Introduction: Navigating the Global Market for irrigation pump pump start relay wiring diagram

Navigating the intricate landscape of irrigation pump pump start relay wiring diagrams can be a daunting challenge for international B2B buyers. With diverse applications ranging from agricultural irrigation systems in Nigeria to landscaping projects in Germany, understanding the technical specifications and sourcing the right components is crucial for operational efficiency. This guide serves as a comprehensive resource, detailing various types of pump start relays, their applications across different regions, and essential wiring diagrams that ensure proper installation and functionality.

As buyers face the complexities of international sourcing, this guide empowers them with actionable insights into supplier vetting processes, cost considerations, and the latest industry standards. By highlighting critical factors such as voltage requirements, compatibility with controllers, and installation best practices, we aim to equip businesses with the knowledge necessary to make informed purchasing decisions.

Whether you are looking to enhance your irrigation systems in South America or seeking reliable components for projects in the Middle East, this guide will provide the clarity and confidence needed to navigate the global market effectively. With a focus on practical solutions and expert recommendations, we are committed to supporting your business in achieving optimal irrigation performance and sustainability.

Understanding irrigation pump pump start relay wiring diagram Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Universal Pump Start Relay | Compatible with various voltage levels (110V/220V) | Agriculture, landscaping | Pros: Versatile; Cons: May require additional configuration. |

| Single Phase Relay | Designed for single-phase motors, straightforward wiring | Residential, small commercial | Pros: Simple installation; Cons: Limited to single-phase systems. |

| Three Phase Relay | Supports three-phase motors for higher power applications | Large-scale agriculture, industry | Pros: High efficiency; Cons: More complex wiring. |

| Integrated Pump Start Relay | Built into irrigation controllers for streamlined setup | Smart irrigation systems | Pros: Easy integration; Cons: Less flexibility in upgrades. |

| Decoding Relay | Utilizes decoders for specific irrigation system requirements | Advanced irrigation setups | Pros: Customizable; Cons: Requires specialized knowledge to install. |

What are the Characteristics of a Universal Pump Start Relay?

The universal pump start relay is versatile, supporting both 110V and 220V applications. Its adaptability makes it suitable for various irrigation systems, whether in agriculture or landscaping. Buyers should consider the relay’s compatibility with existing systems and the need for any additional configuration, as some setups may require more intricate wiring.

When to Use a Single Phase Relay?

Single-phase relays are ideal for residential and small commercial applications. They are designed for straightforward wiring and are typically used with single-phase motors, making them easy for B2B buyers to install. However, their limitation to single-phase systems means that businesses with larger, three-phase motors may need to explore other options.

Why Choose a Three Phase Relay for Large Applications?

Three-phase relays are essential for high-power applications, particularly in large-scale agricultural or industrial settings. These relays are designed to handle three-phase motors, offering high efficiency and reliability. Buyers should be aware that while these relays provide better performance, their wiring can be more complex, requiring skilled technicians for installation.

What Advantages Does an Integrated Pump Start Relay Offer?

Integrated pump start relays are built directly into irrigation controllers, simplifying the installation process. This type is particularly advantageous for smart irrigation systems, as it allows for seamless operation. However, businesses should consider that while integration offers convenience, it may limit flexibility for future upgrades or replacements.

How Does a Decoding Relay Enhance Irrigation Systems?

Decoding relays are designed for advanced irrigation setups that require specific operational characteristics. These relays utilize decoders to communicate with the irrigation system, providing a high level of customization. While they are beneficial for complex systems, buyers must ensure they have the necessary expertise to install and maintain these specialized components.

Key Industrial Applications of irrigation pump pump start relay wiring diagram

| Industry/Sector | Specific Application of irrigation pump pump start relay wiring diagram | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Automating irrigation systems for crop management | Increases efficiency and reduces labor costs | Compatibility with existing systems and voltage ratings |

| Landscaping & Horticulture | Managing water flow for large landscaping projects | Ensures optimal water distribution, enhancing plant health | Durability in harsh environments and ease of installation |

| Commercial Real Estate | Maintaining irrigation in large properties or parks | Enhances property value through attractive landscaping | Scalability for different property sizes |

| Mining & Oil Extraction | Using water pumps for dust suppression and site maintenance | Improves safety and operational efficiency | Compliance with local regulations and safety standards |

| Aquaculture | Regulating water levels in fish farming operations | Supports sustainable fish farming practices | Ability to handle variable water sources and conditions |

How is the Irrigation Pump Start Relay Wiring Diagram Utilized in Agriculture?

In the agriculture sector, irrigation pump start relay wiring diagrams are essential for automating irrigation systems. This automation allows farmers to manage water resources more efficiently, leading to better crop yields and reduced labor costs. Buyers from regions like Africa and South America, where water scarcity can be a significant challenge, must ensure that the relay systems they source are compatible with local voltage standards and can operate in varying climatic conditions.

What Role Does This Wiring Diagram Play in Landscaping & Horticulture?

