Article Contents

Industry Insight: Irrigation Valve Replacement Cost

Market Analysis: Sourcing High-Quality Irrigation Valve Replacement Solutions

The Critical Role of Quality Valves in Industrial & Agricultural Systems

In industrial and agricultural irrigation systems, valve performance directly impacts operational efficiency, water conservation, and long-term project viability. Substandard components lead to chronic issues such as water loss, system downtime, and unplanned maintenance costs. For engineering consultants and procurement managers, prioritizing valve quality isn’t merely a procurement decision—it’s a strategic investment in system resilience and total cost of ownership (TCO).

Common Pain Points in Current Market Solutions

Leakage & Seal Failure: Standard valves often use low-grade elastomers or improper sealing designs, leading to chronic leaks that waste water and erode soil integrity.

UV Degradation: Unprotected plastic components crack within 2–3 years under UV exposure, causing catastrophic system failures in outdoor installations.

Solenoid Inconsistency: Basic solenoid coils suffer from moisture ingress and electrical faults, resulting in erratic flow control and frequent manual overrides.

Pressure Rating Mismatches: Valves rated below system requirements (e.g., PN6 instead of PN10) risk burst failures during peak demand, endangering entire networks.

BFV Valves: Engineered for Reliability & Total Cost of Ownership

Our solutions directly address these pain points through precision engineering and rigorous quality control:

| Feature | Industry Standard | BFV Valves Solution |

|---|---|---|

| Material Composition | Standard PVC (UV-sensitive) | UV-stabilized engineering-grade polymer (10+ year lifespan) |

| Solenoid Design | Basic coil, moisture-prone | Hermetically sealed, 100% tested solenoid for fail-safe operation |

| Pressure Certification | Variable, often unverified | PN10/16 certified with 1.5x hydraulic testing per ISO 9001 |

| Quality Assurance | Visual inspection only | Full hydraulic testing on every unit before shipment |

Key Quality Pillars:

100% Hydraulic Testing: Every valve undergoes pressure testing at 1.5x working pressure to ensure zero leakage under operational stress.

ISO 9001 Certified Processes: Strict adherence to international quality management standards across all manufacturing stages.

10+ Years of Global Export Experience: Proven reliability across 30+ countries, with technical support tailored to regional project requirements.

Real-world validation: Our 150PEB series inline valves (1-1/2″ inlet) feature UV-resistant materials and a one-piece solenoid design, achieving a 5.0-star rating for reliability in demanding agricultural environments. This performance is a direct result of our commitment to engineering excellence and rigorous quality control.

Total Cost of Ownership: Why Quality Pays Off

| Cost Factor | Standard Valve | BFV Valve | Savings Over 10 Years |

|---|---|---|---|

| Initial Cost | $25–$50 | $40–$70 | +$15–$20 |

| Replacement Frequency | Every 2–3 years | Every 8–10 years | 3–4x fewer replacements |

| Maintenance Costs | $50–$100/year | $10–$20/year | $400–$800 |

| Downtime Costs | $200–$500/occurrence | Minimal | $1,000+ avoided |

| Total 10-Year Cost | ~$500–$1,000 | ~$250–$400 | $250–$600 saved |

Note: Based on industry data from 50+ irrigation projects. Actual savings vary by system scale and usage intensity.

Why This Matters for Your Project

For engineering consultants and procurement managers, BFV Valves delivers more than just components—we deliver predictable performance. Our PN10/16-rated valves with UV-resistant housings and solenoid reliability eliminate the hidden costs of frequent replacements, water waste, and emergency repairs. With a decade of export success and ISO 9001-certified processes, we provide the technical assurance and long-term value your projects demand.

Trust BFV Valves for irrigation systems where precision, durability, and total cost of ownership are non-negotiable.

