Introduction: Navigating the Global Market for how to open irrigation control valve

Navigating the complexities of irrigation systems can be a daunting task for international B2B buyers, especially when it comes to understanding how to open irrigation control valves effectively. These crucial components regulate water flow, impacting agricultural productivity and landscape management across diverse regions, including Africa, South America, the Middle East, and Europe. However, the challenge lies not only in the technical know-how but also in sourcing the right tools and suppliers to ensure optimal operation and maintenance of these systems.

This comprehensive guide delves into the various types of irrigation control valves, their specific applications, and the best practices for opening them efficiently. It offers actionable insights on supplier vetting processes, ensuring that buyers can identify reliable manufacturers and distributors that meet international quality standards. Additionally, we will explore cost considerations, helping you make informed purchasing decisions that align with your budget and operational needs.

By equipping you with the knowledge and strategies necessary for navigating the global market for irrigation control valves, this guide empowers B2B buyers to enhance their irrigation systems’ performance. Whether you’re managing large agricultural operations or overseeing municipal water management projects, understanding how to open these valves correctly is essential for achieving efficiency and sustainability in water use.

Understanding how to open irrigation control valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Gate Valve | Operated by hand; requires physical effort to open. | Large agricultural fields | Pros: Simple, low-cost. Cons: Labor-intensive, less precise control. |

| Electric Solenoid Valve | Automated operation; uses electrical signals to open. | Commercial irrigation systems | Pros: Efficient, precise control. Cons: Requires electrical supply and maintenance. |

| Quick Coupling Valve | Allows for fast connection and disconnection; often color-coded. | Residential and small-scale farms | Pros: Easy to use, reduces downtime. Cons: May not be suitable for high-pressure systems. |

| Motorized Ball Valve | Uses a motor for operation; can be controlled remotely. | Smart irrigation systems | Pros: Remote operation, high durability. Cons: Higher initial investment, requires power source. |

| Jar Top Valve | Features a removable top for easy access; often used in low-pressure systems. | Landscaping and gardening | Pros: Easy maintenance, user-friendly. Cons: Limited to specific applications, can be cumbersome. |

What are the Characteristics of Manual Gate Valves?

Manual gate valves are the simplest form of irrigation control, requiring physical effort to open or close. Typically used in large agricultural fields, these valves are cost-effective but labor-intensive. Buyers should consider the operational demands of their irrigation systems, as manual valves may not provide the precision needed for efficient water management.

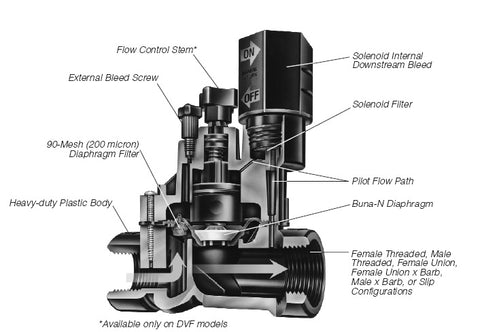

How Do Electric Solenoid Valves Enhance Irrigation Control?

Electric solenoid valves automate the opening and closing process through electrical signals, making them ideal for commercial irrigation systems. Their efficiency and precision help reduce water wastage and improve crop yields. However, buyers must ensure a reliable electrical supply and consider the maintenance needs associated with these systems.

What Advantages Do Quick Coupling Valves Offer for B2B Buyers?

Quick coupling valves are designed for ease of use, allowing for fast connections and disconnections, often color-coded for quick identification. They are particularly suited for residential and small-scale farms, where time-saving is crucial. While they significantly reduce downtime, buyers should note that these valves may not withstand high-pressure applications.

Why Choose Motorized Ball Valves for Smart Irrigation?

Motorized ball valves enable remote operation, making them an excellent choice for smart irrigation systems. Their durability and ability to integrate with automation technologies appeal to modern agricultural practices. However, the higher initial investment and need for a power source are critical factors for buyers to consider.

What Makes Jar Top Valves User-Friendly?

Jar top valves are characterized by their removable tops, which facilitate easy maintenance and access to internal components. Commonly used in landscaping and gardening, they offer user-friendly operation. However, their application may be limited to lower-pressure systems, which buyers should evaluate based on their specific needs.

Key Industrial Applications of how to open irrigation control valve

| Industry/Sector | Specific Application of how to open irrigation control valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Opening irrigation control valves for crop watering systems | Efficient water management, leading to improved crop yields | Durable materials suitable for varying climates; local availability of parts |

| Landscaping Services | Accessing valves in sprinkler systems for maintenance and adjustments | Enhanced service efficiency and reduced downtime | Compatibility with various valve types; ease of use for technicians |

| Municipal Water Supply | Activating valves in public irrigation systems for parks and green spaces | Improved public amenities and community satisfaction | Compliance with local regulations; robust and reliable equipment |

| Golf Course Management | Managing irrigation systems for optimal turf health | Enhanced aesthetic appeal and playability of courses | Precision control features; compatibility with existing systems |

| Horticulture | Opening valves for specialized watering needs in greenhouses | Consistent plant health and growth | Availability of specialized tools; adaptability to different valve designs |

How is ‘how to open irrigation control valve’ utilized in Agriculture?

