Introduction: Navigating the Global Market for knife valve vs gate valve

In the dynamic landscape of industrial operations, selecting the appropriate shut-off valve can pose a significant challenge for B2B buyers, particularly when comparing knife valves versus gate valves. These valves play crucial roles in diverse applications—from managing viscous fluids in wastewater treatment to ensuring the seamless flow of clean water in manufacturing processes. This comprehensive guide aims to demystify the complexities surrounding these two valve types, providing insights into their design, applications, and operational efficiencies.

International buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Brazil—will find valuable information on sourcing, supplier vetting, and cost considerations. By understanding the unique advantages and limitations of knife and gate valves, businesses can make informed decisions that enhance operational performance and reduce downtime. This guide will explore the various types of valves available, their specific applications across industries, and practical tips for ensuring optimal procurement processes.

Equipped with this knowledge, B2B buyers will be empowered to navigate the global market effectively, ultimately leading to improved project outcomes and a competitive edge in their respective sectors.

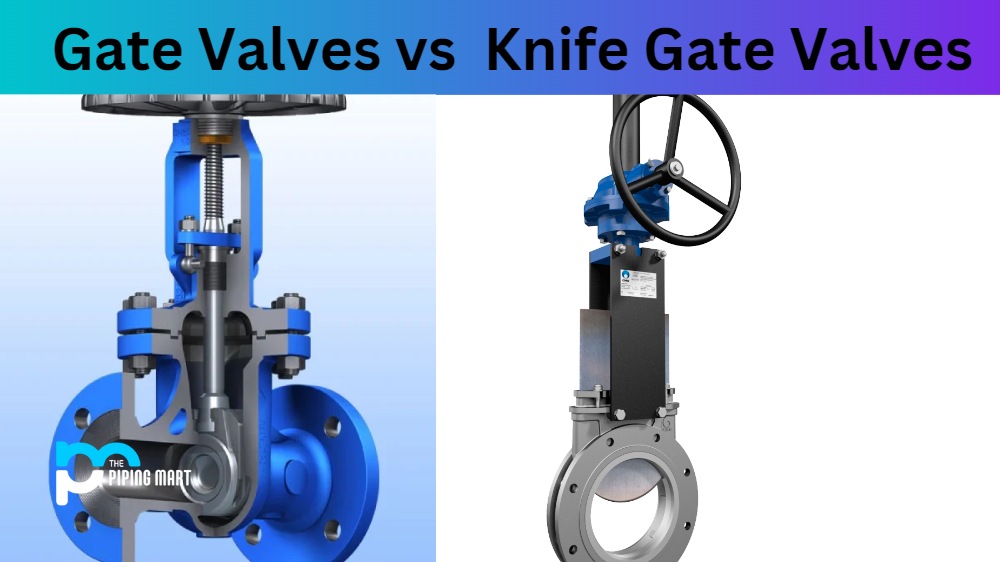

Understanding knife valve vs gate valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Knife Gate Valve | Features a sharpened blade for cutting through viscous media | Pulp and paper, wastewater treatment, heavy oil industries | Pros: Effective for thick fluids; cost-effective. Cons: Limited pressure tolerance; less hygienic. |

| Standard Gate Valve | Flat closure design allowing for minimal flow restriction | Oil and gas, pharmaceuticals, power generation | Pros: Low pressure drop; bi-directional flow. Cons: Requires significant force to operate; bulky. |

| Butterfly Gate Valve | Circular disc that pivots to control flow | Water treatment, HVAC systems, general manufacturing | Pros: Compact design; quick operation. Cons: Not suitable for high-pressure applications; limited sealing capability. |

| Lugged Knife Valve | Designed with lugs for easy installation and maintenance | Chemical processing, mining, and slurry handling | Pros: Easy to install; suitable for heavy-duty applications. Cons: Potential for wear in abrasive environments. |

| Wafer Knife Valve | Slim profile and lightweight, ideal for tight spaces | Wastewater management, food processing, and pulp industries | Pros: Space-saving; cost-effective. Cons: Limited to specific applications; lower durability in extreme conditions. |

What are the Characteristics of Knife Gate Valves?

Knife gate valves are primarily characterized by their sharp blade, which is designed to cut through viscous and solid-laden media. This design makes them particularly suitable for industries like pulp and paper, wastewater treatment, and heavy oil processing, where thick fluids are common. Buyers should consider the valve’s pressure limitations and potential wear issues, particularly in applications involving abrasive materials. The cost-effectiveness of knife gate valves makes them an attractive option for budget-conscious buyers, but their performance may decline in cleaner applications.

How Do Standard Gate Valves Differ in Suitability?

Standard gate valves are recognized for their flat closure mechanism, which allows for a straight flow with minimal resistance. This type is widely used in the oil and gas sector, pharmaceuticals, and power generation, where clean and non-corrosive media are prevalent. Buyers should note that while these valves offer bi-directional flow and a low-pressure drop, they require significant force to operate and can be bulky, making them less ideal for space-sensitive applications.

What Advantages Do Butterfly Gate Valves Offer?

Butterfly gate valves utilize a circular disc that pivots to control flow, providing a compact solution for various applications, including water treatment and HVAC systems. Their quick operation and lightweight design make them appealing to industries that require efficient flow management. However, buyers must consider their limitations, as butterfly valves are not suitable for high-pressure environments and may have reduced sealing capabilities compared to other valve types.

Why Choose Lugged Knife Valves for Heavy-Duty Applications?

Lugged knife valves are specifically designed with lugs that facilitate easy installation and maintenance, making them a preferred choice in chemical processing and mining industries. These valves excel in heavy-duty applications, offering durability and efficiency in handling abrasive materials. However, potential buyers should be aware of the wear that can occur in abrasive environments, which may necessitate more frequent maintenance and replacement.