Landscaping and horticulture industries utilize irrigation pump start relays to manage water flow in extensive projects, such as parks and commercial properties. The wiring diagrams provide a clear guide for installation, ensuring that water distribution is optimized for plant health. Buyers in Europe and the Middle East should consider sourcing relays that are durable and designed to withstand harsh outdoor conditions, ensuring long-term reliability.

How is the Wiring Diagram Beneficial in Commercial Real Estate?

In commercial real estate, maintaining lush landscapes can significantly enhance property value. The irrigation pump start relay wiring diagram facilitates the efficient management of irrigation systems, ensuring that water is distributed evenly across large properties. Buyers need to focus on scalable solutions that can adapt to different property sizes and complexities, particularly in urban environments where space is at a premium.

Why is This Diagram Important in Mining & Oil Extraction?

In the mining and oil extraction sectors, water pumps are often used for dust suppression and site maintenance. The irrigation pump start relay wiring diagram is vital for ensuring these systems operate effectively, enhancing safety and operational efficiency. Buyers must prioritize compliance with local regulations and safety standards, especially in regions prone to environmental scrutiny.

How Does the Wiring Diagram Support Aquaculture Operations?

Aquaculture relies heavily on maintaining optimal water levels for fish farming. The irrigation pump start relay wiring diagram assists in regulating these water levels, contributing to sustainable farming practices. International buyers, particularly from developing nations, should seek relays capable of handling variable water sources and conditions, ensuring the health of aquatic life and the viability of their operations.

3 Common User Pain Points for ‘irrigation pump pump start relay wiring diagram’ & Their Solutions

Scenario 1: Confusion Over Wiring Connections for Different Voltage Systems

The Problem: Many B2B buyers often face challenges when dealing with wiring diagrams for irrigation pump start relays, especially when the relay operates on different voltage systems, such as 110V and 220V. This confusion can lead to improper connections that may damage equipment or cause system failures. For instance, a buyer in Nigeria may be unsure about how to correctly wire a pump start relay that is designed for 220V operation when their existing infrastructure supports only 110V. Such mistakes can be costly, leading to downtime and increased maintenance expenses.

The Solution: To address this issue, it’s crucial to thoroughly understand the specifications of both the pump and the relay. Buyers should always refer to the manufacturer’s wiring diagrams specific to the voltage type in use. When wiring the relay, ensure that the incoming power supply matches the relay’s voltage rating. For example, if using a 220V relay, connect the line and load wires accordingly. Additionally, utilizing color-coded wires and labeling connections can help maintain clarity during installation. If possible, consult with a qualified electrician familiar with irrigation systems to verify that all connections comply with local electrical codes and standards. This proactive approach will minimize errors and ensure reliable operation.

Scenario 2: Inadequate Knowledge of Control Wiring for Automation Systems

The Problem: Another common pain point for B2B buyers is the lack of understanding regarding control wiring, especially when integrating the pump start relay with automated irrigation controllers. Many users may struggle with how to connect the relay to the controller, leading to ineffective system operation. For instance, a buyer in Germany may have a sophisticated irrigation control system but lacks clarity on how to wire the pump relay to ensure it activates correctly during scheduled watering.

The Solution: To effectively integrate the pump start relay with the irrigation controller, buyers should follow the wiring instructions provided by both the relay and the controller manufacturers. Typically, this involves connecting the relay’s common terminal to the controller’s common terminal and the relay’s pump terminal to the designated output on the controller. It’s also advisable to keep wiring runs as short as possible to reduce electromagnetic interference, which can disrupt signal integrity. Utilizing a wiring diagram specific to the controller model can further simplify the process. Additionally, manufacturers often offer customer support to guide users through the installation process, which can be invaluable in ensuring that the system operates as intended.

Scenario 3: Misinterpretation of Wiring Diagrams Leading to System Failures

The Problem: B2B buyers frequently misinterpret the wiring diagrams associated with pump start relays, resulting in incorrect installations that can cause pump failures or inefficiencies. A common scenario involves a buyer from South America who misreads the diagram, leading to improper wiring that prevents the relay from activating the pump when needed. This misstep can lead to significant water supply issues, particularly in agricultural settings where timely irrigation is critical.

The Solution: To prevent misinterpretation of wiring diagrams, buyers should take a structured approach. Start by carefully reviewing the wiring diagram provided by the manufacturer, paying close attention to the labels and color codes of each wire. It’s beneficial to create a step-by-step checklist that outlines each connection point and its corresponding wire. Additionally, using online resources, such as video tutorials or technical support forums, can provide visual guidance that enhances understanding. Engaging with professionals who have experience with similar systems can also provide insights that mitigate risks associated with incorrect installations. Finally, always conduct a test run of the system after installation to ensure that everything operates smoothly before full-scale use. This diligence not only improves operational efficiency but also extends the lifespan of the equipment.

Strategic Material Selection Guide for irrigation pump pump start relay wiring diagram

What Are the Key Materials for Irrigation Pump Start Relay Wiring Diagrams?

When selecting materials for irrigation pump start relay wiring diagrams, it is essential to consider various factors such as electrical conductivity, insulation properties, and environmental resilience. Here, we analyze four common materials used in the wiring of these systems, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

1. Copper Wire

Key Properties:

Copper is known for its excellent electrical conductivity, making it the preferred choice for wiring applications. It has a high melting point (around 1,984°F or 1,085°C) and good corrosion resistance when properly insulated.

