Introduction: Navigating the Global Market for irrigation backflow valves

In an increasingly interconnected world, sourcing reliable irrigation backflow valves presents a significant challenge for international B2B buyers. These critical components ensure the safety of potable water by preventing contamination from irrigation systems, which often contain harmful substances like fertilizers and pesticides. This comprehensive guide aims to equip decision-makers from regions such as Africa, South America, the Middle East, and Europe—including emerging markets like Vietnam and Nigeria—with the essential knowledge needed to navigate the complexities of backflow prevention systems.

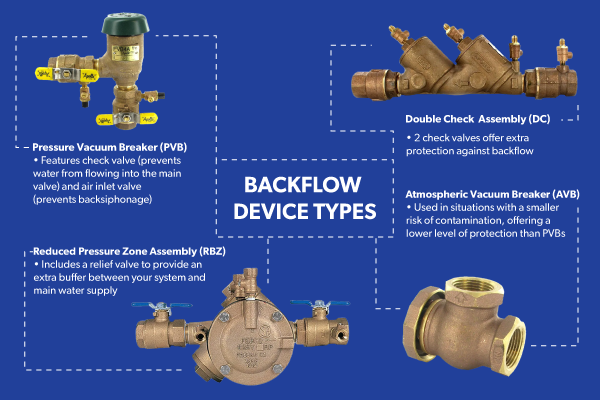

Throughout this guide, we delve into the various types of irrigation backflow valves, including Reduced Pressure Zone (RPZ) Assemblies, Double Check Valves, and Pressure Vacuum Breakers. Each type serves a distinct purpose, with applications spanning residential, commercial, and industrial settings. We also discuss critical factors for supplier vetting, enabling buyers to identify reputable manufacturers that meet their quality and regulatory standards. Additionally, we provide insights on cost considerations, installation requirements, and maintenance practices to help you make informed purchasing decisions.

By understanding the nuances of irrigation backflow valves, this guide empowers B2B buyers to secure the right solutions for their specific needs, ensuring the integrity of water supplies and compliance with local regulations. Whether you are expanding your existing operations or entering new markets, being well-informed will facilitate effective sourcing strategies and foster long-term partnerships in the irrigation sector.

Understanding irrigation backflow valves Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Reduced Pressure Zone (RPZ) | Combines check valves and relief valves for high protection | Commercial irrigation, health hazard areas | Pros: Highest protection level; Cons: More expensive; requires regular testing. |

| Double Check Assembly (DCA) | Two check valves for moderate protection against backflow | Residential and light commercial systems | Pros: Cost-effective; Cons: Limited protection for high-risk applications. |

| Pressure Vacuum Breaker (PVB) | Designed to prevent backsiphonage; freeze-resistant options | Landscape irrigation, residential systems | Pros: Affordable and easy to install; Cons: Not suitable for high hazard situations. |

| Atmospheric Vacuum Breaker (AVB) | Simple design; prevents backsiphonage; requires no moving parts | Small irrigation systems, gardens | Pros: Low-cost; easy maintenance; Cons: Limited to low-risk scenarios; may not meet all regulations. |

| Freeze-Resistant Backflow Preventer | Specifically designed to withstand freezing conditions | Areas with cold climates, outdoor systems | Pros: Prevents damage in cold weather; Cons: Higher upfront cost; may require special installation. |

What Are the Characteristics of Reduced Pressure Zone (RPZ) Assemblies?

RPZ assemblies are the most robust type of backflow preventer, utilizing a combination of check and relief valves to maintain a reduced pressure zone. They are essential in commercial irrigation systems, especially in areas where health hazards are prevalent, such as agricultural operations using fertilizers and pesticides. When considering an RPZ for purchase, B2B buyers should evaluate the installation requirements, the need for regular maintenance, and compliance with local regulations, as these devices must be tested periodically to ensure effectiveness.

How Do Double Check Assemblies (DCA) Function?

Double Check Assemblies employ two check valves to prevent backflow, offering moderate protection suitable for residential and light commercial applications. They are particularly effective in scenarios where the risk of contamination is lower. B2B buyers should consider their cost-effectiveness and ease of installation. However, it’s crucial to understand that DCAs may not be suitable for high-risk environments, and local codes may dictate their use in certain applications.

Why Choose Pressure Vacuum Breakers (PVB)?

Pressure Vacuum Breakers are designed to prevent backsiphonage, making them a popular choice for landscape and residential irrigation systems. Many models are freeze-resistant, adding to their versatility in various climates. Buyers should prioritize ease of installation and affordability when selecting PVBs. However, it is important to note that they do not provide adequate protection in high-hazard situations, which could lead to compliance issues.

What Are the Advantages of Atmospheric Vacuum Breakers (AVB)?

Atmospheric Vacuum Breakers are straightforward devices that prevent backsiphonage without requiring moving parts, making them easy to maintain. They are ideal for small irrigation systems and gardens where the risk of contamination is minimal. B2B buyers appreciate the low cost and simplicity of AVBs; however, their limited application scope and potential regulatory restrictions should be considered when making purchasing decisions.

When to Use Freeze-Resistant Backflow Preventers?

Freeze-resistant backflow preventers are specifically engineered to withstand freezing temperatures, making them essential for outdoor irrigation systems in colder climates. These devices help prevent damage during winter months, ensuring continuous operation. B2B buyers should weigh the benefits of protecting their investments against the higher upfront costs and possible installation complexities associated with these specialized devices.

