Introduction: Navigating the Global Market for irrigation valve wrench

In the competitive landscape of global irrigation systems, sourcing the right tools, such as irrigation valve wrenches, is crucial for maintaining efficiency and reliability in agricultural practices. B2B buyers face the challenge of navigating a diverse market filled with various types of wrenches designed for specific applications—from manual valve keys to precision-engineered tools for complex irrigation setups. This guide offers a comprehensive overview, covering the different types of irrigation valve wrenches, their applications, supplier vetting processes, and cost considerations, all tailored for international buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe, including countries such as Brazil and Nigeria.

By equipping decision-makers with actionable insights and expert recommendations, this guide empowers businesses to make informed purchasing decisions that enhance their irrigation operations. Understanding the nuances of various wrench types and their compatibility with different valve systems will not only streamline maintenance but also contribute to the longevity and efficiency of irrigation setups. As global demand for sustainable agriculture and efficient water management grows, having the right tools is more important than ever. This guide is your essential resource for mastering the intricacies of sourcing irrigation valve wrenches, ensuring that your operations remain productive and cost-effective.

Understanding irrigation valve wrench Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Keyfit Head Wrench | 45-degree angled jaw, drop forged, fits all spray heads | Irrigation maintenance, sprinkler installation | Pros: Versatile, durable, easy to use. Cons: Higher price point. |

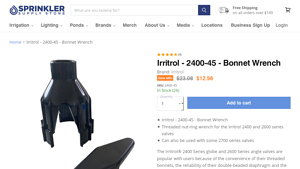

| Bonnet Wrench | Threaded nut-ring design, compatible with specific valves | Service and repair of Irritrol valves | Pros: Quick installation, reliable. Cons: Limited compatibility. |

| Valve Control Key | Available in various lengths, manual operation | Manual valve operation in irrigation systems | Pros: Simple operation, lightweight. Cons: Manual effort required. |

| Sprinkler Head Removal Tool | Designed for easy head removal, minimizes damage | Replacement and repair of sprinkler heads | Pros: Prevents damage, efficient. Cons: May require additional tools. |

| Multi-Function Wrench | Combines various functions for different valve types | Versatile applications in irrigation systems | Pros: Cost-effective, space-saving. Cons: May lack specialization. |

What Are the Key Features of the Keyfit Head Wrench?

The Keyfit Head Wrench is designed with a unique 45-degree angled jaw that allows for easy access to various sprinkler heads, including all brands of spray and rotor heads up to 4 inches in diameter. Its drop-forged construction ensures durability, making it a preferred choice for irrigation professionals. When considering a purchase, B2B buyers should evaluate the tool’s versatility and long-term reliability, as it can streamline maintenance tasks significantly.

How Does the Bonnet Wrench Stand Out?

The Bonnet Wrench is specifically crafted for Irritrol 2400 and 2600 series valves, featuring a threaded nut-ring design that simplifies the servicing process. Its compatibility with various models makes it a valuable asset for businesses focused on irrigation system repair. Buyers should consider the wrench’s ease of use and the efficiency it brings to valve maintenance, although its limited compatibility may be a drawback for some.

What Are the Advantages of Using a Valve Control Key?

Valve Control Keys come in multiple lengths, allowing users to operate manual valves from a distance. This tool is essential for seasonal shutoff and routine maintenance, providing a straightforward solution for controlling irrigation systems. B2B buyers should focus on the tool’s ease of use and lightweight design, but they should also be aware that manual operation requires physical effort.

Why Invest in a Sprinkler Head Removal Tool?

Sprinkler Head Removal Tools are specifically designed to grip and lift sprinkler heads without causing damage to surrounding components. This efficiency is critical during replacement or repair tasks, making it a must-have for landscape professionals. Buyers should weigh the benefits of preventing damage against the potential need for additional tools, which may complicate the repair process.

What Makes Multi-Function Wrenches a Smart Choice?

Multi-Function Wrenches provide a comprehensive solution for various valve types, combining multiple functionalities into one tool. This versatility can be particularly appealing to businesses looking to minimize costs and save space. However, B2B buyers should consider that while these wrenches are cost-effective, they may lack the specialization required for specific tasks, potentially impacting performance in some applications.

Key Industrial Applications of irrigation valve wrench

| Industry/Sector | Specific Application of irrigation valve wrench | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Maintenance of irrigation systems in large farms | Ensures efficient water distribution and crop yield | Durability, compatibility with various valve types, ease of use |

| Landscaping | Installation and repair of irrigation systems in parks | Enhances aesthetic appeal and water efficiency | Portability, lightweight design, availability of sizes |

| Municipal Water Management | Servicing municipal irrigation and water supply systems | Maintains infrastructure reliability and compliance | Material quality, resistance to corrosion, supplier reliability |

| Golf Course Management | Adjusting and maintaining sprinkler systems | Optimizes water usage and turf health | Precision design, compatibility with specific sprinkler brands, warranty |

| Environmental Conservation | Installation of water-efficient irrigation systems | Promotes sustainable practices and resource conservation | Eco-friendly materials, long-term durability, supplier certifications |

How is the irrigation valve wrench utilized in agriculture?

