Article Contents

Industry Insight: Knife Gate Valves

Market Analysis: Sourcing High-Quality Knife Gate Valves

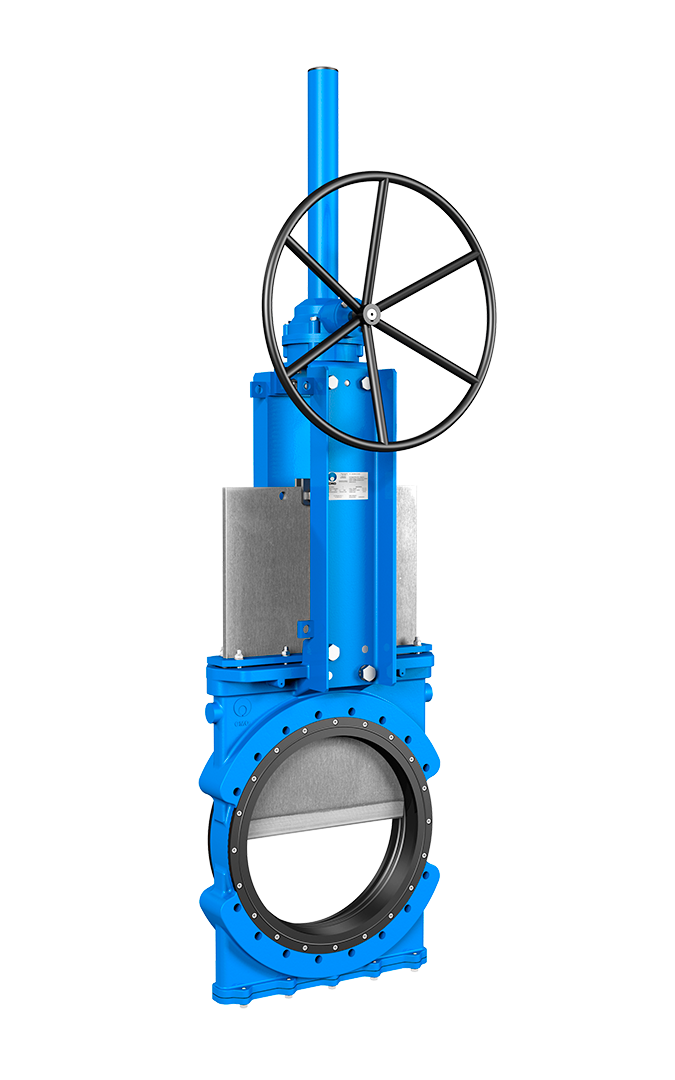

Knife gate valves are critical components in industrial and agricultural applications such as wastewater treatment, mining, pulp & paper processing, and chemical manufacturing. In these environments, valve failure can lead to costly downtime, safety hazards, and environmental risks. Selecting a valve that delivers consistent performance under demanding conditions is not just a procurement decision—it’s a strategic investment in operational reliability.

Common Pain Points in Valve Selection

Inconsistent Sealing Performance: Many valves are designed for uni-directional flow, leading to leakage when reverse flow occurs or when handling abrasive slurries. This results in frequent maintenance and unplanned shutdowns.

Material Degradation: Lower-grade materials in corrosive or high-temperature environments cause premature wear, especially in chemical and mining applications where exposure to aggressive media is common.

Short Service Life: Poor seat design and inadequate testing lead to rapid degradation in slurry applications, increasing replacement costs and operational disruptions.

Non-Compliance with Industry Standards: Valves lacking proper certification (e.g., ASME, ISO) may fail under pressure or temperature extremes, risking project compliance and safety.

How BFV Valves Delivers Uncompromising Reliability

BFV Valves addresses these challenges through advanced engineering, rigorous quality control, and a decade of global export expertise. Our knife gate valves are engineered for mission-critical applications, ensuring long-term performance and operational confidence.

