Introduction: Navigating the Global Market for irrigation valve wiring

In the rapidly evolving landscape of agricultural technology, sourcing the right irrigation valve wiring can pose significant challenges for international B2B buyers. Whether you’re managing large-scale agricultural operations in Brazil or optimizing water management systems in Nigeria, understanding the intricacies of irrigation valve wiring is crucial for ensuring efficient water distribution and system longevity. This guide offers a comprehensive exploration of the various types of irrigation valve wiring, their applications across diverse environments, and the critical factors to consider when selecting suppliers.

Navigating the global market requires a keen understanding of local needs and international standards. This guide not only details the essential components—such as direct burial wire, waterproof connectors, and solenoid connections—but also provides insights into supplier vetting processes, cost considerations, and installation best practices. Our goal is to empower you with the knowledge necessary to make informed purchasing decisions, enhancing your operational efficiency and sustainability.

As you delve into this resource, you will find actionable insights tailored to the unique challenges faced by B2B buyers in Africa, South America, the Middle East, and Europe. By equipping yourself with this information, you can streamline your procurement process, mitigate risks, and ultimately enhance the performance of your irrigation systems.

Understanding irrigation valve wiring Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Direct Burial Wire | Designed for underground use; moisture-resistant sheath | Agricultural irrigation systems | Pros: Durable, protects against moisture. Cons: Installation requires digging. |

| Common Wire | Multi-stranded, available in various gauges; cost-effective | Residential and commercial irrigation | Pros: Affordable, versatile. Cons: May require additional protection for long runs. |

| Flow Sensor Communication Wire | Specially designed for sensor connections; multi-conductor | Automated irrigation systems | Pros: Facilitates real-time monitoring. Cons: More expensive than standard wire. |

| Waterproof Wire Connectors | Sealed connections for moisture exposure; ensures reliability | All irrigation systems | Pros: Enhances durability, prevents short circuits. Cons: Higher upfront cost. |

| Pigtail Plugs | Simple connections for solenoids; easy to install | Quick repairs and installations | Pros: User-friendly, reduces installation time. Cons: Limited to specific applications. |

What Are the Characteristics of Direct Burial Wire in Irrigation Systems?

Direct burial wire is specifically engineered for underground irrigation applications, featuring a robust thermoplastic sheath that guards against moisture and environmental damage. This wire is typically available in 16 and 18 gauges, making it suitable for various lengths and valve configurations. When considering B2B purchases, buyers should evaluate the wire’s gauge based on the distance from the controller to the valves, ensuring that it can handle the required electrical load. Proper installation is essential, as it involves burying the wire to protect it from physical and UV damage.

How Does Common Wire Differ from Other Types of Irrigation Wiring?

Common wire is a versatile option frequently utilized in both residential and commercial irrigation systems. This multi-stranded wire is available in various gauges and colors, allowing for easy identification and installation. Its affordability makes it an attractive choice for budget-conscious buyers, but it may not provide the same level of protection as direct burial wire for long runs. When purchasing, B2B buyers should consider the installation environment and whether additional protective measures, such as conduit, are necessary for optimal performance.

What Role Does Flow Sensor Communication Wire Play in Irrigation Automation?

Flow sensor communication wire is essential for connecting sensors to controllers in automated irrigation systems. This type of wire typically features multiple conductors, allowing for efficient data transfer and real-time monitoring of water flow. While this wire can be more expensive than standard options, its ability to enhance system efficiency and reduce water waste makes it a worthwhile investment for businesses focused on sustainability. Buyers should assess the specific sensor requirements and compatibility with existing systems when making purchasing decisions.

Why Are Waterproof Wire Connectors Important for Irrigation Systems?

Waterproof wire connectors are crucial for ensuring the reliability and longevity of irrigation systems, especially in areas prone to moisture. These connectors provide sealed connections that prevent short circuits and electrical failures, thus minimizing downtime and maintenance costs. While they may come at a higher initial expense, the enhanced durability and performance they offer can lead to significant long-term savings. B2B buyers should prioritize these connectors in their procurement processes to ensure the integrity of their irrigation systems.

How Do Pigtail Plugs Simplify Irrigation System Installations?

Pigtail plugs are designed for quick and easy connections between solenoid valves and controllers, making them ideal for installations and repairs. Their user-friendly design allows for rapid assembly, which can significantly reduce labor costs and installation times. However, their application is somewhat limited to specific scenarios, so buyers should ensure compatibility with their existing systems. For businesses looking to streamline their installation processes, investing in pigtail plugs can provide a practical solution.

Key Industrial Applications of irrigation valve wiring

| Industry/Sector | Specific Application of irrigation valve wiring | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Automated irrigation systems for crop management | Enhanced efficiency in water usage and crop yield | Durability of wiring for harsh environments and moisture |

| Landscaping & Horticulture | Smart irrigation control for parks and gardens | Reduced labor costs and improved water conservation | Compatibility with various sensor technologies |

| Golf Course Management | Centralized control systems for irrigation of greens and fairways | Consistent turf quality and reduced operational costs | Wire gauge selection based on distance and number of valves |

| Municipal Water Management | Infrastructure for urban landscaping irrigation | Sustainable water management and aesthetic enhancement | Compliance with local regulations and standards |

| Greenhouse Operations | Precision irrigation for climate-controlled environments | Optimized water delivery and plant health | Resistance to chemical exposure and UV degradation |

How is irrigation valve wiring utilized in agriculture?