In the agriculture sector, irrigation valve wrenches are essential for maintaining irrigation systems across extensive farmland. These tools facilitate the opening and closing of valves, ensuring that water distribution is both efficient and effective. By using a valve wrench, agricultural businesses can prevent water wastage and promote optimal crop yield. For international buyers, especially in regions like Africa and South America, it’s crucial to source wrenches that are durable and compatible with various valve types to withstand diverse environmental conditions.

What role does the irrigation valve wrench play in landscaping?

In landscaping, the irrigation valve wrench is used for the installation and repair of irrigation systems in parks and public gardens. This tool simplifies the process of accessing and adjusting underground valves, ensuring that landscapes receive adequate hydration. The ability to quickly service these systems helps maintain the aesthetic appeal of green spaces while promoting water efficiency. Buyers from the Middle East and Europe should consider wrenches that are lightweight and portable, making them suitable for on-site use in various landscaping projects.

How does the irrigation valve wrench support municipal water management?

Municipal water management relies heavily on the effective servicing of irrigation and water supply systems. The irrigation valve wrench is instrumental in maintaining these infrastructures, enabling technicians to easily operate valves that control water flow. This ensures compliance with regulations and enhances the reliability of the water supply. For municipal buyers, sourcing high-quality wrenches that resist corrosion and are made from durable materials is essential, particularly in regions with harsh climates.

In what ways does the irrigation valve wrench benefit golf course management?

Golf course management utilizes irrigation valve wrenches to adjust and maintain sprinkler systems that are vital for turf health. These tools allow for precise control over water distribution, which is critical for maintaining lush greens and fairways. By optimizing water usage, golf courses can enhance their playing conditions while conserving resources. Buyers in this sector should seek wrenches designed for compatibility with specific sprinkler brands, ensuring seamless integration and effective maintenance.

How is the irrigation valve wrench used in environmental conservation efforts?

In the field of environmental conservation, irrigation valve wrenches are employed to install water-efficient irrigation systems that reduce water waste. These systems are crucial for promoting sustainable practices in agriculture and landscaping. The ability to easily service and adjust these systems ensures that conservation efforts are effective. International buyers focused on sustainability should prioritize wrenches made from eco-friendly materials that offer long-term durability and come from reputable suppliers with recognized certifications.

3 Common User Pain Points for ‘irrigation valve wrench’ & Their Solutions

Scenario 1: Difficulty in Accessing Deeply Buried Valves

The Problem: B2B buyers often face the challenge of accessing irrigation valves that are buried deep underground or surrounded by dense vegetation. This can be particularly troublesome in regions with varying soil types or during seasonal growth when roots may intertwine with the valve components. Attempting to reach these valves without the right tools not only increases labor costs but can also lead to damage to the surrounding infrastructure, requiring additional repairs and downtime.

The Solution: To effectively address this issue, buyers should invest in adjustable-length irrigation valve wrenches, such as those that come in 30-inch or even longer variants. These tools are specifically designed to operate at a distance, allowing users to reach valves without extensive digging. When sourcing these wrenches, look for features such as ergonomic grips and durable materials that can withstand rough handling. Additionally, consider purchasing wrenches that have multi-functional capabilities, such as those that can open different types of valve styles. This ensures you have a versatile tool that can be used across various systems, minimizing the need for multiple specialized tools.

Scenario 2: Inconsistent Valve Performance Due to Improper Handling

The Problem: Another common issue faced by B2B buyers is the inconsistent performance of irrigation valves, often stemming from improper handling during maintenance or installation. Many users struggle with the torque required to tighten or loosen valves correctly, leading to leaks or failures in the system. This inconsistency can cause water wastage, increased operational costs, and even damage to the irrigation system, impacting overall efficiency.

The Solution: To overcome this challenge, it is crucial to utilize a high-quality wrench that provides a precise fit for the specific valve types being serviced. Buyers should look for wrenches with features such as directional inner teeth that grip better with less pressure, which helps prevent slippage and ensures a secure fit. Additionally, incorporating a torque measurement tool can help ensure that valves are tightened to the correct specifications, reducing the risk of leaks and enhancing the longevity of the valves. Training maintenance staff on proper valve handling techniques will also improve overall performance and reliability.

Scenario 3: Time-Consuming Repairs Due to Inadequate Tools

The Problem: B2B buyers frequently encounter time-consuming repair processes because they lack the appropriate tools for quick and efficient valve servicing. Without the right irrigation valve wrench, tasks such as replacing diaphragm seals or adjusting valve flow can take significantly longer, leading to increased labor costs and potential downtime of irrigation systems. This scenario is particularly critical for businesses that rely on timely irrigation for agricultural productivity.

The Solution: To expedite repair processes, buyers should invest in specialized irrigation valve wrenches designed for specific valve types, such as jar-top or globe valves. These tools often have features that allow for quick access and efficient engagement with the valve components. For instance, wrenches with a lock-up system can hold the valve in place while technicians make necessary adjustments, freeing their hands for more detailed work. Additionally, creating a toolkit that includes all necessary wrenches for various valve types will streamline the repair process and minimize the time spent searching for the right tool. Establishing a routine maintenance schedule and ensuring that all tools are readily available can further enhance operational efficiency.