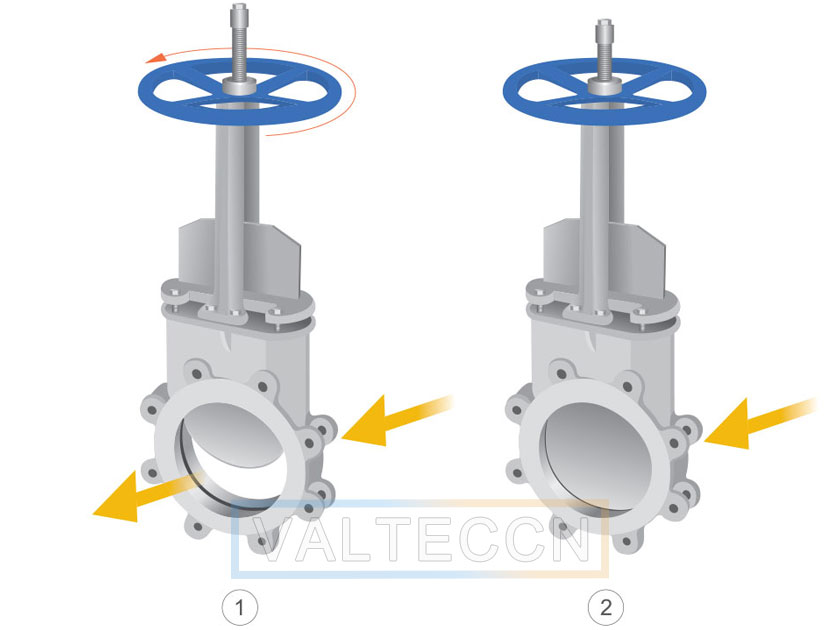

Advanced Sealing Technology: True bi-directional sealing with EPDM or metal seats ensures zero leakage in both flow directions, even in high-solids slurry environments.

Premium Material Selection: SS304/316 stainless steel bodies provide superior corrosion resistance, with full material traceability for compliance with international standards (e.g., ASTM A240, EN 10088).

100% Testing Protocol: Every valve undergoes rigorous functional testing per ISO 5208 standards, including pressure, leakage, and cycle testing, before shipment.

ISO 9001:2015 Certified Manufacturing: Our quality management system ensures consistent production processes and adherence to strict quality benchmarks across all orders.

Proven Global Track Record: With over 10 years of export experience serving clients in 50+ countries, BFV Valves is trusted for mission-critical applications in water treatment, mining, and chemical industries.

BFV Valves’ Quality Assurance Framework

| Feature | Industry Standard | BFV Solution | Impact |

|---|---|---|---|

| Sealing Mechanism | Typically uni-directional; limited reverse flow capability | True bi-directional sealing with EPDM/Metal seats | Eliminates leakage in both flow directions, critical for slurry and variable flow applications |

| Material Certification | Varies; some use lower-grade alloys | SS304/316 bodies with full material traceability | Enhanced corrosion resistance in chemical, wastewater, and mining environments |

| Testing Protocol | Basic pressure testing; occasional sampling | 100% functional testing per ISO 5208 | Zero-defect delivery; reduced field failures and maintenance costs |

| Certification | Some ISO 9001; inconsistent compliance | Full ISO 9001:2015 certified manufacturing | Consistent quality across all export orders and regulatory compliance |

| Field Provenance | Limited global track record | 10+ years serving 50+ countries | Trusted by Fortune 500 clients in critical applications worldwide |

Why Partner with BFV Valves?

As a trusted supplier for engineering consultants, procurement managers, and project contractors, BFV Valves combines technical precision with operational pragmatism. Our valves are rigorously tested to meet ASME Class 150/300 standards (up to 740 psi and 450°F), ensuring reliability in the most demanding slurry, chemical, and wastewater applications. With a focus on durability, compliance, and global support, we eliminate the risks associated with substandard valve solutions—delivering peace of mind from specification to installation.

“In industrial operations, there is no margin for error. BFV Valves’ commitment to 100% testing and ISO-certified quality ensures our projects run safely, efficiently, and without unexpected interruptions.”