Key Industrial Applications of irrigation backflow valves

| Industry/Sector | Specific Application of Irrigation Backflow Valves | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Protecting irrigation systems from contamination | Ensures safe water supply for crops; enhances yield | Compliance with local regulations; durability in harsh climates |

| Landscape Management | Safeguarding potable water in public parks | Maintains water quality; protects public health | Accessibility for maintenance; compatibility with existing systems |

| Golf Course Management | Preventing backflow in irrigation systems | Preserves water quality; prevents costly repairs | High-performance specifications; resistance to chemicals |

| Municipal Water Systems | Backflow prevention in urban irrigation networks | Protects drinking water sources; complies with safety standards | Certification and testing requirements; ease of installation |

| Industrial Landscaping | Controlling water supply in large estates | Reduces risk of contamination; ensures efficient water use | Customization options; ability to handle varying pressure levels |

How Are Irrigation Backflow Valves Used in Agriculture?

In the agriculture sector, irrigation backflow valves are essential for protecting irrigation systems from contamination by fertilizers, pesticides, and other harmful substances. These valves prevent backpressure and backsiphonage, ensuring that only clean water is used for irrigation. International buyers, particularly in regions like Africa and South America, must consider local regulations regarding water safety, as well as the durability of valves in extreme weather conditions. Selecting high-quality backflow prevention devices can significantly enhance crop yield and protect the investment in agricultural production.

What Role Do Irrigation Backflow Valves Play in Landscape Management?

In landscape management, irrigation backflow valves are vital for safeguarding potable water supplies in public parks and recreational areas. These valves ensure that contaminants from irrigation systems do not enter the drinking water supply, thus maintaining public health and safety. Buyers from the Middle East and Europe should prioritize ease of maintenance and compatibility with existing irrigation systems when sourcing these devices. By investing in reliable backflow prevention, landscape managers can ensure the longevity of their systems and provide safe environments for community enjoyment.

Why Are Backflow Preventers Important for Golf Course Management?

Golf course management relies heavily on irrigation systems to maintain lush greens and fairways. Backflow preventers are critical in these settings to prevent the contamination of potable water sources due to fertilizers or herbicides used in maintenance. For buyers in regions like Vietnam, the focus should be on high-performance specifications that can withstand varying weather conditions and chemical exposure. By ensuring proper backflow prevention, golf course managers not only protect water quality but also avoid potential costly repairs and liabilities.

How Do Municipal Water Systems Benefit from Irrigation Backflow Valves?

Municipal water systems utilize irrigation backflow valves to protect drinking water sources from contamination in urban irrigation networks. These valves help maintain compliance with health and safety regulations, ensuring that the water supplied to residents is safe for consumption. Buyers in developing regions should be aware of certification and testing requirements that may vary by locality. Investing in robust backflow prevention solutions can significantly enhance public trust and safety, making it a critical consideration for municipal planners.

What Advantages Do Industrial Landscapers Gain from Using Backflow Valves?

In the realm of industrial landscaping, backflow valves are used to control water supply in large estates and corporate campuses. These devices are crucial for reducing the risk of contamination from irrigation systems, ensuring that water remains clean and usable for various landscaping needs. International buyers should consider customization options that allow for adaptability to different pressure levels and environmental conditions. By implementing effective backflow prevention measures, businesses can optimize water usage and protect their investments in landscaping infrastructure.

3 Common User Pain Points for ‘irrigation backflow valves’ & Their Solutions

Scenario 1: Ensuring Compliance with Local Regulations

The Problem: Many B2B buyers face the daunting challenge of navigating complex local regulations surrounding the installation of irrigation backflow valves. Non-compliance can result in hefty fines, legal issues, or even project shutdowns. For instance, in regions like Europe and South America, stringent regulations often mandate specific types of backflow preventers for different applications. Buyers may struggle to identify which backflow valve meets both the regulatory requirements and the unique needs of their irrigation systems, especially when local codes change frequently or are difficult to interpret.

The Solution: To tackle compliance challenges, B2B buyers should begin by thoroughly researching local regulations and standards applicable to backflow prevention devices. Partnering with local regulatory bodies or industry associations can provide invaluable guidance. Additionally, sourcing products from reputable manufacturers known for their adherence to compliance standards is critical. Buyers should opt for Reduced Pressure Zone (RPZ) assemblies in high-risk areas where contaminants are a concern, as these devices offer the highest protection against backflow. A proactive approach to training staff on local codes and ensuring that the selected valves are certified can further mitigate the risk of non-compliance.

Scenario 2: Addressing Maintenance and Reliability Issues

The Problem: Reliability and maintenance of irrigation backflow valves can be a persistent pain point for businesses. Buyers often report issues with valve failures due to inadequate maintenance protocols or poor-quality components. For instance, valves that freeze in colder climates or corrode in areas with high mineral content can lead to water contamination and costly system downtime. This is particularly problematic for agricultural businesses in regions with extreme weather conditions, where a malfunctioning backflow valve can jeopardize crops and overall productivity.

The Solution: To enhance reliability, buyers should implement a rigorous maintenance schedule that includes regular inspections and testing of backflow prevention devices. This can involve using backflow test kits to ensure that the valves are functioning correctly and that no contaminants are entering the potable water supply. Selecting high-quality materials—such as bronze or corrosion-resistant alloys—can significantly reduce the risk of failure. Additionally, investing in freeze-resistant models, particularly in colder regions, can prevent winter-related issues. Educating staff on proper maintenance techniques and creating a responsive service agreement with suppliers can also ensure that any issues are promptly addressed, thus minimizing downtime.

