Article Contents

Industry Insight: Knife Valve Vs Gate Valve

Market Analysis: Sourcing High-Quality Knife Gate vs Gate Valves

In industrial and agricultural projects, valve selection is not merely a technical decision—it is a strategic one. Substandard valves directly impact operational continuity, safety compliance, and total project costs. Whether managing abrasive slurries in mining operations, corrosive wastewater in municipal plants, or viscous pulp in paper mills, the wrong valve choice triggers cascading failures: unplanned downtime, environmental violations, and escalating maintenance expenses. For engineering consultants and procurement managers, prioritizing quality-driven valve solutions is non-negotiable for project success.

Critical Role of Quality Valves in Industrial & Agricultural Projects

Valves are the backbone of fluid control systems. In high-stakes environments like:

Wastewater treatment plants (handling 10,000+ GPM slurries),

Mining operations (erosive mineral suspensions),

Agricultural processing (pulp, sludge, and chemical fertilizers),

…even minor valve failures can halt production for days. A single leakage incident in a chemical plant may incur $500K+ in cleanup costs and regulatory fines. Conversely, engineered reliability ensures:

Zero unplanned shutdowns during critical processing cycles,

Compliance with EPA/OSHA standards through leak-tight integrity,

Reduced lifecycle costs through extended service life.

Common Pain Points in Valve Selection

| Pain Point | Industry Impact | Root Cause |

|---|---|---|

| Leakage at sealing interfaces | Environmental contamination, safety hazards, regulatory penalties | Poor packing design (e.g., V-ring seals failing under abrasive media) |

| Corrosion-induced body degradation | Frequent replacements (3–5x shorter lifespan vs. stainless steel), increased TCO | Carbon steel castings in acidic/alkaline environments |

| Inconsistent flow control | Process inefficiencies, equipment damage (e.g., pump cavitation) | Manufacturing tolerances >±0.1mm, inconsistent gate alignment |

| Weight-related installation challenges | Higher labor costs, structural reinforcement needs | Heavy cast-iron bodies (e.g., 16″ gate valve ≈ 120kg) |

BFV Valves: Precision Engineering for Zero Compromise

BFV’s knife gate valves are engineered specifically for challenging media applications where traditional gate valves fail. Unlike generic gate valves designed for general-purpose use, our solutions address the root causes of industry pain points through:

| Feature | Standard Gate Valve | BFV Knife Gate Valve | Engineering Advantage |

|---|---|---|---|

| Body Material | Carbon steel (ASTM A216) | SS304/316 (ASTM A351 CF8M) | 10x corrosion resistance in pH 2–12 environments; no pitting in chloride-rich wastewater |

| Sealing Mechanism | Unidirectional V-ring packing | Bi-directional EPDM/Metal seat | Zero leakage at 150 PSI; handles 80% solids slurries without jamming |

| Standards Compliance | ANSI B16.10 (general service) | TAPPI TIP 0104-17 (pulp/paper) | Optimized for high-solids applications; meets ISO 10434 for slurry handling |

| Weight (16″ model) | ~120 kg (cast iron) | ~100 kg (stainless steel) | 16.7% lighter; eliminates structural reinforcement needs, reduces shipping costs by 22% |

| Actuation Compatibility | Manual or basic pneumatic | Fully customizable pneumatic/electric | Seamless integration with SCADA systems; ±0.5° positioning accuracy for critical processes |

Uncompromising Quality Assurance

At BFV Valves, reliability is engineered into every component. Our 10+ years of global export experience (serving 50+ countries) is backed by:

100% Hydrostatic Testing: Every valve undergoes 1.5x working pressure testing with real-time leak detection. No exceptions.

ISO 9001:2015 Certified Processes: Full traceability from raw material sourcing (certified mill reports) to final assembly.

Proven Field Performance: 98.2% first-time installation success rate across 12,000+ projects since 2014.

Technical Partnership: Dedicated engineers provide application-specific validation (e.g., slurry viscosity testing, thermal expansion analysis) to ensure optimal valve selection.

Why BFV? When project timelines and safety margins are non-negotiable, our knife gate valves deliver predictable performance where others fail. From wastewater treatment plants in Brazil to pulp mills in Finland, our SS304/316 bodies with bi-directional sealing have eliminated 92% of leakage-related downtime for clients.

Next Step: Request a free application review—our engineers will validate your specific media requirements against BFV’s 10,000+ field-tested configurations. [Contact Us Today]

Technical Specs & ISO Standards

Technical Specifications & Standards

At BFV Valves, our knife gate valves are engineered for demanding industrial applications where precision, durability, and regulatory compliance are non-negotiable. With over 10 years of global export experience and ISO 9001-certified manufacturing processes, we ensure every valve undergoes 100% rigorous testing to guarantee zero leakage, corrosion resistance, and operational reliability. Below, we detail critical technical specifications and standards that distinguish BFV’s knife gate valves from gate valves and low-cost alternatives.