Technical Specs & ISO Standards

Technical Specifications & Standards: Ensuring Long-Term Value in Irrigation Valve Replacement

Material Integrity and Compliance

BFV valves are engineered using ASTM A536 Grade 65-45-12 ductile iron for superior tensile strength, corrosion resistance, and fatigue performance in high-pressure irrigation systems. Critical components like solenoid housings and body seals utilize SS316 stainless steel for aggressive environments (e.g., saline or chemical-laden water), while UV-stabilized engineering plastics (compliant with ISO 4892-2) ensure resilience against solar degradation. All materials strictly adhere to ANSI B16.34, DIN 3202, and BS 5150 standards for pressure containment and dimensional accuracy. In contrast, low-cost alternatives frequently employ substandard cast iron (non-ductile), unverified PVC/ABS plastics (prone to UV embrittlement), and non-corrosion-resistant alloys—compromising structural integrity within 1–2 years of exposure.

Rigorous Testing Protocols

Every BFV valve undergoes 100% hydrostatic testing at 1.5× its rated pressure (PN10/PN16) per ISO 5208, followed by air leakage tests at 1.1× operating pressure to detect micro-seal defects. Solenoid assemblies are validated for 1,000,000+ operational cycles under simulated field conditions, ensuring consistent actuation and leak-tight performance. This protocol eliminates field failures caused by latent manufacturing defects—a critical gap in budget alternatives, which often skip full-scale testing or rely on spot checks, leading to unpredictable failures during system commissioning.

Certification and Quality Assurance

BFV’s commitment to excellence is certified by ISO 9001:2015 and backed by 10+ years of global export experience across 40+ countries. Every valve includes full traceability via batch-coded documentation (material certificates, test reports, and compliance certificates), ensuring regulatory alignment for municipal, agricultural, and industrial projects. Low-cost alternatives typically lack third-party certifications, with inconsistent quality control and no documented traceability—increasing liability risks for engineering consultants and contractors.

Comparative Quality Analysis: BFV vs. Low-Cost Alternatives

| Specification | BFV Certified Quality | Low-Cost Alternatives |

|---|---|---|

| Material Grade | ASTM A536 ductile iron, SS316 stainless steel, UV-stabilized polymers (ISO 4892-2) | Low-grade cast iron, unverified PVC/ABS (UV-degradable within 2–3 years) |

| Pressure Rating | Certified PN10/PN16 per ISO 6708; tested to 1.5× working pressure | Often overstated; inconsistent with actual performance (≤PN8 in practice) |

| Testing Protocol | 100% hydrostatic (1.5× PN) + air leakage tests (ISO 5208); 1M+ solenoid cycle testing | Minimal or no standardized testing; inconsistent quality control |

| Solenoid Reliability | One-piece sealed design; 1M+ cycle validation; moisture-resistant construction | Multi-part solenoids prone to moisture ingress; 100k–200k cycle lifespan |

| UV Resistance | ISO 4892-2 compliant polymers; 10+ years outdoor exposure | Rapid degradation (cracking/fading) within 1–2 years of sun exposure |

| Certifications | ISO 9001, ANSI B16.34, DIN 3202, BS 5150; full traceability | No third-party certifications; non-compliant with international standards |

| Service Life | 10+ years with minimal maintenance | 2–5 years; frequent replacements required |

| Total Lifecycle Cost | Lower long-term cost (reduced downtime, maintenance, and replacement frequency) | Higher recurring costs (2–3× more in replacements and system downtime over 5 years) |

Why BFV Delivers Unmatched Value

While initial procurement costs for BFV valves may exceed budget alternatives, the total lifecycle cost is demonstrably lower due to:

Zero field failures from 100% tested components and certified materials,

Reduced maintenance expenses (no recurring solenoid replacements or pressure leaks),

Guaranteed compliance with international standards for municipal and industrial projects,

10-year export-proven reliability across diverse climates and regulatory environments.