Scenario 3: Overcoming Sizing and Selection Challenges

The Problem: Choosing the right size and type of irrigation backflow valve for specific applications can be a significant hurdle for B2B buyers. Many report confusion over the various models available, such as Atmospheric Vacuum Breakers (AVB), Pressure Vacuum Breakers (PVB), and RPZ assemblies, leading to potential oversizing or undersizing of the valves. Incorrect selection not only affects system efficiency but can also lead to regulatory compliance failures and increased operational costs.

The Solution: To overcome sizing and selection challenges, buyers should conduct a comprehensive assessment of their irrigation system’s requirements, including flow rates, pressure conditions, and the potential risk of contamination. Collaborating with experienced irrigation specialists or engineers can provide insights into the appropriate valve types for specific applications. For example, an RPZ assembly is ideal for high-risk situations, while a PVB may suffice for lower-risk environments. Utilizing sizing calculators available from manufacturers can also aid in selecting the correct valve size. Lastly, ensuring that installation is performed by qualified technicians can guarantee that the valves operate efficiently and effectively, thus protecting the integrity of the irrigation system.

Strategic Material Selection Guide for irrigation backflow valves

What Are the Key Properties of Common Materials Used in Irrigation Backflow Valves?

When selecting materials for irrigation backflow valves, it is crucial to consider their properties, as these directly affect performance, durability, and suitability for specific applications. Here, we analyze four common materials: brass, bronze, PVC, and stainless steel.

Brass: A Reliable Choice for General Applications

Brass is a popular material for irrigation backflow valves due to its excellent corrosion resistance and good mechanical properties. It typically has a temperature rating of up to 200°F (93°C) and can withstand moderate pressure levels.

Pros: Brass valves are durable and have a long service life, making them suitable for various irrigation applications. They are also relatively easy to manufacture, allowing for cost-effective production.

Cons: However, brass can be more expensive than other materials like PVC. Additionally, it may not be suitable for highly acidic or alkaline environments, which can lead to corrosion over time.

Impact on Application: Brass is compatible with potable water systems and is often used in residential and light commercial applications.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers in regions like Africa and South America should ensure that brass valves meet local regulations regarding drinking water safety.

Bronze: Enhanced Corrosion Resistance for Challenging Environments

Bronze is another excellent material for backflow valves, particularly in harsh environments. It offers superior corrosion resistance compared to brass, withstanding a wider range of temperatures and pressures.

Pros: Bronze valves are highly durable and resistant to pitting and dezincification, making them ideal for applications involving saline or chlorinated water.

Cons: The primary drawback of bronze is its higher cost compared to brass and PVC. Additionally, bronze can be more complex to machine, which may increase manufacturing lead times.

Impact on Application: Bronze is suitable for both potable and non-potable water systems and is often used in industrial irrigation applications.

Considerations for International Buyers: Buyers should verify that bronze valves comply with local standards and regulations, especially in regions with stringent water quality requirements.

PVC: Cost-Effective and Lightweight Solution

Polyvinyl Chloride (PVC) is a widely used material for irrigation backflow valves, particularly in lower-pressure applications. PVC valves are lightweight and have a temperature rating of up to 140°F (60°C).

Pros: The main advantage of PVC is its low cost and ease of installation. It is also resistant to many chemicals, making it suitable for various irrigation applications.

Cons: However, PVC is not as durable as metal options and may become brittle over time, especially when exposed to UV light. Its pressure rating is also lower, limiting its use in high-pressure systems.

Impact on Application: PVC valves are commonly used in residential irrigation systems and applications where cost is a significant factor.

Considerations for International Buyers: Buyers should ensure that PVC products meet local standards, such as ASTM or JIS, particularly in regions where chemical compatibility is critical.

Stainless Steel: Premium Performance in Extreme Conditions

Stainless steel is a high-performance material that offers excellent corrosion resistance and can handle high temperatures and pressures, making it suitable for demanding applications.

Pros: Stainless steel valves are incredibly durable and can last for decades, even in harsh environments. They are also resistant to corrosion, making them ideal for applications involving aggressive chemicals.

Cons: The primary disadvantage is the high cost associated with stainless steel, which can be prohibitive for some buyers. Additionally, manufacturing stainless steel valves can be more complex, leading to longer lead times.

Impact on Application: Stainless steel is often used in industrial applications or areas where water quality is critical, such as in food production or pharmaceutical irrigation systems.

Considerations for International Buyers: Buyers should check for compliance with international standards and certifications, particularly in the Middle East and Europe, where regulations may be stringent.

Summary Table of Material Selection for Irrigation Backflow Valves

| Material | Typical Use Case for irrigation backflow valves | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Residential and light commercial applications | Excellent corrosion resistance | Not suitable for highly acidic environments | Medium |

| Bronze | Industrial irrigation applications | Superior corrosion resistance | Higher cost and manufacturing complexity | High |

| PVC | Residential irrigation systems | Low cost and lightweight | Lower durability and pressure rating | Low |

| Stainless Steel | Industrial applications and critical water quality | Exceptional durability and corrosion resistance | High cost and complex manufacturing | High |

In-depth Look: Manufacturing Processes and Quality Assurance for irrigation backflow valves

What Are the Key Stages in the Manufacturing Process of Irrigation Backflow Valves?

The manufacturing of irrigation backflow valves involves several critical stages, each designed to ensure the final product meets stringent performance and safety standards. The main stages of manufacturing include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Backflow Valve Production?

The first step in the manufacturing process is material preparation. High-quality raw materials, such as brass, bronze, or PVC, are selected based on the valve’s intended application. These materials are then cut, shaped, and treated to enhance their corrosion resistance and durability. For instance, brass components may undergo a plating process to improve their resistance to wear and environmental factors, which is particularly important for valves used in harsh climates.