Strategic Material Selection Guide for irrigation valve wrench

What Materials are Commonly Used for Irrigation Valve Wrenches?

When selecting materials for irrigation valve wrenches, it is essential to consider their properties, performance, and suitability for various applications. Below, we analyze four common materials used in the manufacturing of these tools.

Steel: The Backbone of Durability

Key Properties: Steel wrenches often come with high tensile strength and can withstand significant torque, making them ideal for heavy-duty applications. They typically have good corrosion resistance when treated with coatings like zinc or chrome.

Pros & Cons: Steel is highly durable and can handle high-pressure environments, which is crucial for irrigation systems. However, the cost can be on the higher side, especially for stainless steel variants. Manufacturing complexity increases with the need for additional treatments for corrosion resistance.

Impact on Application: Steel wrenches are suitable for various media, including water and fertilizers, but they may corrode if exposed to aggressive chemicals without proper treatment.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local standards regarding tool safety and material quality. Certifications like ASTM or ISO can be beneficial for ensuring product reliability.

Aluminum: Lightweight and Corrosion-Resistant

Key Properties: Aluminum wrenches are lightweight and have excellent corrosion resistance, making them suitable for outdoor use in various climates.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which makes it easier to handle during prolonged use. However, it may not withstand as much torque as steel, making it less suitable for heavy-duty applications. The manufacturing process can be less complex than steel but may require specialized techniques for anodizing.

Impact on Application: Aluminum is compatible with most irrigation media but may not be ideal for high-pressure systems due to its lower strength.

Considerations for International Buyers: In regions with high humidity or saline environments, such as the Middle East, aluminum’s corrosion resistance is a significant advantage. Buyers should verify that the aluminum meets relevant standards like DIN or JIS.

Plastic: Cost-Effective and Lightweight

Key Properties: Plastic wrenches are generally made from high-density polyethylene (HDPE) or polypropylene, which offer good chemical resistance and are lightweight.

Pros & Cons: The primary advantage of plastic is its low cost and lightweight nature, making it an attractive option for budget-conscious buyers. However, plastic wrenches may not provide the same level of durability and torque resistance as metal options, limiting their application in high-stress environments.

Impact on Application: Plastic wrenches are suitable for use with non-aggressive media, but they may not be appropriate for high-pressure systems or environments with extreme temperatures.

Considerations for International Buyers: In regions like Brazil and Nigeria, where cost sensitivity is high, plastic wrenches can be a viable option. Buyers should ensure that the plastic used complies with local safety and environmental regulations.

Composite Materials: The Best of Both Worlds

Key Properties: Composite wrenches combine materials like fiberglass and resin, offering a balance between weight, strength, and corrosion resistance.

Pros & Cons: The key advantage of composite materials is their durability and resistance to environmental factors, making them suitable for various applications. However, they can be more expensive than traditional materials and may require complex manufacturing processes.

Impact on Application: Composite wrenches are versatile and can handle a range of media, including corrosive substances, without degrading.

Considerations for International Buyers: In Europe, where environmental regulations are stringent, composite materials may meet compliance standards better than traditional materials. Buyers should look for certifications that ensure the sustainability of the materials used.

Summary Table of Material Selection for Irrigation Valve Wrenches

| Material | Typical Use Case for irrigation valve wrench | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty irrigation systems | High durability and torque resistance | Higher cost and corrosion treatment needed | High |

| Aluminum | Outdoor irrigation applications | Lightweight and corrosion-resistant | Lower torque resistance than steel | Medium |

| Plastic | Budget-friendly irrigation setups | Low cost and lightweight | Limited durability and pressure resistance | Low |

| Composite | Versatile applications in various environments | Excellent durability and corrosion resistance | Higher cost and manufacturing complexity | High |

This material selection guide provides a comprehensive overview for B2B buyers, enabling them to make informed decisions based on their specific irrigation needs and regional conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for irrigation valve wrench

What Are the Key Manufacturing Processes for Irrigation Valve Wrenches?

The manufacturing of irrigation valve wrenches involves several critical stages that ensure the final product meets industry standards and customer expectations. Understanding these processes is essential for B2B buyers who wish to source quality tools for their irrigation systems.

How Is Material Prepared for Manufacturing Irrigation Valve Wrenches?

The initial stage of manufacturing starts with material preparation. High-quality steel alloys are commonly used due to their durability and resistance to corrosion. Suppliers may opt for stainless steel or carbon steel, depending on the intended use and environmental conditions. The raw materials undergo a rigorous selection process to eliminate defects. This includes checking for impurities and ensuring that the metal’s mechanical properties meet specifications.

Once the materials are approved, they are cut into the required shapes and sizes. This often involves using advanced laser cutting technology, which provides precision and reduces waste. The materials are then subjected to heat treatment processes to enhance their strength and resilience, ensuring that the wrenches can withstand the demands of regular use in the field.

What Forming Techniques Are Used in the Production of Valve Wrenches?

After material preparation, the next step involves forming the wrench components. This is typically achieved through forging, casting, or machining.

