Introduction: Navigating the Global Market for irrigation system backflow preventer valve

In the intricate landscape of global irrigation systems, sourcing an effective backflow preventer valve is paramount for ensuring the safety and quality of potable water. With increasing concerns over water contamination and stringent regulatory requirements, international B2B buyers—particularly those from regions like Africa, South America, the Middle East, and Europe—face the challenge of selecting the right backflow prevention solutions that align with both local laws and specific agricultural needs.

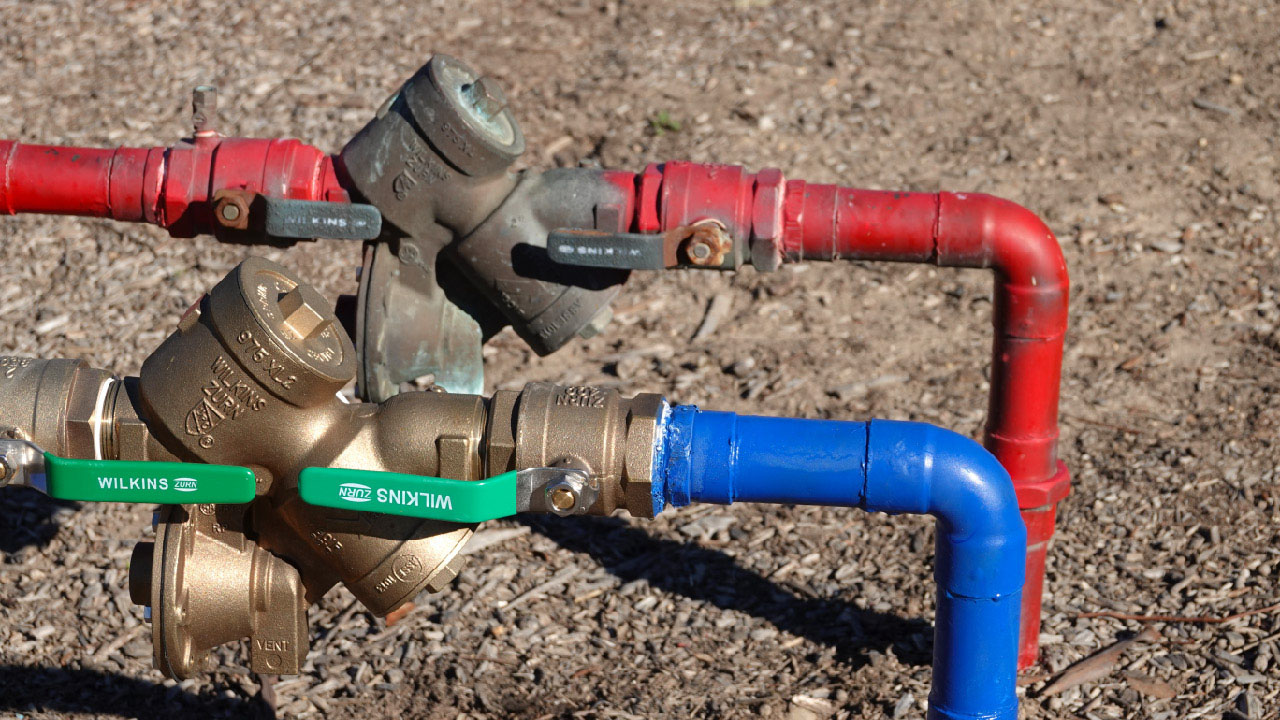

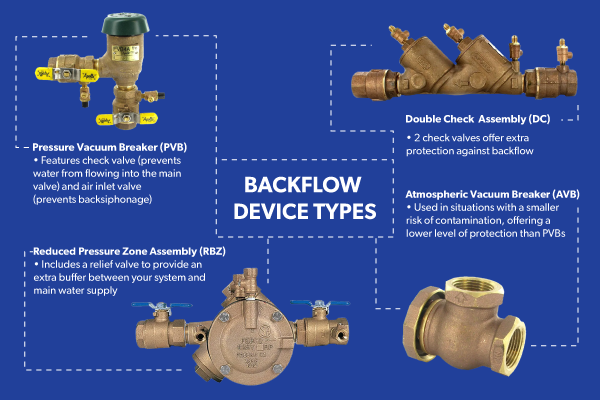

This comprehensive guide delves into the various types of backflow preventer valves, including Pressure Vacuum Breakers (PVB), Double Check Assemblies (DCA), and Reduced Pressure Zone Assemblies (RPZ), among others. Each type is evaluated based on its applications, advantages, and compliance with international standards. Additionally, the guide emphasizes the importance of supplier vetting, providing insights into identifying reliable manufacturers and distributors who can meet the diverse demands of different markets.

Furthermore, we explore cost considerations and best practices for maintenance and installation, empowering buyers to make informed decisions that not only protect their water supply but also enhance the efficiency of their irrigation systems. By navigating this complex market with our expert insights, B2B buyers can confidently invest in backflow preventer valves that ensure safe and sustainable irrigation practices.

Understanding irrigation system backflow preventer valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pressure Vacuum Breaker (PVB) | Prevents backflow through air pressure; typically requires venting. | Residential and commercial irrigation systems. | Pros: Affordable, easy to install. Cons: Vulnerable to freezing. |

| Double Check Assembly (DCA) | Two independent check valves; suitable for low health hazard applications. | Industrial irrigation and fire protection systems. | Pros: Reliable, minimal maintenance. Cons: Not suitable for high hazard situations. |

| Reduced Pressure Zone Assembly (RPZ) | Designed for high-risk applications; maintains pressure below supply pressure. | Fertilizer injection systems and agricultural irrigation. | Pros: Excellent protection against contamination. Cons: Higher cost, complex installation. |

| Atmospheric Vacuum Breaker (AVB) | Uses atmospheric pressure to prevent backflow; typically installed at individual valves. | Residential sprinkler systems. | Pros: Simple design, low cost. Cons: Limited to non-contaminated systems, may not be code compliant in all areas. |

What are the Characteristics of Pressure Vacuum Breakers (PVB)?