Pros & Cons:

Copper wiring is durable and offers low electrical resistance, which translates to efficient energy transfer. However, it is relatively expensive compared to alternatives like aluminum. Manufacturing complexity is moderate, as it requires careful handling to avoid damage during installation.

Impact on Application:

Copper is compatible with various media, including water and chemicals, but it may corrode in highly acidic or alkaline environments without adequate protection.

International Considerations:

In regions like Africa and South America, where electrical standards may vary, it is crucial to ensure compliance with local regulations. Buyers should look for products that meet ASTM standards for copper wiring.

2. Aluminum Wire

Key Properties:

Aluminum is lighter than copper and has a lower conductivity (approximately 61% that of copper). It has a melting point of about 1,221°F (660°C) and is more prone to oxidation.

Pros & Cons:

Aluminum wiring is cost-effective and lightweight, making it easier to handle. However, it is less durable than copper and can suffer from higher resistance, leading to potential overheating. The manufacturing process can also be more complex due to the need for special connectors.

Impact on Application:

Aluminum is suitable for applications where weight is a concern, but its lower conductivity may limit its use in high-power applications.

International Considerations:

In Europe, aluminum wiring must comply with DIN standards. Buyers in the Middle East should ensure that the materials can withstand high temperatures and humidity.

3. PVC Insulation

Key Properties:

Polyvinyl Chloride (PVC) is a versatile plastic known for its excellent insulation properties and resistance to moisture, chemicals, and UV light. It can operate effectively within a temperature range of -40°F to 140°F (-40°C to 60°C).

Pros & Cons:

PVC is lightweight, cost-effective, and easy to install. However, it may not be as durable as other materials in extreme temperatures or prolonged exposure to sunlight.

Impact on Application:

PVC insulation is suitable for outdoor applications, protecting wires from environmental factors. However, it may not be suitable for high-heat environments.

International Considerations:

Buyers should ensure that PVC products meet local environmental regulations, particularly in Europe, where there are strict guidelines on plastic use.

4. Thermoplastic Elastomer (TPE)

Key Properties:

TPE combines the properties of rubber and plastic, offering excellent flexibility and durability. It maintains its performance in a temperature range of -40°F to 212°F (-40°C to 100°C).

Pros & Cons:

TPE is highly resistant to abrasion and weathering, making it ideal for outdoor applications. However, it can be more expensive than PVC and may require specialized manufacturing techniques.

Impact on Application:

TPE is suitable for applications requiring high flexibility and resistance to environmental stressors, making it ideal for irrigation systems exposed to varying weather conditions.

International Considerations:

TPE products must comply with international standards, such as JIS in Japan and ASTM in the U.S. Buyers in Africa and South America should verify compliance with local regulations regarding material safety.

Summary Table of Material Selection

| Material | Typical Use Case for irrigation pump pump start relay wiring diagram | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper Wire | Main wiring for electrical connections in pumps | Excellent electrical conductivity | Higher cost | High |

| Aluminum Wire | Cost-effective wiring for lighter installations | Lightweight and affordable | Lower conductivity | Med |

| PVC Insulation | Insulation for outdoor wiring | Moisture and UV resistance | Less durable in extreme heat | Low |

| Thermoplastic Elastomer | Flexible insulation for dynamic applications | High flexibility and durability | More expensive | Med |

In conclusion, selecting the right materials for irrigation pump start relay wiring diagrams is crucial for ensuring optimal performance and longevity of the system. International buyers should prioritize compliance with local standards and consider the specific environmental conditions of their regions.

In-depth Look: Manufacturing Processes and Quality Assurance for irrigation pump pump start relay wiring diagram

What Are the Main Stages in the Manufacturing Process of Irrigation Pump Start Relay Wiring Diagrams?

The manufacturing process for irrigation pump start relay wiring diagrams involves several critical stages: material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring the final product meets the necessary specifications and quality standards.

Material Preparation

The first step in manufacturing involves sourcing high-quality materials, such as copper wire for electrical connections, durable plastics for casing, and reliable relay components. Suppliers must provide documentation verifying the quality and compliance of these materials with international standards. This stage also includes cutting and stripping wires to the correct lengths, which is crucial for ensuring proper connectivity and reducing installation errors later on.

Forming

During the forming stage, components are shaped to fit specific design requirements. This can involve molding plastic casings and creating circuit boards that house the relay’s electronic components. Advanced technologies such as injection molding are often employed to create precise and durable parts, which are essential for the longevity and reliability of the irrigation system.

Assembly

The assembly stage involves integrating all components into a cohesive unit. Skilled technicians typically perform this task, ensuring that connections are secure and that each relay is assembled according to the wiring diagram specifications. Automation may be used in some cases, but human oversight is crucial to catch any discrepancies that machines may miss.