Forging: Drop forging is a popular method, where heated metal is shaped using dies. This process enhances the material’s grain structure, resulting in improved strength and durability. The precision of drop forging ensures that the wrenches have a consistent shape and size, critical for compatibility with various valve types.

Machining: CNC (Computer Numerical Control) machining is often employed for precision components. This allows for intricate designs and specifications to be met, such as the creation of inner teeth that enhance grip and minimize slippage.

Casting: In some cases, particularly for more complex designs, casting might be used. This involves pouring molten metal into molds, allowing for detailed shapes and features that may not be achievable through forging alone.

How Are Components Assembled in the Manufacturing Process?

Once individual parts are formed, the assembly phase begins. This stage is crucial for ensuring the wrench functions as intended. Components such as handles, jaws, and locking mechanisms are brought together, often using screws or welding techniques.

Quality control checks are integrated throughout the assembly process to ensure that all parts fit correctly and operate smoothly. For example, the alignment of the jaw mechanism must be precise to facilitate easy opening and closing without excessive force.

Automated assembly lines may be utilized for higher production rates, ensuring consistency and efficiency. However, skilled labor remains essential for final adjustments and quality assurance.

What Finishing Processes Are Essential for Irrigation Valve Wrenches?

The finishing stage involves applying protective coatings and surface treatments to enhance durability and resistance to environmental factors. Common finishing processes include:

Plating: Zinc or chrome plating is often used to provide a corrosion-resistant layer, which is particularly important for tools used in outdoor settings.

Powder Coating: This technique adds a durable and aesthetically pleasing finish. It provides additional protection against scratches and UV rays.

Polishing: Final polishing enhances the appearance of the wrench while also providing a smooth surface that minimizes dirt accumulation.

These finishing touches not only improve the tool’s lifespan but also contribute to its overall functionality and user experience.

What Quality Assurance Standards Are Relevant for Irrigation Valve Wrenches?

Quality assurance is paramount in the manufacturing of irrigation valve wrenches. Adherence to international standards, such as ISO 9001, ensures that manufacturers maintain a consistent quality management system. This standard focuses on continuous improvement and customer satisfaction, essential for B2B buyers.

How Do Industry-Specific Certifications Impact Quality Assurance?

In addition to general quality standards, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) can significantly impact product credibility. These certifications demonstrate compliance with safety and performance standards, which are particularly crucial for buyers in regulated markets.

What Are the Key QC Checkpoints During Manufacturing?

Quality control (QC) is integrated at multiple checkpoints throughout the manufacturing process:

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to verify that processes are functioning correctly and that products are within tolerance levels.

Final Quality Control (FQC): After assembly, a comprehensive inspection is performed on the finished products. This includes functional testing to ensure that the wrenches operate as designed.

Testing methods may include tensile strength tests, corrosion resistance evaluations, and dimensional accuracy checks. Each of these tests provides valuable insights into the wrench’s performance and longevity.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take an active role in verifying the quality control practices of their suppliers. Here are several actionable steps:

Conduct Audits: Regular audits of manufacturing facilities can provide firsthand insight into production processes and quality assurance measures.

Request Documentation: Suppliers should be willing to provide quality control reports, certifications, and test results. This documentation is crucial for understanding the supplier’s commitment to quality.

Engage Third-Party Inspectors: Utilizing third-party inspection services can add an additional layer of verification. These independent entities can conduct thorough assessments of the manufacturing processes and products.

What Are the Quality Control Nuances for International B2B Buyers?

For B2B buyers operating in diverse regions like Africa, South America, the Middle East, and Europe, understanding the local regulatory environment is essential. Different regions may have varying standards and certification requirements.

Buyers should also consider the logistics of sourcing from international suppliers, including lead times and potential delays due to customs processes. Establishing clear communication with suppliers regarding quality expectations and compliance can mitigate risks associated with international transactions.

Conclusion

The manufacturing processes and quality assurance practices for irrigation valve wrenches are complex and multifaceted. By understanding these processes, B2B buyers can make informed decisions, ensuring they source high-quality tools that meet their operational needs. Prioritizing suppliers who adhere to international standards and demonstrate robust quality control measures will ultimately lead to more reliable and effective irrigation systems.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘irrigation valve wrench’

Introduction

This guide serves as a practical checklist for B2B buyers aiming to procure an irrigation valve wrench. Whether you are involved in landscaping, agricultural irrigation, or municipal water management, selecting the right tool is essential for ensuring efficient maintenance and operation of irrigation systems. This checklist will help streamline your sourcing process and ensure that you make informed decisions.

Step 1: Define Your Technical Specifications

Understanding the specific requirements for the irrigation valve wrench is paramount. Consider factors such as the types of valves you will be working with, their sizes, and any unique features that might enhance usability.

– Compatibility: Ensure that the wrench is compatible with the valve types in your irrigation system (e.g., Jar-Top valves, globe valves).

– Material Quality: Look for wrenches made from durable materials, such as drop-forged steel, which can withstand rigorous use.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in irrigation tools. Look for companies with a solid reputation in your target markets, such as Africa, South America, and the Middle East.

– Supplier Reviews: Check reviews and ratings from other buyers to gauge reliability and service quality.

