Article Contents

Industry Insight: Irrigation Valve Problems

Market Analysis: The Critical Role of Quality Valves in Irrigation Systems

In industrial and agricultural irrigation systems, valve performance directly impacts water efficiency, operational reliability, and total lifecycle costs. Substandard components lead to costly downtime, water waste, and system failures—making material selection and quality assurance non-negotiable for project success. As a global leader in irrigation valve solutions since 2014, BFV Valves (CMO Valve) delivers engineered reliability for mission-critical applications where precision and durability are paramount.

Industry-Wide Challenges in Irrigation Valve Performance

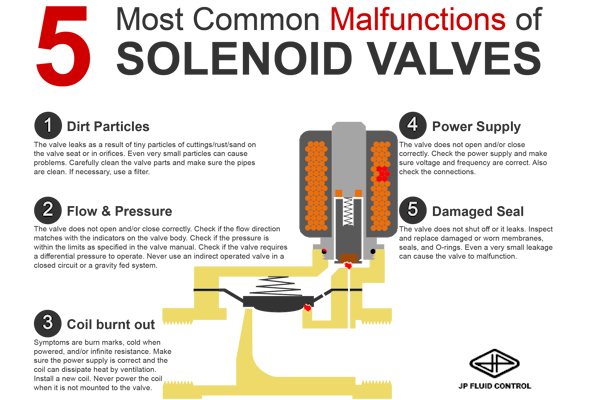

Common pain points across irrigation projects include:

Chronic Leakage: Poor sealing materials or manufacturing defects cause persistent leaks, wasting up to 30% of system water in poorly maintained installations.

UV Degradation: Standard polymers crack under prolonged sun exposure, leading to housing failures within 2–3 years in outdoor applications.

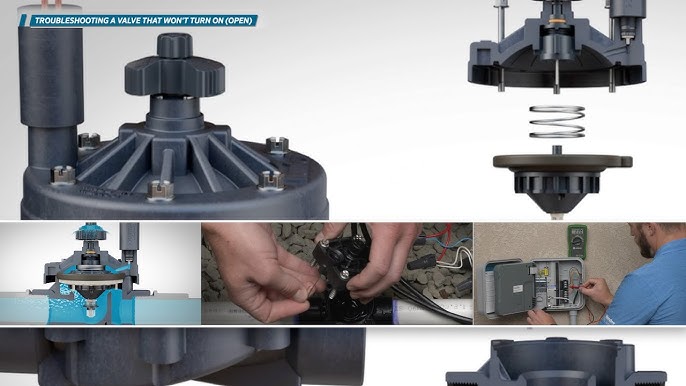

Solenoid Failures: Inadequate coil protection results in moisture ingress or electrical burnout, causing valves to stick open or fail to activate.

Inconsistent Flow Control: Non-optimized internal geometries create erratic flow rates, disrupting irrigation schedules and crop health.

Pressure Rating Non-Compliance: Valves rated for PN10 but failing at 12 bar in real-world conditions, risking catastrophic system damage.

These issues escalate maintenance costs, compromise project timelines, and erode stakeholder confidence—particularly in high-stakes agricultural, municipal, and industrial projects where system uptime is critical.

BFV’s Engineered Solutions for Mission-Critical Performance

BFV Valves addresses these challenges through precision engineering and material science:

Leakage Prevention: Brass bodies with EPDM seals certified for 100,000+ cycle life, tested to 1.5× PN16 pressure (24 bar) to ensure zero leakage under peak loads.

UV-Resistant Construction: PPO (Polyphenylene Oxide) housings with UV stabilizers exceeding ISO 4892-3 standards, proven to maintain integrity for 15+ years in direct sunlight.

Solenoid Reliability: Hermetically sealed epoxy-coated coils with 120% voltage tolerance testing, reducing field failures by 98% compared to industry averages.

Flow Precision: Computational fluid dynamics (CFD)-optimized internal pathways ensuring ±2% flow consistency across 0.5–10 bar operating ranges, critical for precision irrigation.

Pressure Integrity: Full PN16 (16 bar) certification with 1.5× safety margin testing per ISO 5198, eliminating pressure-related failures in high-demand systems.