Finishing

Finally, the finishing stage encompasses testing and quality checks to confirm that the product meets design specifications. This may include applying protective coatings, labeling, and packaging the wiring diagrams for shipment. Proper finishing not only enhances durability but also ensures compliance with safety regulations.

How Is Quality Assurance Implemented in Manufacturing Wiring Diagrams?

Quality assurance (QA) is integral to the manufacturing process, ensuring that products meet both international and industry-specific standards. For irrigation pump start relay wiring diagrams, several QA methodologies are implemented.

Relevant International Standards

Manufacturers often comply with ISO 9001, which outlines criteria for a quality management system. This certification indicates that a manufacturer consistently provides products that meet customer and regulatory requirements. Additionally, CE marking may be necessary for products sold in Europe, signifying compliance with health, safety, and environmental protection standards.

Industry-Specific Standards

For irrigation systems, specific certifications such as the American Petroleum Institute (API) standards may apply, especially if the products are used in environments related to oil and gas. Manufacturers must be aware of the relevant standards that pertain to their products, as these can vary significantly across different regions.

What Quality Control Checkpoints Are Commonly Used?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to ensure product integrity.

Incoming Quality Control (IQC)

At the IQC stage, incoming materials are inspected for compliance with specifications. This includes verifying the quality of raw materials and components before they enter the production line. Any non-conforming materials are rejected or returned to suppliers.

In-Process Quality Control (IPQC)

During the assembly phase, IPQC involves real-time monitoring of the manufacturing process. Technicians check for adherence to assembly protocols and wiring diagram specifications. This minimizes the risk of defects and ensures that any issues are addressed promptly.

Final Quality Control (FQC)

FQC is the last line of defense before products are packaged and shipped. Each irrigation pump start relay undergoes rigorous testing to ensure it functions as intended. This may include electrical testing, performance checks, and visual inspections to catch any physical defects.

What Testing Methods Are Commonly Used to Ensure Quality?

Testing methods vary depending on the specific requirements of the irrigation pump start relay but generally include:

- Electrical Testing: Verifying that the relay operates correctly under various electrical loads and conditions.

- Functional Testing: Ensuring that the relay activates the pump as intended and that all connections work seamlessly.

- Environmental Testing: Subjecting the product to conditions such as temperature extremes and humidity to ensure durability and performance in various climates.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers looking to source irrigation pump start relay wiring diagrams should be diligent in verifying the quality control practices of potential suppliers. Here are some strategies:

Conducting Audits

Buyers should consider conducting on-site audits of potential suppliers to assess their manufacturing processes and quality control measures. This firsthand evaluation provides insights into the supplier’s operational standards.

Requesting Quality Reports

Ask suppliers for documentation related to their quality control processes. This may include testing reports, compliance certificates, and records of any quality issues encountered during production.

Engaging Third-Party Inspectors

Utilizing third-party inspection services can provide an unbiased evaluation of a supplier’s quality control practices. These inspectors can conduct thorough assessments of manufacturing processes, material quality, and product functionality.

What Are the Quality Control Nuances for International Buyers?

International B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

- Cultural Differences: Understand that manufacturing practices and quality standards may vary significantly by region. Buyers should be knowledgeable about local regulations and market expectations.

- Logistical Challenges: International shipping can introduce variables that affect product quality. Buyers should ensure that suppliers have robust logistics and handling procedures to maintain product integrity during transit.

- Regulatory Compliance: Different countries have varying regulations regarding electrical components. Buyers must ensure that suppliers comply with the necessary regulations in both the exporting and importing countries.

By focusing on these aspects, B2B buyers can make informed decisions when sourcing irrigation pump start relay wiring diagrams, ensuring they partner with manufacturers that prioritize quality and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘irrigation pump pump start relay wiring diagram’

This guide serves as a practical checklist for B2B buyers aiming to procure the necessary components and documentation for irrigation pump start relay wiring diagrams. The focus is on ensuring that you select the right products and suppliers to facilitate efficient irrigation system setup.

Step 1: Define Your Technical Specifications

Begin by determining the specific technical requirements for your irrigation system. This includes understanding the voltage (e.g., 110V vs. 220V), pump horsepower, and any specific relay types needed for compatibility. Clear specifications will help streamline your search for suitable products.

- Consider the type of irrigation system (e.g., residential, agricultural) as this influences the pump and relay requirements.

- Identify any additional features you may need, such as timers or remote controls.

Step 2: Research Available Relay Models

Investigate the different models of pump start relays on the market, focusing on their specifications and features. Popular models include the PSR Universal Pump Start Relay, which comes in various voltage configurations.

- Look for models that have proven reliability and positive reviews from other users in similar markets.

- Ensure the model you choose is compliant with local electrical standards and regulations.

Step 3: Evaluate Potential Suppliers

It’s crucial to thoroughly vet suppliers before making a commitment. Request company profiles, case studies, and references from buyers in a similar industry or region.

- Assess the supplier’s experience in the irrigation sector and their ability to provide technical support.

- Check for certifications and warranties that ensure product quality and reliability.

Step 4: Request Technical Documentation

Once you’ve shortlisted suppliers, request comprehensive technical documentation, including wiring diagrams and installation manuals. This documentation is critical for ensuring proper installation and operation.