What Techniques Are Used for Forming and Shaping Backflow Valves?

Once the materials are prepared, the forming process begins. This can involve various techniques such as casting, machining, and forging.

- Casting is often used for complex shapes and allows for a high degree of detail. The molten metal is poured into molds to create the valve body and components.

- Machining involves cutting away material to achieve precise dimensions and smooth surfaces, ensuring tight seals and optimal flow characteristics.

- Forging may be used for specific components to enhance their strength through deformation under heat and pressure.

These forming techniques not only influence the valve’s performance but also its longevity and reliability under operational stresses.

How Are Backflow Valves Assembled for Optimal Performance?

After forming, the next stage is assembly. This involves fitting together various components, such as the check valves, relief valves, and housing. Each component must be aligned and secured to prevent leaks and ensure proper function.

Advanced assembly techniques, such as robotic automation, are increasingly common in manufacturing to enhance precision and efficiency. Additionally, skilled technicians perform final adjustments to ensure each valve meets the specified tolerances and performance criteria.

What Quality Assurance Processes Are Implemented During Manufacturing?

Quality assurance (QA) is a crucial aspect of the manufacturing process for irrigation backflow valves. Ensuring compliance with international standards and industry-specific regulations is essential for maintaining product integrity and safety.

Which International Standards Are Relevant for Backflow Valve Quality Control?

Manufacturers typically adhere to international quality management standards, such as ISO 9001, which outlines requirements for a quality management system (QMS). Compliance with these standards ensures that the manufacturing processes are consistent and that products meet customer and regulatory requirements.

In addition to ISO standards, industry-specific certifications such as CE marking (for compliance with European health, safety, and environmental protection standards) and API standards (American Petroleum Institute) are also significant. These certifications signal to B2B buyers that the products have been tested and meet rigorous safety and performance criteria.

What Are the Key QC Checkpoints in Backflow Valve Production?

Quality control checkpoints are integrated throughout the manufacturing process to ensure consistent quality. Common QC checkpoints include:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards before they enter the production line.

- In-Process Quality Control (IPQC): During manufacturing, periodic inspections are conducted to monitor the production process and identify any deviations from quality standards.

- Final Quality Control (FQC): After assembly, each valve undergoes rigorous testing, including pressure tests and flow tests, to verify functionality and reliability.

These checkpoints help identify issues early, reducing waste and ensuring that only high-quality products reach the market.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers need to ensure that their suppliers maintain high-quality standards. There are several ways to verify a supplier’s QC processes:

What Audits and Reports Should Buyers Request?

Buyers can request documentation of quality control processes, including quality manuals and standard operating procedures. Additionally, suppliers should provide audit reports from recognized third-party organizations that evaluate compliance with relevant standards.

Conducting on-site audits can also provide insight into a supplier’s manufacturing and quality control practices. During these audits, buyers can evaluate the production environment, employee training programs, and the implementation of quality control measures.

How Do Third-Party Inspections Enhance Buyer Confidence?

Third-party inspections serve as an additional layer of assurance for buyers. Engaging independent organizations to conduct inspections at various stages of production can validate the supplier’s adherence to quality standards. This is particularly important for international transactions, where buyers may not have direct oversight of the manufacturing process.

What Quality Control Nuances Should International Buyers Consider?

When sourcing irrigation backflow valves from international suppliers, buyers must navigate various quality control nuances.

How Do Regulatory Differences Impact Quality Standards?

Different regions may have varying regulatory requirements and quality standards. For instance, valves sold in Europe must comply with CE marking, while those sold in the United States may need to meet ANSI or NSF standards. Buyers should ensure that suppliers are familiar with and compliant with the specific regulations applicable to their target market.

What Should Buyers Know About Product Certification and Testing?

Buyers should inquire about the certification process for backflow valves and the testing methods used to ensure compliance with relevant standards. Understanding whether the supplier conducts in-house testing or utilizes third-party laboratories can provide further confidence in the product’s quality.

In conclusion, B2B buyers looking to procure irrigation backflow valves should pay close attention to the manufacturing processes and quality assurance protocols of their suppliers. By understanding the key stages of production, relevant quality standards, and verification methods, buyers can make informed decisions that ensure the integrity and reliability of their irrigation systems.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘irrigation backflow valves’

To facilitate effective procurement of irrigation backflow valves, this guide provides a comprehensive checklist. Following these steps ensures that buyers can make informed decisions, enhancing the safety and efficiency of their irrigation systems.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical requirements for the backflow valves you need. Consider factors such as the type of irrigation system, the flow rates required, and the specific contaminants that need to be prevented from entering the potable water supply. Knowing whether you need a Reduced Pressure Zone (RPZ), Double Check Valve, or other types will help narrow down your options.

Step 2: Research Regulatory Compliance

Understanding the regulations governing backflow prevention in your region is crucial. Different countries and regions have specific codes that dictate the type of backflow preventers that can be used. Ensure that the products you consider meet local safety standards and certifications, as this will protect your potable water supply and help avoid legal complications.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making a commitment. Look for companies with a strong reputation in the industry, and request documentation such as company profiles, case studies, and references from other buyers in similar sectors. This due diligence will help you ensure reliability and quality in the products you are sourcing.

Step 4: Compare Product Features and Pricing

Once you have a shortlist of suppliers, compare the features and pricing of their backflow valves. Look for information on the materials used, flow rates, and any additional features such as freeze resistance or ease of maintenance. This comparison will help you identify the best value for your investment, balancing cost with necessary functionality.