What Makes Wafer Knife Valves Ideal for Space-Constrained Environments?

Wafer knife valves are known for their slim profile and lightweight construction, making them ideal for installations in tight spaces. They are commonly used in wastewater management and food processing industries, where a cost-effective solution is necessary. While these valves offer space-saving advantages, buyers should consider their limitations in extreme conditions, as their durability may not match that of bulkier alternatives.

Key Industrial Applications of knife valve vs gate valve

| Industry/Sector | Specific Application of Knife Valve vs Gate Valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Wastewater Treatment | Knife valves are used for sludge and slurry applications, while gate valves handle clean water flow. | Efficient management of wastewater and reduced downtime in treatment facilities. | Look for robust materials that can withstand corrosive environments. |

| Oil and Gas | Knife valves manage heavy oils and slurries, whereas gate valves are used for pipeline shut-off. | Enhanced operational efficiency and safety in handling viscous materials. | Ensure compatibility with high pressure and temperature standards. |

| Pulp and Paper | Knife valves cut through pulp and prevent blockages, while gate valves are used for process control. | Improved production flow and reduced maintenance costs. | Consider valves that meet industry-specific standards for reliability. |

| Chemical Processing | Knife valves are ideal for viscous media, while gate valves are suitable for clean, non-corrosive fluids. | Streamlined processes and minimized risk of contamination. | Prioritize sourcing from manufacturers who offer customizable solutions. |

| Power Generation | Knife valves are utilized in ash handling systems, while gate valves control water supply. | Increased efficiency and reliability in energy production. | Evaluate the valve’s ability to handle extreme conditions and ensure compliance with safety regulations. |

How Are Knife Valves and Gate Valves Used in Wastewater Treatment?

In wastewater treatment facilities, knife valves are essential for managing sludge and slurry, effectively cutting through thick materials that can block flow. Gate valves, on the other hand, are employed for controlling clean water flow, ensuring a smooth operation. This combination allows for efficient treatment processes, minimizing downtime and enhancing productivity. For international buyers, sourcing robust materials is crucial to withstand corrosive environments typical in wastewater applications.

What Role Do Knife Valves and Gate Valves Play in the Oil and Gas Industry?

In the oil and gas sector, knife valves are favored for their ability to handle heavy oils and slurries, while gate valves are typically used for safe pipeline shut-off operations. This dual use enhances operational efficiency and safety when dealing with viscous materials, critical in maintaining flow integrity. Buyers should ensure that the valves meet high pressure and temperature standards, as well as industry regulations, to avoid costly failures.

How Are Knife Valves and Gate Valves Applied in the Pulp and Paper Industry?

The pulp and paper industry relies heavily on knife valves to cut through stringy pulp, preventing blockages that could disrupt production. Gate valves are utilized for process control, allowing for smooth transitions in flow without introducing contaminants. This synergy leads to improved production flow and reduced maintenance costs. Buyers should consider sourcing valves that meet industry-specific standards to guarantee reliability and performance.

What Are the Applications of Knife Valves and Gate Valves in Chemical Processing?

In chemical processing, knife valves are ideal for handling viscous media, while gate valves are employed for clean, non-corrosive fluids. This distinction is vital for maintaining process integrity and minimizing contamination risks. International B2B buyers should prioritize sourcing from manufacturers that offer customizable solutions to meet specific operational needs and ensure compliance with safety standards.

How Do Knife Valves and Gate Valves Contribute to Power Generation?

In power generation, knife valves are commonly used in ash handling systems, while gate valves control the water supply essential for cooling and operational processes. This application enhances efficiency and reliability in energy production. Buyers should evaluate the valve’s ability to withstand extreme conditions and ensure compliance with safety regulations to maintain operational integrity and minimize downtime.

3 Common User Pain Points for ‘knife valve vs gate valve’ & Their Solutions

Scenario 1: Navigating the Right Valve for Thick Media Applications

The Problem: B2B buyers in industries such as wastewater treatment or pulp and paper often struggle with selecting the right valve for their specific media. Knife valves are designed to handle thick, viscous fluids, but the risk of improper selection can lead to operational inefficiencies and increased maintenance costs. Buyers may experience frustration when a gate valve is mistakenly chosen for applications requiring the cutting action of a knife valve, leading to seal wear, leaks, and potential downtime. This challenge is exacerbated in regions like Africa and South America, where local suppliers may not provide adequate guidance on valve applications.

The Solution: To effectively address this problem, buyers should conduct a thorough assessment of their media characteristics before making a valve purchase. It is essential to gather detailed information about the viscosity, presence of solids, and flow rates of the media involved. When sourcing valves, prioritize suppliers who offer expert consultation services and detailed product specifications. Look for manufacturers that provide case studies or testimonials from similar industries, ensuring that they understand the unique challenges of your application. Consider investing in pilot testing with the selected valve type to gauge performance under real operational conditions. By doing so, buyers can confidently select knife valves for viscous applications, minimizing the risk of operational disruptions.

Scenario 2: Understanding Valve Actuation Requirements

The Problem: Buyers often encounter difficulties in understanding the actuation requirements of knife and gate valves, especially when integrating them into existing systems. A gate valve may require significant force to operate, leading to concerns about space and automation, while knife valves can be easier to actuate but may require specific actuators for optimal function. In regions with limited access to advanced automation technology, this can create additional complications for buyers trying to streamline their operations.