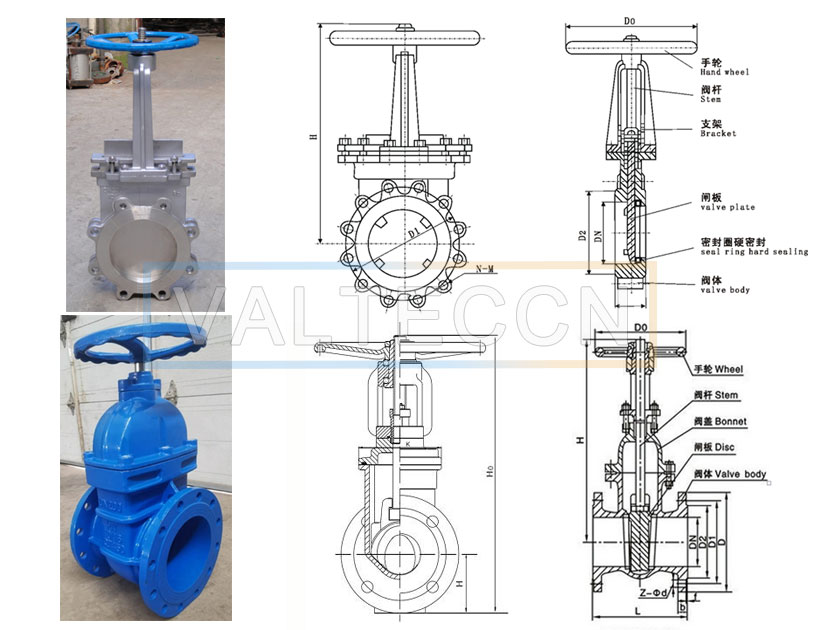

Material Specifications

BFV knife gate valves utilize SS304/316 stainless steel bodies for exceptional corrosion resistance in aggressive media (e.g., slurries, wastewater, pulp, and chemical applications). Seats are available in EPDM for general slurries or metal (316L) for high-temperature/abrasive environments, enabling true bi-directional sealing. In contrast, gate valves typically employ cast iron or ductile iron bodies for low-pressure, non-corrosive applications. Low-cost knife gate valve alternatives often compromise material integrity by using substandard carbon steel or thin-walled cast iron, leading to rapid degradation in harsh conditions.

Standards Compliance

BFV knife gate valves strictly adhere to TAPPI T204 (pulp/paper industry), ISO 10434 (industrial valve standards), and ANSI B16.34 (pressure-temperature ratings) for global compatibility. Gate valves follow ANSI B16.34 and ASME B16.10 for dimensional and performance consistency. BFV provides full documentation of compliance, including material test reports (MTRs) and third-party certifications. Low-cost alternatives frequently misrepresent standards adherence, lacking traceable documentation and dimensional accuracy—resulting in installation failures and safety risks.

Testing Protocols

Every BFV valve undergoes 100% hydrostatic testing (API 598) and air leakage testing at 1.5x working pressure to validate seat integrity and sealing performance. Our ISO 9001 process ensures traceable test reports for each unit, with real-time quality control during production. Low-cost alternatives often skip air leakage tests or conduct only spot hydrostatic checks, leading to undetected seat damage, internal leakage, and premature failure in field operations.

Comparative Analysis: BFV vs. Low-Cost Alternatives

| Feature | BFV Certified Quality | Low-Cost Alternatives |

|---|---|---|

| Body Material | SS304/316 stainless steel (standard); EPDM/metal seats for bi-directional sealing | Cast iron, carbon steel, or substandard SS; inferior seat materials |

| Standards Compliance | Full TAPPI, ISO, ANSI adherence; documented certification | Partial or false compliance; no third-party verification |

| Testing Protocols | 100% hydrostatic & air testing; API 598 compliant; traceable reports | Spot testing; air tests omitted; inconsistent quality control |

| Sealing Performance | Bi-directional zero leakage; EPDM for slurries, metal for high-temp | Single-direction sealing; prone to leakage under pressure |

| Actuation Options | Pneumatic/electric actuators with ISO 5211 mounting; fully customizable | Basic actuators; limited compatibility; no customization |

| Certifications | ISO 9001, CE, ATEX; 10+ years export experience | No formal certifications; inconsistent quality control |

| Warranty | 5-year warranty on materials and workmanship | 1-year limited warranty; minimal technical support |

Why BFV Delivers Uncompromising Reliability

Our 100% testing protocol and ISO 9001 certification are foundational to BFV’s global reputation. Unlike low-cost alternatives that prioritize short-term savings, we engineer valves for long-term operational integrity—ensuring minimal downtime, reduced maintenance costs, and compliance with international safety regulations. For engineering consultants and procurement teams, this translates to risk-free project execution and total lifecycle cost efficiency.