- Ensure the documentation includes detailed wiring diagrams that align with your specific relay model and pump type.

- Verify that the manuals cover troubleshooting and maintenance procedures.

Step 5: Confirm Compatibility with Existing Systems

Before finalizing your purchase, ensure that the pump start relay is compatible with your existing irrigation controllers and systems. This prevents operational issues after installation.

- Check that the relay can handle the load of your pump and is designed for the correct voltage.

- Consult with your supplier to confirm compatibility with your irrigation controller, especially if it involves unique wiring configurations.

Step 6: Assess After-Sales Support and Training

Consider the level of after-sales support and training offered by the supplier. This is particularly important for complex systems where proper installation and troubleshooting are critical.

- Inquire if the supplier provides installation services or training for your staff.

- Evaluate their responsiveness to inquiries and willingness to provide ongoing support.

Step 7: Negotiate Terms and Pricing

Finally, negotiate the terms and pricing with your chosen supplier. Ensure that you understand the total cost of ownership, including shipping, installation, and potential future maintenance.

- Look for bulk purchasing options or discounts for long-term contracts, especially if you plan to source regularly.

- Clarify the payment terms, return policies, and warranty coverage to avoid unexpected costs.

By following this checklist, B2B buyers can make informed decisions when procuring irrigation pump start relay wiring diagrams, ensuring optimal performance and reliability in their irrigation systems.

Comprehensive Cost and Pricing Analysis for irrigation pump pump start relay wiring diagram Sourcing

What Are the Key Cost Components for Sourcing Irrigation Pump Start Relay Wiring Diagrams?

When sourcing irrigation pump start relay wiring diagrams, several cost components come into play. Materials typically account for a significant portion of the overall cost, including the wiring, relays, connectors, and circuit boards. These materials vary in price based on quality and specifications. Labor costs are influenced by the expertise required for installation and configuration, particularly in regions with specialized electrical standards.

Manufacturing overhead encompasses expenses related to production facilities, utilities, and equipment maintenance. Tooling costs, which are associated with the production of custom parts or high-precision components, can also impact pricing. Quality control (QC) measures are essential for ensuring compliance with international standards, thereby adding to the overall cost structure. Logistics costs, including transportation and handling, should not be overlooked, especially for international shipments where tariffs and shipping fees can significantly affect pricing.

How Do Price Influencers Affect the Cost of Wiring Diagrams?

Several factors can influence the pricing of irrigation pump start relay wiring diagrams. Volume and minimum order quantities (MOQ) play a crucial role; larger orders often result in discounted rates due to economies of scale. Specifications and customization needs will also impact costs—tailored solutions typically incur higher prices due to additional design and manufacturing processes.

The quality of materials used, as well as certifications (such as ISO or CE marks), can lead to price variations. Suppliers with established reputations for quality may charge a premium but can offer more reliable products. Supplier factors such as location, production capabilities, and financial stability can also influence pricing. Lastly, understanding Incoterms is vital for international buyers to ascertain who is responsible for shipping costs, insurance, and tariffs, which can significantly affect the total expenditure.

What Buyer Tips Can Help Optimize Costs for International Purchases?

B2B buyers should adopt strategic approaches to negotiate better pricing and improve cost efficiency. Negotiation is key—engaging suppliers in discussions about pricing flexibility can lead to favorable terms, especially for bulk orders. Buyers should also consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also installation, maintenance, and potential downtime costs.

Additionally, understanding pricing nuances specific to various regions can aid in making informed decisions. For instance, buyers from Africa may face different logistical challenges compared to those in Europe or South America, which can affect delivery times and costs. Establishing relationships with local suppliers can mitigate some international shipping costs and lead to quicker turnaround times.

Are There Any Price Disclaimers Buyers Should Be Aware Of?

Buyers should be aware that prices can fluctuate based on market conditions, currency exchange rates, and changes in material costs. Therefore, it is advisable to seek indicative prices rather than fixed quotes, especially when planning long-term procurement strategies. Regularly reviewing supplier contracts and seeking competitive bids can also help ensure that buyers are receiving the best value for their investment.

In conclusion, understanding the comprehensive cost and pricing analysis for irrigation pump start relay wiring diagrams is essential for making informed purchasing decisions in the B2B landscape. By focusing on key cost components, recognizing price influencers, and employing strategic negotiation techniques, international buyers can optimize their sourcing processes for better outcomes.

Alternatives Analysis: Comparing irrigation pump pump start relay wiring diagram With Other Solutions

Introduction: Understanding Alternative Solutions for Irrigation Pump Control

When it comes to managing irrigation systems, the wiring diagram for a pump start relay is a popular method for activating pumps in response to irrigation demands. However, there are other viable solutions available that can achieve similar goals. Evaluating these alternatives can help international B2B buyers make informed decisions based on their specific requirements and operational contexts.

