, where regulatory frameworks around sustainability are stringent, are particularly focused on sourcing from suppliers who can demonstrate compliance with these standards. By aligning purchasing strategies with sustainability goals, businesses can enhance their brand reputation while contributing positively to global environmental efforts.

How Has the Evolution of Irrigation Valve Boxes Shaped Current Offerings?

The evolution of irrigation valve boxes has been marked by advancements in materials and design aimed at improving functionality and durability. Initially, valve boxes were predominantly made from basic materials with limited durability, often leading to frequent replacements and maintenance challenges. As the industry evolved, manufacturers began incorporating robust materials such as high-density polyethylene (HDPE) and other composites that resist corrosion and impact, thus extending the lifespan of these essential components.

Furthermore, the design of valve boxes has adapted to accommodate modern irrigation systems. Innovations such as built-in pipe slots, removable tops for easy access, and adjustable sizes cater to diverse irrigation setups, making it easier for operators to manage their systems effectively. This evolution reflects a broader trend in the agricultural sector towards increased efficiency and sustainability, ensuring that irrigation systems can meet the demands of modern farming while minimizing environmental impact. As international B2B buyers evaluate their options, understanding the historical context of these products can inform better purchasing decisions and align with current agricultural practices.

Frequently Asked Questions (FAQs) for B2B Buyers of irrigation valve box sizes

How do I determine the appropriate size for an irrigation valve box?

Choosing the right size for an irrigation valve box is critical for efficient maintenance and operation. Start by assessing the number of valves and their configuration in your irrigation system. A box should comfortably accommodate all valves while allowing sufficient working space for repairs and replacements. If you plan to use a valve manifold, opt for a larger box to ensure ease of access. Additionally, consider the depth of the box, which should be flush with the ground for protection yet accessible for maintenance.What is the best material for irrigation valve boxes in diverse climates?

The best materials for irrigation valve boxes depend on the climate and environmental conditions. For areas with extreme weather, such as high heat or freezing temperatures, high-density polyethylene (HDPE) and polypropylene are excellent choices due to their durability and resistance to UV rays and cracking. In regions prone to flooding, opt for water-resistant materials. Always consider local conditions and select products that can withstand specific environmental stressors while maintaining structural integrity.Can I customize the irrigation valve boxes for my specific needs?

Yes, many suppliers offer customization options for irrigation valve boxes. You can request specific dimensions, materials, or features such as built-in drainage slots or reinforced lids. Customization is especially beneficial for unique installations or to accommodate specific valve configurations. It’s advisable to discuss your requirements with your supplier and inquire about any additional costs or minimum order quantities associated with custom products.What are the common minimum order quantities (MOQs) for irrigation valve boxes?

Minimum order quantities can vary significantly between suppliers, often depending on the type of product and manufacturing capabilities. For standard valve boxes, MOQs may range from 10 to 100 units. Custom products typically have higher MOQs due to the additional resources required for tailored production. When sourcing internationally, confirm MOQs with suppliers and explore options for smaller orders or samples to assess product quality before making larger commitments.How do I vet suppliers for irrigation valve boxes?

To effectively vet suppliers, start by reviewing their industry experience and customer testimonials. Check for certifications and compliance with international quality standards, such as ISO or local regulations. Request samples to evaluate product quality and durability. Additionally, inquire about their manufacturing processes, lead times, and after-sales support. Engaging in direct communication and building a relationship can also provide insights into their reliability and responsiveness.What payment terms are typically offered by suppliers for irrigation valve boxes?

Payment terms can vary based on the supplier and the size of the order. Common arrangements include payment in full upfront, a deposit with the balance due upon shipment, or net payment terms (e.g., net 30 or net 60). For larger orders, some suppliers may offer financing options or payment plans. Always clarify payment terms before placing an order and consider securing a written agreement to avoid misunderstandings.What quality assurance measures should I expect from irrigation valve box suppliers?

Reputable suppliers typically implement strict quality assurance measures to ensure product reliability. This includes rigorous testing of materials and finished products for durability, weather resistance, and functionality. Look for suppliers who provide certifications and detailed quality control processes. Additionally, ask about warranties or guarantees, which can offer further assurance of product quality and supplier accountability.What logistics considerations should I keep in mind when importing irrigation valve boxes?

When importing irrigation valve boxes, consider shipping methods, lead times, and customs regulations in your destination country. Discuss logistics with your supplier to understand their shipping capabilities and whether they handle customs clearance. Factor in additional costs such as tariffs, handling fees, and insurance. It’s also wise to work with freight forwarders experienced in handling agricultural equipment imports, as they can help streamline the process and mitigate potential delays.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 3 Irrigation Valve Box Sizes Manufacturers & Suppliers List

1. Sprinkler Supply Store – Irrigation Valve Boxes

Domain: sprinklersupplystore.com

Registered: 2010 (15 years)

Introduction: Irrigation Valve Boxes protect sprinkler valves and manifolds from damage and facilitate maintenance. They are essential for keeping valves in a clean and safe environment, preventing issues caused by direct burial in soil. The boxes are available in rectangular or circular shapes, featuring traditional green removable tops and built-in pipe slots for easy water pipe access. The products are sourc…

2. NDS – Valve, Meter, and Telecom Boxes

Domain: ndspro.com

Registered: 1996 (29 years)

Introduction: NDS valve, meter, and telecom boxes are available in a range of sizes from 6 in. round to 17 in. x 30 in. rectangular. The product line includes: Standard Series Valve Boxes, ideal for residential or commercial use with a double wall at the top cover seat area and structural support ribs; Pro-Spec Series Valve Boxes, engineered for heavy-duty use with thick, corrugated sidewalls and reinforced cov…

3. Rain Bird – VB Series Valve Boxes

Domain: rainbird.com

Registered: 1995 (30 years)

Introduction: VB Series Valve Boxes are designed for easy installation and durability. Key features include unique knock-outs for pipe placement, engineered to maintain integrity under load, pest prevention bolt hole knock-out, and shovel access slot. Made from 100% recycled materials (black boxes and lids only), they are environmentally friendly and LEED-compliant. Dimensions vary by model: 7 Inch Round (8.4″ …

Strategic Sourcing Conclusion and Outlook for irrigation valve box sizes

In conclusion, effective strategic sourcing of irrigation valve boxes is pivotal for ensuring the longevity and efficiency of irrigation systems. Selecting the appropriate size and design not only enhances operational efficiency but also significantly reduces maintenance challenges. By opting for high-quality valve boxes that provide easy access and robust protection for valves, businesses can safeguard their investments and streamline their irrigation management processes.

For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, understanding the diverse options available is essential. Investing in the right valve box size tailored to specific irrigation needs can lead to improved system performance and reduced operational costs. Brands like Rain Bird and NDS offer a range of durable and reliable products that cater to various requirements.

As the global demand for efficient irrigation solutions continues to grow, now is the time to evaluate your sourcing strategies. Embrace the opportunity to enhance your irrigation systems by choosing the right valve box sizes that align with your operational goals. Let us move forward together, ensuring your irrigation infrastructure is not only effective but also sustainable for the future.