The Solution: To mitigate this pain point, buyers should engage with valve manufacturers who provide comprehensive information about actuation options. When evaluating valve types, consider the available space for installation and the force required for manual or automated actuation. For gate valves, assess the need for electric or pneumatic actuators that can be integrated into your system. For knife valves, verify if the actuator can handle the specific media and pressure conditions. Investing in modular actuators that can be easily adapted to different valve types can also enhance flexibility. Additionally, collaborating with local suppliers who understand the regional capabilities can provide insights into the most suitable actuation solutions.

Scenario 3: Addressing Maintenance and Longevity Concerns

The Problem: B2B buyers often face challenges related to the maintenance and longevity of knife and gate valves. Knife valves, while efficient for thick media, can suffer from seal wear and performance degradation over time, particularly in dry bulk applications. Conversely, gate valves may exhibit issues related to thermal expansion and operational force. Buyers in the Middle East and Europe are particularly concerned about minimizing downtime and maximizing the lifespan of their equipment due to the high costs associated with repairs and replacements.

The Solution: To address maintenance concerns, buyers should focus on selecting valves with durable materials that are resistant to wear and corrosion. When sourcing knife valves, prioritize those with robust packing systems designed for high-abrasion environments. Regular maintenance schedules should be established, including routine inspections and timely replacement of seals and packing materials to prevent leaks. For gate valves, consider investing in models with thermal expansion compensation features to mitigate issues caused by temperature fluctuations. Buyers should also seek training from manufacturers on proper maintenance practices and use predictive maintenance technologies that can monitor valve health in real-time, allowing for proactive interventions before failures occur. By prioritizing quality and maintenance, buyers can significantly extend the lifespan of their valves, ensuring efficient operations.

Strategic Material Selection Guide for knife valve vs gate valve

What Are the Key Materials for Knife Valves and Gate Valves?

When selecting knife valves and gate valves, the choice of materials is critical to ensure optimal performance, durability, and compliance with industry standards. Below are analyses of four common materials used in the construction of these valves, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. Carbon Steel

Key Properties:

Carbon steel is known for its high strength and durability, with a temperature rating up to 400°F (204°C) and pressure ratings that can reach 1500 psi (pounds per square inch). It offers moderate corrosion resistance when treated with protective coatings.

Pros & Cons:

The primary advantage of carbon steel is its cost-effectiveness and strength, making it suitable for high-pressure applications. However, it is prone to rust and corrosion, particularly in humid or corrosive environments, which may necessitate additional coatings or treatments.

Impact on Application:

Carbon steel is ideal for applications involving clean water, oil, and gas. However, it is less suitable for corrosive media or environments with high humidity.

Considerations for International Buyers:

Buyers from regions like Africa and South America should ensure compliance with ASTM standards for carbon steel valves. In the Middle East, where high temperatures are common, selecting a high-grade carbon steel with appropriate coatings is essential.

2. Stainless Steel

Key Properties:

Stainless steel offers excellent corrosion resistance, with temperature ratings exceeding 1000°F (537°C) and pressure ratings similar to carbon steel. Its composition includes chromium, which provides a protective oxide layer.

Pros & Cons:

The key advantage of stainless steel is its durability and resistance to corrosion, making it suitable for harsh environments. However, it is more expensive than carbon steel and may require specialized machining.

Impact on Application:

Stainless steel is commonly used in applications involving corrosive fluids, such as chemicals and wastewater. Its ability to withstand high temperatures makes it suitable for steam applications as well.

Considerations for International Buyers:

Compliance with international standards such as ASTM and DIN is crucial. Buyers in Europe and the Middle East often prefer stainless steel for its longevity and reliability in demanding applications.

3. PVC (Polyvinyl Chloride)

Key Properties:

PVC is lightweight and offers excellent chemical resistance, with temperature ratings up to 140°F (60°C) and pressure ratings around 150 psi. It is not suitable for high-temperature applications.

Pros & Cons:

PVC is cost-effective and easy to install, making it a popular choice for low-pressure applications. However, its lower temperature and pressure ratings limit its use in industrial settings.

Impact on Application:

PVC valves are ideal for handling water, sewage, and certain chemicals. They are not suitable for high-pressure or high-temperature applications.

Considerations for International Buyers:

Buyers in regions like South America should ensure that PVC valves meet local environmental regulations. Compliance with ASTM standards is also important for quality assurance.

4. Alloy Materials (e.g., Hastelloy, Monel)

Key Properties:

Alloy materials like Hastelloy and Monel offer superior corrosion resistance and can withstand extreme temperatures and pressures, often exceeding 1000°F (537°C) and 3000 psi.

Pros & Cons:

The main advantage is their exceptional durability and resistance to aggressive chemicals. However, they are significantly more expensive and may require specialized manufacturing processes.

Impact on Application:

These alloys are suitable for highly corrosive environments, such as chemical processing and petrochemical applications. Their robustness makes them ideal for critical applications where failure is not an option.

Considerations for International Buyers:

Compliance with international standards is essential, especially for buyers in Europe and the Middle East, where stringent regulations apply. The high cost may be a barrier for some buyers, necessitating a thorough cost-benefit analysis.

Summary Table

| Material | Typical Use Case for knife valve vs gate valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Oil and gas, clean water | Cost-effective and strong | Prone to rust and corrosion | Low |

| Stainless Steel | Chemicals, wastewater, steam applications | Excellent corrosion resistance | Higher cost and machining complexity | High |

| PVC | Water, sewage, low-pressure applications | Lightweight and easy to install | Limited temperature/pressure ratings | Low |

| Alloy Materials | Chemical processing, petrochemical applications | Exceptional durability and resistance | High cost and specialized manufacturing | High |

This strategic material selection guide provides B2B buyers with essential insights into the various materials used for knife and gate valves, helping them make informed decisions based on application needs, cost considerations, and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for knife valve vs gate valve

What Are the Main Stages in the Manufacturing Process of Knife and Gate Valves?