Comparison Table of Irrigation Pump Control Solutions

| Comparison Aspect | Irrigation Pump Pump Start Relay Wiring Diagram | Smart Irrigation Controller | Mechanical Timer |

|---|---|---|---|

| Performance | Reliable activation of pumps based on zone demands | Offers precise scheduling and remote control | Simple on/off control with set intervals |

| Cost | Moderate initial investment, potential for high long-term savings | Higher upfront cost, but may reduce water usage | Low-cost solution, minimal investment |

| Ease of Implementation | Requires electrical knowledge for wiring | User-friendly interfaces, easy installation | Straightforward installation, no electrical work needed |

| Maintenance | Requires periodic checks and potential troubleshooting | Minimal maintenance if properly set up | Very low maintenance; typically lasts for years |

| Best Use Case | Ideal for complex systems needing precise pump control | Best for large, modern systems with varied irrigation needs | Suitable for small gardens or simple setups |

Detailed Breakdown of Alternatives

1. Smart Irrigation Controller

Smart irrigation controllers utilize advanced technology to automate and optimize irrigation schedules based on environmental factors such as weather forecasts and soil moisture levels. The integration of these controllers with pump systems allows for precise control over water usage, leading to significant water conservation.

Pros: They offer remote access via smartphone apps, can be programmed to adjust schedules automatically, and often include analytics features to monitor water usage and system performance.

Cons: The initial investment can be higher compared to traditional solutions, and they may require a Wi-Fi connection, which could be a limitation in remote areas.

2. Mechanical Timer

Mechanical timers are simple devices that allow users to set specific times for pumps to turn on and off. They are often used in smaller irrigation systems or residential setups where advanced control is not necessary.

Pros: They are cost-effective, easy to install, and require no electrical expertise. Users can set their desired watering schedule quickly, making them ideal for straightforward irrigation needs.

Cons: Mechanical timers lack the flexibility of smart controllers and do not adjust based on environmental conditions, which can lead to overwatering or underwatering. They are best suited for low-demand applications.

Conclusion: Choosing the Right Solution for Your Irrigation Needs

For B2B buyers evaluating irrigation pump control solutions, the choice between a pump start relay wiring diagram, smart irrigation controllers, and mechanical timers should be guided by specific operational needs and budget considerations. Buyers should assess the complexity of their irrigation systems, desired features such as remote access or environmental responsiveness, and the overall investment they are willing to make. By weighing these factors, organizations can select the most effective solution to enhance their irrigation efficiency and sustainability.

Essential Technical Properties and Trade Terminology for irrigation pump pump start relay wiring diagram

What Are the Essential Technical Properties of an Irrigation Pump Start Relay Wiring Diagram?

Understanding the technical specifications of an irrigation pump start relay wiring diagram is crucial for B2B buyers, particularly those involved in agricultural or landscaping operations. Here are some key properties to consider:

Voltage Rating

The voltage rating indicates the maximum electrical voltage the relay can handle. Common ratings include 110V and 220V, depending on the region and application. Knowing the correct voltage is essential to ensure compatibility with existing systems, reducing the risk of equipment failure and enhancing operational efficiency.Current Capacity

This specification defines the maximum current the relay can manage, typically measured in Amperes (A). It is vital for matching the relay to the pump motor’s requirements. A relay with insufficient current capacity can lead to overheating and potential system failures, which can disrupt operations and incur significant repair costs.Wiring Type and Gauge

The type and gauge of wiring used in the installation affect the overall performance and safety of the irrigation system. Thicker wires (lower gauge numbers) can carry more current, which is necessary for high-power pumps. Ensuring the correct wire type and gauge is crucial for minimizing energy loss and preventing overheating.Relay Configuration

This refers to how the relay is designed and connected within the system. Common configurations include Normally Open (NO) and Normally Closed (NC). Understanding the configuration is essential for proper functionality, as it determines how the relay responds to signals from the irrigation controller.Operating Temperature Range

The operating temperature range indicates the environmental conditions under which the relay can function effectively. This is important for regions with extreme weather conditions, ensuring the relay remains operational and reliable regardless of external temperatures.Protection Features

Features such as surge protection, waterproofing, and thermal fuses enhance the reliability of the relay. These properties are especially important in agricultural applications, where equipment is often exposed to harsh conditions. Investing in relays with robust protection can extend equipment lifespan and reduce maintenance costs.

What Are Common Trade Terms Associated with Irrigation Pump Start Relay Wiring Diagrams?

Familiarity with industry jargon can streamline communication and negotiations for B2B buyers. Here are some common terms:

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces components that are used in another company’s end product. In the context of irrigation systems, knowing the OEM of the pump start relay can help buyers ensure compatibility and quality.MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for buyers to manage inventory costs effectively, particularly when sourcing components for large-scale irrigation projects.RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to solicit price quotes for specific products. In the irrigation industry, submitting an RFQ for pump start relays allows buyers to compare options and negotiate better deals.Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. Familiarity with these terms helps buyers understand shipping costs, risks, and responsibilities, which is crucial when importing components like pump relays from other countries.Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. Understanding lead times for pump start relays can help buyers plan their projects more effectively and avoid delays in installation.Warranty Period

The warranty period is the duration during which a manufacturer guarantees the performance of a product. Knowing the warranty terms for pump start relays can provide peace of mind to buyers, ensuring they are covered in case of defects or failures.

