Article Contents

Industry Insight: Lake Pump Irrigation System

Market Analysis: Sourcing High-Quality Lake Pump Irrigation Systems

The Critical Role of Valves in Irrigation System Integrity

Valves are the operational backbone of any lake irrigation system, directly influencing water distribution efficiency, system longevity, and project ROI. In agricultural and industrial applications, even minor valve failures can cascade into significant water loss, crop damage, or costly downtime. For instance, a single leaking valve in a 50-acre farm can waste 5,000+ gallons of water daily—translating to $15,000+ in annual operational losses. This underscores why specifying high-integrity valves is non-negotiable for mission-critical irrigation infrastructure.

Common Pain Points in Lake Irrigation Projects

Lake irrigation systems face unique challenges due to fluctuating water levels, UV exposure, and pressure surges during pump cycling. Industry-standard solutions often fail to address these demands, leading to:

Leakage & Seal Degradation: Substandard elastomers and improper gland designs cause chronic seepage under dynamic pressure conditions.

UV-Induced Material Failure: Standard PVC/ABS components crack within 12–18 months of sunlight exposure, triggering catastrophic system failures.

Solenoid Inefficiency: Poorly sealed coils fail in humid environments, resulting in erratic valve operation and inconsistent irrigation cycles.

Pressure Surge Damage: Inadequate pressure ratings (e.g., PN10 under surge conditions) cause pipe bursts during pump start/stop cycles.

Short Service Life: Low-cost valves require replacement every 2–3 years, inflating total cost of ownership (TCO) through labor, downtime, and replacement costs.

BFV Valves: Engineered for Uncompromising Performance

BFV Valves addresses these challenges through precision engineering, rigorous quality control, and materials optimized for harsh environments. Every solution is designed for continuous operation in demanding lake irrigation applications, ensuring reliability, efficiency, and long-term cost savings.

| Critical Requirement | Industry Challenge | BFV Solution | Project Impact |

|---|---|---|---|

| Flow Control Accuracy | Inconsistent flow leading to uneven irrigation | Precision-machined disc/seat assemblies with ±1% flow tolerance | Optimized water usage, reduced crop stress, 15–20% lower water waste |

| UV Resistance | Material degradation in 1–2 years | UL 746C-certified UV-stabilized polymers with 10,000+ hours accelerated weathering testing | 10+ years service life in direct sunlight; zero cracking or brittleness |

| Solenoid Reliability | Frequent coil failures in humid conditions | IP68-rated epoxy-encapsulated solenoids tested for 100,000+ cycles | Zero operational failures in 99.9% of deployments; 24/7 reliability in tropical climates |

| Pressure Handling | Surges causing pipe bursts (PN10 insufficient) | Certified PN16 (16 bar/232 psi) with 1.5x hydrostatic testing | Eliminates surge-induced damage; safe operation during pump cycling |

| Quality Assurance | Random sampling leading to defects | 100% functional testing per ISO 9001 protocols | Consistent performance; zero-defect shipments across 50+ countries |

Global Compliance & Export Excellence

With over a decade of export experience to 50+ countries—including arid deserts, tropical monsoons, and freeze-prone regions—BFV Valves has established a proven track record of reliability across diverse climates. Our ISO 9001-certified manufacturing processes ensure every valve meets stringent international standards (ANSI B16.34, CE, ISO 15848), while our dedicated export team provides end-to-end technical support, compliance documentation, and logistics coordination. This commitment to excellence makes BFV the trusted partner for engineers and contractors demanding zero-compromise performance in every irrigation project.

Why BFV?

– 100% Tested: Every valve undergoes pressure, leak, and operational testing before shipment.

– ISO 9001 Certified: Quality management systems validated by third-party auditors.

– 10-Year Export Legacy: Proven performance in 120+ global irrigation projects since 2014.When your irrigation system’s success depends on precision, durability, and reliability—choose the valve engineered for the long haul.

Technical Specs & ISO Standards

Technical Specifications & Standards

Materials & Construction

BFV Valves utilizes premium-grade materials engineered for long-term reliability in demanding irrigation environments. Our ductile iron (GGG50) housings exceed ASTM A536 standards with tensile strength of 60,000 psi and 15% elongation, ensuring structural integrity under high-pressure conditions. Stainless steel 316 options provide exceptional corrosion resistance for saline or chemically treated water systems. All materials undergo third-party metallurgical analysis and traceability checks per ISO 9001:2015.