In the agricultural sector, opening irrigation control valves is critical for managing water supply to crops. This process allows farmers to optimize irrigation schedules, ensuring that crops receive the necessary hydration for growth. Efficient water management directly correlates with improved crop yields and reduced wastage, which is especially vital in regions facing water scarcity. International buyers should consider sourcing durable and weather-resistant valve-opening tools to withstand varying climatic conditions, ensuring long-term reliability.

What role does ‘how to open irrigation control valve’ play in Landscaping Services?

Landscaping professionals frequently encounter various types of irrigation control valves in sprinkler systems. Mastering the technique of opening these valves is essential for routine maintenance, adjustments, and repairs. Efficient service translates to reduced downtime and enhanced customer satisfaction, making it a vital skill for landscape technicians. When sourcing tools, buyers should prioritize compatibility with a range of valve types and ensure that the equipment is user-friendly for technicians operating in diverse environments.

How does ‘how to open irrigation control valve’ impact Municipal Water Supply?

Municipal water supply systems utilize irrigation control valves to manage water distribution across public parks and green spaces. Opening these valves allows for the activation of irrigation systems, which is essential for maintaining lush, green environments that enhance community appeal. The efficiency of these systems directly affects public satisfaction and the overall health of urban landscapes. Buyers in this sector should focus on sourcing equipment that complies with local regulations and offers robust performance in high-traffic areas.

Why is ‘how to open irrigation control valve’ crucial for Golf Course Management?

In golf course management, the ability to open irrigation control valves is vital for maintaining optimal turf health. This process allows course managers to manage water distribution effectively, ensuring that greens and fairways remain in peak condition for players. The aesthetic appeal and playability of a golf course are significantly enhanced through proper irrigation practices. Buyers should seek precision control features in their tools, ensuring compatibility with existing irrigation systems to maintain consistency in care.

How is ‘how to open irrigation control valve’ relevant to Horticulture?

In horticulture, opening irrigation control valves is essential for meeting the specific watering needs of plants in greenhouses or specialized growing environments. This precision in watering helps maintain consistent plant health and promotes growth, which is crucial for commercial operations. Buyers in this sector should consider the availability of specialized tools that cater to different valve designs, as well as the adaptability of these tools to various horticultural settings.

3 Common User Pain Points for ‘how to open irrigation control valve’ & Their Solutions

Scenario 1: Difficulty Identifying the Right Valve Type

The Problem: Many B2B buyers, especially those managing large agricultural operations or commercial landscaping services, face challenges identifying the specific type of irrigation control valve they need to open. With various types available—such as quick coupling valves, anti-siphon valves, and gate valves—the confusion can lead to delays in operations and potential damage to the irrigation system. Misidentifying the valve can result in using the wrong tools or techniques, compounding the issue and leading to costly repairs or service interruptions.

The Solution: To effectively navigate this challenge, buyers should invest time in understanding the types of valves in their systems. A practical step is to create a detailed inventory of all irrigation components, noting the valve types and their specific locations. Additionally, consulting manufacturer manuals or technical specifications can provide clarity on the proper operation for each valve type. When in doubt, contacting a professional irrigation service for an initial assessment can save time and resources. It is also beneficial to have a set of multi-purpose tools designed for irrigation systems, allowing for easy adjustments regardless of the valve type.

Scenario 2: Inaccessible Valves Due to Depth or Soil Conditions

The Problem: Another common pain point arises when irrigation valves are buried too deep or obstructed by soil and debris. This is especially prevalent in regions with varying soil types or where heavy rainfall has caused erosion, making it difficult for maintenance teams to access the valves quickly. This situation not only delays irrigation schedules but can also lead to system failures if valves cannot be opened when needed.

The Solution: To address this issue, B2B buyers should consider implementing a proactive maintenance plan that includes regular inspections and clearing of valve boxes. Utilizing specialized tools such as long-handled valve keys or impact drivers with extensions can provide the necessary leverage to open hard-to-reach valves. Additionally, establishing an above-ground manifold system can simplify future maintenance and access issues by relocating valves to a more manageable height. Investing in training for maintenance personnel on effective excavation techniques can also enhance efficiency when dealing with deep or blocked valves.

Scenario 3: Lack of Proper Tools for Valve Operation

The Problem: Many irrigation professionals encounter difficulties due to a lack of appropriate tools for opening valves, particularly when they are designed for specific types of operation. Using improvised tools can lead to damaging the valves or causing leaks, ultimately resulting in expensive repairs and service disruptions. This is often exacerbated by the fact that some valves require specific handling techniques that are not well-documented.

The Solution: To overcome this challenge, B2B buyers should prioritize investing in a comprehensive toolkit specifically designed for irrigation valve maintenance. This toolkit should include items such as channel locks, specialized valve keys, and lubricants to facilitate smooth operation. Additionally, establishing relationships with reputable suppliers for quick access to the right tools can significantly reduce downtime. Training staff on the proper use of these tools and the techniques for different valve types will further enhance operational efficiency and reduce the risk of damage during maintenance tasks. Regularly reviewing and updating tool inventories based on evolving irrigation technology can also keep teams prepared for any valve-related challenges.