Understanding these technical properties and trade terms is essential for international B2B buyers, as it equips them with the knowledge to make informed purchasing decisions and enhance their irrigation system’s efficiency and reliability.

Navigating Market Dynamics and Sourcing Trends in the irrigation pump pump start relay wiring diagram Sector

What Are the Current Market Dynamics and Key Trends in the Irrigation Pump Pump Start Relay Wiring Diagram Sector?

The irrigation pump pump start relay wiring diagram sector is experiencing significant transformation driven by technological advancements and increased demand for efficient water management solutions. Globally, the surge in agricultural practices necessitating irrigation, especially in regions like Africa and South America, is a primary driver. These areas face challenges such as water scarcity and inconsistent rainfall, prompting the adoption of advanced irrigation systems to optimize water use. As a result, B2B buyers are increasingly seeking reliable wiring solutions that integrate seamlessly with modern irrigation systems.

Emerging trends include the integration of smart technologies into irrigation systems. IoT-enabled devices are becoming more prevalent, allowing for remote monitoring and control of pump operations. This trend is particularly prominent in developed markets in Europe and the Middle East, where precision agriculture is on the rise. Moreover, there is a growing emphasis on modular and scalable designs that can be customized to meet specific operational needs. International buyers are also focusing on suppliers that offer comprehensive technical support and detailed wiring diagrams to ensure proper installation and maintenance of these systems.

How Does Sustainability and Ethical Sourcing Impact the Irrigation Pump Sector?

Sustainability has become a cornerstone of B2B purchasing decisions in the irrigation pump sector. The environmental impact of irrigation practices is under scrutiny, with an increasing demand for solutions that minimize resource waste. Buyers are now prioritizing products that utilize ‘green’ materials and technologies that reduce energy consumption.

Moreover, ethical sourcing is gaining traction, especially among European buyers, who are keen on ensuring that their suppliers adhere to responsible manufacturing practices. Certifications such as ISO 14001 for environmental management and other ‘green’ labels are becoming critical in supplier evaluations. Companies that demonstrate commitment to sustainable practices not only enhance their marketability but also build trust with buyers who are increasingly aware of their supply chain’s ecological footprint. For instance, sourcing components made from recycled materials or those that support energy-efficient operations can significantly elevate a supplier’s standing in the marketplace.

What Is the Brief Evolution of Irrigation Pump Technology and Its Wiring Diagrams?

The evolution of irrigation pump technology has been marked by significant advancements from simple mechanical systems to sophisticated electronic solutions. Initially, irrigation relied heavily on manual systems that were labor-intensive and inefficient. However, the introduction of electric pumps in the mid-20th century revolutionized the sector, allowing for greater efficiency and control.

As technology progressed, the development of pump start relays became integral to automating irrigation systems. Early wiring diagrams were rudimentary, often requiring extensive troubleshooting. Over time, manufacturers have refined these diagrams to enhance clarity and usability, enabling easier installation and maintenance. This evolution reflects a broader trend in the irrigation industry toward automation and precision, aligning with the needs of modern agricultural practices. Today, comprehensive wiring diagrams not only facilitate the installation of pump start relays but also support the integration of smart technologies, catering to a more tech-savvy market.

Frequently Asked Questions (FAQs) for B2B Buyers of irrigation pump pump start relay wiring diagram

How do I troubleshoot wiring issues with my irrigation pump start relay?

To troubleshoot wiring issues with your irrigation pump start relay, first ensure that all connections are secure and correctly placed according to the wiring diagram. Check for any signs of damage or wear in the wires, particularly at connection points. If the relay is not activating the pump, verify that the controller is sending the correct voltage (usually 24VAC) to the relay. Additionally, inspect the power source and ensure the relay is compatible with your pump’s voltage specifications, whether 110V or 220V. If issues persist, consult a licensed electrician for expert assistance.What is the best pump start relay for agricultural irrigation systems?

The best pump start relay for agricultural irrigation systems often depends on your specific setup and requirements. Look for relays with robust specifications, such as the PSR Universal Pump Start Relay, which can handle both 110V and 220V systems. Key features to consider include compatibility with your irrigation controller, the ability to handle the pump’s horsepower, and protection against electrical surges. Additionally, consider relays that are easy to wire and come with comprehensive documentation to assist with installation.What are the common voltage specifications for irrigation pump start relays?

Irrigation pump start relays commonly operate at either 110V or 220V, depending on the region and specific system requirements. In North America, 110V systems are more prevalent, while many international markets, including Europe and parts of Africa, often use 220V. When sourcing a relay, it’s crucial to confirm the voltage compatibility with your existing irrigation setup to ensure optimal performance and prevent electrical issues.How can I ensure the quality of my irrigation pump start relay from suppliers?

To ensure quality when sourcing irrigation pump start relays, conduct thorough supplier vetting. Check for industry certifications such as ISO or CE, which indicate adherence to quality standards. Request product samples and test them in your system to assess performance. Additionally, seek references or reviews from other businesses that have purchased from the supplier. Establish clear quality assurance terms in your purchase agreement to hold the supplier accountable for any defects or issues.What are the typical minimum order quantities (MOQs) for irrigation pump start relays?