Pressure Vacuum Breakers (PVB) are essential for preventing backflow through air pressure mechanisms. They are commonly utilized in residential and commercial irrigation systems, where they help maintain the integrity of potable water supplies. B2B buyers should consider their affordability and ease of installation, though they must be cautious of their vulnerability to freezing temperatures, which can lead to damage in colder climates.

How Does a Double Check Assembly (DCA) Function?

The Double Check Assembly (DCA) consists of two independent check valves that provide a reliable barrier against backflow. This type is primarily used in industrial settings where the risk of contamination is lower. Buyers looking for a dependable solution with minimal maintenance requirements will find the DCA appealing. However, it is not recommended for high-hazard applications, which limits its versatility.

Why Choose a Reduced Pressure Zone Assembly (RPZ)?

Reduced Pressure Zone Assemblies (RPZ) are designed to provide superior protection against backflow in high-risk scenarios, such as those involving fertilizer injection in agricultural irrigation. The RPZ maintains pressure below the supply line, ensuring that contaminants cannot enter the potable water supply. While they offer excellent protection, B2B buyers should be prepared for higher costs and a more complex installation process.

What Makes Atmospheric Vacuum Breakers (AVB) Unique?

Atmospheric Vacuum Breakers (AVB) are characterized by their simple design and reliance on atmospheric pressure to prevent backflow. They are typically installed at individual valves in residential sprinkler systems. While they are cost-effective and easy to install, B2B buyers must be aware that AVBs are limited to non-contaminated systems and may not meet local codes in all areas, potentially complicating compliance efforts.

Key Industrial Applications of irrigation system backflow preventer valve

| Industry/Sector | Specific Application of Irrigation System Backflow Preventer Valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Protecting water supply in crop irrigation systems | Ensures safe irrigation, preventing contamination from fertilizers | Compliance with local agricultural regulations and standards |

| Landscaping and Horticulture | Ensuring clean water for residential and commercial landscaping | Enhances plant health and maintains aesthetic appeal | Selection of durable materials suitable for varying climates |

| Municipal Water Supply | Safeguarding public drinking water from contamination in irrigation | Protects public health and meets legal requirements | Adherence to municipal codes and standards for backflow preventers |

| Golf Courses and Sports Facilities | Maintaining water quality in irrigation systems for turf management | Improves turf health and playability, reducing maintenance costs | Need for high-capacity valves to handle large irrigation systems |

| Industrial Facilities | Preventing backflow in water used for cooling systems and landscaping | Protects equipment and ensures regulatory compliance | Evaluation of system pressure requirements and valve specifications |

How is the Irrigation System Backflow Preventer Valve Used in Agriculture?

In agriculture, irrigation system backflow preventer valves are crucial for protecting the water supply used in crop irrigation. These valves prevent contaminated water, which may contain fertilizers or pesticides, from flowing back into the potable water supply. This is particularly vital in regions where agricultural runoff can pose serious health risks. Buyers must ensure compliance with local agricultural regulations, which may dictate specific types of backflow preventers suitable for different irrigation methods.

What Role Does the Backflow Preventer Play in Landscaping and Horticulture?

In landscaping and horticulture, backflow preventer valves are employed to ensure that the water used in irrigation systems remains uncontaminated. This is essential for both residential and commercial projects, as it directly affects the health of plants and the visual appeal of landscapes. Buyers in this sector should consider durable materials that can withstand varying weather conditions, especially in regions with extreme climates, to ensure longevity and reliability.

How Does Backflow Prevention Work in Municipal Water Supply?

Municipal water supply systems utilize backflow preventer valves to protect public drinking water from potential contamination during irrigation. These systems are vital in urban areas where irrigation may occur near water supply lines. Compliance with local and national regulations is critical for municipalities, requiring backflow preventers that meet specific safety standards. Buyers must verify that their selected valves adhere to municipal codes to avoid legal repercussions.

Why Are Backflow Preventers Important for Golf Courses and Sports Facilities?

Golf courses and sports facilities integrate irrigation system backflow preventer valves to maintain high water quality for turf management. These valves ensure that only clean water is used for irrigation, which is essential for turf health and playability. Additionally, they help reduce maintenance costs by preventing the need for expensive repairs due to contamination. Buyers should seek high-capacity valves that can accommodate extensive irrigation systems typical of these facilities.

How Do Industrial Facilities Benefit from Backflow Preventers?

In industrial facilities, backflow preventer valves are essential for protecting water used in cooling systems and landscaping from contamination. These valves help ensure compliance with environmental regulations and protect sensitive equipment from damage caused by polluted water. When sourcing, businesses need to evaluate system pressure requirements and valve specifications to ensure optimal performance and reliability in their unique operational environments.

3 Common User Pain Points for ‘irrigation system backflow preventer valve’ & Their Solutions

Scenario 1: Navigating Local Compliance and Regulation Challenges

The Problem: B2B buyers often face significant hurdles in understanding and complying with local regulations regarding backflow prevention devices. In regions like Saudi Arabia or Nigeria, where regulatory frameworks may not be as established, buyers can struggle to identify which type of backflow preventer is legally required for their irrigation systems. The risk of non-compliance not only jeopardizes public health but can also lead to hefty fines or project delays, creating a pressing need for clarity in this area.

The Solution: To effectively navigate compliance issues, buyers should engage local authorities or consult with regional experts who understand the specific laws governing backflow prevention in their area. It is also advisable to conduct thorough research on applicable regulations, including necessary certifications and installation standards. When sourcing backflow preventers, prioritize suppliers that provide detailed documentation and compliance guarantees. This ensures that your chosen devices meet local standards and can be easily integrated into your irrigation systems without regulatory complications.