The manufacturing process for knife valves and gate valves encompasses several key stages, each critical for ensuring high-quality performance and durability. Understanding these stages is essential for B2B buyers looking to source reliable valves for their operations.

Material Preparation: What Materials Are Used?

The first step in the manufacturing process involves selecting the appropriate materials. Knife valves are typically made from stainless steel, carbon steel, or specialized alloys to withstand corrosive environments. Gate valves often utilize similar materials but may also include bronze and PVC for specific applications. The chosen material must meet industry standards for strength, corrosion resistance, and temperature tolerance.

Before manufacturing begins, the raw materials undergo rigorous inspection and testing to confirm they meet the required specifications. This ensures that the final product will perform reliably under the conditions it will face in the field.

How Are Knife and Gate Valves Formed?

Once the materials are prepared, the forming stage begins. This involves techniques such as casting, forging, and machining.

Casting is commonly used for both knife and gate valves, where molten metal is poured into molds to create the valve body. This method allows for complex shapes and is cost-effective for large production runs.

Forging is another technique, primarily used for high-performance applications. It involves shaping the metal using localized compressive forces, resulting in a stronger product.

Machining follows the initial forming process, where precise dimensions and surface finishes are achieved through processes such as turning, milling, and drilling. This is particularly important for the valve seat and sealing surfaces, which must fit tightly to prevent leaks.

What Does the Assembly Process Entail?

The assembly stage involves integrating various components, including the valve body, gate or blade, stem, and seals. During this phase, careful attention is paid to ensure that all parts fit together precisely.

For knife valves, the assembly includes the installation of the sharp-edged gate designed to cut through thick media. In contrast, gate valves feature a flat closure mechanism. Sealing elements are also installed to ensure leak-proof operation.

Additionally, some manufacturers may employ automated assembly techniques to enhance efficiency and reduce human error, which is crucial for maintaining consistent quality.

What Finishing Techniques Are Commonly Used?

The finishing stage is where the valves receive their final touches. This includes surface treatments such as painting, powder coating, or applying anti-corrosion coatings. These treatments not only improve the aesthetic appeal but also enhance the valve’s resistance to environmental factors.

Final inspections are conducted to ensure that the valves meet dimensional and performance specifications before they are packaged for shipment.

How Is Quality Assurance Implemented in Knife and Gate Valve Manufacturing?

Quality assurance (QA) is a critical component of the manufacturing process for knife and gate valves. It ensures that each valve produced meets the required performance and safety standards.

What International and Industry-Specific Standards Are Relevant?

B2B buyers should be aware of the various international and industry-specific standards that govern valve manufacturing. The most recognized standard is ISO 9001, which outlines the requirements for a quality management system. Compliance with ISO 9001 indicates that a manufacturer has established processes for ensuring quality at every stage of production.

Other relevant standards include:

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: The American Petroleum Institute sets standards specifically for valves used in the oil and gas industry. These standards ensure that valves can handle the pressures and conditions typical in these applications.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are established throughout the manufacturing process to ensure each valve meets the required specifications. These checkpoints typically include:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet the specified criteria.

- In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor the quality of the process and identify any deviations early.

- Final Quality Control (FQC): Once the valves are completed, they undergo thorough testing for functionality, pressure resistance, and leak tests before leaving the factory.

Common testing methods include hydrostatic tests, pneumatic tests, and non-destructive testing (NDT) methods such as ultrasonic testing and radiographic testing.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control measures implemented by their suppliers. Here are several effective strategies:

Supplier Audits: Conducting on-site audits can provide insights into the manufacturing processes and quality control systems in place. This also allows buyers to assess the overall capabilities of the supplier.

Requesting Quality Reports: Suppliers should be able to provide detailed quality assurance reports, including results from IQC, IPQC, and FQC. This documentation serves as proof of compliance with established standards.

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased evaluation of the supplier’s quality control practices. These agencies can conduct random checks and testing to ensure compliance with international standards.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential.

Cultural and Regulatory Differences: Different regions may have varying regulations regarding valve performance and safety. Buyers should be familiar with local standards and ensure their suppliers comply with them.

Logistics and Supply Chain Considerations: The complexity of international logistics can introduce additional risks. Ensuring that suppliers have robust quality control processes in place can mitigate these risks and ensure timely delivery of high-quality products.

Communication and Transparency: Establishing clear communication channels with suppliers can facilitate better understanding of quality control processes and expectations. Transparency in operations can lead to stronger partnerships and more reliable supply chains.

In conclusion, the manufacturing processes and quality assurance measures for knife and gate valves play a crucial role in ensuring product reliability and performance. B2B buyers must take the time to understand these processes, verify supplier capabilities, and ensure compliance with relevant standards to make informed purchasing decisions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘knife valve vs gate valve’

In the competitive landscape of industrial procurement, selecting the right valve—be it a knife valve or a gate valve—can significantly impact operational efficiency and cost management. This guide provides a structured checklist to assist B2B buyers in making informed decisions when sourcing these critical components.

Step 1: Define Your Technical Specifications

Before engaging suppliers, clearly outline the technical requirements for your application. Consider factors such as fluid type, viscosity, pressure, and temperature ranges. Different valves perform better under specific conditions; for instance, knife valves excel in handling viscous fluids and slurries, while gate valves are ideal for clean, non-corrosive media.