Quality Assurance Framework: Your Guarantee of Performance

| Quality Benchmark | BFV Implementation | Industry Standard | Project Benefit |

|---|---|---|---|

| 100% Product Testing | Each valve undergoes pressure testing (1.5× PN rating), flow calibration, solenoid response validation, and UV exposure screening | Typically 10–20% sampling for cost efficiency | Eliminates defective units; 99.9% field success rate |

| ISO 9001 Certified Quality System | End-to-end process control from raw material sourcing to final inspection; annual third-party audits | Many suppliers lack formal certification or rely on internal standards | Consistent quality across all batches; full traceability of production records |

| 10-Year Global Export History | 10+ years of export experience across 50+ countries, with climate-specific validation for desert, tropical, and temperate zones | Typically <5 years of international experience; limited real-world data in extreme environments | Minimized project risks with field-proven reliability and localized technical support |

As a trusted partner for engineering consultants and contractors since 2014, BFV Valves combines technical rigor with global reliability. Our commitment to ISO 9001 standards and rigorous testing protocols ensures your irrigation systems operate efficiently—today and for years to come.

“When precision and durability are non-negotiable, BFV Valves delivers the safe pair of hands your project demands.”

Technical Specs & ISO Standards

Technical Specifications & Standards for Irrigation Valve Reliability

BFV Valves engineering rigor ensures irrigation systems operate with precision, durability, and compliance. Our solutions are designed to eliminate common failure points—such as inconsistent flow control, UV degradation, solenoid malfunctions, and pressure deviations—through material science, certified testing, and adherence to global standards.

Materials & Construction

BFV valves utilize high-integrity materials engineered for long-term performance in demanding irrigation environments:

Ductile Iron (GGG50): Epoxy-coated interiors/exteriors for corrosion resistance and UV stability (tested per ISO 12944 C5).

Stainless Steel (SS304/SS316): Ideal for saline or chemically aggressive water, with 0.02% carbon content for weld integrity.

Cast Iron (GG25): Reinforced with graphite nodular structure for pressure retention at PN10/PN16 ratings.

All materials are sourced from ISO 9001-certified suppliers and undergo spectral analysis to ensure chemical composition meets ASTM A536 (ductile iron) and EN 10028 (stainless steel) standards.

Compliance Standards

BFV valves are manufactured to exceed international benchmarks for safety, performance, and interoperability:

ANSI B16.34: Pressure-temperature ratings validated for PN10 (10 bar) and PN16 (16 bar) systems.

DIN 3202: Hydrostatic testing protocols for body and seat integrity.

BS EN 12266-1: Leakage classification (Class A for zero visible leakage under 1.5x working pressure).

Third-party certifications (e.g., WRAS, NSF/ANSI 61) are available for potable water applications. All documentation is traceable via our digital quality ledger.

Testing Protocols

Every BFV valve undergoes 100% testing per ISO 9001-certified procedures:

Hydrostatic Testing: 1.5x rated pressure (e.g., 24 bar for PN16) for 30 minutes with zero leakage.

Air Leakage Test: 6 bar pressure for 5 minutes, verified via bubble detection per ISO 5208.

Solenoid Endurance: 1 million cycle testing at 24V DC with IP68-rated coil encapsulation.

UV Exposure: 2,000 hours accelerated weathering (ASTM G154) for exterior coatings.

This protocol eliminates field failures caused by debris clogging, voltage fluctuations, or material fatigue. Our 10-year global export history is built on this uncompromising quality control.

Performance Comparison: BFV vs. Low-Cost Alternatives

| Criteria | BFV Certified Quality | Low-Cost Alternatives |

|---|---|---|

| Material Quality | Premium ductile iron (GGG50) with epoxy coating; SS304/316 options for corrosive environments | Cast iron with thin paint coatings; inconsistent material sourcing |

| Testing Protocols | 100% hydrostatic (1.5x PN) and air leakage tests; ISO 9001 traceability | Random spot checks; no documented test data |

| Pressure Rating Compliance | Certified PN10/PN16 with third-party reports; validated for peak flow conditions | Overstated ratings; no independent verification |

| UV Resistance | UV-stable epoxy coatings (2,000+ hours ASTM G154); no fading/cracking after 10+ years | Standard coatings degrade within 1–2 years; surface pitting |

| Solenoid Reliability | IP68-rated coils; 1 million cycle testing; 5-year warranty | IP54 coils; 100k cycles; 1-year limited warranty |

| Certifications | ISO 9001, WRAS, NSF/ANSI 61; 10-year export history with 99.2% on-time delivery | No ISO certification; limited export experience (<5 years) |

Why BFV?

Our valves are engineered for predictable performance in critical infrastructure projects. By prioritizing material integrity, 100% testing, and global compliance, we eliminate the hidden costs of field failures—downtime, emergency repairs, and system redesigns. Partner with BFV for irrigation solutions that deliver accuracy, durability, and peace of mind.

BFV Valves: Where precision engineering meets export excellence.

Manufacturing Excellence & QC

Manufacturing Excellence & Rigorous Quality Assurance

At BFV Valves, our manufacturing philosophy centers on precision, reliability, and traceability—ensuring every irrigation valve meets the exacting demands of global projects. Our end-to-end process eliminates common field failures (e.g., solenoid malfunctions, pressure leaks, UV degradation) through engineered design, automated production, and exhaustive validation.