Scenario 2: Selecting the Right Backflow Preventer Type for Specific Applications

The Problem: Many B2B buyers encounter confusion when selecting the appropriate type of backflow preventer for their specific irrigation applications. With various options available—such as Pressure Vacuum Breakers (PVB), Double Check Assemblies (DCA), and Reduced Pressure Zone Assemblies (RPZ)—the decision-making process can be overwhelming. Choosing the wrong type can lead to inadequate protection against contamination, especially in agricultural settings where fertilizers and pesticides are used.

The Solution: To streamline the selection process, buyers should conduct a comprehensive assessment of their irrigation systems and the potential contaminants involved. Consulting with irrigation specialists can provide valuable insights into which backflow preventer type will best suit their needs. Additionally, buyers should consider devices that allow for the use of fertilizers in the irrigation system while maintaining compliance with safety standards. Establishing relationships with reputable suppliers who can offer technical guidance and product demonstrations will also enhance decision-making and ensure the right equipment is selected.

Scenario 3: Maintenance and Operational Reliability of Backflow Preventers

The Problem: Ensuring the operational reliability of backflow preventers is a common challenge for B2B buyers, especially in regions with extreme weather conditions or variable water quality. Buyers often struggle with regular maintenance and the potential for device failure, which can compromise water quality and lead to costly repairs or replacements. In areas with harsh climates, such as the Middle East, the risk of freeze damage or corrosion can further complicate the longevity of these devices.

The Solution: To mitigate maintenance issues, buyers should implement a routine inspection and maintenance schedule for their backflow preventers. This includes checking for signs of wear, ensuring proper functioning of valves, and conducting annual testing to comply with local regulations. Investing in high-quality, weather-resistant backflow preventers can significantly reduce long-term operational risks. Additionally, buyers should consider training staff on maintenance best practices and investing in backflow test kits to facilitate regular checks. Establishing a partnership with local service providers for professional inspections can further enhance reliability and ensure systems operate efficiently year-round.

Strategic Material Selection Guide for irrigation system backflow preventer valve

What Are the Key Materials for Irrigation System Backflow Preventer Valves?

When selecting backflow preventer valves for irrigation systems, the choice of material plays a critical role in performance, durability, and compliance with local regulations. Below, we analyze four common materials used in the manufacturing of these valves: brass, plastic, stainless steel, and bronze. Each material has unique properties and implications for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe.

How Does Brass Perform in Backflow Preventer Valves?

Brass is a widely used material for backflow preventer valves due to its excellent corrosion resistance and ability to withstand high temperatures and pressures. With a typical pressure rating of up to 300 psi and a temperature tolerance of -40°F to 180°F, brass is suitable for various irrigation applications.

Pros: Brass valves are durable and resistant to wear and tear, making them ideal for long-term use. They also provide a reliable seal, minimizing the risk of leaks.

Cons: The primary drawback of brass is its higher cost compared to plastic alternatives. Additionally, brass can be susceptible to dezincification if exposed to aggressive water conditions, which may lead to premature failure.

Application Impact: Brass is compatible with potable water, making it a preferred choice for systems that require stringent health standards.

International Considerations: Buyers should ensure that brass valves comply with local standards such as ASTM F877 or DIN 50930-6, particularly in regions with strict regulations regarding drinking water safety.

What Advantages Do Plastic Materials Offer?

Plastic materials, particularly PVC and CPVC, are increasingly popular for backflow preventer valves due to their lightweight nature and resistance to corrosion. These materials can handle pressures up to 150 psi and temperatures ranging from 32°F to 140°F.

Pros: Plastic valves are cost-effective and easy to install, reducing labor costs. They are also resistant to chemical corrosion, making them suitable for systems that use fertilizers or other additives.

Cons: The main limitation of plastic is its lower temperature and pressure ratings compared to metals. Additionally, plastic can become brittle over time, especially under UV exposure.

Application Impact: Plastic is suitable for non-potable water systems, but caution should be exercised when used in potable applications due to potential leaching of chemicals.

International Considerations: Compliance with standards such as ASTM D1785 for PVC pipes is essential. Buyers in regions with hot climates should also consider UV-resistant options.

Why Choose Stainless Steel for Backflow Preventers?

Stainless steel is known for its exceptional strength and corrosion resistance, making it a preferred material for high-pressure applications. It typically has a pressure rating of up to 600 psi and can withstand temperatures from -50°F to 450°F.

Pros: The durability and longevity of stainless steel make it an excellent investment for irrigation systems. It is also highly resistant to rust and corrosion, ensuring reliable performance over time.

Cons: The primary drawback is the higher cost associated with stainless steel, which can be a barrier for budget-conscious buyers. Additionally, its weight can complicate installation.

Application Impact: Stainless steel is ideal for systems that require high durability and resistance to harsh chemicals or extreme conditions.

International Considerations: Buyers should verify compliance with standards such as ASTM A312 for stainless steel pipes, especially in regions where regulations are stringent.

What Role Does Bronze Play in Backflow Preventer Valves?

Bronze is another robust material used in backflow preventer valves, known for its excellent corrosion resistance and strength. It typically has a pressure rating similar to brass, around 300 psi, and can handle temperatures from -20°F to 250°F.

Pros: Bronze valves are durable and provide excellent resistance to corrosion, particularly in marine environments. They also maintain a good seal, reducing leakage risks.

Cons: Like brass, bronze can be more expensive than plastic options. Additionally, it may not be as readily available in all regions.

Application Impact: Bronze is suitable for both potable and non-potable water applications, making it versatile for various irrigation needs.