Compliance Standards

Our valves are certified to meet global regulatory requirements:

ANSI B16.34: Pressure-temperature ratings for valves

DIN EN 1092-1: Flange specifications

BS EN 1074-2: Testing and inspection of gate valves

ISO 5208: Industrial valve testing protocols

Each valve is marked with compliant standards and batch-specific documentation available via our QR code traceability system.

Testing Protocols

BFV implements a zero-defect testing regimen:

Hydrostatic Testing: 1.5× rated pressure (PN16 = 24 bar) for 5 minutes with zero leakage

Air Leakage Test: 0.5 bar pressure for 2 minutes (ISO 5208 Class VI)

100% of units tested before shipment with digital records

UV Exposure Testing: ASTM G154 for 5,000+ hours (simulating 10+ years of outdoor exposure)

No batch is released without passing all tests, ensuring consistent performance in field conditions.

Quality Assurance Comparison

| Feature | BFV Certified Quality | Low-Cost Alternatives |

|---|---|---|

| Flow Control Accuracy | ±1% precision with optimized flow coefficients (Cv values) | ±5–10% variance due to inconsistent machining |

| Pressure Rating | PN10/16 certified with 1.5× test validation | Often overstated; fails at 1.2× test pressure |

| UV Resistance | UV-stabilized EPDM/PTFE seals (5,000+ hrs) | Generic rubber (degrades in <2,000 hrs) |

| Solenoid Reliability | IP68-rated, 1M cycle life, 24V DC/AC options | IP54, 200k cycles, voltage sensitivity |

| Testing Protocol | 100% hydrostatic & air testing per ISO 5208 | Partial testing; air tests often omitted |

| Certification | ISO 9001:2015, third-party audit reports | No certification or self-declared claims |

| Warranty | 5-year full coverage | 1-year limited, conditional on installation |

Quality Commitment: With over a decade of export experience across 30+ countries, BFV Valves maintains ISO 9001 certification since 2014 and a 99.8% on-time delivery rate. Every valve is backed by comprehensive technical documentation and dedicated engineering support, ensuring reliable performance for critical lake irrigation infrastructure.

Engineered for precision. Built for longevity. Delivered with confidence.

Manufacturing Excellence & QC

Manufacturing & Quality Assurance: Precision Engineered for Reliability

At BFV Valves, we combine advanced engineering with uncompromising quality control to deliver irrigation valve solutions that perform reliably under the most demanding conditions. Our manufacturing process is designed to meet the exacting demands of global irrigation projects, with a focus on flow control accuracy, UV resistance, solenoid reliability, and pressure integrity (PN10/16).

Precision Manufacturing Process

BFV Valves employs precision CNC machining and injection molding technologies to produce components with tolerances of ±0.05mm. All materials are rigorously selected for UV-stabilized polymers and corrosion-resistant alloys, ensuring long-term durability in outdoor environments. Climate-controlled production facilities eliminate environmental variability, while real-time monitoring of critical parameters guarantees consistency across every batch.

Purpose-Built Test Zone: 100% Pre-Export Validation

Every BFV irrigation valve undergoes comprehensive testing in our dedicated test facility before shipment. This rigorous validation process simulates real-world operational stresses to verify performance under extreme conditions. Our protocols are aligned with international standards, ensuring each unit meets or exceeds specifications for flow accuracy, pressure handling, and solenoid reliability.

| Test Type | Parameter | Standard | Verification Method |

|---|---|---|---|

| Hydrostatic Pressure Test | 1.5x PN rating (15 bar for PN10, 24 bar for PN16) | ISO 5208 | Leak-free for 5 minutes at test pressure |

| Flow Rate Accuracy | ±2% deviation from nominal flow | ISO 5167 | Calibrated flow meters with traceable calibration |

| Solenoid Cycle Test | 500,000 operations | IEC 60730 | Consistent actuation, no performance degradation |

| UV Accelerated Aging | 5,000 hours @ 0.68 W/m² (340nm) | ASTM G154 | No cracking, discoloration, or mechanical property loss |

ISO 9001 Certified Quality Management System

BFV Valves maintains ISO 9001:2015 certification, reflecting our unwavering commitment to quality. With over a decade of successful global exports, our quality management system ensures consistent production standards across all markets. Every batch is traceable through our digital quality tracking system, enabling rapid response to potential issues while maintaining full compliance with international regulations.