— Senior Project Engineer, Global Mining Consortium

Technical Specs & ISO Standards

Technical Specifications & Standards

BFV Valves adheres to rigorous international standards to ensure reliability and performance across demanding industrial applications. Our knife gate valves are engineered for precision, durability, and compliance with global specifications—providing engineering consultants and procurement managers with a trusted solution for critical flow control.

Material Specifications & Compliance

Body Materials: SS304 (ASTM A240), SS316L (ASTM A240), Ductile Iron (ASTM A536 Grade 65-45-12), and Cast Iron (ASTM A126 Class B) with epoxy or fusion-bonded coatings for corrosive environments. All materials are certified with mill test reports (MTRs) traceable to ISO 9001.

Seat Options: EPDM for general-purpose applications (up to 120°C), metal seats (Stellite 6, SS316) for high-temperature, abrasive, or chemical services. All seats comply with MSS SP-135 for sealing integrity.

Standards Compliance: ANSI B16.34 (pressure-temperature ratings), ISO 5208 (leakage testing), DIN 3352 (knife gate valve design), BS 5155 (industrial valve specifications), and MSS SP-135 (severe service knife gate valves).

Sealing & Performance Standards

BFV knife gate valves feature true bi-directional sealing capability, certified to MSS SP-135, ensuring reliable shut-off in both flow directions. Key performance metrics:

Pressure Ratings: ASME Class 150 (up to 740 psi at 100°F) and Class 300 (up to 1500 psi at 100°F)

Temperature Range: -20°C to 150°C (EPDM seats), -20°C to 450°C (metal seats)

Zero-Leakage Design: ISO 5208 Class A compliance for bubble-tight shut-off under reverse flow conditions

Testing Protocols & Quality Assurance

Every BFV knife gate valve undergoes 100% testing before shipment, ensuring uncompromising quality:

Hydrostatic Testing: 1.5x working pressure for 15 minutes (per ISO 5208 Class A)

Air Leakage Test: 0.6 bar pressure with zero visible leakage at seat

Full Quality Traceability: ISO 9001-certified quality management system with documented test records for each unit

Global Export Heritage: 10+ years of consistent delivery to 50+ countries, backed by rigorous in-house QA protocols

BFV Certified Quality vs. Low-Cost Alternatives

| Feature | BFV Valves | Low-Cost Alternatives |

|---|---|---|

| Material Certification | Full traceability via ASTM/ISO MTRs; SS304/316L with 100% chemical analysis | Inconsistent material grades; limited or no MTRs; substandard alloys common |

| Testing Protocols | 100% hydrostatic (1.5x PN) & air leakage tests per ISO 5208 Class A | Selective testing; often visual inspection only; no standardized pressure validation |

| Sealing Integrity | Bi-directional sealing certified to MSS SP-135 (≤0% leakage) | Uni-directional design only; reverse flow leakage up to 5% (non-compliant) |

| Compliance Standards | Full compliance with ANSI B16.34, ISO 5208, DIN 3352, BS 5155, MSS SP-135 | Partial compliance (e.g., pressure ratings only); no seat testing certification |

| Long-Term Reliability | 10+ years global export history; ISO 9001 certified; 5-year warranty; dedicated technical support | Limited traceability; inconsistent QC; 1-year warranty or none; no regional support |

Why BFV?

Our commitment to 100% tested, ISO 9001-certified, and globally validated quality ensures your projects meet stringent safety, regulatory, and operational requirements—without compromise. With over a decade of export success, BFV Valves delivers consistent performance where failure is not an option.

Manufacturing Excellence & QC

Manufacturing Excellence & Rigorous Quality Assurance

Precision Manufacturing Process

BFV Valves employs a meticulous, end-to-end manufacturing protocol for SS304/316 knife gate valves, ensuring compliance with ASTM A276/A182 and ASME B16.34 standards. Critical steps include:

Material Verification: Spectrometry testing of all raw materials to confirm chemical composition, with full traceability via mill test reports (MTRs).

CNC Machining: Sub-micron precision (±0.001mm) for gate and seat surfaces, achieving Ra ≤ 0.8μm surface roughness for optimal sealing.

Cleanroom Assembly: ISO Class 8 environment with laser-guided alignment to prevent particulate contamination during final assembly.