International Considerations: Ensure that bronze valves meet local standards, such as ASTM B584, particularly in regions where water quality is critical.

Summary Table of Material Selection for Backflow Preventer Valves

| Material | Typical Use Case for Irrigation System Backflow Preventer Valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Potable water systems | Excellent corrosion resistance | Higher cost, potential dezincification | High |

| Plastic | Non-potable water systems | Cost-effective, lightweight | Lower pressure/temperature ratings | Low |

| Stainless Steel | High-pressure and harsh chemical applications | Exceptional durability and strength | Higher cost, heavier weight | High |

| Bronze | Versatile for both potable and non-potable applications | Good corrosion resistance | More expensive, availability issues | Med |

This analysis provides B2B buyers with actionable insights into material selection for irrigation system backflow preventer valves, considering performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for irrigation system backflow preventer valve

What Are the Main Stages of Manufacturing Irrigation System Backflow Preventer Valves?

The manufacturing of irrigation system backflow preventer valves involves several key stages, each critical to ensuring the final product meets quality and performance standards. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step is selecting appropriate materials, typically brass, plastic, or stainless steel, depending on the valve type and application. These materials must be sourced from reputable suppliers to ensure durability and resistance to corrosion. Quality checks on raw materials are essential to prevent defects in the final product. This may include verifying material certifications and conducting initial testing for composition and strength.

Forming Techniques

Once materials are prepared, the forming process begins. Techniques such as casting, machining, and injection molding are commonly employed. For instance, brass and plastic components may be molded into shape, while metal parts often undergo CNC machining for precision. These processes must be closely monitored to maintain dimensional accuracy and ensure that components fit together correctly.

Assembly Process

After forming, the next stage is assembly. This involves bringing together all components, including the valve body, internal mechanisms, and seals. Skilled technicians often perform this task, ensuring that components are aligned correctly and securely fastened. Automated assembly lines can also be used for efficiency, particularly in high-volume production settings.

Finishing Operations

The final manufacturing stage involves finishing processes, which may include surface treatment, plating, or coating to enhance durability and resistance to environmental factors. This step is crucial for backflow preventers, as they often operate in harsh conditions. Quality checks during this phase focus on ensuring that the finish meets specified standards and that there are no defects that could compromise performance.

How Is Quality Assurance Implemented in the Manufacturing of Backflow Preventer Valves?

Quality assurance (QA) is vital throughout the manufacturing process to ensure that irrigation system backflow preventer valves meet international standards and customer specifications. Various international and industry-specific standards guide the QA processes.

International Standards and Certifications

Compliance with ISO 9001 is a cornerstone of quality management in manufacturing. This standard outlines requirements for a quality management system (QMS) and emphasizes continuous improvement and customer satisfaction. Additionally, industry-specific certifications such as CE marking for compliance with European health, safety, and environmental protection standards, or API certification for products used in the oil and gas industry, may also apply.

Quality Control Checkpoints

To maintain high quality, manufacturers implement various quality control (QC) checkpoints throughout the production process:

Incoming Quality Control (IQC): This checkpoint verifies the quality of incoming materials before they enter the production process. Testing may include material composition analysis and dimensional checks.

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing stages ensures that processes remain within specified tolerances. Random sampling and testing of components can identify issues early, reducing waste and rework.

Final Quality Control (FQC): Once assembly and finishing are complete, FQC involves comprehensive testing of the final product. Common tests include pressure testing, leak detection, and performance assessments to ensure the valves meet operational specifications.

What Testing Methods Are Commonly Used for Backflow Preventer Valves?

Testing methods play a critical role in verifying the reliability and safety of backflow preventer valves. Common techniques include:

Pressure Testing: This method assesses the ability of the valve to withstand operating pressures without leaking. Valves are subjected to higher-than-normal pressures to ensure they can handle extreme conditions.

Leak Testing: Manufacturers conduct various leak tests, such as water or air leak tests, to detect any potential leaks in the valve assembly. This is crucial for ensuring that the device effectively prevents backflow.

Functional Testing: This involves simulating actual operating conditions to evaluate how the valve performs in real-world scenarios. Testing may include assessing the valve’s response to back pressure and ensuring it maintains proper flow direction.

How Can B2B Buyers Verify the Quality Control Processes of Their Suppliers?

For B2B buyers, verifying the quality control processes of suppliers is crucial for ensuring product reliability and compliance with standards. Here are key strategies:

Supplier Audits: Conducting on-site audits allows buyers to assess the supplier’s manufacturing processes, quality control measures, and adherence to international standards. This helps in verifying the supplier’s capabilities and commitment to quality.

Reviewing Quality Reports: Requesting access to quality reports, including IQC, IPQC, and FQC documentation, can provide insights into the supplier’s quality management practices and the results of their testing processes.

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased assessment of the supplier’s quality control measures. These agencies can conduct audits and testing, ensuring compliance with relevant standards and providing certification if necessary.

What Are the Specific QC and Certification Nuances for International B2B Buyers?

International B2B buyers should be aware of specific QC and certification nuances that may affect their procurement process. These include:

Regional Compliance Requirements: Different regions may have varying regulations regarding backflow preventer valves. For example, buyers in Europe may require CE marking, while those in the Middle East may need to comply with local standards that are often influenced by international guidelines.

Documentation and Traceability: Buyers should ensure that suppliers provide comprehensive documentation for all products, including certificates of compliance, test reports, and traceability information for materials used. This is particularly important for industries like agriculture, where product reliability directly impacts health and safety.