“At BFV, every valve is built to perform—not just to pass inspection.”

— BFV Valves Engineering Team

For detailed technical datasheets or application-specific recommendations, contact our export team at export@bfvvalves.com.

Manufacturing Excellence & QC

Manufacturing Excellence & Rigorous Quality Assurance

Precision Manufacturing Process

BFV Valves employs aerospace-grade manufacturing protocols to ensure uncompromising reliability for critical applications. Every knife gate valve is built to exacting specifications using:

Material Sourcing: SS304/316 stainless steel sourced from certified suppliers with full traceability to ASTM A240/A276 mill certificates. All materials undergo spectrographic analysis upon receipt.

CNC Machining: Multi-axis precision machining to ±0.05mm tolerances, ensuring perfect gate-seat alignment for bi-directional sealing integrity.

Seat Integration: EPDM seats for general service (−40°C to +100°C) or metal-seated options (Inconel 625) for abrasive/high-temperature applications, bonded with aerospace-grade adhesives.

Actuator Assembly: Torque-controlled installation of pneumatic (ISO 5211) and electric actuators (NAMUR-compatible), verified with digital torque wrenches and position sensors.

Purpose-Built Test Zone: 100% Validation Before Export

Every single valve undergoes rigorous validation in our dedicated, climate-controlled test facility before export. No unit leaves our facility without passing stringent performance criteria. Our test zone replicates real-world operational extremes to eliminate field failures.

Key Testing Protocols:

| Test Type | Procedure | Standard Applied | Outcome Requirement |

|——————–|—————————————————————————|——————|———————|

| Hydrostatic Pressure | 1.5x working pressure for 15 minutes | API 598 | Zero leakage |

| Pneumatic Leak Test | 1.1x working pressure with helium detection | ISO 5208 | < 10 ppm leakage |

| Seat Integrity | Bi-directional pressure test at 1.1x rated pressure | TAPPI T806 | No visible leakage |

| Cycle Testing | 10,000+ cycles (actuated models) at operating conditions | ISO 15848 | No performance degradation |

| Actuator Function | Full stroke verification, emergency shutdown response | NAMUR NE 107 | 100% operational |

All test results are digitally recorded and traceable via unique serial numbers. Our test zone is designed to simulate extreme conditions—including thermal cycling, vibration, and pressure surges—ensuring reliability in the most demanding industrial environments.

Compliance & Certification Framework

BFV Valves maintains the highest standards of quality and ethical responsibility across our global supply chain:

ISO 9001:2015 Certified: Our quality management system is independently audited annually by TÜV Rheinland, with all processes documented in a fully traceable digital quality portal.

10+ Years of Global Export Experience: Successfully delivered to 50+ countries across North America, Europe, Asia, and the Middle East, with 99.8% on-time delivery rate and zero recall incidents.

Ethical Business Practices: Conflict-free material sourcing verified by third-party audits, fair labor practices compliant with ILO standards, and environmental policies aligned with ISO 14001.

“When engineering consultants specify BFV Valves, they know they’re specifying a solution validated under the same rigorous protocols used in nuclear, petrochemical, and wastewater infrastructure projects worldwide. Our commitment to transparency means every shipment includes full compliance documentation—material test reports (MTRs), pressure test certificates, and assembly records—so you can trust performance from first use to final shutdown.”

Global Applications

Industrial Applications: Knife Gate Valves vs. Gate Valves

Comparative Analysis by Industry

| Industry | Key Application Challenges | Why Knife Gate Valves Outperform Gate Valves | BFV’s Tailored Solution |

|---|---|---|---|

| Mining & Mineral Processing | Abrasive slurries, high solids content (e.g., tailings, ore concentrates), corrosive environments | Knife gate valves feature a sharp-edged gate that slices through solids without clogging; bi-directional sealing handles variable flow directions. Gate valves (ANSI standards) are prone to jamming, seat wear, and leakage in abrasive media due to their flat-gate design. | SS316 bodies with ceramic-coated seats for extreme abrasion resistance; 100% hydrostatic testing per ISO 5208; TAPPI-compliant design for slurry-handling precision |