Step 5: Request Samples for Testing

Before finalizing your order, request samples from your shortlisted suppliers. Testing samples in real-world conditions can provide insights into the performance and reliability of the backflow valves. This step is particularly important for ensuring compatibility with your existing irrigation systems and identifying any potential issues before bulk purchasing.

Step 6: Verify After-Sales Support and Warranty Terms

Evaluate the after-sales support offered by suppliers, including warranty terms and availability of replacement parts. A strong support system is essential for troubleshooting and maintenance, which can save time and costs in the long run. Ensure that the warranty covers the specific conditions under which the valves will be used.

Step 7: Finalize Your Order and Establish a Relationship

Once you have selected a supplier based on thorough evaluation, finalize your order while ensuring clear communication about delivery timelines and payment terms. Establishing a good relationship with your supplier can lead to better pricing, priority support, and access to future innovations in irrigation technology.

By following this checklist, B2B buyers can navigate the complexities of sourcing irrigation backflow valves effectively, ensuring compliance and operational efficiency in their irrigation systems.

Comprehensive Cost and Pricing Analysis for irrigation backflow valves Sourcing

What Are the Key Cost Components for Irrigation Backflow Valves?

Understanding the cost structure of irrigation backflow valves is critical for B2B buyers. The primary cost components include:

Materials: The choice of materials significantly impacts the cost. Common materials such as bronze, plastic, and stainless steel vary in price and durability. High-quality materials may have a higher upfront cost but can lead to lower maintenance expenses over time.

Labor: Labor costs encompass assembly and installation. Skilled labor may demand higher wages, especially in regions with a limited workforce. Therefore, sourcing from regions with a skilled labor pool can provide cost advantages.

Manufacturing Overhead: This includes costs associated with utilities, equipment depreciation, and factory maintenance. Companies with efficient manufacturing processes can reduce overhead, thus offering competitive pricing.

Tooling: The initial setup for manufacturing backflow valves requires investment in specialized tools and molds. This upfront cost can be amortized over larger production runs, making it essential to consider minimum order quantities (MOQs).

Quality Control (QC): Rigorous QC processes ensure that the valves meet industry standards, which can add to costs. However, investing in quality control can reduce long-term warranty claims and improve customer satisfaction.

Logistics: Transportation and shipping costs are significant, particularly for international buyers. Factors such as distance, shipping methods, and packaging can influence overall logistics costs.

Margin: Suppliers typically build a profit margin into the price, which can vary based on the market demand, competition, and perceived value of the product.

How Do Price Influencers Impact the Cost of Backflow Valves?

Several factors influence the pricing of irrigation backflow valves:

Volume/MOQ: Purchasing in bulk often leads to lower per-unit costs. Suppliers are usually willing to negotiate better pricing for larger orders, making it advantageous for buyers to plan ahead.

Specifications and Customization: Customized solutions that meet specific requirements may incur additional costs. Buyers should balance the need for customization with budget constraints.

Materials and Quality Certifications: Products certified for quality (e.g., ISO, NSF) may cost more due to the rigorous testing involved. However, these certifications can assure buyers of the product’s reliability, potentially justifying the higher price.

Supplier Factors: The reputation and location of the supplier can significantly affect pricing. Established suppliers with a strong track record may charge a premium, while emerging suppliers might offer lower prices to gain market share.

Incoterms: Understanding shipping terms is crucial for international buyers. Incoterms define the responsibilities of buyers and sellers regarding transportation costs, risks, and insurance, which can affect the total cost of acquisition.

What Buyer Tips Can Help Navigate the Costs of Backflow Valves?

For B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, navigating the complexities of pricing can lead to significant savings:

Negotiate: Engage in open discussions with suppliers about pricing, especially if you have a long-term partnership or are purchasing large volumes. Many suppliers are willing to offer discounts for loyalty or bulk purchases.

Focus on Cost-Efficiency: Evaluate the total cost of ownership rather than just the purchase price. Consider factors like maintenance, energy consumption, and durability to make informed decisions.

Understand Pricing Nuances for International Transactions: Be aware of currency fluctuations and tariffs that can affect pricing when sourcing internationally. It’s advisable to factor these into your budget to avoid unexpected expenses.

Research and Compare: Gather quotes from multiple suppliers to identify competitive pricing. This can also provide leverage when negotiating terms.

Consider Local Suppliers: Whenever possible, explore local suppliers to minimize logistics costs and ensure quicker delivery times.

Disclaimer on Indicative Prices

Prices for irrigation backflow valves can vary significantly based on the factors mentioned above. It is essential for buyers to conduct thorough market research and consult with multiple suppliers to obtain accurate pricing tailored to their specific needs.

Alternatives Analysis: Comparing irrigation backflow valves With Other Solutions

Exploring Alternatives to Irrigation Backflow Valves

When considering solutions for preventing backflow in irrigation systems, it is crucial for B2B buyers to evaluate various alternatives to traditional irrigation backflow valves. While backflow valves are designed specifically to safeguard potable water supplies from contaminants, other technologies and methods may also offer effective solutions. This section provides a comparative analysis of irrigation backflow valves and their alternatives, helping decision-makers choose the best option for their specific applications.