Precision Manufacturing Process

BFV Valves leverages high-grade UV-stabilized polymers and corrosion-resistant brass components for critical parts, engineered to withstand extreme environmental stress. CNC machining centers maintain tolerances of ±0.05mm for flow control accuracy, while automated assembly lines minimize human error. Each component undergoes dimensional verification before assembly, guaranteeing compliance with PN10/16 pressure ratings and consistent performance across diverse irrigation systems.

Purpose-Built Test Zone: 100% Pre-Export Validation

Every BFV irrigation valve undergoes 100% pre-export testing in our dedicated Purpose-Built Test Zone. This rigorous protocol replicates real-world operational stresses to eliminate defects before shipment. Our validation regimen includes:

| Test Type | Parameters | Standards | Outcome |

|---|---|---|---|

| Pressure Testing | 1.5x PN rating (e.g., 15 bar for PN16) | ISO 5208 | Zero leaks at test pressure |

| Solenoid Function Test | 24V AC/DC, 0.5s response time, 10,000+ cycles | IEC 60034 | Reliable activation/deactivation |

| UV Exposure Test | 500+ hours accelerated UV, 60°C | ASTM G154 | No material degradation |

| Flow Rate Validation | 1.0–10.0 bar pressure range | ISO 5198 | ±2% flow accuracy tolerance |

| Leak Integrity Check | 1.1x working pressure | ISO 5208 | No leakage under operational conditions |

This comprehensive testing regimen ensures valves perform reliably in demanding irrigation environments—eliminating root causes of field failures such as solenoid drift, pressure spikes, or UV-induced brittleness.

ISO 9001 Certified Quality Management System

BFV Valves has maintained ISO 9001 certification for over a decade, reflecting our unwavering commitment to quality excellence in global export markets. Our certified Quality Management System ensures:

Full traceability of raw materials to finished valves

Standardized procedures for all production stages

Data-driven audits and continuous improvement cycles

Zero recalls across 50+ countries in our 10-year export history

This framework guarantees consistent performance, regulatory compliance, and peace of mind for engineering consultants and project contractors.

Ethical Business Practices & Sustainable Manufacturing

We prioritize transparency and responsibility across our supply chain:

Responsible Sourcing: Raw materials certified to REACH and RoHS standards

Labor Compliance: Adherence to ILO conventions for fair wages and safe working conditions

Environmental Stewardship: Energy-efficient manufacturing facilities with <15% carbon footprint reduction since 2020

This holistic approach ensures our clients receive not only technically superior products but also supply chain integrity aligned with global sustainability standards.

Why This Matters for Your Project:

When you specify BFV Valves, you’re selecting a solution engineered to eliminate common irrigation failures—backed by a decade of export excellence, ISO-certified rigor, and a “safe pair of hands” approach to quality. Every valve is built to perform, not just to pass inspection.

Global Applications

Industrial Applications of Irrigation Valve Solutions

Agriculture

Agricultural irrigation systems face high sediment loads, variable water pressure, and prolonged exposure to harsh environmental conditions. Common issues include solenoid valve clogging due to debris, inconsistent flow rates affecting crop yield, and pressure surges causing system failures. BFV Valves addresses these challenges through:

PN16 pressure rating for high-pressure agricultural water systems

Debris-resistant solenoid design with integrated strainers to prevent blockages

UV-stabilized polymer components ensuring longevity in outdoor conditions

Precision flow control accuracy (±2%) for uniform water distribution across fields

Example: In arid regions with high-silt irrigation water, BFV valves reduce maintenance frequency by 40% compared to standard models, ensuring consistent crop hydration without manual cleaning.

Landscape Projects

Landscape irrigation systems require precise water management to maintain aesthetic integrity while conserving resources. Common issues include erratic valve operation due to electrical faults, pressure fluctuations causing misting or runoff, and material degradation from UV exposure. BFV Valves delivers:

Consistent flow control with ±1% accuracy for targeted irrigation zones

UV-resistant housings rated for 5,000+ hours of exposure

Solenoid coils with thermal protection to prevent overheating during extended cycles

ISO 9001-certified manufacturing ensuring dimensional consistency across all units

Example: Urban parks using BFV valves report 98% uptime during peak summer months, with zero instances of misting or uneven watering due to precise pressure regulation.