Purpose-Built Test Zone: 100% Pre-Shipment Validation

Every BFV knife gate valve undergoes 100% functional testing in our dedicated test facility before export. Our standardized protocols exceed industry benchmarks, ensuring reliability in slurry, chemical, and wastewater applications.

| Test Type | Standard | Procedure Details | Acceptance Criteria |

|---|---|---|---|

| Hydrostatic Pressure | API 598 | 1.5× working pressure for 15 minutes | Zero visible leakage |

| Pneumatic Leakage | ISO 5208 Class VI | 1.1× working pressure with helium tracer gas | ≤ 0.1% leakage rate |

| Bi-Directional Seal | MSS SP-135 | Pressure applied from both directions at 1.5× WP | No measurable leakage |

| Actuator Cycle | MSS SP-135 | 5,000+ cycles at rated pressure | No degradation in sealing performance |

ISO 9001:2015 Certified Quality Management

BFV’s ISO 9001:2015 certification is embedded in every process stage—from raw material procurement to final shipment. Annual third-party audits by TÜV SÜD validate our system, with all test data digitally logged and traceable via unique batch codes. This ensures consistent quality and rapid resolution of any non-conformities through our closed-loop corrective action protocol.

Ethical Sourcing & Sustainable Operations

We maintain strict supplier vetting to ensure compliance with RoHS, REACH, and conflict-mineral regulations. All manufacturing facilities adhere to SA8000 labor standards, with third-party audits for workplace safety and environmental compliance. Energy-efficient processes reduce CO₂ emissions by 18% compared to industry averages, aligning with global sustainability goals.

10+ Years of Global Export Excellence

Since 2014, BFV has delivered 50,000+ knife gate valves to clients across 50+ countries, maintaining a zero-recall record and 98% on-time delivery rate. Every export shipment includes comprehensive compliance documentation (Certificate of Origin, MTRs, and test reports) for seamless customs clearance and regulatory adherence. Our decade-long track record underscores BFV as a trusted partner for mission-critical valve solutions.

Global Applications

Industrial Applications of Knife Gate Valves

Knife gate valves are engineered for demanding industrial environments where precision, durability, and sealing integrity are non-negotiable. BFV Valves delivers tailored solutions for critical applications across mining, pulp & paper, wastewater, and chemical processing sectors—ensuring compliance with global standards and operational reliability.

Mining Industry

Mining operations require valves that withstand abrasive slurries, high solids content, and corrosive chemicals. BFV’s knife gate valves are engineered for these extreme conditions with precision-engineered components and rigorous quality control.

| Key Challenge | BFV Solution | Compliance |

|---|---|---|

| Abrasive slurries and high solids content | SS316 body with hardened metal seats for superior wear resistance | MSS SP-135, ASME B16.34 Class 150/300 |

| Variable flow direction in tailings systems | Bi-directional sealing with EPDM or metal seats ensuring zero leakage | API 598 leakage testing |

| Corrosive environments (e.g., cyanide leaching) | 316 stainless steel construction with chemical-resistant elastomers | ASTM A240, NACE MR0175 |

Pulp & Paper Industry

In pulp and paper processing, knife gate valves must manage fiber-laden slurries, chemical exposures, and precise flow control. BFV’s designs ensure minimal maintenance and maximum uptime in critical production lines.

| Key Challenge | BFV Solution | Compliance |

|---|---|---|

| High fiber content in pulp slurries | Knife-edge design with clean-cut sealing to prevent clogging | MSS SP-135, ANSI B16.34 |

| Chemical exposure (e.g., bleach, caustic) | EPDM seats for chemical resistance or metal seats for high temperature | ASTM A240, ISO 15848 |

| Bi-directional flow in process lines | Dual sealing system ensuring zero leakage in both directions | API 598, ASME B16.34 |

Wastewater Treatment

Wastewater facilities require valves that handle sludge, grit, and corrosive elements while supporting automated operations. BFV’s robust designs ensure reliable performance in demanding municipal and industrial settings.