| Comparison Aspect | Irrigation Backflow Valves | Pressure Vacuum Breakers (PVB) | Double Check Assemblies (DCA) |

|---|---|---|---|

| Performance | High protection against backflow; suitable for high-risk applications. | Good for preventing backsiphonage; moderate performance. | Moderate protection; suitable for low to medium-risk systems. |

| Cost | Higher initial investment; maintenance costs can vary. | Generally lower upfront cost; simple to install. | Moderate initial cost; similar maintenance to backflow valves. |

| Ease of Implementation | Requires professional installation; must comply with regulations. | Easier to install; can be installed by non-professionals. | Requires professional installation; must meet local codes. |

| Maintenance | Regular testing and maintenance required to ensure functionality. | Minimal maintenance; easy to service if needed. | Regular maintenance needed; less frequent than backflow valves. |

| Best Use Case | High-risk irrigation systems with potential contaminants (e.g., fertilizers, chemicals). | Residential or light commercial applications with lower risk. | Low- to medium-risk systems where backflow is a concern but not critical. |

Understanding Pressure Vacuum Breakers (PVB)

Pressure Vacuum Breakers (PVB) are a viable alternative to traditional backflow valves, particularly in residential and light commercial irrigation systems. They work by breaking the vacuum created during water flow, thus preventing backsiphonage. One of the main advantages of PVBs is their lower initial cost and ease of installation, often allowing for DIY setups. However, they do not provide the same level of protection against backpressure as backflow valves, making them less suitable for applications involving significant contamination risks.

Evaluating Double Check Assemblies (DCA)

Double Check Assemblies (DCA) offer another alternative, particularly for low- to medium-risk irrigation systems. They consist of two check valves that provide moderate protection against backflow. The primary benefits of DCAs include a relatively moderate cost and simpler maintenance compared to backflow valves. However, like PVBs, DCAs may not be suitable for high-risk applications, especially where chemicals or fertilizers are present, as they do not protect against backpressure.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate backflow prevention solution requires a careful assessment of the specific requirements of your irrigation system. B2B buyers should consider factors such as the level of contamination risk, budget constraints, and installation capabilities. While irrigation backflow valves provide the highest level of protection, alternatives like Pressure Vacuum Breakers and Double Check Assemblies can be effective in lower-risk scenarios. Ultimately, the right choice will align with the operational needs and regulatory standards applicable to your irrigation system, ensuring safe and efficient water management.

Essential Technical Properties and Trade Terminology for irrigation backflow valves

Understanding the technical properties and trade terminology associated with irrigation backflow valves is crucial for B2B buyers, especially when making informed purchasing decisions. Here’s a concise overview of the essential specifications and terminology that will aid in navigating this industry.

What Are the Key Technical Properties of Irrigation Backflow Valves?

Material Grade

– Definition: Refers to the quality and type of materials used in the construction of backflow valves, such as bronze, PVC, or stainless steel.

– Importance: The material grade directly affects the valve’s durability, resistance to corrosion, and overall lifespan. Higher-grade materials are essential in regions with harsh weather conditions or high chemical exposure, ensuring long-term reliability and reduced maintenance costs.Pressure Rating

– Definition: Indicates the maximum pressure the valve can withstand, typically measured in pounds per square inch (PSI).

– Importance: Understanding the pressure rating is vital for ensuring that the backflow valve can handle the specific pressures in your irrigation system. This prevents premature failures and potential contamination of potable water supplies.Flow Rate

– Definition: The volume of water that can pass through the valve per unit of time, usually expressed in gallons per minute (GPM).

– Importance: A proper flow rate is crucial for maintaining efficient irrigation practices. Buyers must match the flow rate of the valve to their irrigation system’s requirements to optimize performance and avoid water wastage.Backpressure and Backsiphonage Protection

– Definition: Backpressure refers to the pressure in the system that can cause water to flow backward, while backsiphonage occurs when a drop in system pressure creates a vacuum that pulls water back into the system.

– Importance: Different types of backflow preventers (e.g., RPZ, PVB) provide varying levels of protection against these phenomena. Understanding these protections helps buyers select the appropriate device for their specific applications and regulatory compliance.Testing and Certification Standards

– Definition: Refers to industry standards and certifications that backflow valves must meet, such as ASSE, AWWA, or CSA.

– Importance: Compliance with these standards ensures that the valves are reliable and safe for use in irrigation systems. Buyers should look for certified products to ensure adherence to quality and safety regulations.

What Are Common Trade Terms Related to Irrigation Backflow Valves?

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEMs helps buyers identify reputable manufacturers of backflow valves, ensuring quality and compatibility with existing systems.MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ is essential for B2B buyers to manage inventory effectively and assess the feasibility of purchasing from a supplier, especially in bulk.RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and terms for specified products or services.

– Importance: An RFQ is a critical tool for procurement, allowing buyers to compare offers from multiple suppliers and negotiate better pricing and terms.Incoterms (International Commercial Terms)

– Definition: A set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms helps B2B buyers understand shipping costs, risks, and responsibilities, ensuring smoother international trade transactions.Lead Time

– Definition: The time taken from placing an order until the product is received.

– Importance: Knowing the lead time is crucial for planning and scheduling installations, especially in regions with seasonal irrigation needs.

In conclusion, understanding these technical properties and trade terms empowers B2B buyers to make informed decisions when sourcing irrigation backflow valves. This knowledge not only facilitates better product selection but also enhances overall supply chain efficiency.

Navigating Market Dynamics and Sourcing Trends in the irrigation backflow valves Sector

What Are the Current Market Dynamics for Irrigation Backflow Valves?

The global irrigation backflow valves market is experiencing significant growth, driven by increasing awareness of water conservation and the need to protect potable water supplies. As agricultural practices evolve, especially in regions like Africa, South America, and the Middle East, the demand for efficient irrigation systems is on the rise. Key trends include the integration of smart technology into irrigation systems, allowing for real-time monitoring and control of water flow and pressure. This shift towards automation not only enhances efficiency but also minimizes water wastage, making backflow prevention systems essential in maintaining system integrity.