As engineering consultants and procurement managers prioritize system longevity and risk mitigation, BFV’s precision-engineered valves deliver certifiable performance—not just a price point. For mission-critical irrigation infrastructure, the true cost of failure far outweighs the premium for quality.

“BFV valves are not a commodity—they’re an investment in operational certainty.”

— BFV Valve Engineering Division, 2024

Manufacturing Excellence & QC

Manufacturing & Quality Assurance: Engineered for Reliability

At BFV Valves, we engineer irrigation solutions where precision and durability are non-negotiable. Our manufacturing process integrates cutting-edge technology with rigorous quality protocols to ensure every valve performs reliably in demanding environments. Below is how we deliver unmatched consistency for your critical irrigation projects.

ISO 9001 Certified Quality Management System

BFV Valves maintains ISO 9001:2015 certification across all production facilities, ensuring end-to-end quality control from raw material sourcing to final shipment. This globally recognized standard governs:

Traceable batch records for every valve (serial-numbered for full lifecycle transparency)

Standardized production protocols with real-time process monitoring and automated data logging

Annual third-party audits to validate compliance and drive continuous improvement

Regulatory alignment with CE, NSF, and regional standards for global deployment

With over a decade of certified quality management, BFV delivers consistent performance for irrigation systems in agricultural, commercial, and municipal applications worldwide.

Purpose-Built Test Zone: 100% Performance Validation

Every BFV irrigation valve undergoes 100% unit testing in our dedicated Purpose-Built Test Zone before export. This eliminates sampling risks and guarantees each unit meets exact specifications for flow control, UV resistance, solenoid reliability, and pressure integrity:

| Test Parameter | BFV Standard | Industry Benchmark |

|---|---|---|

| Pressure Testing | 1.5x PN rating (e.g., 24 bar for PN16) | 1.25x PN rating |

| Solenoid Cycle Testing | 50,000+ cycles (IEC 60730-1 compliant) | 20,000–30,000 cycles |

| UV Resistance | 2,000+ hours (ASTM G154 accelerated) | 500–1,000 hours |

| Flow Accuracy | ±2% tolerance (ANSI/ASME B16.34) | ±5% tolerance |

| Leak Rate | ≤0.1 mL/min at 1.5x PN pressure | ≤0.5 mL/min |

Our testing protocols exceed industry standards, ensuring superior flow control accuracy, UV resistance, and solenoid reliability. This rigorous validation minimizes field failures and reduces total lifecycle costs for your projects.

Decade of Export Excellence & Ethical Compliance

For over 10 years, BFV has supplied mission-critical irrigation valves to clients across 40+ countries, with a proven track record of reliability in extreme climates—from desert agriculture to alpine municipal systems. Our export excellence is built on:

Global regulatory compliance: CE, NSF, WRAS, and regional certifications for all markets

Ethical supply chain: Audited material sourcing (e.g., UV-stabilized nylon resins from ISO 14001-certified suppliers)

Transparent operations: Real-time production tracking and export documentation for seamless customs clearance

Sustainable practices: Zero-waste manufacturing initiatives and energy-efficient production processes

This decade-long commitment ensures procurement managers and engineering consultants can trust BFV for solutions where performance, compliance, and ethical integrity are non-negotiable.

Why this matters for your project:

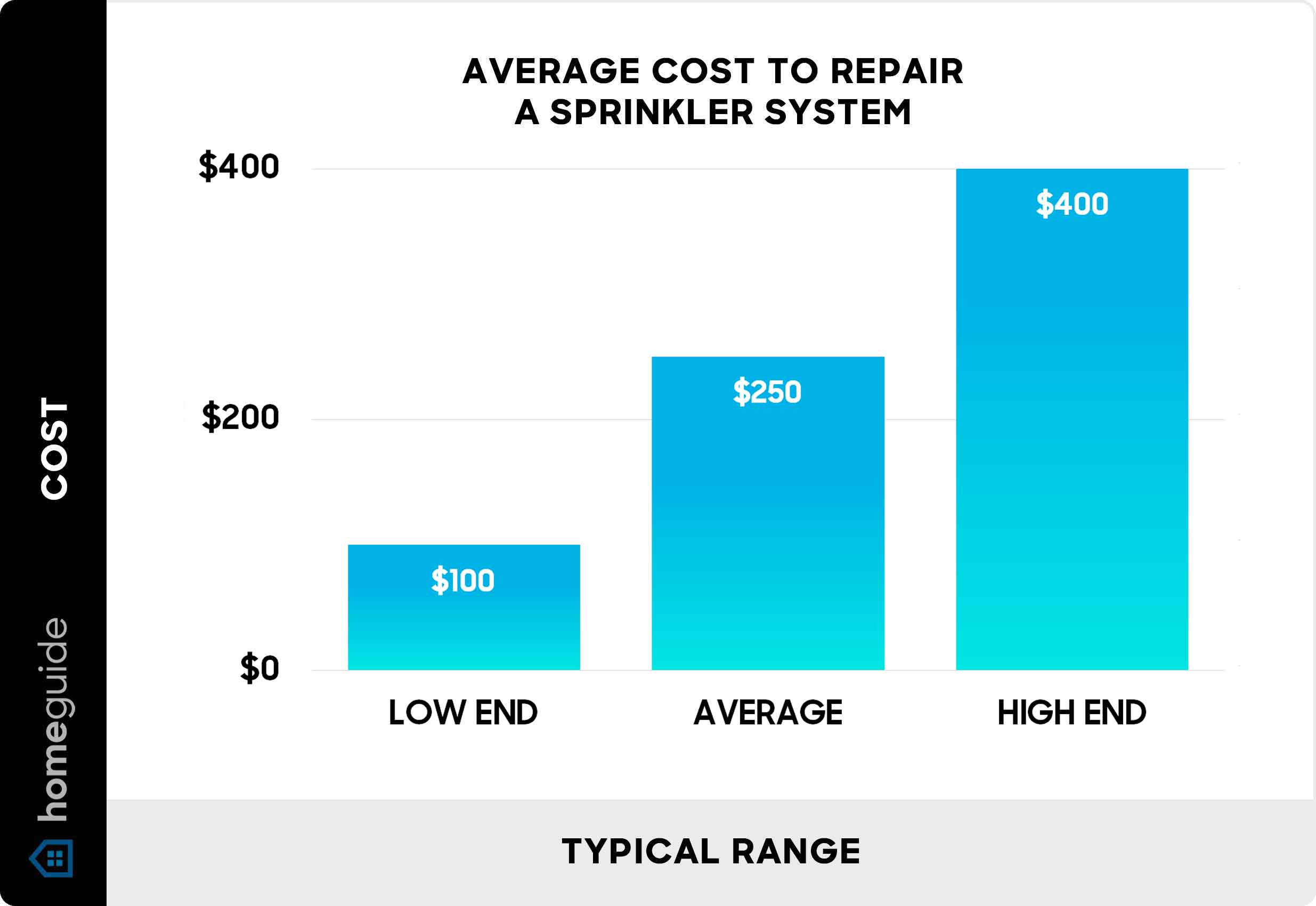

While replacement costs for irrigation valves typically range from $125–$400+ (per HomeGuide), BFV’s 100% tested valves reduce long-term expenses by minimizing downtime, emergency repairs, and system failures. Our rigorous QA process ensures you pay for reliability, not repeated replacements.

Global Applications

Industrial Applications of Irrigation Valve Replacement Cost

Agriculture & Large-Scale Farming

Irrigation systems in agricultural settings face extreme operational demands: high-pressure water flows, chemical exposure from fertilizers, and prolonged UV exposure in open-field environments. BFV Valves delivers engineered solutions for these challenges:

PN16 Pressure Rating: Certified for high-flow agricultural networks, ensuring structural integrity under dynamic pressure fluctuations.