Strategic Material Selection Guide for how to open irrigation control valve

When considering the strategic material selection for tools used to open irrigation control valves, it’s essential to analyze various materials based on their properties, advantages, disadvantages, and suitability for specific applications. This analysis will help international B2B buyers make informed decisions based on their regional needs and compliance standards.

What Are the Key Properties of Common Materials Used in Valve Opening Tools?

Stainless Steel

– Key Properties: Stainless steel is known for its high corrosion resistance and strength, making it suitable for various environmental conditions. It can withstand high temperatures and pressures, which is critical in irrigation systems that may experience fluctuations.

– Pros & Cons: The durability of stainless steel tools ensures a long lifespan, reducing the need for frequent replacements. However, the manufacturing process can be complex, leading to higher costs compared to other materials. Additionally, while it is robust, it may not be as lightweight as aluminum.

– Impact on Application: Stainless steel tools are compatible with various media, including water and fertilizers, without risk of contamination. They are particularly beneficial in regions with high humidity or saline conditions.

– Considerations for International Buyers: Buyers should ensure that the stainless steel grades comply with local standards, such as ASTM or DIN. In regions like Europe and the Middle East, specific grades (e.g., 316) may be preferred for their enhanced corrosion resistance.Aluminum

– Key Properties: Aluminum is lightweight and has good corrosion resistance, making it easy to handle. It is suitable for lower-pressure applications and can be anodized for additional protection.

– Pros & Cons: The primary advantage of aluminum tools is their low weight, which facilitates ease of use in the field. However, they may not be as durable as stainless steel, especially in high-pressure environments. Additionally, aluminum can be more prone to bending or deformation.

– Impact on Application: Aluminum is compatible with water and many agricultural chemicals but may not be suitable for high-pressure applications. Its lightweight nature makes it ideal for portable valve-opening tools.

– Considerations for International Buyers: Buyers should verify that the aluminum used meets relevant standards and is suitable for the specific environmental conditions of their region, particularly in areas with extreme temperatures.Plastic (Polypropylene or PVC)

– Key Properties: Plastic materials like polypropylene and PVC are resistant to many chemicals and are lightweight. They are often used in applications where corrosion is a concern.

– Pros & Cons: The affordability of plastic tools is a significant advantage, making them accessible for various markets. However, they may not withstand high temperatures or pressures, limiting their application in more demanding environments.

– Impact on Application: Plastic tools are suitable for opening valves in irrigation systems where chemical exposure is a concern, such as in agricultural settings. They are also less likely to corrode when exposed to fertilizers.

– Considerations for International Buyers: Compliance with local regulations is crucial, especially in regions where agricultural standards are stringent. Buyers should ensure that the plastic materials used are durable enough for their specific applications.Bronze

– Key Properties: Bronze offers excellent corrosion resistance and strength, particularly in marine environments. It is often used in applications where durability and resistance to wear are essential.

– Pros & Cons: The durability of bronze tools makes them suitable for long-term use, especially in harsh conditions. However, they can be more expensive than other materials, and their weight may be a disadvantage for portable applications.

– Impact on Application: Bronze tools are ideal for irrigation systems that require robust and reliable equipment, particularly in coastal areas where saltwater exposure is a concern.

– Considerations for International Buyers: Buyers should check for compliance with international standards and ensure that the bronze alloys used are appropriate for their specific application requirements.

Summary Table of Material Selection for Valve Opening Tools

| Material | Typical Use Case for how to open irrigation control valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-pressure irrigation systems | High durability and corrosion resistance | Higher cost and weight | High |

| Aluminum | Portable valve-opening tools | Lightweight and easy to handle | Less durable under high pressure | Medium |

| Plastic | Chemical exposure irrigation systems | Cost-effective and corrosion resistant | Limited temperature and pressure tolerance | Low |

| Bronze | Marine or coastal irrigation systems | Excellent corrosion resistance | Higher cost and weight | High |

This strategic material selection guide provides essential insights for B2B buyers in various regions, enabling them to choose the most suitable tools for opening irrigation control valves based on their specific needs and environmental conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for how to open irrigation control valve

What Are the Key Stages in the Manufacturing Process of Irrigation Control Valves?

The manufacturing process of irrigation control valves involves several critical stages that ensure the product meets the required performance standards. These stages include material preparation, forming, assembly, and finishing.

How is Material Prepared for Irrigation Control Valve Manufacturing?

Material preparation is the foundational step in manufacturing irrigation control valves. Common materials used include brass, stainless steel, and high-grade plastics, each selected for their durability and resistance to corrosion. The preparation process involves sourcing raw materials from verified suppliers who adhere to international quality standards. B2B buyers should verify the material specifications through material certifications, ensuring compliance with international standards such as ASTM or ISO.

What Forming Techniques Are Employed in Irrigation Control Valve Production?

Once materials are prepared, the forming stage utilizes various techniques such as machining, molding, and casting. Machining is often employed for metal components, where precision equipment cuts, shapes, and finishes the material to exact specifications. For plastic components, injection molding is a prevalent technique, allowing for complex shapes and consistent quality. B2B buyers should inquire about the specific forming techniques used by suppliers, as these directly impact the valve’s performance and longevity.

How Are Irrigation Control Valves Assembled?