Cultural and Operational Differences: Understanding the operational practices and cultural norms of suppliers in regions like Africa or South America can enhance communication and ensure that quality expectations are met. Establishing clear agreements and expectations upfront can mitigate potential misunderstandings.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing irrigation system backflow preventer valves, ensuring they receive high-quality products that meet their specific needs and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘irrigation system backflow preventer valve’

In this guide, we provide a practical checklist for B2B buyers seeking to procure irrigation system backflow preventer valves. This essential equipment plays a critical role in safeguarding potable water supplies from contamination, making it vital for agricultural, commercial, and residential irrigation systems. Follow these steps to ensure a successful procurement process.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful sourcing process. Determine the type of backflow preventer you need based on your irrigation system’s requirements, such as Pressure Vacuum Breakers (PVB), Double Check Assemblies (DCA), or Reduced Pressure Zone Assemblies (RPZ). Consider factors like inlet and outlet sizes, pressure ratings, and material compatibility to ensure the chosen valve integrates seamlessly into your existing system.

Step 2: Research Regulatory Requirements

Understanding local regulations and compliance standards is critical when sourcing backflow preventers. Many regions have specific laws regarding the installation of backflow prevention devices, especially in areas prone to contamination risks. Familiarize yourself with the legal requirements in your target market, which may include certifications or testing standards that the devices must meet.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations to ensure reliability and quality. Request company profiles, product catalogs, and case studies demonstrating their experience in supplying backflow preventers. Additionally, seek references from other buyers in similar industries or regions to gauge their satisfaction and the supplier’s performance history.

Step 4: Request Samples and Product Testing

Whenever possible, request samples of the backflow preventers to assess their quality firsthand. Testing samples allows you to evaluate the materials, craftsmanship, and functionality of the devices. It’s essential to ensure that the product meets your specifications and performs effectively under various conditions, especially if your irrigation system is subject to fluctuations in pressure or chemical exposure.

Step 5: Compare Pricing and Value

While cost is a significant factor, it’s important to look beyond the price tag to assess the overall value offered by each supplier. Obtain quotes from multiple suppliers and compare not just the prices but also the warranty terms, after-sales support, and additional services such as installation guidance or maintenance training. A slightly higher upfront cost may be justified by superior quality or better support services.

Step 6: Verify Supplier Certifications

Ensure that your chosen supplier has the necessary certifications and compliance with international quality standards. Look for certifications such as ISO 9001 or local equivalents that demonstrate a commitment to quality management. This verification helps mitigate risks related to product performance and reliability, which is especially important in regions with stringent health and safety regulations.

Step 7: Plan for Long-Term Support and Maintenance

Lastly, consider the long-term support and maintenance needs of your backflow preventer valves. Inquire about the supplier’s capabilities for providing ongoing support, including spare parts availability, technical assistance, and repair services. Establishing a relationship with a supplier who can offer comprehensive support will help ensure your irrigation system operates smoothly and efficiently over time.

By following this checklist, B2B buyers can navigate the complexities of sourcing irrigation system backflow preventer valves effectively, ensuring they select the right products for their specific needs while adhering to industry standards and regulations.

Comprehensive Cost and Pricing Analysis for irrigation system backflow preventer valve Sourcing

What Are the Key Cost Components in Sourcing Irrigation System Backflow Preventer Valves?

When analyzing the cost structure for irrigation system backflow preventer valves, several key components play a significant role:

Materials: The choice of materials greatly affects costs. Common materials include brass, plastic, and stainless steel. Brass is typically more expensive due to its durability and corrosion resistance, making it suitable for high-quality applications. In contrast, plastic options may be cheaper but can compromise on longevity.

Labor: Labor costs can vary significantly based on the region of manufacturing. Countries with lower labor costs may offer a more competitive pricing structure. However, skilled labor is essential for maintaining quality in production, particularly for complex backflow preventer designs.

Manufacturing Overhead: This includes costs related to factory operations, utilities, and administrative expenses. Efficient manufacturing processes can help reduce overhead, thereby allowing for more competitive pricing.

Tooling: Initial tooling costs can be substantial, particularly for custom or specialized designs. The more complex the valve, the higher the tooling investment. However, once established, these costs are spread across larger production runs.

Quality Control (QC): Implementing rigorous QC processes ensures that the backflow preventers meet safety and performance standards. While this adds to the cost, it is critical for minimizing returns and ensuring compliance with international regulations.

Logistics: Shipping and handling costs can fluctuate based on distance, shipping method, and the volume of the order. International buyers should consider these costs, particularly when sourcing from manufacturers located far from their operations.

Margin: Supplier margins will vary based on market positioning and competition. Understanding the market landscape can aid in negotiating better prices.

What Influences Pricing for Backflow Preventer Valves?

Several factors can influence the pricing of irrigation system backflow preventer valves:

Volume/MOQ: Bulk purchasing often leads to lower per-unit costs. Buyers should consider negotiating minimum order quantities (MOQ) to achieve cost savings.

Specifications and Customization: Custom-designed valves may incur higher costs due to the need for specialized tooling and materials. Buyers should balance the need for customization against budget constraints.

Material Quality and Certifications: Higher quality materials and certifications (like ISO or NSF) may increase costs but provide assurance of reliability and safety, which is crucial for applications involving potable water.

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers with a history of quality assurance may charge a premium, but this often translates into reduced risk.

Incoterms: Understanding Incoterms is essential for international transactions. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly impact the total landed cost of products.

What Buyer Tips Can Enhance Cost Efficiency in Sourcing?

To optimize the sourcing process for backflow preventer valves, buyers should consider the following tips:

Negotiate Effectively: Leverage volume purchases and long-term relationships to negotiate better pricing. Building rapport with suppliers can also lead to additional perks or discounts.

Evaluate Total Cost of Ownership (TCO): Beyond the purchase price, consider maintenance, replacement, and operational costs over the lifespan of the product. Selecting higher-quality valves may incur a higher initial cost but result in lower long-term costs.

Understand Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of import duties, taxes, and currency fluctuations that can affect total costs. Understanding local regulations regarding backflow prevention can also guide decisions on necessary certifications and compliance.