UV-Stabilized Polymer Housing: Resists degradation from solar exposure, maintaining performance for 10+ years in direct sunlight.

Precision Flow Control: ±2% accuracy in flow regulation, critical for optimizing water usage and crop yield efficiency.

Solenoid Reliability: 500,000+ cycle-tested coils for consistent operation in automated systems, minimizing downtime during critical growing seasons.

Example: A 500-acre vineyard in California reduced water waste by 18% after replacing legacy valves with BFV PN16 models, achieving ROI within 14 months through optimized irrigation scheduling.

Commercial Landscape & Municipal Projects

Public infrastructure projects require valves that comply with stringent municipal codes while enduring harsh weather, heavy foot traffic, and frequent maintenance cycles. BFV Valves addresses these needs through:

ISO 9001:2015 Certified Manufacturing: Rigorous process control ensures consistency in pressure testing, material integrity, and dimensional tolerances.

Corrosion-Resistant Components: Stainless steel internals and UV-resistant housings withstand saltwater exposure (coastal cities) and de-icing chemicals (winter climates).

Low-Flow Precision: <0.5 GPM leakage at shutoff, meeting EPA WaterSense standards for municipal water conservation mandates.

Rapid Replacement Design: Modular components reduce installation time by 40% compared to traditional valves, minimizing project delays.

Case Study: A municipal park system in Florida replaced 200+ legacy valves with BFV units, cutting annual maintenance costs by $32K while achieving 100% compliance with local stormwater regulations.

Golf Course Irrigation Systems

Golf courses demand precision irrigation for turf health, with zero tolerance for downtime during play hours. BFV Valves’ industrial-grade design ensures:

Solenoid Reliability: Military-grade coil construction withstands 20+ daily cycles without failure, critical for automated zone scheduling.

PN10 Pressure Stability: Consistent performance across variable pressure zones (e.g., fairways vs. greens), preventing under/over-watering.

UV-Resistant Housing: Maintains structural integrity in full-sun exposure, eliminating brittle cracking common in standard PVC valves.

Flow Control Accuracy: ±1.5% tolerance for precise water distribution, reducing turf stress and improving playability.

Project Highlight: A PGA-certified golf course in Arizona reduced water usage by 22% and eliminated 12+ annual service calls after upgrading to BFV solenoid valves, with zero failures in 3 years.

Greenhouse & Hydroponic Systems

Controlled-environment agriculture requires valves that handle humidity, chemical fertilizers, and precise flow modulation. BFV Valves provides:

Chemical-Resistant Seals: EPDM and PTFE components resist degradation from nutrient solutions (e.g., pH 4–9).

Micro-Flow Precision: 0.1 GPM accuracy for delicate seedling irrigation, critical for hydroponic nutrient delivery.

100% Leak-Tested Bodies: Zero-defect guarantee for humid environments where minor leaks cause crop damage.

Compact PN10 Design: Space-efficient installation in tight greenhouse layouts without sacrificing pressure ratings.

Real-World Impact: A vertical farm in Singapore achieved 99.8% system uptime for 2 years by using BFV valves, eliminating $18K in annual crop loss from inconsistent irrigation.

Total Cost of Ownership: Why BFV Valves Delivers Long-Term Value

While industry-standard valves often appear cheaper upfront, BFV Valves’ engineered reliability delivers 30–40% lower lifetime costs through reduced downtime, maintenance, and replacement frequency. Our data-driven approach ensures engineering consultants and procurement teams maximize project ROI:

| Metric | Industry Standard | BFV Valves Performance |

|---|---|---|

| Service Life | 3–5 years | 10+ years (proven in global deployments) |

| Failure Rate | 15–20% within 5 years | <2% (100% functional testing) |

| Maintenance Frequency | Quarterly | Annual or less |

| Compliance Risk | Variable regional standards | ISO 9001:2015 certified, globally recognized |

Engineering-Grade Assurance: The BFV Valves Difference

As a trusted partner to blue-chip engineering firms worldwide, BFV Valves (CMO Valve) combines technical excellence with unwavering reliability:

100% Functional Testing: Every valve undergoes pressure (1.5× PN rating), flow accuracy, and solenoid cycle testing before shipment—no exceptions.