The assembly stage is crucial in integrating the different components of the irrigation control valve. This process may involve manual assembly or automated systems, depending on the supplier’s capabilities. Each valve component, such as the body, actuator, and seals, must be assembled with precision to ensure proper functionality. B2B buyers should assess the assembly processes in place, as inconsistencies can lead to operational failures and increased maintenance costs.

What Finishing Processes Are Applied to Irrigation Control Valves?

Finishing processes enhance the aesthetic and functional qualities of irrigation control valves. Techniques such as surface treatment, coating, and quality polishing are commonly applied to improve corrosion resistance and overall durability. For instance, electroplating can provide a protective layer against environmental factors. Buyers should request information on the finishing processes and any certifications related to environmental compliance, particularly if the valves will be used in sensitive ecological areas.

What Quality Assurance Practices Are Essential for Irrigation Control Valves?

Quality assurance (QA) is integral to the manufacturing process, ensuring that irrigation control valves meet stringent performance and safety standards. International standards such as ISO 9001 provide a framework for quality management systems that manufacturers should adhere to. Additionally, industry-specific certifications like CE marking and API standards may be applicable, depending on the region and application of the valves.

Which International Standards Should B2B Buyers Consider?

B2B buyers must be aware of relevant international standards that govern the manufacturing and quality assurance of irrigation control valves. ISO 9001 focuses on consistent quality management practices, while CE marking indicates compliance with European health, safety, and environmental protection standards. In regions like Africa and South America, understanding local compliance requirements is equally important to ensure that products meet regional regulations.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process. Incoming Quality Control (IQC) checks raw materials for compliance with specifications. In-Process Quality Control (IPQC) monitors ongoing production to identify and rectify issues early. Finally, Final Quality Control (FQC) ensures that the finished product meets all design and performance criteria before shipping. B2B buyers should request detailed QC reports from suppliers, which outline the processes and results of these checkpoints.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that a supplier adheres to stringent quality control standards, B2B buyers should employ several verification strategies. Conducting audits of the supplier’s manufacturing facilities can provide insight into their QA processes and compliance with international standards. Additionally, requesting quality control reports and certifications can substantiate a supplier’s claims regarding their product quality.

What Common Testing Methods Are Used for Irrigation Control Valves?

Testing methods play a vital role in ensuring the reliability and performance of irrigation control valves. Common tests include pressure testing, leak testing, and performance testing under various conditions. These tests help verify that the valves can withstand operational demands and environmental factors. B2B buyers should inquire about the specific testing methods employed by suppliers and seek third-party inspection reports for added assurance.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, must navigate varying quality control expectations. In Europe, rigorous standards may apply, while in other regions, local regulations may dictate different compliance requirements. Buyers should familiarize themselves with the specific standards relevant to their market and ensure that suppliers provide documentation demonstrating compliance.

Conclusion

Understanding the manufacturing processes and quality assurance practices associated with irrigation control valves is essential for B2B buyers looking to make informed purchasing decisions. By evaluating each stage of production, from material preparation to finishing, and ensuring compliance with international standards, buyers can mitigate risks and ensure the long-term performance of their irrigation systems. Engaging in thorough supplier verification practices will further enhance the reliability of procurement in the international market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to open irrigation control valve’

To successfully open an irrigation control valve, it’s essential to follow a structured approach that ensures efficiency and effectiveness. This guide will provide a detailed checklist that B2B buyers can use when sourcing tools and equipment necessary for valve operation.

Step 1: Identify the Type of Valve

Understanding the specific type of irrigation control valve you are dealing with is crucial. There are various types, such as manual, automatic, and quick-coupling valves. Identifying the type will help you determine the appropriate tools and methods needed for opening it.

- Manual vs. Automatic: Manual valves often require a physical key or handle, whereas automatic valves may need electronic controls.

- Quick-Coupling Valves: These typically have a unique coupling mechanism that may require specific tools for operation.

Step 2: Gather Required Tools

Ensure you have the right tools at your disposal before attempting to open the valve. Common tools include valve keys, channel locks, and screwdrivers. Having the correct tools not only speeds up the process but also minimizes the risk of damaging the valve.

- Valve Keys: Essential for manual valves, these keys fit into the valve mechanism.

- Channel Locks: Useful for gaining leverage on stubborn or deep-set valves.

Step 3: Prepare the Work Area

A clean and organized workspace is vital for efficient valve operation. Remove any debris, dirt, or obstructions around the valve box to access it easily. This preparation can prevent delays and make the process smoother.

- Clear Space: Ensure you can easily maneuver your tools and yourself around the valve.

- Safety Precautions: Always wear appropriate safety gear, such as gloves and goggles, to protect against potential hazards.

Step 4: Assess Valve Condition

Before opening the valve, inspect it for any signs of wear or damage. Checking for leaks or corrosion can prevent further complications down the line. A thorough assessment ensures that you address any issues before attempting to open the valve.

- Look for Leaks: Visible leaks may indicate that the valve is not functioning properly.

- Corrosion Checks: Corroded components can be fragile; handle them with care.

Step 5: Follow Manufacturer Guidelines

Always refer to the manufacturer’s guidelines for specific instructions on how to open the valve. Different valves may have unique mechanisms or requirements that should be adhered to for safe operation.