Step 2: Assess Application Suitability

Identify the specific applications for which you need the valves. Knife valves are typically used in industries like wastewater treatment and pulp and paper, where cutting through thick media is essential. Conversely, gate valves are suited for applications requiring a straight flow with minimal restrictions, such as in oil and gas or pharmaceutical sectors.

Step 3: Evaluate Potential Suppliers

Conduct a thorough vetting of potential suppliers to ensure reliability and quality. Request detailed company profiles, including their certifications, production capabilities, and industry experience. Look for reviews and references from similar industries or regions to gauge their performance and customer service.

Step 4: Verify Compliance with Industry Standards

Ensure that the valves meet relevant industry standards and certifications, such as ANSI for gate valves or TAPPI for knife valves. Compliance with these standards ensures safety, reliability, and compatibility with your operational requirements. Ask suppliers for documentation that confirms adherence to these standards.

Step 5: Compare Pricing and Cost-Effectiveness

Analyze pricing structures among various suppliers while considering the total cost of ownership. While knife valves may be more cost-effective upfront, evaluate long-term maintenance and operational costs. Factor in potential downtime or inefficiencies caused by subpar valve performance.

Step 6: Request Samples or Demonstrations

Whenever possible, request samples or demonstrations of the valves. This will allow you to assess their physical characteristics and operational performance firsthand. Pay attention to aspects like ease of actuation, sealing performance, and overall build quality, which can influence long-term reliability.

Step 7: Establish After-Sales Support and Warranty Terms

Finally, inquire about after-sales support and warranty terms. A reputable supplier should offer robust customer service, including technical support and maintenance services. Understanding warranty coverage will protect your investment and ensure you have recourse in case of defects or operational issues.

By following this checklist, B2B buyers can make informed decisions when procuring knife valves or gate valves, ensuring that their selection aligns with operational needs and industry standards.

Comprehensive Cost and Pricing Analysis for knife valve vs gate valve Sourcing

What Are the Key Cost Components for Knife Valves and Gate Valves?

When sourcing knife valves and gate valves, it is crucial to understand the various cost components that contribute to their overall pricing. These include:

Materials: The choice of materials significantly impacts the cost. Knife valves may use a combination of stainless steel and resilient materials for the blade, while gate valves typically consist of metal with specific coatings for enhanced durability. The quality of these materials will also influence the price, especially in applications involving corrosive substances.

Labor: Labor costs encompass the workforce required for manufacturing, assembly, and quality control. Given that knife valves often require more intricate machining due to their specialized design, labor costs can be higher compared to gate valves.

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and facility expenses. Given the specialized nature of knife valves, manufacturers may incur higher overheads, affecting pricing.

Tooling: The initial investment in tooling for both valve types can vary. Custom tooling for unique specifications in knife valves can be costly, while standard gate valve tooling may have lower upfront costs.

Quality Control (QC): Rigorous QC processes are essential to ensure product reliability. Knife valves, often employed in demanding environments, may require more extensive testing, adding to the overall cost.

Logistics: Transportation costs can vary based on the weight and dimensions of the valves. Knife valves generally weigh less, which can lead to lower shipping costs. However, international logistics also hinge on the chosen Incoterms, affecting the final price.

Margin: Manufacturers and suppliers typically apply a profit margin based on the complexity and demand for the valves. Knife valves may have a higher margin due to their specialized applications.

How Do Price Influencers Affect Knife Valve and Gate Valve Pricing?

Several factors influence the pricing of knife valves and gate valves, including:

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for bulk purchases. Understanding the MOQ can help buyers negotiate better pricing.

Specifications and Customization: Custom features can drive up costs. Buyers should assess whether they need specific adaptations or if standard models will suffice.

Materials and Quality Certifications: Higher quality materials and certifications (e.g., ISO, API) can increase prices. Buyers should weigh the benefits of these certifications against the potential cost savings.

Supplier Factors: Supplier reputation, reliability, and geographic location can impact pricing. Local suppliers may offer better shipping rates but could have higher material costs compared to international manufacturers.

Incoterms: Different shipping terms can alter the total landed cost. For instance, choosing Ex Works (EXW) might lead to lower initial costs, but buyers must factor in additional shipping and handling fees.

What Are Effective Buyer Tips for Sourcing Valves?

Negotiation Strategies: Engage suppliers in discussions about pricing based on volume. Highlighting potential long-term relationships can sometimes lead to favorable terms.

Focus on Cost-Efficiency: Evaluate the total cost of ownership (TCO), not just the upfront price. This includes maintenance, operational costs, and potential downtime, especially for knife valves that may require more frequent servicing.

Pricing Nuances for International Buyers: When sourcing from regions such as Africa, South America, the Middle East, and Europe, consider currency fluctuations and tariffs, which can impact final costs. Understanding local market conditions can also provide leverage in negotiations.

Assess Quality vs. Price: While lower-priced options may seem attractive, they can lead to higher long-term costs due to failures or inefficiencies. Always consider the balance between quality and pricing.

Disclaimer on Indicative Prices: Prices can vary widely based on market conditions, supplier negotiations, and specific project requirements. Always seek multiple quotes and validate against current market trends to ensure competitive pricing.

By understanding these cost structures, pricing influences, and effective sourcing strategies, international B2B buyers can make informed decisions when procuring knife valves and gate valves for their operations.

Alternatives Analysis: Comparing knife valve vs gate valve With Other Solutions

Introduction: Exploring Alternatives to Knife and Gate Valves

In the realm of industrial fluid control, selecting the right valve is crucial for ensuring operational efficiency and effectiveness. While knife valves and gate valves are popular choices for on/off flow applications, several alternative solutions exist that may better suit specific needs. Understanding these alternatives can help international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, make informed decisions tailored to their unique operational environments.