– Industry Experience: Prioritize suppliers with experience in your specific region, as they will better understand local needs and conditions.

Step 3: Verify Supplier Certifications

Before finalizing your supplier choice, ensure they hold the necessary certifications and adhere to industry standards. This step is crucial for guaranteeing product quality and compliance with safety regulations.

– Quality Assurance: Look for ISO certifications or other relevant quality management certifications that indicate a commitment to high standards.

– Safety Compliance: Ensure that the supplier meets any local or international safety standards relevant to irrigation tools.

Step 4: Request Samples or Demonstrations

Whenever possible, request samples or demonstrations of the irrigation valve wrench from potential suppliers. This hands-on approach allows you to evaluate the tool’s performance and ergonomics before making a bulk purchase.

– Functionality Testing: Assess how well the wrench operates with your existing valves. Look for ease of use, grip, and leverage.

– Durability Assessment: Examine the tool for signs of durability, including resistance to wear and tear under normal working conditions.

Step 5: Compare Pricing and Payment Terms

Gather quotes from multiple suppliers and compare not only the prices but also the payment terms. Understanding the total cost of ownership will help you make a financially sound decision.

– Bulk Discounts: Inquire about discounts for larger orders, which can significantly reduce your overall costs.

– Payment Flexibility: Look for suppliers offering flexible payment terms that align with your budget and cash flow needs.

Step 6: Check After-Sales Support and Warranty

Evaluate the after-sales support and warranty options provided by the supplier. A strong support system can save you time and money in case of product defects or operational issues.

– Warranty Length: Consider the warranty duration and coverage details. A longer warranty often indicates supplier confidence in their product’s durability.

– Customer Service Availability: Assess the responsiveness and availability of customer service for troubleshooting and support.

By following these steps, B2B buyers can confidently navigate the procurement process for irrigation valve wrenches, ensuring they select the best tools for their operational needs.

Comprehensive Cost and Pricing Analysis for irrigation valve wrench Sourcing

What Are the Key Cost Components in Sourcing Irrigation Valve Wrenches?

When sourcing irrigation valve wrenches, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margins.

Materials: The choice of materials significantly influences the cost. High-quality steel or aluminum is often preferred for durability and performance, but these materials come at a premium. Suppliers may offer variations in material grades, which can affect pricing.

Labor: Labor costs vary based on the region and the complexity of the manufacturing process. For instance, countries with higher wages may lead to increased production costs, while regions with lower labor costs might offer more competitive pricing.

Manufacturing Overhead: This includes indirect costs related to production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce overhead, allowing suppliers to offer more competitive prices.

Tooling: Tooling costs can be substantial, especially for custom designs. The initial investment in molds and dies needs to be amortized over the production run, impacting unit prices.

Quality Control: Implementing stringent QC measures ensures product reliability but can also add to costs. Suppliers that provide certifications for their products may charge higher prices due to these added assurances.

Logistics: Shipping costs, including freight and insurance, are significant, especially for international buyers. The choice of Incoterms can affect who bears these costs, impacting the overall pricing structure.

Margin: Suppliers typically add a margin to cover their operational costs and profit. This can vary widely based on market conditions and competition.

How Do Price Influencers Affect Irrigation Valve Wrench Costs?

Several factors influence the pricing of irrigation valve wrenches, particularly for B2B buyers in different regions.

Volume/MOQ: Purchasing in bulk often leads to lower per-unit costs due to economies of scale. Suppliers are more willing to negotiate prices for larger orders, making it beneficial for buyers to assess their needs carefully.

Specifications and Customization: Custom specifications can increase costs due to additional tooling and production complexities. Buyers should weigh the need for customization against budget constraints.

Materials and Quality: Higher-quality materials and certifications often command higher prices. However, investing in quality can lead to lower Total Cost of Ownership (TCO) due to reduced maintenance and replacement needs.

Supplier Factors: Established suppliers with a proven track record may charge more due to their reputation and reliability. It’s essential to consider not only price but also the supplier’s reliability and service levels.

Incoterms: The choice of Incoterms affects shipping costs and responsibilities. Understanding these terms can help buyers negotiate better deals and avoid unexpected costs.

What Are Some Effective Buyer Tips for Sourcing Irrigation Valve Wrenches?

To maximize cost-efficiency in sourcing irrigation valve wrenches, buyers should consider the following strategies:

Negotiation: Engage in negotiations with suppliers to secure better pricing, especially for larger orders. Clearly communicating your needs and expectations can foster a collaborative relationship.

Total Cost of Ownership: Evaluate the TCO rather than just the initial purchase price. Consider factors such as durability, maintenance costs, and the potential for failure, which can lead to additional expenses over time.

Pricing Nuances for International B2B Buyers: Buyers from regions such as Africa, South America, and the Middle East should be aware of currency fluctuations, import duties, and local taxes, which can significantly impact total costs. Developing a solid understanding of local market conditions can aid in making informed decisions.

Research and Comparison: Conduct thorough market research to compare prices and specifications among different suppliers. Utilizing online platforms and trade shows can provide valuable insights into current market trends and pricing.