In the agriculture sector, irrigation valve wiring is essential for automated irrigation systems that manage water distribution across vast fields. This technology enables farmers to optimize water usage, ensuring crops receive the appropriate amount of water without wastage. For international buyers, especially in regions like Africa and South America, sourcing durable wiring that withstands harsh weather and soil conditions is critical. Additionally, understanding local agricultural practices and regulations can aid in selecting the right components for effective irrigation solutions.

What are the applications of irrigation valve wiring in landscaping and horticulture?

In landscaping and horticulture, irrigation valve wiring supports smart irrigation control systems that manage water flow in parks, gardens, and residential landscapes. These systems can be programmed to adjust watering schedules based on weather conditions or moisture levels, significantly reducing labor costs and conserving water. Buyers from the Middle East and Europe should consider the compatibility of wiring with various sensor technologies and ensure that the materials can endure outdoor conditions while maintaining functionality.

How does irrigation valve wiring enhance golf course management?

Golf course management relies heavily on centralized irrigation control systems facilitated by effective wiring solutions. This technology ensures consistent watering of greens and fairways, promoting healthy turf and enhancing the overall playing experience. For B2B buyers, especially in regions with varied climates, it is crucial to select the appropriate wire gauge based on the distance from the controller to the valves and the number of zones being managed. This consideration helps in maintaining efficiency and reducing operational costs.

In what ways is irrigation valve wiring applied in municipal water management?

Municipal water management utilizes irrigation valve wiring to automate irrigation systems for urban landscaping, ensuring aesthetic appeal while promoting sustainable water use. These systems can help cities manage their water resources effectively, especially in regions facing water scarcity. International buyers must be aware of local regulations concerning water usage and materials to ensure compliance and efficiency in their sourcing decisions.

How is irrigation valve wiring critical for greenhouse operations?

In greenhouse operations, irrigation valve wiring is pivotal for precision irrigation systems designed to deliver water in a controlled manner. This technology helps optimize water delivery, enhancing plant health and growth rates. Buyers should focus on sourcing wiring that is resistant to chemical exposure and UV degradation, which are common in greenhouse environments. Such considerations ensure long-term reliability and effectiveness of the irrigation systems in place.

3 Common User Pain Points for ‘irrigation valve wiring’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Wire Gauge for Installation

The Problem: B2B buyers often find themselves unsure about which wire gauge to select for their irrigation systems, particularly when dealing with varying lengths and numbers of valves. Choosing a wire that is either too thin or too thick can lead to inefficiencies, increased energy costs, or even equipment failure. This uncertainty can cause delays in project timelines and escalate costs, especially in regions where access to technical support is limited.

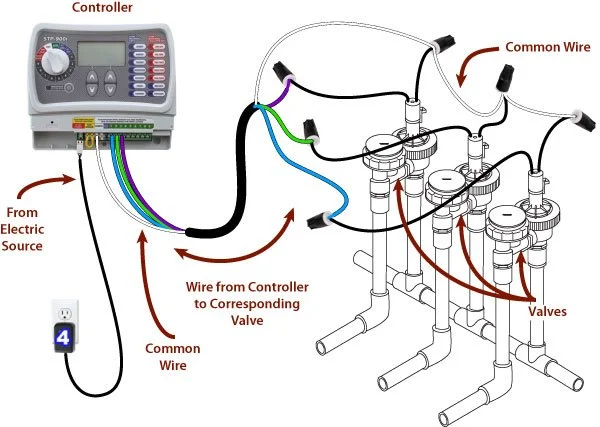

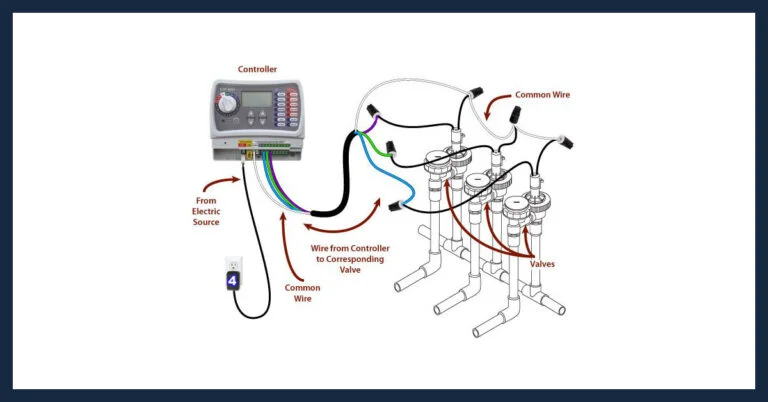

The Solution: To navigate this issue, it is crucial to understand the specific requirements of your irrigation setup. Generally, for shorter runs and fewer valves, an 18-gauge wire may suffice. However, for longer distances or systems controlling multiple valves, a 16-gauge wire is recommended. Buyers should consult the irrigation system’s manual or technical specifications to determine the optimal wire gauge. Additionally, sourcing wire from reputable suppliers who offer detailed product descriptions and customer support can enhance confidence in making the right selection. Consider investing in a multimeter to test wire resistance and ensure optimal performance during installation.

Scenario 2: Ensuring Weatherproof Connections in Challenging Climates

The Problem: In regions with extreme weather conditions—such as heavy rains, intense sunlight, or fluctuating temperatures—B2B buyers face the challenge of ensuring that their irrigation valve wiring remains functional and intact. Poorly sealed connections can lead to water ingress, corrosion, and ultimately, system failure. This can result in costly downtime and repairs, especially for businesses relying on irrigation for agriculture or landscaping.