Conclusion

The market for irrigation system backflow preventer valves is influenced by various cost components and pricing factors. By understanding these elements and employing strategic sourcing practices, B2B buyers can navigate the complexities of procurement and ensure they obtain high-quality products at competitive prices. Always consider reaching out to multiple suppliers to gather quotes and compare offerings before making a final decision.

Alternatives Analysis: Comparing irrigation system backflow preventer valve With Other Solutions

Introduction to Alternative Solutions for Backflow Prevention

In the realm of irrigation systems, ensuring the protection of potable water from contamination is paramount. While the irrigation system backflow preventer valve is a widely accepted solution, various alternatives can also serve this critical function. Understanding these options allows B2B buyers to make informed decisions tailored to their specific operational needs, compliance requirements, and budget constraints.

Comparison of Backflow Prevention Solutions

| Comparison Aspect | Irrigation System Backflow Preventer Valve | Pressure Vacuum Breaker (PVB) | Reduced Pressure Zone Assembly (RPZ) |

|---|---|---|---|

| Performance | Effectively prevents backflow; essential for irrigation systems. | Good for low to moderate hazard; prevents backsiphonage. | Highly effective for high hazard situations; protects against both backpressure and backsiphonage. |

| Cost | Moderate initial investment; varies by brand and specifications. | Generally lower cost; typically more affordable than RPZ. | Higher upfront cost; suitable for high-risk applications. |

| Ease of Implementation | Requires professional installation; must meet local codes. | Easier to install; often requires fewer modifications. | Complex installation; needs professional expertise for compliance. |

| Maintenance | Regular testing required; may require part replacements. | Minimal maintenance; check valves may need occasional cleaning. | Requires frequent testing and professional maintenance due to complexity. |

| Best Use Case | Ideal for residential and commercial irrigation systems with moderate risk. | Best for residential applications with low contamination risk. | Recommended for industrial and agricultural applications with high contamination risk. |

Detailed Breakdown of Alternatives

Pressure Vacuum Breaker (PVB)

The Pressure Vacuum Breaker (PVB) is a popular choice for many irrigation systems, particularly where the risk of contamination is considered low. It operates by allowing water to flow in one direction while preventing backsiphonage, making it a reliable option for residential applications. The main advantages of PVBs are their lower cost and simpler installation process compared to backflow preventer valves. However, they are not suitable for high-hazard situations, and local codes may limit their use in certain applications.

Reduced Pressure Zone Assembly (RPZ)

The Reduced Pressure Zone Assembly (RPZ) is designed for high-hazard applications, providing superior protection against both backpressure and backsiphonage. This makes it the go-to solution for environments where chemicals or fertilizers are injected into the irrigation system. While the RPZ offers unparalleled safety, it comes at a higher cost and requires complex installation and regular maintenance. The need for professional expertise to ensure compliance with regulations can also add to the overall expense.

Conclusion: Choosing the Right Backflow Prevention Solution

When selecting a backflow prevention solution, B2B buyers should carefully assess their specific needs, including the level of contamination risk, budget, and regulatory requirements. The irrigation system backflow preventer valve is a robust option for most irrigation systems, but alternatives like PVBs and RPZs can offer distinct advantages depending on the situation. By weighing the performance, cost, ease of implementation, and maintenance requirements of each option, buyers can make informed decisions that align with their operational priorities and compliance obligations.

Essential Technical Properties and Trade Terminology for irrigation system backflow preventer valve

What Are the Essential Technical Properties of an Irrigation System Backflow Preventer Valve?

When evaluating irrigation system backflow preventer valves, several critical technical properties must be considered to ensure optimal performance and compliance with industry standards. Understanding these specifications not only aids in product selection but also enhances system reliability and safety.

Material Grade: Backflow preventers are commonly constructed from materials such as brass, PVC, or stainless steel. Brass is often preferred for its durability and resistance to corrosion, making it suitable for various environmental conditions. The choice of material directly impacts the longevity and maintenance needs of the valve, which is crucial for B2B buyers in sectors where irrigation systems are heavily utilized.

Pressure Rating: This refers to the maximum pressure the valve can handle, typically expressed in pounds per square inch (PSI). A higher pressure rating indicates a more robust valve capable of withstanding the demands of commercial irrigation systems. Buyers should assess the pressure requirements of their specific applications to avoid premature valve failure.

Flow Rate: Measured in gallons per minute (GPM), the flow rate indicates how much water can pass through the valve without causing backflow. This is vital for ensuring adequate water supply across irrigation systems. B2B buyers should match the flow rate of the backflow preventer with the specifications of their irrigation system to maintain efficiency.

Backflow Prevention Method: Different backflow preventers utilize various methods to prevent contamination. Common types include Pressure Vacuum Breakers (PVB), Double Check Assemblies (DCA), and Reduced Pressure Zone Assemblies (RPZ). Each method has unique advantages, and understanding these can help buyers select the appropriate device based on their system design and potential contamination risks.

Size and Connection Types: Backflow preventers come in various sizes, typically ranging from ¾ inch to 2 inches in diameter. Compatibility with existing piping systems is crucial, requiring buyers to consider inlet and outlet sizes and connection types (e.g., threaded, flanged). Incorrect sizing can lead to installation challenges and inefficiencies.

Compliance Standards: Many regions have specific regulations governing the installation and operation of backflow preventers. Familiarity with local codes is essential for compliance and to avoid penalties. This is particularly relevant for international buyers, who must navigate different regulatory environments.

What Are Common Trade Terms Related to Irrigation System Backflow Preventer Valves?

Understanding trade terminology is crucial for effective communication and negotiation in the B2B landscape. Here are some key terms relevant to backflow preventer valves:

OEM (Original Equipment Manufacturer): This term refers to companies that produce components or products that are used in another company’s end product. Knowing the OEM can help buyers assess product quality and compatibility with existing systems.