In conclusion, by understanding the cost components, price influencers, and effective buying strategies, B2B buyers can navigate the complexities of sourcing irrigation valve wrenches more effectively. This knowledge not only aids in making informed decisions but also ensures that investments yield maximum returns.

Alternatives Analysis: Comparing irrigation valve wrench With Other Solutions

When evaluating tools for managing irrigation systems, understanding the available alternatives to the irrigation valve wrench is essential for making informed purchasing decisions. Buyers should consider various solutions that not only fulfill the functional requirements but also align with their operational priorities, budget constraints, and ease of use. Below is a comparative analysis of the irrigation valve wrench against two viable alternatives: the Sprinkler Valve Key and the Sprinkler Head Removal Tool.

| Comparison Aspect | Irrigation Valve Wrench | Sprinkler Valve Key | Sprinkler Head Removal Tool |

|---|---|---|---|

| Performance | High precision for valve adjustments | Effective for opening/closing valves | Efficiently removes sprinkler heads |

| Cost | Moderate ($50 – $100) | Low ($10 – $30) | Moderate ($20 – $50) |

| Ease of Implementation | Requires some training | User-friendly, minimal training needed | Simple operation, requires little skill |

| Maintenance | Low maintenance, durable | Low maintenance | Moderate, depends on wear and tear |

| Best Use Case | Adjusting and servicing valves | Quick access to manual valves | Replacing or repairing sprinkler heads |

What Are the Advantages and Disadvantages of Using a Sprinkler Valve Key?

The Sprinkler Valve Key is a straightforward tool primarily used to open and close manual irrigation valves. Its simplicity and low cost make it an appealing choice for smaller operations or seasonal users. However, while the valve key is effective for basic valve operations, it lacks the precision and multi-functionality of an irrigation valve wrench. Thus, it is better suited for routine tasks rather than detailed adjustments or repairs.

How Does the Sprinkler Head Removal Tool Compare?

The Sprinkler Head Removal Tool is designed specifically for removing and replacing sprinkler heads. This tool offers an efficient solution for maintenance tasks, allowing users to quickly access and replace sprinkler components without damaging surrounding areas. However, its functionality is limited compared to the irrigation valve wrench, which can adjust and service valves in addition to managing sprinkler heads. The head removal tool may require additional tools for complete system maintenance, thus increasing overall operational complexity.

Conclusion: Which Solution is Right for Your Needs?

Choosing the right tool for irrigation management depends on the specific needs of the operation. For businesses focused on extensive valve adjustments and servicing, the irrigation valve wrench is invaluable due to its precision and versatility. On the other hand, smaller operations or those requiring straightforward valve access may find the sprinkler valve key sufficient. Meanwhile, if the primary task involves frequent head replacements, investing in a specialized sprinkler head removal tool may be the best course of action. Ultimately, assessing the scale of irrigation needs, budget, and desired functionality will guide B2B buyers in selecting the most appropriate solution.

Essential Technical Properties and Trade Terminology for irrigation valve wrench

What are the Essential Technical Properties of an Irrigation Valve Wrench?

When selecting an irrigation valve wrench, understanding its technical properties is crucial for ensuring durability, efficiency, and compatibility with various irrigation systems. Here are several key specifications to consider:

Material Grade

The material used in the construction of an irrigation valve wrench is a primary determinant of its strength and longevity. Common materials include high-carbon steel or stainless steel, which provide resistance to corrosion and wear. For B2B buyers, selecting a wrench made from high-quality materials ensures that the tool can withstand harsh environmental conditions, particularly in regions like Africa and South America where irrigation systems may face extreme weather.Jaw Design and Grip

The design of the wrench’s jaws directly impacts its functionality. Features such as angled jaws and directional inner teeth enhance grip and minimize slippage when working with various valve types. A wrench that incorporates these design elements is more efficient, allowing for quicker adjustments and repairs. This is particularly important for irrigation professionals who rely on tools that facilitate rapid service in the field.Size Compatibility

An irrigation valve wrench must be compatible with different valve sizes and types, often ranging from 1-inch to 4-inch fittings. Wrenches that accommodate multiple sizes reduce the need for multiple tools, making them cost-effective for businesses. Ensuring that the wrench can handle the specific types of valves used in a buyer’s region is essential for seamless operation.Lock-Up System

Some advanced models feature a lock-up system that secures the jaws in place while the user works. This feature is beneficial in maintaining precision and control, especially in tight spaces. For irrigation professionals, this means fewer interruptions and increased productivity when performing adjustments or repairs.Weight and Portability

The weight of the wrench affects its ease of use and transportability. Lightweight designs are preferable for fieldwork, allowing professionals to carry tools without added strain. For international buyers, especially those in remote areas, the portability of tools can significantly impact their operational efficiency.

What Common Trade Terminology Should B2B Buyers Understand?