The Solution: Implementing weatherproof connectors is essential for maintaining the integrity of irrigation wiring in harsh climates. Buyers should prioritize products specifically designed for outdoor use, such as waterproof wire connectors and heat-shrink tubing, which provide an additional layer of protection against moisture and temperature fluctuations. When installing wiring, ensure that all connections are made securely and use electrical tape or conduit to shield exposed wiring from environmental elements. Regular maintenance checks should be scheduled to inspect for signs of wear or damage, allowing for proactive repairs before issues escalate.

Scenario 3: Troubleshooting Wiring Issues in the Field

The Problem: Many B2B buyers experience frustration when their irrigation systems fail to operate correctly due to wiring issues, such as shorts or disconnections. This problem can be particularly acute in regions where irrigation systems are deployed in expansive agricultural fields or landscaping projects, making it difficult to pinpoint the source of the issue quickly. Downtime can lead to significant losses, especially during critical growth periods.

The Solution: To effectively troubleshoot wiring problems, investing in a quality multimeter is crucial. This tool can help identify voltage issues and determine whether current is reaching the solenoid valves from the controller. Buyers should familiarize themselves with basic electrical diagnostics, such as checking for continuity in the wiring and inspecting connections for corrosion or damage. Establishing a systematic approach to troubleshooting—starting from the controller and working towards the valves—can help isolate the problem efficiently. Additionally, keeping a stock of spare connectors and wiring on hand can minimize downtime during repairs, allowing for quick replacements and maintaining the irrigation system’s functionality.

Strategic Material Selection Guide for irrigation valve wiring

When selecting materials for irrigation valve wiring, it is essential to consider the unique properties and performance characteristics of different wire types. The choice of material can significantly impact the efficiency, durability, and overall effectiveness of an irrigation system, particularly in diverse environments such as those found in Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Copper Wire for Irrigation Valve Wiring?

Copper wire is a popular choice for irrigation valve wiring due to its excellent electrical conductivity and mechanical strength. It typically operates well in a temperature range of -40°C to 90°C, making it suitable for various climates. Additionally, copper has good corrosion resistance, especially when coated or insulated properly.

Pros: The primary advantage of copper wire is its superior conductivity, which ensures minimal energy loss. It is also relatively easy to work with, allowing for straightforward installation and maintenance.

Cons: However, copper is more expensive than alternatives like aluminum and can be prone to corrosion if not adequately protected in certain soil conditions. This can lead to increased long-term costs due to maintenance or replacement.

Impact on Application: Copper wire is compatible with various irrigation systems, including those that require high power for solenoids and controllers.

Considerations for International Buyers: B2B buyers should ensure compliance with local standards, such as ASTM or DIN, and consider the availability of copper wire in their regions. In countries like Brazil and Nigeria, sourcing reliable suppliers who adhere to these standards is crucial.

How Does Aluminum Wire Compare for Irrigation Valve Wiring?

Aluminum wire is another option that is often used in irrigation systems. It has a lower conductivity than copper but is significantly lighter and less expensive.

Pros: The primary advantage of aluminum wire is its cost-effectiveness, making it an attractive option for large-scale irrigation projects. Its lightweight nature also simplifies installation, especially in remote areas.

Cons: On the downside, aluminum is more susceptible to corrosion, particularly in moist or saline environments. This susceptibility can lead to reduced lifespan and reliability.

Impact on Application: Aluminum wire is suitable for low to moderate power applications and can be used effectively in systems with fewer electrical demands.

Considerations for International Buyers: Buyers must consider local environmental conditions that may affect aluminum wire’s performance. Compliance with regional standards and ensuring that the wire is adequately insulated to prevent corrosion is vital.

What Are the Benefits of Direct Burial Wire for Irrigation Valve Wiring?

Direct burial wire is specifically designed for underground installation, featuring a protective thermoplastic sheath that prevents moisture ingress and damage from soil conditions.

Pros: The key advantage of direct burial wire is its durability and resistance to environmental factors, which makes it ideal for long-term installations. It is designed to withstand the rigors of underground use.

Cons: However, direct burial wire can be more expensive than standard wiring due to its specialized construction. Additionally, installation may require more effort to ensure proper burial depth and protection.

Impact on Application: This type of wire is highly suitable for connecting solenoid valves to controllers in outdoor settings, ensuring reliable operation without the need for additional conduit.

Considerations for International Buyers: Buyers should verify that the wire meets local standards for direct burial applications. In regions with extreme weather, such as the Middle East, ensuring that the wire can withstand high temperatures is crucial.

How Does UV-Resistant Wire Enhance Irrigation Valve Wiring Durability?

UV-resistant wire is designed for above-ground applications where exposure to sunlight can degrade standard wiring materials over time.

Pros: The primary advantage of UV-resistant wire is its longevity when exposed to sunlight, which reduces the need for frequent replacements. This type of wire is also typically flexible, making installation easier.

Cons: The downside is that UV-resistant wire may not be suitable for underground applications unless specifically designed for dual use. Additionally, it can be more expensive than standard wire.

Impact on Application: This wire is ideal for applications where wiring runs above ground, such as connecting sensors or controllers located in open fields.

Considerations for International Buyers: Buyers should ensure that the UV-resistant wire complies with local standards and is available in the appropriate gauges for their specific irrigation systems.

Summary Table of Material Selection for Irrigation Valve Wiring

| Material | Typical Use Case for irrigation valve wiring | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper Wire | Connecting solenoid valves to controllers | Superior conductivity | Higher cost and corrosion risk | High |

| Aluminum Wire | Low to moderate power applications | Cost-effective and lightweight | Susceptible to corrosion | Medium |

| Direct Burial Wire | Underground connections | Durable and moisture-resistant | Higher initial cost and installation effort | Medium |

| UV-Resistant Wire | Above-ground applications | Longevity in sunlight exposure | Not suitable for underground use unless dual-rated | Medium |

This strategic material selection guide provides essential insights for B2B buyers looking to optimize their irrigation valve wiring solutions, ensuring compliance and performance in diverse international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for irrigation valve wiring

What Are the Key Stages in the Manufacturing Process of Irrigation Valve Wiring?