Comparison Table

| Comparison Aspect | Knife Valve Vs Gate Valve | Alternative 1: Butterfly Valve | Alternative 2: Ball Valve |

|---|---|---|---|

| Performance | Effective for viscous fluids; prone to wear in dry applications | Offers quick operation; not suitable for high-pressure applications | Provides tight sealing; versatile across various media |

| Cost | Generally cost-effective | Mid-range pricing | Higher initial cost but long-term savings due to durability |

| Ease of Implementation | Straightforward installation; may require specific alignment | Simple installation; requires less space | Easy to install; minimal maintenance needed |

| Maintenance | Requires regular checks due to potential seal wear | Low maintenance; occasional cleaning needed | Very low maintenance; rarely requires servicing |

| Best Use Case | Ideal for slurries and wastewater | Suitable for large flow rates and quick shut-off | Excellent for chemical and gas applications requiring tight seals |

Detailed Breakdown of Alternatives

Butterfly Valve

Butterfly valves are an excellent alternative, particularly in applications requiring quick operation and minimal space. They consist of a disc that rotates to open or close the flow. Their design allows for efficient flow control with low pressure drop, making them ideal for large pipelines. However, they may not perform well under high-pressure conditions and can be less effective when handling viscous fluids compared to knife valves. Buyers should consider butterfly valves for applications in water treatment, HVAC, and large-scale fluid transport.

Ball Valve

Ball valves are known for their robust sealing capabilities and are versatile across various applications, including chemical processing, oil and gas, and water systems. They feature a spherical disc that allows for smooth flow control and tight sealing, making them suitable for both low and high-pressure environments. While the initial investment may be higher than that of knife or gate valves, their long lifespan and minimal maintenance requirements can lead to cost savings in the long run. B2B buyers should consider ball valves when dealing with critical applications where leakage prevention is paramount.

Conclusion: How to Choose the Right Valve Solution for Your Needs

When selecting between knife valves, gate valves, and their alternatives, B2B buyers must evaluate their specific application requirements, including fluid type, pressure conditions, and installation constraints. Each valve type offers distinct advantages and potential drawbacks, making it essential to align the choice with operational goals. By carefully analyzing the performance, cost, and maintenance aspects of each option, buyers can ensure they invest in the most suitable solution for their unique industrial applications.

Essential Technical Properties and Trade Terminology for knife valve vs gate valve

What Are the Key Technical Properties of Knife Valves and Gate Valves?

Understanding the technical properties of knife valves and gate valves is essential for making informed purchasing decisions. Below are critical specifications that B2B buyers should consider:

1. Material Grade

Both knife valves and gate valves can be manufactured from various materials, including stainless steel, carbon steel, and ductile iron. The choice of material affects the valve’s durability, corrosion resistance, and suitability for specific applications. For instance, stainless steel valves are ideal for corrosive environments, while carbon steel may be more cost-effective for less demanding conditions. Selecting the right material is crucial for ensuring long-term performance and reducing maintenance costs.

2. Pressure Rating

Pressure rating is a critical specification that indicates the maximum pressure a valve can handle without failing. Common pressure ratings for these valves range from ANSI Class 150 to Class 300 and above. Understanding the required pressure rating for your application helps prevent valve failure and ensures the safety of the operation. Buyers should match the valve’s pressure rating with the operational conditions of their systems.

3. End Connections

Knife and gate valves come with various end connections, such as flanged, threaded, or welded. The type of connection impacts installation and compatibility with existing piping systems. Flanged valves are often easier to install and remove, while threaded valves may be more compact. Buyers should assess their piping layout and choose a valve that fits seamlessly into their infrastructure.

4. Flow Direction

Knife valves are typically uni-directional, while gate valves can be bi-directional. This distinction is important for applications where the flow direction may change. Selecting the appropriate valve type based on flow direction ensures optimal performance and minimizes the risk of leaks or malfunctions.

5. Size and Dimensions

The dimensions of the valve, including its diameter and overall length, are vital for ensuring a proper fit in the pipeline. Larger valves may be needed for high-flow applications, while smaller ones are suitable for low-flow conditions. Buyers should consider both the physical space available and the flow requirements of their systems when choosing valve sizes.

6. Operating Mechanism

Knife valves often feature a blade mechanism that cuts through media, while gate valves use a flat closure that slides open and closed. Understanding the operating mechanism is essential for assessing the valve’s suitability for specific applications, such as those involving viscous fluids or solids.

What Are Common Trade Terms Related to Knife and Gate Valves?

Familiarizing yourself with industry jargon can enhance your purchasing experience and communication with suppliers. Here are essential terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of valves, understanding OEM specifications ensures that buyers source high-quality products that meet their application requirements.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell. This term is crucial for B2B buyers as it impacts inventory management and overall costs. Understanding MOQ can help buyers negotiate better terms and manage budgets effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. This process allows buyers to compare options and make informed decisions. Including detailed specifications in an RFQ can lead to more accurate and competitive quotes.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade. They clarify responsibilities between buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms helps buyers manage logistics and avoid unexpected costs.

5. API (American Petroleum Institute) Standards

API standards are specifications set by the American Petroleum Institute for the oil and natural gas industry. Valves that comply with API standards ensure reliability and safety in demanding applications. Buyers should verify that valves meet relevant API standards for their specific use cases.

6. TAPPI Standards

TAPPI standards are guidelines specific to the pulp and paper industry. These standards ensure that valves used in these applications can handle the unique challenges presented by pulp and slurry. Familiarity with TAPPI standards can assist buyers in selecting the right valve for their processes.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when selecting between knife valves and gate valves, ensuring that they choose the best solutions for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the knife valve vs gate valve Sector

What Are the Current Market Dynamics for Knife Valves and Gate Valves?