- Consult Manuals: Manufacturer manuals often provide detailed steps and safety warnings.

- Seek Support: If available, customer support can provide insights on specific valve models.

Step 6: Test the System Post-Operation

After successfully opening the valve, conduct a test to ensure it operates correctly. Monitor for any irregularities in water flow or pressure, and check for leaks. This step is crucial for confirming that the valve is functioning as intended.

- Flow Monitoring: Observe the water flow to ensure it meets expected standards.

- Leak Check: Inspect the valve and surrounding areas for any signs of leakage.

Step 7: Document the Process

Keep a record of the tools used, any issues encountered, and the steps taken. Documentation is essential for future reference and can improve the efficiency of subsequent operations. It also aids in identifying patterns or recurring issues that may need addressing.

- Create a Log: Documenting the process can help in troubleshooting future valve operations.

- Review and Improve: Use the log to refine your techniques and tool selection over time.

By following these steps, B2B buyers can ensure they are well-equipped to open irrigation control valves effectively and efficiently, ultimately enhancing the performance of their irrigation systems.

Comprehensive Cost and Pricing Analysis for how to open irrigation control valve Sourcing

What Are the Key Cost Components in Sourcing Irrigation Control Valves?

When sourcing irrigation control valves, several cost components significantly impact the overall pricing structure. These include:

Materials: The quality and type of materials used (e.g., plastic vs. brass) can greatly influence costs. High-quality materials may result in higher initial costs but can offer better durability and longer lifespans, leading to lower replacement rates.

Labor: Labor costs encompass the wages paid to skilled workers for manufacturing and installation. In regions with higher labor costs, such as Europe, these expenses can be substantial.

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and other operational expenses necessary for production. Efficient manufacturing processes can reduce these costs.

Tooling: The initial investment in tools and equipment for valve production can be significant. Suppliers often spread these costs over production volume, impacting pricing.

Quality Control (QC): Implementing stringent QC measures ensures product reliability but may add to overall costs. Certifications (like ISO) can also impact pricing structures due to compliance requirements.

Logistics: Shipping and handling costs are crucial, especially for international buyers. Factors like distance, shipping methods, and customs duties can significantly affect final pricing.

Margin: Suppliers will typically add a profit margin to cover their risks and ensure sustainability. This margin varies by supplier and market conditions.

How Do Price Influencers Affect the Sourcing of Irrigation Control Valves?

Several factors can influence the pricing of irrigation control valves, particularly for B2B buyers:

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to significant discounts. Suppliers are more willing to negotiate prices for larger orders, which can be advantageous for businesses with extensive irrigation needs.

Specifications and Customization: Custom valves tailored to specific requirements may incur additional costs. Standardized products are generally less expensive, while bespoke solutions can demand higher pricing due to the complexity involved.

Material Quality and Certifications: Higher-quality materials or certified products often come at a premium. Buyers should weigh the long-term benefits against the initial costs when considering certification.

Supplier Factors: Supplier reputation, reliability, and geographic location can influence pricing. Local suppliers may offer reduced shipping costs but might not always match the quality or pricing of international suppliers.

Incoterms: Understanding Incoterms is crucial for international transactions, as they define responsibilities regarding shipping costs, insurance, and liability. This knowledge can help buyers optimize their total costs.

What Are the Best Buyer Tips for Negotiating Prices on Irrigation Control Valves?

To maximize value and minimize costs, B2B buyers should consider the following strategies:

Negotiation: Always engage in discussions to negotiate better pricing. Suppliers may have flexibility in their pricing, especially for larger orders or long-term contracts.

Cost-Efficiency: Evaluate the total cost of ownership rather than just the purchase price. Consider maintenance, longevity, and operational efficiency to determine the best overall value.

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, trade tariffs, and import/export regulations. These factors can significantly influence pricing and should be factored into budget planning.

Seek Multiple Quotes: Obtaining quotes from various suppliers can provide insight into market rates and help identify the most cost-effective options.

Disclaimer on Indicative Prices

Pricing for irrigation control valves can vary significantly based on market dynamics, geographic location, and specific project requirements. The figures provided in sourcing discussions are indicative and should be verified with suppliers for accuracy and relevance to current market conditions.

Alternatives Analysis: Comparing how to open irrigation control valve With Other Solutions

Exploring Alternatives for Opening Irrigation Control Valves

In the context of irrigation systems, effectively opening control valves is essential for ensuring optimal water distribution. However, various methods and technologies can serve the same purpose, each with its advantages and disadvantages. This section analyzes the traditional method of opening irrigation control valves alongside modern alternatives, enabling B2B buyers to make informed decisions tailored to their operational needs.

Comparison Table

| Comparison Aspect | How To Open Irrigation Control Valve | Alternative 1: Motorized Valves | Alternative 2: Above Ground Manifold Valves |

|---|---|---|---|

| Performance | Reliable but labor-intensive | Highly efficient and automated | Easy to service, effective water flow |

| Cost | Low initial cost | Higher upfront investment | Moderate cost, but saves on labor |

| Ease of Implementation | Requires manual effort and tools | Requires installation expertise | Simple installation and minimal tools needed |

| Maintenance | Regular maintenance required | Minimal maintenance needed | Low maintenance, but occasional checks needed |

| Best Use Case | Suitable for small to medium systems | Ideal for large, automated systems | Best for easy access and frequent adjustments |

Detailed Breakdown of Alternatives

Motorized Valves: Are They Worth the Investment?