The manufacturing process of irrigation valve wiring involves several critical stages that ensure the product meets industry standards and customer expectations.

Material Preparation: The process begins with sourcing high-quality materials, such as copper for wires and durable thermoplastics for insulation. This stage may involve the selection of specific alloys or compounds that enhance conductivity and resistance to corrosion, which are crucial for underground applications.

Forming: This stage includes the wire drawing process, where raw copper is drawn into thin wires of various gauges (commonly 16 and 18 AWG). The forming process may also involve twisting and bundling multiple conductors together, ensuring that they can withstand the rigors of installation and use. Advanced techniques such as extrusion may be employed to create insulated wires, ensuring that they are suitable for both direct burial and above-ground applications.

Assembly: In this stage, the wires are cut to specified lengths and assembled with necessary components like waterproof connectors and pigtail plugs. Automated machinery may be used to enhance precision and efficiency. This phase is vital for ensuring that all components fit together seamlessly, which is crucial for the reliability of irrigation systems.

Finishing: The final stage involves applying protective coatings and insulation to the wires. This is typically done using thermoplastic or PVC sheathing, which provides moisture resistance and UV protection. The finished products are then labeled and packaged for distribution, ensuring that they are ready for transport and installation.

How Is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance (QA) is integral to the manufacturing of irrigation valve wiring, ensuring that products meet international and industry-specific standards.

International Standards: Many manufacturers adhere to ISO 9001, which outlines a framework for quality management systems. Compliance with this standard indicates a commitment to consistent quality and customer satisfaction. Additionally, European products may need to meet CE marking requirements, which confirm compliance with health, safety, and environmental protection standards.

Industry-Specific Standards: Depending on the market, irrigation valve wiring may also need to comply with standards set by organizations such as the American Petroleum Institute (API) for products used in oil and gas applications or specific agricultural standards in different regions.

What Are the Critical Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are essential to ensuring that products meet specified standards throughout the manufacturing process.

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon receipt. Suppliers must provide documentation verifying compliance with relevant standards. Common checks include verifying the gauge of wire and the integrity of insulation materials.

In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections are performed at various stages, such as wire drawing and assembly. This includes monitoring the dimensions and electrical properties of the wires, ensuring that they meet the required specifications.

Final Quality Control (FQC): Once the product is completed, a thorough inspection is conducted before packaging. This includes testing the wiring for electrical continuity and insulation resistance. Any defective products are identified and removed from the production line.

What Testing Methods Are Commonly Used for Irrigation Valve Wiring?

Various testing methods are employed to ensure the quality and performance of irrigation valve wiring, including:

Electrical Testing: This involves checking for continuity and insulation resistance using multimeters. These tests confirm that the wiring can conduct electricity effectively without any leaks.

Environmental Testing: Products may be subjected to environmental simulations to assess their performance under various conditions, such as extreme temperatures and moisture levels. This is crucial for ensuring longevity, particularly for wiring intended for underground use.

Mechanical Testing: Mechanical stress tests evaluate the durability of connections and insulation. This ensures that the wiring can withstand physical stresses during installation and operation.

How Can B2B Buyers Verify Supplier Quality Control Practices?

International B2B buyers can employ several strategies to verify the quality control practices of suppliers:

Conducting Audits: Buyers should consider conducting on-site audits of potential suppliers. This allows them to assess manufacturing processes, quality control checkpoints, and compliance with international standards firsthand.

Reviewing Quality Assurance Reports: Suppliers should provide documentation of their quality assurance processes, including test results and compliance certifications. Regularly updated reports can offer insights into the supplier’s commitment to quality.

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s manufacturing processes and quality control measures. This is particularly important for buyers in regions where local standards may differ from international norms.

What Are the Unique QC and Certification Nuances for International Buyers?

For buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is crucial:

Regional Standards: Different regions may have varying standards and certifications. For instance, while CE marking is essential in Europe, buyers in Africa may need to consider local certifications that reflect regional compliance.

Documentation Requirements: International transactions often require thorough documentation, including certificates of compliance, test results, and shipping details. Buyers should ensure that suppliers provide all necessary documentation to facilitate customs clearance and compliance with local regulations.

Cultural Considerations: Building relationships with suppliers can enhance trust and transparency. Understanding cultural nuances can aid in effective communication regarding quality expectations and standards.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions and select suppliers that meet their needs for reliable and high-quality irrigation valve wiring.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘irrigation valve wiring’

When it comes to procuring irrigation valve wiring for efficient water management systems, a structured approach is essential. This guide serves as a practical checklist for B2B buyers, ensuring that you make informed decisions during the sourcing process. Follow these steps to streamline your procurement and achieve optimal results in your irrigation projects.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Consider factors such as wire gauge (16 or 18 AWG), type of insulation, and whether the wire will be used for direct burial. This ensures compatibility with your irrigation system and prevents future issues related to performance or durability.

- Key Considerations:

- Determine the length of wire needed based on your system layout.

- Assess the number of valves and controllers to gauge power requirements.

Step 2: Research Reliable Suppliers

Identifying reputable suppliers is critical for sourcing quality materials. Look for suppliers with a proven track record in the irrigation sector, especially those who understand the specific needs of your region, such as climate and soil conditions.