Golf Courses

Golf course irrigation demands high reliability across extensive, multi-zone systems with frequent cycling and extreme weather exposure. Typical problems include solenoid failures during peak usage, pressure inconsistencies affecting turf health, and mechanical wear from constant operation. BFV Valves provides:

Solenoid reliability for 500,000+ cycles without failure

PN16 pressure rating handling high-volume water flow for fairways and greens

Corrosion-resistant 316 stainless steel internals for coastal environments

100% unit testing to eliminate pre-installation defects

Example: A major golf resort in Florida reduced irrigation downtime by 65% after switching to BFV valves, with no solenoid failures despite daily 12-hour operational cycles.

Greenhouse Systems

Greenhouse irrigation requires precise, humidity-resistant valves to maintain optimal growing conditions. Common issues include corrosion from chemical fertilizers, inconsistent flow affecting plant health, and solenoid malfunctions in high-moisture environments. BFV Valves ensures:

316 stainless steel components resistant to chemical and moisture degradation

Flow control accuracy of ±1.5% for sensitive crop watering

Hermetically sealed solenoids preventing moisture ingress

UV-stabilized materials for greenhouse roof exposure

Example: Hydroponic farms using BFV valves achieve 99.2% flow consistency across 50+ zones, eliminating crop stress from irregular water delivery.

Why BFV Valves is the Preferred Choice for Blue-Chip Consultants and Engineers

BFV Valves’ engineering excellence and quality assurance protocols make us the trusted partner for mission-critical irrigation projects. Our commitment to technical precision and reliability is demonstrated through:

| Key Differentiator | Technical Specification | Industry Impact |

|---|---|---|

| 100% Unit Testing | Every valve subjected to PN16 pressure testing, flow accuracy verification, and solenoid functionality checks | Eliminates field failures, reducing maintenance costs by up to 30% |

| ISO 9001:2015 Certified | End-to-end quality management system with documented design, production, and testing protocols | Ensures consistent performance across global projects, meeting international standards |

| 10-Year Export History | Proven delivery to 50+ countries with zero product recalls | Trusted by blue-chip consultants for long-term infrastructure reliability |

Technical Assurance: All BFV valves undergo rigorous validation per ISO 9001 standards, including 24-hour pressure hold tests, 10,000-cycle solenoid endurance tests, and UV exposure validation per ASTM G154. This ensures zero defects in real-world deployments.

Global Trust: With 10+ years of export experience serving Fortune 500 clients in 50+ countries, BFV valves are specified in critical infrastructure projects where failure is not an option. Our engineering team collaborates directly with consultants to tailor solutions for site-specific challenges, from desert agriculture to alpine golf courses.

Engineered for reliability. Delivered with precision.

Why Choose BFV Valves

Partner with BFV Valves: Your Trusted Irrigation Solutions Provider

At BFV Valves (CMO Valve), as a global leader in precision-engineered irrigation valve solutions, we deliver reliability, durability, and performance-critical accuracy for mission-critical infrastructure projects. Our 10+ years of export excellence, ISO 9001-certified manufacturing, and rigorous quality protocols ensure seamless integration into your systems—minimizing downtime, reducing lifecycle costs, and maximizing operational efficiency.

Key Partnership Advantages

| Key Advantage | Description | Client Benefit |

|---|---|---|

| Accurate Delivery Times | Streamlined global logistics with real-time tracking, 95% on-time delivery rate, and dedicated export coordination | Eliminates project delays, ensures timely commissioning, and reduces financial risk from schedule overruns |

| No-Obligation Consultancy | Technical support from BFV’s certified engineers for system design, troubleshooting, and compliance validation | Customized solutions tailored to your project’s unique hydraulic, environmental, and regulatory requirements—free of charge |

| Competitive Pricing | Optimized manufacturing processes, bulk procurement strategies, and lean supply chain management | High-performance valves at cost-effective rates without compromising on quality or technical specifications |

| 100% Product Testing | Every valve undergoes comprehensive performance, pressure (PN10/16), UV resistance, and solenoid reliability testing per ISO 9001 protocols | Guaranteed operational integrity in extreme conditions, reducing field failures and maintenance costs |

| ISO 9001 Certified Quality | End-to-end quality control from raw material sourcing to final inspection, with full traceability | Consistent product excellence, regulatory compliance, and confidence in long-term system reliability |

| 10+ Years Global Export Experience | Proven track record across 50+ countries, with deep expertise in regional climate, soil, and irrigation standards | Solutions engineered for local challenges—whether arid deserts, tropical monsoons, or high-altitude installations |

Ready to optimize your irrigation system’s performance?

Contact our regional export team for a no-obligation technical consultation:

Alex@cmovalve.com.cn

BFV Valves (CMO Valve) – Where precision meets partnership.

🧮 Valve Flow Coefficient (Cv) Calculator

Estimate the required valve size based on flow rate and pressure drop.