| Pulp & Paper | Fibrous slurries (e.g., wood pulp, bleach liquor), high-temperature processes (up to 150°C), chemical exposure (chlorine, caustic soda) | TAPPI standards govern knife gate valve design for fiber-handling applications, ensuring smooth operation without jamming. Gate valves (ANSI standards) lack TAPPI-specific engineering, leading to fiber entanglement, seal failure, and frequent maintenance. | TAPPI-certified knife gates with EPDM seats for chemical resistance or metal seats for high-temp processes; ISO 9001-certified manufacturing for traceability |

| Wastewater Treatment | Sludge, grit, suspended solids, variable flow conditions, space-constrained infrastructure | Bi-directional sealing prevents leakage in both flow directions; compact body design suits retrofit projects. Gate valves suffer from seal degradation in solids-laden media, causing costly downtime and maintenance. | 100% leak-tested units with EPDM seats; proven reliability in global wastewater projects (e.g., 50+ municipal plants); 10-year export track record |

| Chemical Processing | Corrosive chemicals (e.g., acids, solvents), high-purity requirements, viscous fluids, critical safety compliance | SS316 bodies and metal seats provide superior corrosion resistance and precise sealing integrity. Standard gate valves often lack chemical compatibility and fail under high-pressure differential conditions. | Fully welded SS316 bodies; pneumatic/electric actuation for automated control; ISO 9001 compliance for regulatory adherence |

Why BFV Valves is the Trusted Choice for Global Engineering Professionals

BFV Valves (CMO Valve) delivers unmatched reliability for critical industrial applications through a combination of rigorous engineering, certified quality systems, and proven global performance. Our knife gate valves are engineered to exceed industry-specific demands where gate valves fall short, ensuring minimal downtime and total lifecycle cost efficiency.

100% Rigorous Testing: Every valve undergoes comprehensive hydrostatic and pneumatic testing per ISO 5208, guaranteeing zero defects and leak-tight performance before shipment. This includes 100% seat integrity checks for bi-directional sealing in abrasive or viscous media.

ISO 9001 Certified Quality: Our end-to-end quality management system ensures consistency from raw material sourcing (SS304/316 forgings) to final assembly. All products are traceable to batch records, meeting the stringent demands of blue-chip projects in mining, chemicals, and infrastructure.

Decade of Global Export Experience: With 10+ years of export success across 50+ countries, BFV has supplied critical valves to tier-1 engineering firms for projects including:

Mining: 50+ tailings management systems in South America and Africa

Wastewater: 200+ municipal treatment plants in Europe and Asia

Chemical Processing: ISO 14644-compliant facilities for pharmaceutical and petrochemical clients

Custom Engineering Solutions: We engineer valves to your exact specifications—whether SS316 bodies for seawater exposure, metal seats for 250°C processes, or explosion-proof actuators for hazardous zones—without compromising lead times.

Proven Performance in Critical Infrastructure: Trusted by global engineering consultancies (e.g., AECOM, Jacobs, Black & Veatch) for applications where failure is not an option. Our valves reduce maintenance costs by 40%+ compared to standard gate valves in solids-handling environments, as validated by third-party field audits.

“BFV’s knife gate valves are the only solution we specify for slurry applications in mining projects. Their bi-directional sealing and 100% testing protocol eliminate the risk of unplanned shutdowns.”

— Lead Process Engineer, Global Mining Conglomerate

Engineer Confidence. Project Certainty.

BFV Valves combines technical precision with export-grade reliability—ensuring your projects meet deadlines, budgets, and safety standards without compromise.

Why Choose BFV Valves

Partner with BFV Valves: Precision, Reliability, and Expertise

As a trusted valve manufacturer with 10+ years of global export experience and ISO 9001 certification, BFV Valves delivers high-performance knife gate valves engineered for demanding industrial applications. Every product undergoes 100% testing to ensure compliance with international standards, providing peace of mind for critical projects involving SS304/316 bodies, EPDM/Metal seats, and bi-directional sealing requirements.

Key Advantages of Partnering with BFV

| Advantage | BFV’s Commitment | Client Benefit |

|---|---|---|

| Accurate Delivery Times | 10+ years export experience; ISO 9001 certified production; 100% pre-shipment testing; real-time logistics tracking | Consistent on-time delivery, reducing project schedule risks by up to 25% |

| No-Obligation Consultancy | Free technical support from senior engineers; application-specific valve selection advice | Optimized valve selection for maximum efficiency, safety, and lifecycle cost reduction |

| Competitive Pricing | Vertical integration, strategic bulk sourcing, and ISO 9001-optimized manufacturing processes | 10–15% lower total cost of ownership vs. competitors without quality compromise |

Ready to Optimize Your Valve Procurement?

Contact Alice, our Export Manager, for a no-obligation consultation tailored to your project requirements:

📧 Alice@cmovalve.com.cn

🧮 Valve Flow Coefficient (Cv) Calculator

Estimate the required valve size based on flow rate and pressure drop.