- What to Look For:

- Customer reviews and case studies that demonstrate successful installations.

- Experience in supplying irrigation systems in your target markets, like Africa or South America.

Step 3: Evaluate Product Quality

Not all wiring products are created equal. It’s vital to assess the quality of the irrigation valve wiring to ensure longevity and reliability. Look for features such as UV resistance and waterproof capabilities that are essential for outdoor applications.

- Quality Indicators:

- Certifications or compliance with international standards.

- Warranty offerings that reflect the supplier’s confidence in their products.

Step 4: Compare Pricing and Terms

Conduct a thorough market analysis to compare pricing across various suppliers. While cost is important, consider the total value offered, including shipping, customer support, and after-sales service.

- Pricing Strategies:

- Look for bulk purchase discounts or favorable payment terms.

- Evaluate the cost of potential delays in delivery against the price.

Step 5: Verify Supplier Certifications

Before finalizing your order, ensure that your chosen supplier holds the necessary certifications and licenses. This step protects your investment and ensures compliance with local regulations.

- Certification Types:

- ISO certifications that indicate quality management systems.

- Local certifications relevant to electrical components in irrigation systems.

Step 6: Request Samples for Testing

Prior to making a large purchase, request samples of the irrigation valve wiring. Testing these samples in your specific application can help verify their performance and compatibility with your system.

- Testing Focus Areas:

- Conduct stress tests to assess durability under operational conditions.

- Check for ease of installation and compatibility with existing equipment.

Step 7: Establish a Relationship with Your Supplier

Building a strong relationship with your supplier can lead to better service and support in the long run. Open lines of communication can help resolve issues quickly and provide insights into new products or technologies.

- Relationship Benefits:

- Regular updates on new products or technologies relevant to irrigation systems.

- Access to technical support for troubleshooting and installation challenges.

By following this checklist, B2B buyers can navigate the complexities of sourcing irrigation valve wiring effectively, ensuring they select the best products to meet their operational needs.

Comprehensive Cost and Pricing Analysis for irrigation valve wiring Sourcing

What Are the Key Cost Components in Irrigation Valve Wiring?

When sourcing irrigation valve wiring, understanding the cost structure is essential for effective budgeting. The primary cost components include:

Materials: The choice of wire gauge, insulation type, and connectors significantly influences the material costs. Common wire gauges for irrigation systems are 16 and 18 AWG, with variations in insulation quality affecting durability and performance.

Labor: Installation complexity can vary, impacting labor costs. Skilled labor may be required for electrical work, particularly in regions with specific installation codes or practices.

Manufacturing Overhead: This encompasses costs associated with running production facilities, including utilities, salaries, and equipment maintenance. Efficient manufacturing processes can reduce overhead and subsequently lower prices.

Tooling: Special tools may be required for custom wiring solutions or specific installations, contributing to the overall cost.

Quality Control (QC): Stringent QC measures ensure product reliability, particularly in harsh environments. Higher QC standards can lead to increased costs but can prevent future failures.

Logistics: Shipping costs vary based on distance, volume, and method. Incoterms play a critical role in determining responsibilities for freight and insurance, impacting overall expenses.

Margin: Supplier margins can differ based on market conditions, brand reputation, and service levels, influencing the final pricing.

How Do Price Influencers Affect Irrigation Valve Wiring Costs?

Several factors can influence the pricing of irrigation valve wiring, which international buyers should consider:

Volume/MOQ: Higher order volumes typically lead to lower per-unit costs due to economies of scale. Establishing a minimum order quantity (MOQ) can help negotiate better pricing.

Specifications and Customization: Custom wiring solutions tailored to specific irrigation systems may incur additional costs. Standard products generally offer better pricing.

Materials and Quality Certifications: The choice of materials (e.g., UV-resistant, direct burial wire) impacts costs. Products with certifications (like UL or CE) may command higher prices but provide assurance of quality and safety.

Supplier Factors: Reliability, reputation, and service levels of suppliers can affect pricing. Established suppliers may charge more due to their track record of quality and service.

Incoterms: Understanding shipping terms is crucial, as they dictate cost responsibilities. Buyers should clarify who bears the cost of freight, insurance, and duties to avoid unexpected expenses.

What Are the Best Buyer Tips for Cost-Efficiency in Sourcing?

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should consider the following strategies to maximize cost-efficiency:

Negotiate Prices: Engage suppliers in discussions about pricing, especially when placing large orders or if you can offer a long-term partnership. Flexibility in payment terms can also facilitate better deals.

Evaluate Total Cost of Ownership (TCO): Consider not just the initial purchase price but also installation, maintenance, and potential downtime costs. A lower-priced product may have higher long-term costs due to poor quality or reliability.

Understand Pricing Nuances: Different regions may have varying price structures based on local demand and supply chains. Be aware of these differences when sourcing internationally.

Research Market Trends: Keeping abreast of market conditions and material costs can empower buyers during negotiations. This knowledge can provide leverage when discussing pricing with suppliers.

Consider Local Suppliers: When possible, sourcing from local suppliers can reduce logistics costs and lead times. Additionally, local suppliers may have a better understanding of regional needs and regulations.