MOQ (Minimum Order Quantity): MOQ specifies the least number of units a supplier is willing to sell. This term is significant for B2B buyers, particularly when managing inventory levels and budgeting for large-scale purchases.

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For irrigation system components, including backflow preventers, submitting an RFQ can facilitate competitive pricing and better procurement decisions.

Incoterms (International Commercial Terms): These are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for navigating shipping costs, risk, and insurance in cross-border transactions.

Lead Time: This term refers to the amount of time it takes from placing an order to receiving the product. For irrigation projects, where timely installation is critical, understanding lead times helps buyers plan accordingly.

Warranty: A warranty is a guarantee provided by the manufacturer regarding the lifespan and performance of a product. Buyers should carefully review warranty terms to ensure adequate protection against defects and failures, which is especially important for components like backflow preventers that play a vital role in system integrity.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance the efficiency and reliability of their irrigation systems.

Navigating Market Dynamics and Sourcing Trends in the irrigation system backflow preventer valve Sector

What Are the Current Market Dynamics and Key Trends in the Irrigation System Backflow Preventer Valve Sector?

The irrigation system backflow preventer valve market is witnessing substantial growth driven by increasing awareness regarding water safety and regulatory compliance. Countries in Africa, South America, the Middle East, and Europe are experiencing a surge in agricultural activities, necessitating effective irrigation practices. As urbanization expands and agricultural demands increase, the need for reliable backflow preventers to safeguard potable water sources has become critical. Furthermore, emerging technologies such as IoT-enabled backflow prevention systems are gaining traction, offering enhanced monitoring capabilities and real-time alerts for maintenance needs. This trend aligns with the broader digital transformation seen across various sectors, allowing international B2B buyers to make data-driven decisions regarding their irrigation systems.

Additionally, the market is influenced by stringent regulations surrounding water quality and environmental safety. Countries such as Saudi Arabia and Nigeria have implemented laws that mandate the installation of backflow preventers in irrigation systems, providing an impetus for manufacturers to innovate and improve their offerings. Buyers are increasingly seeking suppliers who can provide not only high-quality products but also extensive technical support and compliance with local regulations. As a result, partnerships between suppliers and local distributors are becoming vital for ensuring seamless market entry and customer satisfaction.

How Are Sustainability and Ethical Sourcing Impacting the Irrigation System Backflow Preventer Valve Sector?

Sustainability has emerged as a key consideration for B2B buyers in the irrigation system backflow preventer valve sector. The environmental impact of manufacturing processes and the materials used in these devices is under scrutiny. Consequently, buyers are increasingly favoring suppliers who prioritize eco-friendly practices and materials. The adoption of ‘green’ certifications, such as ISO 14001, signifies a supplier’s commitment to sustainable practices, which is becoming a prerequisite for many international buyers.

Moreover, ethical sourcing is gaining prominence, especially in regions where supply chain transparency is crucial. Buyers are looking for suppliers who can demonstrate responsible sourcing of materials, ensuring that their products do not contribute to environmental degradation or exploitative labor practices. This shift not only supports corporate social responsibility but also resonates with end consumers who are becoming more environmentally conscious. As a result, suppliers who embrace sustainability and ethical practices are likely to gain a competitive edge in the market.

How Has the Irrigation System Backflow Preventer Valve Sector Evolved Over Time?

The evolution of backflow preventer valves can be traced back to the early 20th century when the need for safe drinking water became paramount. Initial designs focused primarily on mechanical solutions to prevent contamination, but as technology advanced, so did the sophistication of these devices. The introduction of materials such as brass and high-grade plastics improved durability and performance, making backflow preventers more reliable.

In recent decades, regulatory frameworks have played a significant role in shaping the market, with many countries enacting laws requiring backflow prevention systems in irrigation and plumbing applications. The integration of smart technology represents the latest evolution, allowing for automated monitoring and control, which enhances both efficiency and safety. This historical context underscores the importance of innovation and compliance in meeting the evolving needs of B2B buyers across various regions.

Frequently Asked Questions (FAQs) for B2B Buyers of irrigation system backflow preventer valve

1. How do I select the right backflow preventer for my irrigation system?

Selecting the appropriate backflow preventer hinges on understanding your irrigation system’s requirements and local regulations. First, identify the type of irrigation you are using—whether it’s drip, sprinkler, or a hybrid system—as this will determine the suitable backflow preventer type (e.g., Pressure Vacuum Breaker, Reduced Pressure Zone Assembly). Additionally, consult local building codes and health regulations, as certain areas may mandate specific devices. Working with a knowledgeable supplier can also provide insights into the best options tailored to your unique needs.2. What are the different types of backflow preventers and their applications?

Backflow preventers come in various types, including Pressure Vacuum Breakers (PVB), Reduced Pressure Zone Assemblies (RPZ), Double Check Assemblies (DCA), and Atmospheric Vacuum Breakers (AVB). PVBs are ideal for residential irrigation systems, while RPZs are used in commercial settings where chemicals or fertilizers are present. DCAs are typically employed where non-health hazards exist. Understanding the specific application of each type is crucial for compliance and ensuring the safety of potable water supplies.3. What are the legal requirements for backflow preventers in my region?

Legal requirements for backflow preventers vary significantly by country and even local jurisdictions. In many regions, including parts of Europe, the Middle East, and Africa, installation is often mandated by law, particularly in commercial and agricultural applications. To ensure compliance, it’s essential to check with local authorities or consult legal experts familiar with water safety regulations in your area. Non-compliance can lead to severe penalties and health risks.4. How can I ensure the quality and reliability of backflow preventers from suppliers?