Motorized valves are an advanced solution for irrigation control. They can be operated remotely via smartphones or control systems, making them ideal for large-scale operations where manual valve management would be cumbersome. The primary advantages include efficiency and reduced labor costs, as they can be programmed to open and close automatically. However, the initial installation cost is higher, and there may be compatibility issues with existing systems. For businesses looking to modernize their irrigation systems, motorized valves provide a compelling option, particularly in regions with significant labor costs.

Above Ground Manifold Valves: Simplifying Irrigation Management

Above ground manifold valves are gaining traction due to their ease of access and maintenance. Unlike traditional buried valves, these systems are installed above ground, allowing for quick adjustments and servicing without the need for digging. This design is particularly beneficial in areas prone to flooding or where soil conditions make maintenance challenging. While they may require a moderate initial investment, their low maintenance needs and ease of access can lead to significant savings in labor and time. This solution is particularly appealing for smaller agricultural operations or landscaping businesses that prioritize efficiency.

Conclusion: Choosing the Right Solution for Your Irrigation Needs

When selecting a method for opening irrigation control valves, B2B buyers must consider their specific operational requirements, including the scale of their irrigation system, budget constraints, and maintenance capabilities. While traditional methods remain effective for smaller systems, alternatives like motorized valves and above-ground manifold systems can offer enhanced efficiency and ease of use. By evaluating the pros and cons of each option, businesses can choose a solution that not only meets their immediate needs but also supports long-term sustainability and operational efficiency in their irrigation practices.

Essential Technical Properties and Trade Terminology for how to open irrigation control valve

What Are the Key Technical Properties of Irrigation Control Valves?

When considering the opening of irrigation control valves, understanding the technical properties is essential for ensuring efficient and effective operation. Here are some critical specifications that international B2B buyers should be aware of:

Material Grade

The material used for irrigation control valves typically includes PVC, brass, or stainless steel. Each material has distinct advantages: PVC is lightweight and corrosion-resistant, brass offers durability and longevity, while stainless steel combines strength with resistance to rust. The choice of material can significantly affect the valve’s lifespan and performance, making it crucial for buyers to select valves that match their operational environment.Pressure Rating

This specification indicates the maximum pressure the valve can withstand, typically expressed in pounds per square inch (PSI). Understanding the pressure rating is vital for ensuring that the valve will function correctly under the specific pressures of the irrigation system. Choosing a valve with an inadequate pressure rating can lead to leaks or failures, which can disrupt irrigation schedules and lead to costly repairs.Flow Rate

Measured in gallons per minute (GPM), the flow rate indicates how much water can pass through the valve at a given time. This property is essential for maintaining the desired irrigation coverage. Buyers should assess their water supply and system requirements to ensure they select a valve that can deliver the necessary flow rate without causing pressure drops or inefficiencies.Operating Temperature

The operating temperature range specifies the environmental conditions under which the valve can effectively function. Valves that operate in extreme temperatures—either hot or cold—require materials and designs that can withstand these conditions without deteriorating. This property is particularly important in regions with varying climates, ensuring the longevity and reliability of the irrigation system.Tolerance

Tolerance refers to the allowable deviation from a specified measurement. In the context of valve manufacturing, it ensures that components fit together correctly and function as intended. High-precision tolerances can minimize wear and improve the performance of the valve, which is essential for long-term reliability in irrigation applications.

What Are Common Trade Terminology and Jargon Used in Irrigation Systems?

Understanding industry terminology is crucial for effective communication and negotiation in the B2B space. Here are some common terms that buyers should familiarize themselves with:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. Knowing whether a valve is an OEM product can help buyers assess quality and compatibility with existing systems.MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. Understanding MOQ is important for buyers to ensure they can meet their needs without being forced to over-order, which can tie up capital unnecessarily.RFQ (Request for Quotation)

An RFQ is a document that solicits price quotes from suppliers for specific products. B2B buyers use RFQs to compare prices and features across different suppliers, facilitating informed purchasing decisions.Incoterms

These are international commercial terms that define the responsibilities of buyers and sellers in shipping. Familiarity with Incoterms helps buyers understand shipping costs, risks, and obligations, which is crucial for international transactions.Valve Box

A valve box is an enclosure that protects irrigation valves from environmental factors. Understanding the specifications and installation requirements for valve boxes is essential for ensuring the longevity and accessibility of irrigation control valves.Flow Control

This term refers to the mechanisms used to regulate water flow through irrigation systems. Knowledge of flow control options helps buyers optimize their systems for efficiency and effectiveness, ensuring proper irrigation coverage.

By grasping these essential technical properties and industry terms, B2B buyers can make informed decisions when selecting irrigation control valves, ultimately enhancing the performance and reliability of their irrigation systems.