| Key Challenge | BFV Solution | Compliance |

|---|---|---|

| Sludge and grit handling | Robust SS304/316 body with self-cleaning knife edge | ASME B16.34, EN 12266-1 |

| Corrosive environments (H₂S, chlorides) | 316 stainless steel with EPDM seats for chemical resistance | ISO 9001, NACE MR0175 |

| Automation needs for remote operations | Pneumatic/electric actuators with fail-safe options | ISO 5211, NAMUR standards |

Chemical Processing

Chemical plants demand valves that withstand aggressive media, extreme temperatures, and stringent purity requirements. BFV’s precision-engineered solutions meet the highest safety and reliability standards.

| Key Challenge | BFV Solution | Compliance |

|---|---|---|

| Highly corrosive media (acids, solvents) | SS316L body with PTFE or metal seats for chemical compatibility | ASTM A240, ASME B16.34 |

| High-pressure and temperature conditions | Metal-seated options rated up to 740 psi and 450°F | ASME Class 300, ISO 10497 |

| Zero contamination requirements | Full weldability and polished surfaces for sanitary applications | FDA-compliant materials, ISO 15848 |

Why BFV Valves is the Preferred Choice for Blue-Chip Consultants and Engineers

BFV Valves has established itself as a trusted partner for engineering consultants and procurement managers worldwide through unwavering commitment to quality, compliance, and global reliability. Our solutions are backed by rigorous standards and decades of proven performance.

| Key Strength | Technical Advantage | Industry Validation |

|---|---|---|

| 100% Pressure Testing | Every valve undergoes 1.5× working pressure testing to ensure leak-tight performance | Per API 598 and ISO 15848 standards |

| ISO 9001:2015 Certified Quality System | Rigorous process control from raw material to final inspection | Global quality management standard |

| 10+ Years of Global Export Experience | Proven reliability across 50+ countries in critical applications | CE, PED, ASME certifications |

BFV’s knife gate valves integrate SS304/316 stainless steel bodies, EPDM/metal seats for versatile sealing, bi-directional flow capability, and integrated pneumatic/electric actuation—all engineered to meet the exacting demands of global industrial projects. With zero compromise on quality and a track record of delivering mission-critical solutions, BFV is the definitive choice for consultants and engineers who demand precision, durability, and peace of mind.

Why Choose BFV Valves

Partner with BFV Valves

As a trusted global supplier under BFV Valves (CMO Valve), we deliver precision-engineered knife gate valves engineered for demanding industrial applications. Our products feature SS304/316 stainless steel bodies, EPDM/metal seats, bi-directional sealing, and pneumatic/electric actuation options – designed to meet stringent performance requirements in slurry, wastewater, pulp & paper, mining, and chemical processing environments. With a decade of export expertise and ISO-certified quality systems, we provide a safe pair of hands for mission-critical valve solutions worldwide.

Key Advantages for Global Projects

| Advantage | BFV Implementation | Client Benefit |

|---|---|---|

| Accurate Delivery Times | Optimized production scheduling with real-time tracking; 95% on-time delivery rate | Minimized project delays, predictable supply chain for tight deadlines |

| No-Obligation Consultancy | Dedicated engineering team providing free technical assessments and application-specific recommendations | Informed decisions without upfront costs; tailored solutions for complex projects |

| Competitive Pricing | Direct manufacturing with lean operations; bulk procurement economies of scale | Cost-effective solutions without compromising quality or performance |

Quality Assurance & Compliance

100% Functional Testing: Every valve undergoes rigorous pressure testing and leakage verification per ISO 9001 standards, ensuring zero defects before shipment.

ISO 9001 Certified: Adherence to international quality management systems guarantees consistent product reliability and process excellence.

10-Year Export History: Proven track record across 50+ countries, with expertise in diverse regulatory environments and industry-specific requirements (including MSS SP-135, ASME Class 150/300).

Regional Support

For project-specific inquiries, technical support, or to request a quotation, contact our regional experts directly:

Alice@cmovalve.com.cn

🧮 Valve Flow Coefficient (Cv) Calculator

Estimate the required valve size based on flow rate and pressure drop.