Minimum order quantities (MOQs) for irrigation pump start relays can vary widely based on the supplier and the type of relay. Generally, MOQs may range from 10 to 100 units, especially for specialized products. Some suppliers may offer flexibility for smaller orders, particularly for first-time buyers or long-term contracts. It’s advisable to discuss your needs directly with the supplier to negotiate favorable terms that suit your business requirements.What payment terms should I expect when sourcing irrigation pump start relays internationally?

Payment terms for international sourcing of irrigation pump start relays typically include options such as advance payment, letters of credit, or payment on delivery. Common practices involve a 30% deposit upon order confirmation, with the remaining 70% due before shipment. Ensure to clarify the payment methods accepted by the supplier, as well as any fees associated with currency exchange or international transactions. Establishing clear payment terms can help mitigate risks in international trade.How can I manage logistics when importing irrigation pump start relays?

Managing logistics for importing irrigation pump start relays involves selecting reliable shipping partners, understanding customs regulations, and ensuring proper documentation. Consider using a freight forwarder familiar with your target market to streamline the shipping process. It’s essential to factor in lead times, potential delays at customs, and costs associated with duties and taxes. Communicate regularly with your supplier to track shipment status and resolve any issues that may arise during transport.What customization options are available for irrigation pump start relays?

Customization options for irrigation pump start relays may include specific voltage configurations, relay types, or additional features such as surge protection or integrated timers. Some manufacturers offer tailored solutions to meet unique operational needs, especially for large-scale agricultural projects. When discussing customization, clearly outline your requirements to the supplier and request detailed specifications to ensure the final product aligns with your operational goals.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Irrigation Pump Pump Start Relay Wiring Diagram Manufacturers & Suppliers List

1. {product_details: Rainbird – Irrigation Solutions}

Domain: rainbird.com

Registered: 1995 (30 years)

Introduction: CRITICAL: You MUST output ONLY the JSON object, with no other text, commentary, or markdown formatting. The entire response must be a single, valid JSON object like this: {“product_details”: “string”}. If no info is found, use an empty string for the value.

2. Hunter – PSR-22 Irrigation Start Pump Relay

Domain: doityourself.com

Registered: 1995 (30 years)

Introduction: PSR-22 Hunter irrigation start pump relay, 220 volt source, 1 1/2 HP sprinkler pump, Hunter X Core controller with internal transformer, 120VAC and 24VAC wires.

3. Hydrawise – Pump Start Relay

Domain: support.hydrawise.com

Registered: 2011 (14 years)

Introduction: Pump Start Relay (PSR) is used to activate a pump whenever a zone is activated from the controller. It is essential for systems requiring a booster pump or pulling water from natural sources. Hydrawise controllers support 6- to 54-zone valves. Wiring recommendations include maintaining a minimum distance of 15′ (4.5 m) between the controller and relay to reduce electromagnetic noise. Maximum one-w…

4. Hunter – PSR22 Pump Start Relay

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Looking for a well pump controller with sprinkler start relay wiring diagram. Current setup includes a 3-wire submersible pump, a 3-wire pump controller, and a low/high pressure cut on/off switch. Desired additions are a remote pump start relay (Hunter PSR22) and a spring-wound timer switch (Intermatic FF60MC). Seeking detailed wiring diagram for integration.

5. LawnSite – Pump Start Relay

Domain: lawnsite.com

Registered: 2000 (25 years)

Introduction: Pump Start Relay (PSR) with Manual On/Off Switch; designed for use with irrigation controllers; allows manual operation of the pump; typically handles pumps up to 2HP; can be integrated with pressure switches and pressure tanks to minimize cycling; wiring options discussed include tapping power before the PSR for manual control.

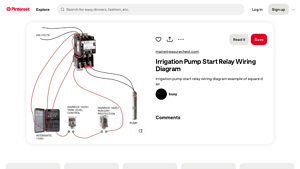

6. Pinterest – Irrigation Pump Start Relay Wiring

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Irrigation Pump Start Relay Wiring Diagram

Strategic Sourcing Conclusion and Outlook for irrigation pump pump start relay wiring diagram

In conclusion, understanding the intricacies of irrigation pump start relay wiring diagrams is essential for optimizing water management systems across diverse agricultural landscapes. Key takeaways highlight the importance of precise wiring to ensure seamless operation between controllers and pumps, ultimately enhancing system efficiency and reliability. Strategic sourcing of high-quality components, such as universal pump start relays, not only streamlines installation but also mitigates potential operational issues that could arise from substandard parts.

International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, should prioritize partnerships with reputable suppliers who can provide detailed technical specifications and support. Investing in reliable irrigation technology is crucial for improving agricultural productivity and sustainability in a rapidly changing global climate.

As you look ahead, consider the impact of innovative irrigation solutions on your operational efficiency. By making informed purchasing decisions now, you position your business to thrive in the competitive landscape of modern agriculture. Take action today to secure the best resources for your irrigation needs and drive your success forward.