Emerging B2B tech trends in this sector encompass the use of IoT-enabled backflow prevention devices that provide data analytics for predictive maintenance. This capability is particularly beneficial for international buyers looking to enhance operational efficiency and reduce costs. Additionally, there is a growing trend towards sourcing locally manufactured backflow valves to mitigate supply chain disruptions, especially in light of recent global events. B2B buyers should be aware of regional regulations regarding backflow prevention, as compliance is critical in preventing contamination and ensuring safe drinking water.

How Is Sustainability Influencing Sourcing Trends for Irrigation Backflow Valves?

Sustainability has become a cornerstone in the decision-making process for B2B buyers in the irrigation sector. The environmental impact of traditional manufacturing processes has prompted a shift towards more sustainable practices. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to ethical sourcing and sustainable materials. This includes the use of recycled metals and eco-friendly coatings in the production of backflow valves.

Moreover, obtaining ‘green’ certifications is becoming a significant factor in supplier selection. Certifications such as ISO 14001 for environmental management systems can serve as a competitive advantage, reassuring buyers of a manufacturer’s commitment to minimizing environmental impact. As water scarcity becomes a pressing global issue, selecting suppliers that adhere to sustainable practices not only aligns with ethical considerations but also enhances brand reputation in a market that increasingly values corporate responsibility.

What Is the Historical Context of Irrigation Backflow Valves Development?

The development of irrigation backflow valves can be traced back to the early 20th century, when concerns over water contamination became more pronounced. Initially designed for agricultural applications, these valves have evolved to meet the demands of modern irrigation systems, which now incorporate advanced technology and stringent regulatory standards. Over the decades, the introduction of various backflow prevention devices, such as Reduced Pressure Zone (RPZ) assemblies and Pressure Vacuum Breakers (PVB), has significantly improved the reliability and effectiveness of irrigation systems.

As global awareness of water safety and conservation continues to grow, the evolution of backflow valves reflects a broader commitment to protecting potable water supplies. This historical context underscores the importance of ongoing innovation in the sector, providing B2B buyers with insights into the reliability and functionality of contemporary backflow prevention solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of irrigation backflow valves

1. How do I choose the right type of irrigation backflow valve for my needs?

Choosing the right irrigation backflow valve depends on several factors, including the level of risk posed by contaminants, local regulations, and the specific design of your irrigation system. For high-risk applications, a Reduced Pressure Zone (RPZ) valve is recommended as it provides the highest level of protection against backpressure. For lower-risk systems, consider a Double Check Valve or Pressure Vacuum Breaker. It’s crucial to consult with local regulations and possibly an irrigation expert to ensure compliance and optimal functionality.2. What are the key factors to consider when vetting suppliers for backflow valves?

When vetting suppliers, consider their reputation, experience in the industry, and product certifications. Look for suppliers with proven track records in your region, as they will be more familiar with local regulations and quality standards. Additionally, inquire about their manufacturing processes, material quality, and warranty policies. It’s advisable to request samples or references from previous clients to assess the reliability and performance of their products before making a commitment.3. What is the minimum order quantity (MOQ) for irrigation backflow valves?

Minimum order quantities (MOQs) can vary significantly between suppliers, typically ranging from 10 to 100 units. It’s important to discuss MOQs upfront, especially if you are a smaller business or a new buyer. Some suppliers may offer flexibility on MOQs for first-time customers or larger contracts, while others may enforce strict limits based on production capabilities. Always consider your projected usage to avoid excess inventory or stockouts.4. Are customization options available for backflow valves?

Yes, many suppliers offer customization options for backflow valves, including size, materials, and specific features tailored to your irrigation system’s needs. Customization can be crucial for meeting local regulations or specific environmental conditions. When discussing customization, ensure to communicate your requirements clearly and verify the supplier’s capabilities to meet those specifications. This may also impact lead times and pricing, so factor these into your planning.5. What are the typical payment terms for international orders of irrigation backflow valves?

Payment terms for international orders can vary widely but typically include options such as advance payment, Letter of Credit (LC), or net 30/60/90 days after delivery. It’s essential to negotiate terms that align with your cash flow needs and risk tolerance. Ensure that all payment terms are clearly outlined in the contract to avoid disputes later on. Additionally, consider using secure payment methods to protect your investment.6. How can I ensure quality assurance (QA) for backflow valves sourced internationally?

To ensure quality assurance, establish clear specifications and standards that the supplier must meet before production begins. Request third-party testing or certifications that validate the products meet international standards. It’s also beneficial to conduct regular audits of the supplier’s manufacturing processes. If possible, arrange for pre-shipment inspections to verify that the products conform to your quality requirements before they are shipped.7. What logistics considerations should I keep in mind when importing backflow valves?

When importing backflow valves, consider shipping methods, lead times, and customs regulations in your destination country. Engage with a logistics partner familiar with international shipping to navigate potential challenges such as tariffs, duties, and import permits. Ensure that your supplier provides all necessary documentation for customs clearance, including invoices, packing lists, and certificates of origin. Planning ahead can help avoid delays and additional costs.8. How do I handle after-sales support and warranty claims for backflow valves?