The global market for knife valves and gate valves is experiencing significant growth, driven by various factors including industrial expansion, infrastructural development, and the increasing demand for efficient fluid control solutions across diverse sectors. Key industries such as oil and gas, wastewater treatment, and manufacturing are the primary consumers of these valves. In regions like Africa, South America, the Middle East, and Europe, there is a growing emphasis on the modernization of infrastructure, which boosts the demand for reliable valve systems.

Emerging trends indicate a shift towards automation and smart technologies in valve operation. B2B buyers are increasingly seeking valves that integrate with IoT solutions for enhanced monitoring and control. This trend is particularly pronounced in the oil and gas sector, where real-time data analytics can optimize performance and reduce downtime. Additionally, as supply chains become more globalized, international B2B buyers are looking for suppliers that can provide consistent quality and reliability, regardless of location.

The market is also seeing a rise in custom solutions to meet specific application needs, especially in industries dealing with viscous fluids and slurries. This customization is crucial for buyers in regions with unique operational challenges, such as extreme temperatures or corrosive environments. Moreover, competitive pricing is a significant factor for buyers in emerging markets like Brazil and Saudi Arabia, where cost-effective solutions are essential for project viability.

How Does Sustainability Impact the Sourcing of Knife Valves and Gate Valves?

Sustainability is becoming a critical consideration for B2B buyers in the valve sector, influencing procurement decisions significantly. The environmental impact of manufacturing processes and the lifecycle of the products are under scrutiny. Buyers are increasingly favoring suppliers that adopt sustainable practices, such as reducing waste and utilizing eco-friendly materials.

Ethical sourcing has gained traction, prompting companies to evaluate their supply chains for transparency and responsibility. This includes ensuring that raw materials are sourced from suppliers that adhere to environmental regulations and labor standards. Certifications such as ISO 14001 for environmental management and materials that are recyclable or biodegradable are becoming essential benchmarks for buyers.

In the context of knife valves and gate valves, manufacturers are responding to these demands by developing products that minimize environmental impact. For example, valves that are designed for longer service life reduce the frequency of replacements, thus conserving resources. Additionally, innovations in materials science are leading to the creation of valves that perform better while being more environmentally friendly, such as using corrosion-resistant alloys that extend the lifespan of valves in harsh conditions.

What Is the Historical Context of Knife Valves and Gate Valves in B2B Markets?

The evolution of knife valves and gate valves can be traced back to the early 20th century when industrialization began to accelerate, necessitating more efficient fluid control systems. Knife valves were initially developed for the pulp and paper industry, designed to handle thick and viscous materials. Their unique blade mechanism allowed them to effectively cut through solid media, making them indispensable in applications involving slurries and waste products.

Gate valves, on the other hand, emerged as a simpler solution for on-off flow control. Their design, which allows for minimal pressure drop when fully open, made them suitable for a wide range of applications, particularly in oil and gas and water treatment sectors. Over the decades, both types of valves have undergone significant technological advancements, including the incorporation of better sealing technologies and materials that enhance durability and performance.

Today, as industries continue to evolve, knife and gate valves are integral components in modern fluid management systems, with ongoing innovations aimed at improving efficiency, sustainability, and adaptability to complex industrial processes.

Frequently Asked Questions (FAQs) for B2B Buyers of knife valve vs gate valve

How do I choose between a knife valve and a gate valve for my application?

Choosing between a knife valve and a gate valve depends on the specific needs of your application. Knife valves are ideal for handling viscous fluids, slurries, and applications where solids are present, as their sharp edges can cut through thick media. In contrast, gate valves are better suited for clean fluids and applications requiring minimal pressure drop during flow. Evaluate the media type, required flow characteristics, and installation space to make an informed decision.What is the best valve type for handling wastewater?

For wastewater management, knife valves are often the best choice due to their ability to handle viscous fluids and solids that may clog other types of valves. Their design allows them to cut through sludge and maintain a reliable shut-off. Gate valves can also be used, but they are more suitable for clean water applications. Always assess the specific conditions of your wastewater to ensure optimal valve performance.What are the key factors to consider when sourcing valves internationally?

When sourcing valves internationally, consider factors such as quality certifications (like API or ANSI), supplier reliability, shipping logistics, and customs regulations. Evaluate the manufacturer’s production capabilities, compliance with international standards, and past performance with similar products. Additionally, ensure that they can meet your specific requirements regarding materials, dimensions, and customization options to avoid delays and additional costs.How can I vet suppliers for knife and gate valves?

Vetting suppliers involves researching their credentials, industry reputation, and customer reviews. Request references from previous clients and check for certifications that indicate adherence to international standards. It’s also advisable to conduct factory visits or audits if possible, to assess production processes and quality control measures. Engaging with local distributors who are familiar with the market can provide additional insights into reliable suppliers.What are the typical minimum order quantities (MOQs) for knife and gate valves?

Minimum order quantities (MOQs) for knife and gate valves can vary significantly by supplier and product type. Generally, MOQs may range from 10 to 100 units, depending on the manufacturing process and material costs. When negotiating with suppliers, inquire about flexibility in MOQs, especially if you are testing a new product line or entering a new market. Some suppliers may offer lower MOQs for first-time orders or for specific models.What payment terms should I expect when sourcing valves from international suppliers?