Disclaimer: Prices for irrigation valve wiring components can fluctuate based on market conditions, material availability, and geopolitical factors. Always conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing irrigation valve wiring With Other Solutions

Exploring Alternatives for Irrigation Valve Wiring Solutions

In the pursuit of efficient irrigation management, businesses often seek alternatives to traditional irrigation valve wiring. These alternatives may offer various advantages depending on the specific needs of the agricultural or landscaping operation. Here, we compare irrigation valve wiring with two viable alternative solutions: wireless irrigation control systems and drip irrigation systems.

| Comparison Aspect | Irrigation Valve Wiring | Wireless Irrigation Control Systems | Drip Irrigation Systems |

|---|---|---|---|

| Performance | Reliable connectivity; effective for large areas | Flexible coverage; potential signal interruptions | Highly efficient water usage; precise application |

| Cost | Moderate initial investment; ongoing maintenance costs | Higher upfront costs; potential savings on water | Varies widely; can be cost-effective in the long run |

| Ease of Implementation | Requires installation expertise; labor-intensive | Easier setup; minimal physical infrastructure needed | Moderate complexity; requires planning for layout |

| Maintenance | Regular checks needed; susceptible to wear | Low maintenance; software updates may be required | Minimal if properly installed; occasional emitter cleaning |

| Best Use Case | Large agricultural fields needing zoned control | Urban landscaping and gardens needing flexibility | Water-scarce regions needing efficient usage |

What Are the Pros and Cons of Wireless Irrigation Control Systems?

Wireless irrigation control systems utilize radio signals to communicate between controllers and valves, eliminating the need for extensive wiring. The primary advantage is flexibility; these systems can easily adapt to changes in the landscape or irrigation needs. They are particularly beneficial for urban landscaping, where physical wiring may be impractical. However, they can be susceptible to signal interference and may require a higher initial investment compared to traditional wiring solutions.

How Do Drip Irrigation Systems Compare?

Drip irrigation systems deliver water directly to the plant roots through a network of tubing and emitters. This method significantly reduces water waste and is ideal for arid regions. One of the main advantages is its efficiency in water usage, allowing for precise application that can lead to healthier plants and reduced water costs. However, the installation process can be complex and may require careful planning to ensure proper coverage. Maintenance involves periodic checks of the emitters to prevent clogging, which can be labor-intensive.

How Should B2B Buyers Choose the Right Irrigation Solution?

When selecting the appropriate irrigation solution, B2B buyers should consider their specific needs, including the scale of the operation, budget constraints, and environmental conditions. If a business operates on a large scale and requires zoned control, traditional irrigation valve wiring may be the best choice. For those seeking flexibility and ease of installation, wireless systems could be more suitable. Conversely, businesses in water-scarce areas would benefit from the efficiency of drip irrigation systems. Ultimately, the right decision hinges on aligning the irrigation method with operational goals and resource availability.

Essential Technical Properties and Trade Terminology for irrigation valve wiring

What Are the Critical Technical Properties of Irrigation Valve Wiring?

Understanding the technical specifications of irrigation valve wiring is crucial for effective and reliable system performance. Here are some key properties that B2B buyers should consider:

Wire Gauge (AWG)

– The American Wire Gauge (AWG) system indicates the thickness of the wire. Common gauges for irrigation systems are 16 and 18 AWG. A lower number indicates a thicker wire, which can carry more current. For long runs or multiple valves, a thicker wire (such as 16 AWG) is often necessary to prevent voltage drop, ensuring that solenoids function correctly.Conductor Material

– Most irrigation wires are made from copper due to its excellent conductivity. Copper wires facilitate efficient electrical flow, which is vital for reliable operation of solenoid valves. Some wires may be aluminum, which is less conductive but lighter and often cheaper. B2B buyers should prioritize copper for enhanced performance and longevity.Insulation Rating

– The insulation of the wire must be rated for underground use, typically with a durable thermoplastic sheath that protects against moisture, chemicals, and physical damage. Proper insulation ensures that the wiring remains operational over time, reducing the risk of short circuits or system failures.Direct Burial Capability

– Wires designed for direct burial are specifically constructed to withstand harsh underground conditions without additional conduit. These wires are typically UV resistant and designed to endure moisture and soil pressure. Selecting direct burial wires can save costs and simplify installation, making them a preferred choice for many irrigation systems.Temperature Rating

– Wires should be rated to function within a specific temperature range. High temperatures can degrade insulation and affect performance. Understanding the temperature ratings is essential for ensuring that the wiring can withstand local climate conditions, especially in regions with extreme heat or cold.Number of Conductors

– The number of conductors in a wire determines how many zones or valves can be controlled simultaneously. Common configurations include 4, 5, or more conductors. B2B buyers need to assess their system requirements to choose the right configuration that allows efficient control over multiple irrigation zones.

What Are Common Trade Terms Related to Irrigation Valve Wiring?

Familiarity with industry terminology is essential for effective communication and negotiation. Here are several terms commonly encountered in the irrigation wiring sector:

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce components that are used in another company’s end products. In the context of irrigation, OEM parts are essential for ensuring compatibility and quality, and B2B buyers often seek reliable OEM suppliers for their projects.MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for B2B buyers as it affects inventory management and purchasing strategies. Larger orders may reduce costs but require careful planning to avoid excess inventory.RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing information for specific products or services. This is a standard practice in B2B transactions, allowing buyers to compare costs and terms from various suppliers before making purchasing decisions.Incoterms (International Commercial Terms)

– These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers, especially when dealing with suppliers across different countries, as they clarify shipping costs, risk, and delivery terms.Voltage Drop

– This term refers to the reduction in voltage in the electrical circuit between the source and the load. Excessive voltage drop can lead to inadequate performance of irrigation systems. Understanding voltage drop is vital for selecting the appropriate wire gauge and ensuring reliable system operation.Pigtail Connectors

– Pigtail connectors are short lengths of wire with connectors on either end, used for making quick and easy connections in irrigation systems. Knowing about pigtail connectors can help B2B buyers streamline installation processes and enhance system flexibility.