After-sales support is crucial for maintaining the performance of your irrigation system. Ensure that your supplier provides clear warranty terms, including duration and coverage for defects or failures. Establish a communication channel for support and claims processing, and inquire about the process for returning defective items. Consider suppliers who offer comprehensive after-sales services, as this can significantly reduce downtime and enhance your operational efficiency.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 1 Irrigation Backflow Valves Manufacturers & Suppliers List

1. Conbraco – 4A-505-02(F) – 1 Freeze Resistant Pressure Vacuum Breaker

Domain: sprinklersupplystore.com

Registered: 2010 (15 years)

Introduction: [{‘name’: ‘Conbraco – 4A-505-02(F) – 1″ Freeze Resistant Pressure Vacuum Breaker’, ‘size’: ‘1″‘, ‘type’: ‘Pressure Vacuum Breaker Assembly’, ‘material’: ‘Bronze’, ‘original_price’: ‘$275.29’, ‘current_price’: ‘$206.47’, ‘discount’: ‘25%’, ‘stock’: ‘In Stock (7)’}, {‘name’: ‘Febco – 825EBVFEB – 825Y 1″ RPZ Backflow Preventer w/Ball Valve’, ‘size’: ‘1″‘, ‘type’: ‘Reduced Pressure Zone Assembly w/ Ba…

Strategic Sourcing Conclusion and Outlook for irrigation backflow valves

What Are the Key Takeaways for B2B Buyers of Irrigation Backflow Valves?

In conclusion, strategic sourcing of irrigation backflow valves is crucial for ensuring the safety and integrity of potable water systems. Buyers must prioritize quality and compliance with local regulations, as the right backflow prevention device protects against contamination from fertilizers, pesticides, and other harmful substances. Understanding the different types of valves—such as Reduced Pressure Zone Assemblies (RPZ), Double Check Assemblies, and Pressure Vacuum Breakers—will enable buyers to select the most appropriate solutions for their specific irrigation systems.

How Can Strategic Sourcing Enhance Your Procurement Process?

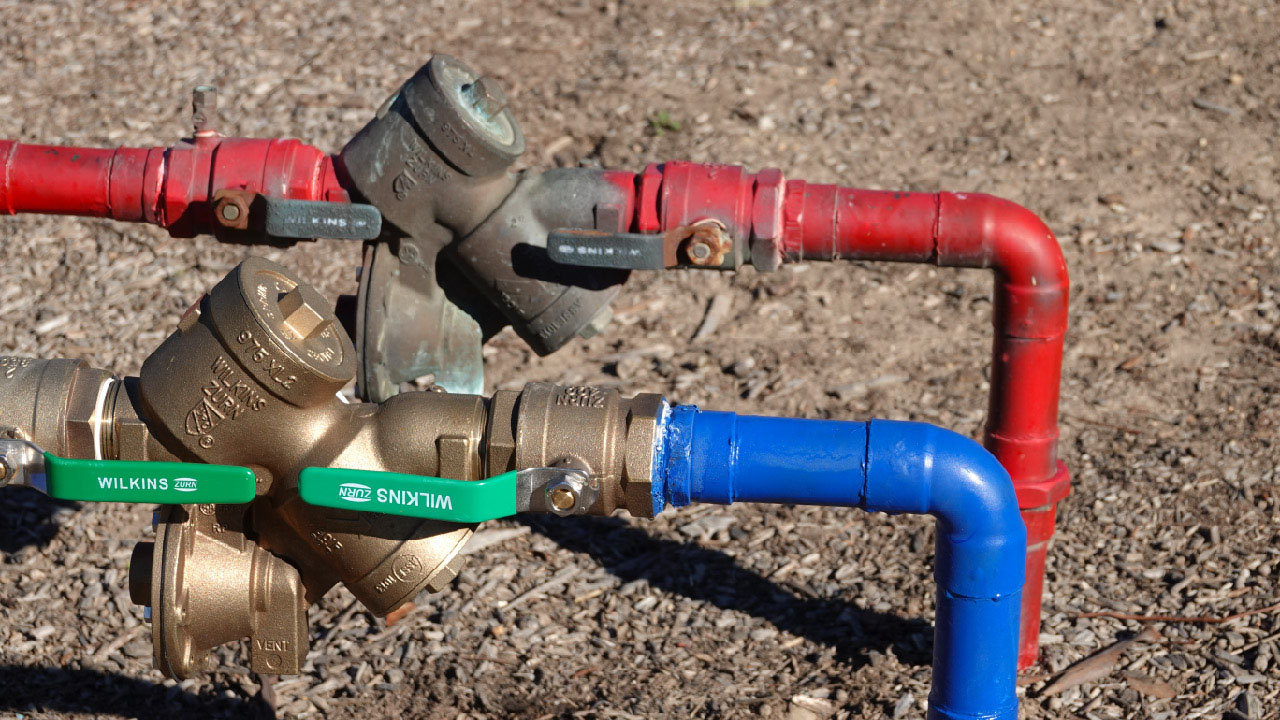

Emphasizing strategic sourcing can lead to significant cost savings, improved supplier relationships, and enhanced reliability in water safety systems. Engaging with reputable manufacturers like Conbraco, Febco, and Wilkins ensures access to high-quality products backed by industry expertise. By proactively evaluating suppliers and leveraging competitive pricing, buyers can enhance their procurement strategy.

What’s Next for International B2B Buyers in Emerging Markets?

As global demand for sustainable irrigation solutions continues to rise, now is the time for international buyers from Africa, South America, the Middle East, and Europe to invest in reliable backflow prevention systems. By focusing on strategic sourcing, businesses can position themselves at the forefront of water safety innovation. Take the next step—assess your current irrigation systems, explore reputable suppliers, and secure the right backflow valves to safeguard your water resources for the future.