Understanding industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are some common terms related to irrigation valve wrenches:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of irrigation tools, knowing the OEM can help buyers ensure compatibility and quality, as parts from reputable manufacturers are often more reliable.MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. For B2B buyers, understanding MOQ is vital for budgeting and inventory management. Ordering below the MOQ might lead to higher costs or unavailability of products.RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers. It typically includes specifications, quantities, and delivery timelines. Creating a comprehensive RFQ is crucial for obtaining accurate pricing and ensuring that suppliers understand the buyer’s needs.Incoterms (International Commercial Terms)

These terms define the responsibilities of buyers and sellers regarding shipping and delivery. For international transactions, understanding Incoterms helps buyers clarify shipping costs, risks, and responsibilities, which is crucial when sourcing irrigation tools from different countries.Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. Knowledge of lead times is essential for planning and maintaining irrigation systems, especially in regions with seasonal demands.

By familiarizing themselves with these technical properties and trade terminologies, B2B buyers can make informed purchasing decisions, ensuring they select the right irrigation valve wrenches that meet their operational needs.

Navigating Market Dynamics and Sourcing Trends in the irrigation valve wrench Sector

What Are the Key Trends Influencing the Global Irrigation Valve Wrench Market?

The irrigation valve wrench market is experiencing significant growth driven by increasing agricultural productivity demands, particularly in regions like Africa, South America, the Middle East, and Europe. The need for efficient water management systems, coupled with a growing emphasis on sustainable agriculture, is propelling the demand for specialized tools such as irrigation valve wrenches.

Key trends include the adoption of advanced materials and manufacturing processes, which enhance the durability and functionality of these tools. B2B buyers are increasingly seeking wrenches that feature ergonomic designs and multi-functionality, allowing for easier handling and improved efficiency during maintenance tasks. Additionally, the integration of technology, such as smart irrigation systems, is influencing tool design, leading to the development of wrenches that can accommodate various valve types and sizes seamlessly.

International buyers are also navigating the complexities of global sourcing, with an emphasis on local suppliers who can provide timely delivery and support. The rise of e-commerce platforms has simplified procurement, enabling buyers to compare products, read reviews, and make informed purchasing decisions. However, fluctuating raw material prices and supply chain disruptions remain challenges that buyers must consider when sourcing irrigation valve wrenches.

How Are Sustainability and Ethical Sourcing Impacting the Irrigation Valve Wrench Sector?

Sustainability and ethical sourcing have become paramount in the irrigation valve wrench market. The environmental impact of manufacturing processes is under scrutiny, leading to a shift towards greener practices. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their carbon footprint through energy-efficient manufacturing and sustainable materials.

The use of recycled metals and environmentally friendly coatings is becoming more prevalent, aligning with the global push for sustainable products. Certifications such as ISO 14001 for environmental management systems and the use of eco-labels can serve as indicators of a supplier’s commitment to sustainability.

Moreover, ethical supply chains are crucial for B2B buyers who want to ensure that their procurement practices do not contribute to human rights violations or environmental degradation. By choosing suppliers who adhere to fair labor practices and sustainable sourcing, buyers can enhance their corporate social responsibility profiles and meet the growing demand for ethical products in their markets.

How Has the Irrigation Valve Wrench Market Evolved Over Time?

The evolution of the irrigation valve wrench market reflects broader advancements in irrigation technology. Initially, basic manual tools dominated the sector, but as agricultural practices became more sophisticated, the demand for specialized tools grew. The introduction of ergonomic designs and precision engineering has transformed irrigation valve wrenches into essential components of modern irrigation systems.

In recent decades, the integration of technology has further shaped the market. Tools have evolved to accommodate various valve types and sizes, with manufacturers focusing on multi-functional designs that enhance usability. As irrigation systems become more automated, the role of specialized tools like valve wrenches continues to adapt, ensuring they remain relevant in an ever-changing agricultural landscape.

This historical context provides B2B buyers with insights into the importance of investing in high-quality, innovative tools that can meet the demands of modern irrigation practices while aligning with sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of irrigation valve wrench

1. How do I select the right irrigation valve wrench for my needs?

Choosing the right irrigation valve wrench involves assessing the specific types of valves you will be working with. Look for wrenches that are compatible with a range of valve sizes and types, such as Jar-Top valves and rotor heads. Consider features like angled jaws for better access, grip strength, and durability of materials. If you operate in diverse environments, ensure the wrench is resistant to corrosion and wear, especially for regions with high humidity or saline conditions.2. What is the best irrigation valve wrench for different valve types?

The best irrigation valve wrench varies based on the valve types you frequently service. For instance, a Keyfit Head Wrench is ideal for spray heads and rotor heads up to 4 inches in diameter, providing a secure grip and ease of access. If working with threaded bonnets, consider wrenches specifically designed for those models, like the Irritrol bonnet wrench. Always ensure compatibility with the brands and models in your irrigation system to maximize efficiency.3. How can I verify the quality of irrigation valve wrenches from suppliers?

To verify the quality of irrigation valve wrenches from suppliers, request samples and inspect them for durability and design features. Look for certifications or compliance with international standards, such as ISO or ANSI. Check for customer reviews and testimonials regarding the supplier’s products. Additionally, inquire about the manufacturing processes, materials used, and any warranties offered, as these factors significantly influence product longevity and performance.4. What are the typical minimum order quantities (MOQs) for irrigation valve wrenches?