When sourcing backflow preventers, it’s critical to vet suppliers thoroughly. Look for suppliers with established reputations, positive reviews, and certifications that comply with international standards. Request product samples and certifications to assess quality. Additionally, inquire about the supplier’s warranty and return policy, as these can provide insight into their commitment to quality and customer satisfaction.5. What are common issues that necessitate backflow preventer replacement?

Common indicators that a backflow preventer may need replacement include visible corrosion, leaks, or a failure to maintain proper water pressure. Additionally, if the device frequently triggers or fails inspections, it may indicate underlying issues. Regular maintenance and testing can help identify problems early. If a backflow preventer is over five years old or has undergone significant wear and tear, consider replacing it to ensure continued compliance and safety.6. What is the typical minimum order quantity (MOQ) for backflow preventers?

Minimum order quantities (MOQs) for backflow preventers can vary based on the supplier and the specific product. Generally, MOQs range from 10 to 100 units, depending on the manufacturer’s capabilities and the type of backflow preventer. When negotiating with suppliers, it’s essential to discuss MOQs upfront and explore options for lower quantities, especially for new buyers or small projects. This can help manage inventory and cash flow more effectively.7. What payment terms should I expect when sourcing backflow preventers internationally?

Payment terms for international transactions can vary widely among suppliers. Common practices include payment in advance, net 30, or net 60 days, depending on the buyer-supplier relationship and order size. It’s advisable to discuss payment methods upfront, including options for letters of credit, wire transfers, or escrow services for larger purchases. Understanding these terms can help mitigate risks associated with international transactions and ensure a smooth procurement process.8. How do logistics impact the sourcing of backflow preventers?

Logistics play a crucial role in the sourcing of backflow preventers, especially for international buyers. Factors such as shipping costs, delivery timelines, and customs regulations can affect the overall procurement process. It’s essential to work with suppliers who have robust logistics capabilities and can provide transparent shipping options. Additionally, understanding local customs duties and regulations can help prevent unexpected delays or additional costs, ensuring timely delivery of your backflow preventers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Irrigation System Backflow Preventer Valve Manufacturers & Suppliers List

1. DripWorks – Backflow Prevention Devices

Domain: dripworks.com

Registered: 1998 (27 years)

Introduction: Irrigation Backflow Prevention Devices and Valves. Products include: Febco 765 Backflow Preventor ($184.65 – $208.95 MSRP), Febco 850 Inline Backflow Preventor ($291.65 – $303.95 MSRP), Febco 825Y Backflow Preventer ($565.35 – $595.55 MSRP), Vacuum Breakers ($3.25 – $8.95 MSRP), Check Valves ($16.95 – $34.95 MSRP), Hunter Air/Vacuum Relief Valve ¾ in. MPT ($14.70 MSRP), Air Bleed Valves ($5.95 – $…

2. Cheap Sprinklers – Irrigation Backflow Prevention Devices

Domain: cheapsprinklers.com

Registered: 2014 (11 years)

Introduction: Irrigation backflow prevention devices are installed on water lines to allow water to flow in one direction, protecting against back-siphonage and back-pressure of contaminated water to the potable water supply. They prevent non-potable water from contaminating potable water, which can cause health hazards. Backflow preventers are often required by law in settings with contamination risks, such as…

3. Conbraco – 4A-505-02(F) Freeze Resistant Pressure Vacuum Breaker

Domain: sprinklersupplystore.com

Registered: 2010 (15 years)

Introduction: [{“name”:”Conbraco – 4A-505-02(F) – 1″ Freeze Resistant Pressure Vacuum Breaker, Backflow”,”size”:”1″”,””material”:”Bronze”,”original_price”:”$275.29″,”current_price”:”$206.47″,”discount”:”25%”,”stock”:”In Stock (7)”},{“name”:”Febco – 825EBVFEB – 825Y 1″ RPZ Backflow Preventer w/Ball Valve”,”size”:”1″”,””material”:”Bronze”,”original_price”:”$760.70″,”current_price”:”$760.52″,”discount”:”0%”,”stock…

4. Reddit – Sprinkler Backflow Preventer

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Sprinkler backflow preventer is necessary to protect health and prevent cross-contamination, especially when using well water. Local codes may require installation by a licensed plumber.

5. Backflow Preventers – Essential Devices for Drip Irrigation

Domain: diy.stackexchange.com

Registered: 2009 (16 years)

Introduction: Backflow preventers are essential for drip irrigation systems to prevent contaminated water from entering the potable water supply. Approved backflow prevention devices include: (1) Atmospheric vacuum breaker, (2) Pressure vacuum breaker, (3) Spill-resistant pressure vacuum breaker, (4) Reduced pressure vacuum breaker. A pressure reducing valve does not serve as a backflow preventer. It’s recommen…

Strategic Sourcing Conclusion and Outlook for irrigation system backflow preventer valve

In the rapidly evolving landscape of irrigation system management, strategic sourcing of backflow preventer valves is paramount for ensuring both compliance and safety. These devices not only protect potable water supplies from contamination but also play a critical role in maintaining the integrity of irrigation systems. As such, understanding the various types—such as Pressure Vacuum Breakers, Double Check Assemblies, and Reduced Pressure Zone Assemblies—is essential for making informed purchasing decisions that align with local regulations and agricultural practices.

For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, leveraging strategic sourcing can unlock significant value, driving cost efficiencies while enhancing operational reliability. By establishing relationships with reputable suppliers and staying abreast of innovations in backflow prevention technology, businesses can improve their water management practices and mitigate risks associated with contamination.

Looking ahead, the demand for effective backflow prevention solutions is set to rise as global awareness of water quality issues increases. Now is the time to invest in reliable backflow preventers that meet both regulatory standards and your specific irrigation needs. Explore your options today and secure a cleaner, safer water supply for your agricultural operations.