Navigating Market Dynamics and Sourcing Trends in the how to open irrigation control valve Sector

Market Overview & Key Trends in the Irrigation Control Valve Sector

The global irrigation control valve market is witnessing significant transformation driven by several factors. First, the increasing demand for efficient water management practices is essential, especially in regions facing water scarcity, such as parts of Africa and the Middle East. This urgency is propelling B2B buyers to seek advanced irrigation solutions that not only optimize water usage but also minimize waste. Additionally, technological advancements in automation and smart irrigation systems are emerging as pivotal trends. The integration of IoT-enabled devices allows for remote monitoring and control, enhancing operational efficiency and reducing labor costs.

Emerging markets in South America and Africa are also experiencing a shift towards modern agricultural practices, where the adoption of automated irrigation systems is becoming commonplace. This shift necessitates a deeper understanding of the tools and techniques required to open and maintain irrigation control valves. As these regions invest in agricultural technology, international buyers must stay informed about the latest innovations and sourcing strategies that can facilitate efficient irrigation management.

Moreover, the European market is increasingly influenced by stringent environmental regulations, which are pushing manufacturers to develop more sustainable and compliant irrigation solutions. This regulatory landscape is critical for B2B buyers looking to partner with suppliers who can provide not only high-quality products but also demonstrate adherence to environmental standards.

How is Sustainability & Ethical Sourcing Impacting the Irrigation Control Valve Market?

Sustainability is becoming a cornerstone of purchasing decisions in the irrigation control valve sector. Buyers are increasingly prioritizing products that have minimal environmental impact throughout their lifecycle. This includes the sourcing of materials, manufacturing processes, and the overall carbon footprint associated with the product. B2B buyers should seek suppliers that utilize recycled materials and environmentally friendly manufacturing practices, as these factors can enhance their brand reputation and meet consumer demand for responsible sourcing.

Ethical supply chains are gaining traction as well, with buyers demanding transparency from manufacturers regarding labor practices and sourcing conditions. Certifications such as ISO 14001 for environmental management and various green certifications for products can serve as indicators of a supplier’s commitment to sustainability. By aligning with suppliers who prioritize ethical sourcing, international B2B buyers can mitigate risks associated with supply chain disruptions and enhance their corporate social responsibility profiles.

Furthermore, the trend towards “green” technologies in irrigation systems, such as solar-powered valves and energy-efficient designs, is shaping the market landscape. As global agricultural practices evolve, investing in sustainable irrigation solutions not only addresses environmental challenges but also provides long-term cost savings and efficiency gains.

What is the Brief Evolution of Irrigation Control Valve Technology?

The evolution of irrigation control valve technology can be traced back to traditional mechanical systems, which were primarily manual and required significant labor. Over the decades, innovations have led to the development of more sophisticated valve designs that enhance operational efficiency and ease of use. Early models were often made from metal, which posed challenges such as rust and corrosion. The introduction of durable plastic materials has significantly improved the longevity and reliability of these valves.

As technology advanced, the incorporation of automation and smart controls became prevalent. Today, modern irrigation control valves can be integrated with smart sensors and IoT technology, allowing for real-time monitoring and control via mobile applications. This evolution not only simplifies the process of opening and managing valves but also optimizes water usage in response to environmental conditions. For B2B buyers, understanding this historical context is vital for making informed sourcing decisions that align with current technological trends and market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of how to open irrigation control valve

How do I open an irrigation control valve that is stuck?

To open a stuck irrigation control valve, first, ensure that the area around the valve is clear of debris and dirt. Use a wrench or channel locks to gently apply pressure to the valve bonnet or control mechanism. If the valve is still resistant, consider applying a penetrating oil to the joints and allowing it to soak for a few minutes. In cases where the valve is buried deep, utilizing a long extension tool or an impact driver may provide the leverage needed to open it without damaging the valve.What tools are essential for opening an irrigation control valve?

Essential tools for opening an irrigation control valve include a valve key, channel locks, and a wrench. For valves that are deeper in a valve box, an impact driver with a long extension can be effective. Additionally, having a penetrating oil on hand can help loosen stuck components. These tools will facilitate easy access and operation, ensuring that the process is efficient and minimizes the risk of damage to the valve.What should I consider when sourcing irrigation control valves internationally?

When sourcing irrigation control valves internationally, consider the supplier’s reputation, product quality, and compliance with local regulations. It’s vital to assess whether the supplier provides detailed product specifications and certifications. Additionally, consider their experience in handling logistics and customs clearance, especially for shipments to regions such as Africa or South America. Engaging in direct communication can help clarify any doubts regarding product performance and after-sales support.How do I vet suppliers for irrigation control valves?

To vet suppliers for irrigation control valves, start by reviewing their company history and client testimonials. Request references and check their compliance with industry standards. Additionally, evaluate their production capabilities and quality assurance processes. It’s also beneficial to ask for samples of their valves to assess quality firsthand. Engaging in a video call can provide further insights into their operations and professionalism.What are typical payment terms for purchasing irrigation control valves?

Typical payment terms for purchasing irrigation control valves can vary by supplier and region but often include options such as a deposit upfront (usually 30-50%) with the balance due upon delivery or after inspection. Some suppliers may offer net payment terms (e.g., net 30 or net 60) for established clients. Always clarify payment methods accepted (e.g., bank transfer, letters of credit) and ensure that these terms are documented in your purchase agreement to avoid disputes.What minimum order quantities (MOQ) should I expect for irrigation control valves?