By grasping these essential properties and terminology, B2B buyers can make informed decisions when sourcing irrigation valve wiring, ensuring optimal performance and reliability for their irrigation systems.

Navigating Market Dynamics and Sourcing Trends in the irrigation valve wiring Sector

What Are the Key Market Drivers and Trends Influencing Irrigation Valve Wiring?

The irrigation valve wiring sector is experiencing notable growth, driven by several global factors. Increasing agricultural demands due to population growth, alongside the urgent need for sustainable water management practices, have propelled the adoption of sophisticated irrigation systems. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, this landscape presents both opportunities and challenges.

Emerging technologies, such as smart irrigation systems and automation, are transforming how irrigation is managed. These systems require robust wiring solutions to connect controllers, sensors, and solenoid valves effectively. The demand for high-quality, durable wiring products is rising, with buyers seeking components that can withstand harsh environmental conditions. Notably, direct burial wires are becoming essential, as they facilitate underground installations while ensuring the longevity and reliability of the system.

Sourcing trends are also evolving; buyers are increasingly leaning towards suppliers who offer comprehensive solutions, including not just wiring but also connectors, tools, and installation support. This shift towards integrated sourcing can streamline procurement processes and reduce project timelines. As the market adapts to these dynamics, understanding regional nuances—such as local regulations and climate considerations—will be crucial for successful sourcing strategies.

How Important Is Sustainability and Ethical Sourcing in the Irrigation Valve Wiring Sector?

Sustainability is becoming a pivotal concern within the irrigation valve wiring sector. The environmental impact of traditional wiring materials, often derived from non-renewable resources, is prompting buyers to seek more eco-friendly alternatives. This shift is not just a trend but a necessity, as the agricultural sector faces increasing scrutiny regarding its environmental footprint.

Ethical sourcing practices are equally important. B2B buyers are encouraged to partner with suppliers that uphold transparent supply chains and prioritize fair labor practices. This not only enhances brand reputation but also aligns with the values of a growing consumer base that favors sustainability and ethical production.

Moreover, the use of ‘green’ certifications and materials in irrigation valve wiring is gaining traction. Buyers should look for products that meet environmental standards, such as those that are recyclable or made from recycled materials. Investing in sustainable wiring solutions not only supports eco-friendly practices but can also lead to long-term cost savings through enhanced durability and reduced maintenance needs.

What Is the Evolution of Irrigation Valve Wiring Technology?

The evolution of irrigation valve wiring has been closely tied to advancements in agricultural technology. Initially, simple manual systems dominated the landscape, utilizing basic wiring methods that lacked the efficiency and reliability of modern solutions. Over the decades, the introduction of automatic and smart irrigation systems revolutionized the sector, necessitating more sophisticated wiring solutions to support enhanced functionality.

As technology advanced, the focus shifted towards creating durable, moisture-resistant, and UV-protected wiring options, capable of withstanding the rigors of outdoor environments. This evolution has not only improved the efficiency of irrigation systems but also contributed to water conservation efforts globally. Today, the integration of smart technology, such as sensors and controllers, represents the forefront of innovation, making irrigation systems more responsive and efficient than ever before. B2B buyers must stay informed of these technological advancements to ensure they are sourcing the most effective and sustainable wiring solutions for their irrigation projects.

Frequently Asked Questions (FAQs) for B2B Buyers of irrigation valve wiring

How do I solve common wiring issues in irrigation systems?

Common wiring issues in irrigation systems often stem from improper connections or damaged wires. To troubleshoot, start by checking all connections to ensure they are secure and weatherproof. Look for signs of wear or damage in the wiring, particularly in underground installations. Using a multimeter can help identify voltage irregularities or short circuits. If issues persist, consider consulting with a professional irrigation technician to assess the system and recommend repairs or upgrades.What is the best wire gauge for irrigation valve wiring?

The best wire gauge for irrigation valve wiring typically falls between 16 and 18 AWG. The choice depends on the length of the wire run and the number of valves being controlled. For longer distances or systems with multiple valves, a 16-gauge wire is recommended to minimize voltage drop and ensure reliable operation. Conversely, 18-gauge wire may suffice for shorter runs or fewer valves, making it a cost-effective option for smaller systems.What factors should I consider when selecting irrigation valve wiring suppliers?

When selecting suppliers for irrigation valve wiring, consider their product quality, industry experience, and reputation. Evaluate their certifications and compliance with international standards, particularly if you are sourcing from different regions. Additionally, inquire about their customer service, lead times, and return policies. It can also be beneficial to request samples to assess the wire’s durability and performance before making a bulk purchase.What is the minimum order quantity (MOQ) for irrigation wiring products?

Minimum order quantities (MOQs) for irrigation wiring products vary by supplier and can depend on the type of wire and customization options. Typically, MOQs can range from 100 to 500 meters, but some suppliers may offer flexibility for smaller orders, especially for new clients. It’s essential to clarify MOQs during the negotiation phase to ensure your order aligns with your project’s scale and budget.What payment terms should I expect when sourcing irrigation wiring internationally?

Payment terms can vary widely among suppliers, but common practices include upfront payments, deposits, or payment upon delivery. For international transactions, you may encounter options such as Letters of Credit (LC) or payment via escrow services for added security. It’s advisable to negotiate favorable terms that align with your cash flow needs while ensuring the supplier’s confidence in the transaction.How can I ensure quality assurance for irrigation wiring products?