Minimum order quantities (MOQs) for irrigation valve wrenches can vary significantly based on the supplier and the specific product. Many manufacturers may set MOQs ranging from 50 to 200 units, particularly for customized tools. It’s advisable to discuss your needs with potential suppliers to negotiate MOQs that align with your purchasing capacity. Consider consolidating orders with other products to meet MOQs if necessary, ensuring cost-efficiency.5. What payment terms should I expect when purchasing irrigation valve wrenches internationally?

Payment terms for international purchases of irrigation valve wrenches often include options like advance payment, letters of credit, or payment upon delivery. Common practices involve a 30% deposit upon order confirmation, with the balance due prior to shipment. Discuss payment flexibility with suppliers, especially if you are a repeat customer or if the order volume is substantial. Always ensure that payment methods are secure and offer protection against fraud.6. How can I ensure timely delivery of irrigation valve wrenches?

To ensure timely delivery of irrigation valve wrenches, establish clear timelines with your supplier from the outset. Discuss lead times for production and shipping, and opt for suppliers who provide tracking options. Consider the logistics involved, including customs clearance and local regulations, especially when importing to regions like Africa or South America. Maintain regular communication with your supplier to address any potential delays proactively.7. Are there customization options available for irrigation valve wrenches?

Many suppliers offer customization options for irrigation valve wrenches, which may include branding with your company logo, specific sizes, or unique features tailored to your operational needs. Discuss your requirements early in the negotiation process to explore available options. Customization may affect MOQs and lead times, so it’s essential to plan accordingly to integrate these wrenches into your existing inventory seamlessly.8. What quality assurance (QA) processes should I expect from suppliers?

Reputable suppliers of irrigation valve wrenches typically implement stringent quality assurance (QA) processes, including material inspections, production quality checks, and final product testing. Inquire about their QA protocols to ensure products meet your standards. Suppliers may also provide certificates of quality or compliance with industry standards. Establishing a clear QA agreement can help mitigate risks associated with product defects and ensure reliability in your supply chain.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Irrigation Valve Wrench Manufacturers & Suppliers List

1. Reddit – DIY Sprinkler Valve Wrench

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: A DIY wrench made for accessing sprinkler valve tops, designed to fit in tight spaces where traditional tools cannot reach. The creator used PVC pipe to construct the wrench, aiming for a cost-effective solution. Suggestions from commenters included adding handles for better leverage and using alternative tools like oil filter wrenches or channel locks for similar tasks.

2. Irritrol – Irritrol Bonnet Wrench

Domain: sprinklersupplystore.com

Registered: 2010 (15 years)

Introduction: {“product_name”: “Irritrol Bonnet Wrench”, “model”: “2400-45”, “brand”: “Irritrol”, “original_price”: “$23.08”, “current_price”: “$12.98”, “sku”: “2400-45”, “availability”: “In Stock (26)”, “description”: “Threaded nut-ring wrench for the Irritrol 2400 and 2600 series valves. Can also be used with some 2700 series valves.”, “features”: [“Convenient threaded bonnets”, “Reliable double-beaded diaphr…

3. Champion Irrigation – Valve Control Key 30

Domain: championirrigation.com

Registered: 1998 (27 years)

Introduction: Valve Control Key 30″ – Champion Irrigation Products

– Available lengths: 6″, 30″, and 54″

– Purpose: Used to turn on manual sprinkler valves

– SKU: 30-30

– Category: Tools & Accessories

– Case Size: 12

4. Makita – 18V Impact Driver

Domain: lawnsite.com

Registered: 2000 (25 years)

Introduction: Makita 18V impact driver with a long extension; Dewalt impact driver; TurnFAST Jar Top Valve Wrench; adjustable torque drill; rubber strap wrench; channel locks; gasket pipe lube.

5. Accu Products – 30 Sprinkler Valve Key

Domain: accuproducts.com

Registered: 1998 (27 years)

Introduction: {“name”: “30” Sprinkler Valve Key”, “price”: “$10.00”, “description”: “For opening valves with cross handles.”, “SKU”: “85482”, “category”: “Pumps & Irrigation”, “weight”: “2 lbs”, “dimensions”: “30 × 4 × .25 in”}

Strategic Sourcing Conclusion and Outlook for irrigation valve wrench

In the competitive landscape of irrigation solutions, the importance of strategic sourcing for irrigation valve wrenches cannot be overstated. By aligning with reliable suppliers who offer high-quality, precision-engineered tools, businesses can enhance their operational efficiency and service reliability. The diverse range of wrenches available, from specialized models like the Keyfit Head Wrench to versatile valve control keys, allows B2B buyers to cater to various irrigation needs, ensuring that maintenance and installation tasks are executed with ease and precision.

Investing in quality irrigation tools not only minimizes downtime but also enhances the overall performance of irrigation systems. As the global demand for efficient water management solutions continues to rise, particularly in regions such as Africa, South America, the Middle East, and Europe, the opportunity for businesses to strengthen their sourcing strategies is significant.

Now is the time for international B2B buyers to explore partnerships that prioritize quality, innovation, and sustainability in their sourcing decisions. By doing so, they will not only secure a competitive edge but also contribute to the advancement of sustainable irrigation practices worldwide. Embrace this opportunity to elevate your irrigation solutions today.