Minimum order quantities (MOQ) for irrigation control valves can range significantly based on the manufacturer and specific valve types. Some suppliers may set an MOQ as low as 50 units, while others, especially for custom valves, may require orders of 500 or more. It’s essential to discuss your requirements with potential suppliers to negotiate favorable terms that suit your purchasing needs and inventory management strategies.How can I ensure the quality of irrigation control valves from international suppliers?

To ensure the quality of irrigation control valves from international suppliers, request detailed product specifications and certifications. Implementing a quality assurance process, such as third-party inspections or audits, can also be beneficial. Additionally, consider establishing a trial order to evaluate the product’s performance and durability. Regular communication and feedback loops with the supplier can help address any quality concerns proactively.What logistics considerations should I be aware of when importing irrigation control valves?

When importing irrigation control valves, consider the logistics involved, such as shipping methods, transit times, and customs regulations specific to your country. Collaborate with a logistics partner familiar with international shipping to navigate any potential issues, including tariffs and duties. Ensure that you have the necessary documentation, such as commercial invoices and packing lists, to facilitate smooth customs clearance and timely delivery of your valves.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 How To Open Irrigation Control Valve Manufacturers & Suppliers List

1. Horizon – Checkmate 3 & Checker Plus

Domain: horizononline.com

Registered: 1997 (28 years)

Introduction: Horizon offers troubleshooting guidance for irrigation valves, including steps for electrical and mechanical checks. Key products mentioned include the Checkmate 3 and Checker Plus for solenoid operation verification, and Checker Jr. as a kick-start device. Repair kits and replacement valves are available at Horizon stores. The troubleshooting process involves checking water supply, controller fun…

2. JustAnswer – Irrigation System Troubleshooting

Domain: justanswer.com

Registered: 2004 (21 years)

Introduction: Irrigation system issue: One station stuck on despite controller being off, causing flooding. Possible causes include debris in the valve, damaged diaphragm, malfunctioning solenoid, or manual override left on. Immediate solution: Manually shut off water supply to the irrigation system. Permanent fix: Inspect and clean or replace solenoid, manually lift valve diaphragm, check wiring connections.

3. The Spruce – Essential Tools and Materials

Domain: thespruce.com

Registered: 2009 (16 years)

Introduction: Equipment / Tools: Flat-head screwdriver, Sprinkler valve key (as needed), Pen or pencil, Pliers (as needed). Materials: Notepad or scrap paper.

4. Christie’s Landscapes – Sprinkler Valves

Domain: christieslandscapes.com.au

Introduction: Sprinkler valves are a vital part of irrigation systems, translating instructions from the control box into changes in water flow. The most common type used today are electronic solenoid valves, which are ‘normally closed’. They remain closed due to water pressure unless activated by a signal from the control box. Manual operation is possible by flipping a switch or turning the solenoid counter-cl…

5. DIG – Irrigation Controllers

Domain: bigfrogsupply.com

Registered: 2014 (11 years)

Introduction: Enjoy fast and free shipping on all orders over $89! Contact us (855) 424-4376. Products include: DIG Irrigation (Controllers, Valves, Solenoids, Drip Line, Accessories), Hunter (Controllers, Valves), Hydro-Rain (Controllers), Rain Bird (Controllers, Rotors, Nozzles, Spray, Impact, Valves, Drip Line, Accessories), Toro (Controllers, Valves, Spray, Nozzles), Irritrol (Controllers, Valves), K-Rain (…

6. Lawn Forum – Brass Irrigation Control Valves

Domain: thelawnforum.com

Registered: 2017 (8 years)

Introduction: Irrigation Control Valves, approximately 20 years old, identified as older brass control valves with two cross handles that are extremely tight and cannot be turned by hand. Concerns about breaking them if tools are used. They may be manual shut-off valves that were once used for manual control before being replumbed with solenoid valves for automatic control.

Strategic Sourcing Conclusion and Outlook for how to open irrigation control valve

What Are the Key Takeaways for Opening Irrigation Control Valves?

In conclusion, understanding how to effectively open irrigation control valves is crucial for maintaining efficient irrigation systems. Key considerations include identifying the right tools, such as long valve keys or channel locks, and being aware of the specific valve types, like quick couplers or anti-siphon valves. Proper training and knowledge in valve operation not only enhance the longevity of irrigation systems but also prevent costly repairs and downtime.

How Can Strategic Sourcing Enhance Your Irrigation Operations?

Strategic sourcing plays a vital role in optimizing the procurement of irrigation components. By fostering relationships with reliable suppliers and manufacturers, B2B buyers can secure high-quality products that meet their operational needs, especially in regions like Africa, South America, the Middle East, and Europe. This approach not only streamlines procurement processes but also ensures that businesses are equipped with the latest technology and tools for effective irrigation management.

What’s Next for International Buyers in the Irrigation Sector?

As we look toward the future, it’s imperative for international buyers to stay ahead of technological advancements in irrigation control. Investing in smart irrigation solutions and efficient valve systems will be key in meeting the growing demand for sustainable agricultural practices. Embrace the opportunity to enhance your operations by connecting with trusted suppliers and exploring innovative irrigation solutions tailored to your specific needs. Engage proactively in the marketplace, and ensure your irrigation systems are not only functional but also future-ready.