To ensure quality assurance for irrigation wiring products, request detailed specifications and certifications from suppliers. Look for compliance with international standards such as ISO or IEC. Conducting factory audits or arranging third-party inspections can also help verify product quality. Additionally, ask for a warranty or guarantee period to protect against defects and ensure reliability in your irrigation systems.What logistics considerations should I keep in mind when importing irrigation wiring?

Logistics considerations for importing irrigation wiring include shipping methods, lead times, and customs regulations. Determine the most cost-effective shipping option based on your timeline and budget, whether by sea, air, or land. Familiarize yourself with import duties and taxes that may apply, and consider working with a freight forwarder to navigate complex logistics and ensure timely delivery.Can I customize irrigation valve wiring for specific projects?

Yes, many suppliers offer customization options for irrigation valve wiring, including wire gauge, length, and insulation materials. When discussing customization, provide detailed specifications and requirements for your project. Some suppliers may also accommodate branding or labeling requests. Be sure to confirm any additional costs or lead time associated with customized products to avoid delays in your project timeline.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Irrigation Valve Wiring Manufacturers & Suppliers List

1. Sprinkler Warehouse – Key Supplies for Irrigation Wiring

Domain: school.sprinklerwarehouse.com

Registered: 1999 (26 years)

Introduction: Key supplies needed for wiring an irrigation valve to an irrigation controller include: 1. A bundle of wires (16-gauge or 18-gauge) with multiple color wires and one common white wire. 2. Waterproof connectors filled with silicone to protect against water damage and corrosion. 3. Color-coded wires for connecting to valve solenoids. 4. Electrical tape for securing wires to irrigation pipes. 5. Wire…

2. Reddit – Irrigation Control System Components

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Irrigation valve wiring, irrigation zones, control system, blue caps, valve knob, solenoid, common wire, master wire, add a zone device.

3. ConnectOzo – 3 Wire Connectors

Domain: community.rachio.com

Registered: 2013 (12 years)

Introduction: 3 Wire Connectors, ConnectOzo Electrical IDC 314-BOX; Toro Solenoids (Model: 89-0114); DryConn Small Waterproof Wire Connectors (Aqua, Orange, 20-Pack); Terminal blocks from Lowe’s; 18 gauge thermostat wire; Petroleum jelly or silicon grease for moisture protection.

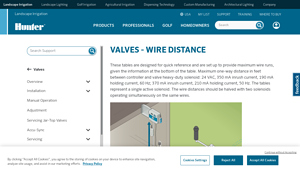

4. Hunter – Heavy-Duty Solenoid Specifications

Domain: hunterirrigation.com

Registered: 2001 (24 years)

Introduction: Maximum one-way distance in feet between controller and valve for heavy-duty solenoid: 24 VAC, 350 mA inrush current, 190 mA holding current, 60 Hz; 370 mA inrush current, 210 mA holding current, 50 Hz. Wire distances vary by wire gauge: 18 AWG (Control Wire: 850 ft, Ground Wire: 1040 ft), 16 AWG (Control Wire: 1040 ft, Ground Wire: 1340 ft), 14 AWG (Control Wire: 1210 ft, Ground Wire: 1650 ft), 1…

5. Irritrol – 2400 Solenoid Replacement

Domain: diy.stackexchange.com

Registered: 2009 (16 years)

Introduction: Irritrol 2400 solenoid; replacement solenoid for sprinkler systems; cost under $15; available at local sprinkler supply stores and online; no special tools required for installation; solenoid twists off for easy replacement.

6. Sunshower – Irrigation Cable Solutions

Domain: sunshoweronline.com.au

Introduction: Wiring for solenoid valves requires specific sizes of irrigation cable based on the number of valves: Up to 2 valves: 3 Core Irrigation Cable; Up to 4 valves: 5 Core Irrigation Cable; Up to 6 valves: 7 Core Irrigation Cable; Up to 8 valves: 9 Core Irrigation Cable; Up to 12 valves: 13 Core Irrigation Cable. Each solenoid valve requires one individual wire and one common wire. Recommended practice …

7. Angi – Sprinkler Valve Installation Guide

Domain: angi.com

Registered: 1996 (29 years)

Introduction: Skill Level: Intermediate, Completion Time: 60 minutes, Cost: $50–$100, Tools Needed: Wire stripper, Screwdriver, Supplies Needed: Sprinkler valves, Sprinkler wires, Waterproof connectors.

8. Pinterest – Irrigation Valve Wiring Guide

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: How To Wire An Irrigation Valve To An Irrigation Controller | Sprinkler School

Strategic Sourcing Conclusion and Outlook for irrigation valve wiring

Strategic sourcing in irrigation valve wiring is essential for optimizing water management systems globally. By prioritizing quality electrical components, such as durable burial wires and reliable waterproof connectors, buyers can ensure the longevity and efficiency of their irrigation systems. Understanding the specific needs of different environments—whether in the arid regions of Africa or the varied climates of Europe—enables businesses to tailor their sourcing strategies effectively.

Furthermore, leveraging local suppliers not only fosters community development but can also lead to cost savings and improved logistics. As the demand for sustainable agricultural practices grows, investing in high-quality irrigation wiring solutions becomes increasingly vital. This not only enhances operational efficiency but also supports environmental stewardship.

Looking ahead, international B2B buyers are encouraged to engage with suppliers who offer comprehensive support and a wide range of products tailored to their unique challenges. By adopting a proactive approach to strategic sourcing, businesses can position themselves for success in the evolving landscape of agricultural technology. Embrace innovation in irrigation wiring to drive sustainable growth and ensure your operations are future-ready.