Payment terms can vary widely among suppliers, but typical arrangements include payment in advance, partial payment with the order, or payment upon delivery. For large orders, negotiating favorable terms, such as net 30 or net 60 days, can help manage cash flow. Ensure that payment methods are secure and consider using letters of credit for higher-value transactions to mitigate risks associated with international trade.How do I ensure quality assurance for valves sourced from abroad?

To ensure quality assurance, request detailed product specifications and compliance certifications from your supplier. Implement a quality control process that includes pre-shipment inspections or third-party audits to verify product integrity. Establish clear communication channels for addressing any quality issues promptly. Additionally, consider sourcing samples before placing large orders to assess the valve’s performance and suitability for your application.What are the logistics considerations when importing valves?

Logistics considerations include shipping methods, lead times, and customs clearance processes. Choose a reliable freight forwarder familiar with importing industrial equipment to streamline the process. Factor in shipping costs, potential tariffs, and delivery timelines to your final destination. Ensure that all documentation, such as bills of lading and customs declarations, is accurate and complete to avoid delays or additional charges during transit.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Knife Valve Vs Gate Valve Manufacturers & Suppliers List

1. Crane Engineering – Gate Valves and Knife Gate Valves

Domain: blog.craneengineering.net

Registered: 2003 (22 years)

Introduction: Gate Valves and Knife Gate Valves are primarily used for on/off service and are not recommended for flow regulation due to potential wear from vibration. Both types are designed to open and close slowly to prevent water hammer. They are suitable for applications involving slurries, heavy oils, non-flammable viscous fluids, wastewater, and clean water. The key differences include:

1. Knife gate va…

2. Dombor – Knife Valves

Domain: dombor.com

Registered: 2021 (4 years)

Introduction: Knife Valves: Designed for on and off service, primarily in the pulp and paper industry. Features a sharp edge to cut through viscous fluids and prevent flow shut-off. Advantages include easy actuation, lightweight, and affordability. Disadvantages include low-pressure limitations, less suitability for cleanliness, and potential downtime due to seal abrasion. Typical applications include heavy oil…

3. Vortex Global – Knife Gate Valve

Domain: vortexglobal.com

Registered: 2011 (14 years)

Introduction: Knife Gate Valve: Designed to cut through clogging of heavy liquids; originally for pulp and paper industry; features a sharp, beveled edge; easy to actuate; low-pressure limitations; not suitable for dry bulk applications; seals can become abraded, leading to leaks; heavy metal construction makes maintenance cumbersome.

Slide Gate Valve: Specifically engineered for dry bulk powders, pellets, an…

4. BM Engineering – Knife Gate Valves

Domain: bmengineering.co.uk

Registered: 2009 (16 years)

Introduction: Knife Gate Valves: Used for shut-off operations, particularly in applications with solids in the media. They feature a blade or gate that cuts through the media, making them suitable for non-flammable viscous fluids, wastewater, heavy oils, and slurries. Available in uni-directional and bi-directional options, with lugged or wafer body designs and no flanges. Seats can be metal or resilient types….

5. AV Kvalves – Knife Gate Valves

Domain: avkvalves.eu

Introduction: Knife gate valves are designed for on-off and isolation services in systems with high content of suspended solids. They are particularly effective for handling slurry, viscous, corrosive, and abrasive media. Key features include minimized pressure drop in fully open position, ease of actuation, relatively low weight, and cost-effectiveness. Knife gate valves are suitable for harsh environments and…

6. Anything Flows – Knife Gate Valve

Domain: anythingflows.com

Registered: 2020 (5 years)

Introduction: Knife Gate Valve: Used in wastewater applications, designed to slice through solid materials, suitable for harsh environments, should only be used in fully open or closed applications, built to American National Standards Institute standards, compact design, bi-directional. Slide Gate Valve: Used for dry bulk materials like powders and granulates, designed for regulating dry materials, built accor…

7. Valve Types – Usage Guide

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Various types of valves mentioned include ball, gate, knife, globe, butterfly, and needle valves. The inquiry seeks information on when to use specific valves for liquid flow (e.g., water pumping applications) and gas flow, as well as situations where certain valves should not be used.

8. CareWater Solutions – Knife Gate Valves

Domain: carewater.solutions

Introduction: Knife gate valves and gate valves are primarily designed for on-off services, not for regulating flow. Knife gate valves have a sharpened disc for cutting through viscous media, a short face-to-face length, and are lightweight compared to gate valves. They are typically used in wastewater treatment, chemical plants, and mining, while gate valves are found in drinking water systems. Knife gate valv…

Strategic Sourcing Conclusion and Outlook for knife valve vs gate valve

What Are the Key Takeaways for Choosing Between Knife Valves and Gate Valves?

In the competitive landscape of industrial applications, selecting the right valve is crucial for operational efficiency and cost-effectiveness. Knife valves excel in handling viscous fluids, slurries, and applications involving solids, making them ideal for industries such as wastewater treatment and heavy oil processing. Conversely, gate valves are preferable for clean, non-corrosive fluids, serving sectors like pharmaceuticals and general manufacturing where minimal pressure drop is essential.

Strategic sourcing plays a pivotal role in ensuring that international buyers from regions like Africa, South America, the Middle East, and Europe secure the most suitable valves for their specific needs. By understanding the unique characteristics of each valve type, businesses can enhance their supply chain resilience, mitigate risks, and optimize procurement costs.

How Can You Enhance Your Procurement Strategy Moving Forward?

As you move forward, consider leveraging local and global suppliers to access a diverse range of valve options that meet industry standards and regulations. Engage in thorough supplier evaluations and foster relationships that can lead to better pricing and service agreements. With the right strategic sourcing approach, you can ensure your operations are equipped with the most effective valve solutions, driving long-term success and sustainability in your projects.