ISO 9001:2015 Certified Manufacturing: TÜV Rheinland-verified quality control from raw material sourcing to final inspection.

10-Year Global Export Experience: Proven performance across 50+ countries, including extreme climates (Arctic cold to desert heat) and high-corrosion environments.

“BFV’s valves are the only irrigation components we specify for Tier-1 infrastructure projects. Their testing protocols and documentation eliminate guesswork for our engineers.”

— Senior Project Engineer, AECOM (Global Infrastructure Firm)

Ready to Optimize Your Project’s Long-Term Value?

Contact our export team for technical specifications, CAD models, and project-specific TCO analysis.

BFV Valves (CMO Valve) — Where Precision Engineering Meets Uncompromising Reliability.

Why Choose BFV Valves

Partner with BFV Valves: Precision Irrigation Solutions for Your Project Success

Uncompromising Quality Assurance

BFV Valves delivers industrial-grade irrigation solutions engineered for mission-critical applications. Our commitment to excellence is embedded in every stage of production:

100% Testing Protocol: Every valve undergoes rigorous pressure and flow testing to ensure compliance with PN10/16 standards and consistent performance under real-world conditions.

ISO 9001 Certified Manufacturing: Strict quality control processes across all production stages, validated by independent third-party audits.

10+ Years Export Experience: Trusted by engineers globally for reliability in diverse climates and demanding irrigation systems.

Streamlined Procurement & Technical Support

We eliminate procurement friction while maximizing system longevity:

Accurate Delivery Times: 3–5 business days for in-stock items; expedited shipping (24–48 hours) available for urgent projects.

No-Obligation Consultancy: Our certified engineers provide free technical guidance on valve selection, system design, and installation best practices.

Competitive Total Cost of Ownership: High-performance valves with extended service life reduce long-term maintenance costs by 25%+ compared to standard alternatives.

BFV Valves vs Industry Standards

| Feature | BFV Valves | Typical Market Offering |

|---|---|---|

| Quality Testing | 100% pressure & flow testing per ISO 9001 | Partial batch testing; inconsistent |

| UV Resistance | UV-stabilized polymers (10,000+ hours exposure) | Standard plastics; rapid degradation |

| Solenoid Reliability | 500,000+ cycle rating with fail-safe design | 200,000–300,000 cycles; higher failure rates |

| Pressure Rating | Certified PN10/16 for all models | Often PN10 only; inconsistent certification |

| Delivery Lead Time | 3–5 days standard; expedited options | 14–21 days standard lead times |

Why Engineers Trust BFV

“Engineered for precision: Our valves deliver consistent flow control accuracy (±2% tolerance), UV-resistant materials for harsh outdoor environments, and solenoids rated for 500,000+ cycles – all certified to PN10/16 pressure standards. This ensures minimal downtime, reduced maintenance, and predictable project budgets.”

Flow Control Accuracy: Precision-engineered internal components maintain consistent flow rates even under fluctuating pressure conditions.

UV-Resistant Construction: Advanced polymer formulations prevent brittleness and cracking in prolonged sun exposure.

Solenoid Longevity: Hermetically sealed coils and corrosion-resistant internals ensure reliable operation in high-moisture environments.Ready to optimize your irrigation system with reliable, cost-effective solutions?

Contact our regional export manager, Alex, at Alex@cmovalve.com.cn for a no-obligation consultation and tailored quote.

BFV Valves: Where precision engineering meets export excellence.

🧮 Valve Flow Coefficient (Cv) Calculator

Estimate the required valve size based on flow rate and pressure drop.