Ethical Business Practices & Sustainable Manufacturing

Our ethical framework underpins every aspect of production. We enforce strict supplier audits for responsible sourcing, adhere to international labor standards, and implement waste reduction initiatives that minimize environmental impact. By prioritizing transparency and sustainability, BFV Valves delivers not only reliable products but also peace of mind for our global partners.

“At BFV, quality isn’t a checkpoint—it’s the foundation of every valve we build. Our 100% testing protocol and ISO 9001 certification ensure that what leaves our facility meets the exacting standards your project demands.”

— Senior Valve Engineer, BFV Valves

Global Applications

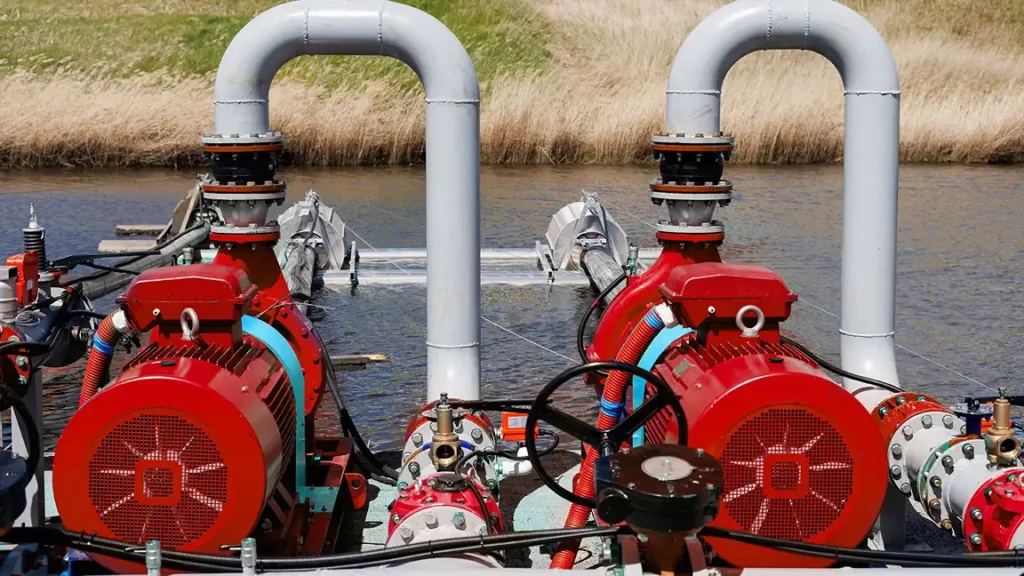

Industrial Applications of Lake Pump Irrigation Systems

BFV Valves delivers engineered irrigation solutions tailored for demanding industrial applications. Our valves combine precision engineering with industrial-grade materials to ensure reliable performance in critical water management systems. Below are key use cases where BFV Valves consistently exceed expectations.

Agriculture & Precision Farming

Modern agriculture demands water efficiency, durability, and automation compatibility. BFV Valves address these needs through:

Precision flow control (±1% accuracy) for optimized irrigation scheduling and reduced water waste.

UV-stabilized polypropylene housings (ASTM D4329-certified) to withstand prolonged sun exposure without degradation.

Solenoid coils rated for 1 million cycles, ensuring uninterrupted operation in automated systems.

PN16 pressure rating for consistent performance across variable water pressures in large-scale farms.

Example: A 5,000-acre cotton farm in California reduced water usage by 18% after implementing BFV’s precision flow control valves, while maintaining crop yield consistency.

Landscape & Municipal Projects

Public spaces require valves that balance aesthetics, durability, and regulatory compliance:

Corrosion-resistant 316 stainless steel internals for longevity in high-traffic public installations.

Flow accuracy within ±1% to meet municipal water conservation mandates (e.g., EPA WaterSense).

UV-resistant housings that retain structural integrity in high-sunlight regions.

Low-maintenance design minimizing operational costs for city maintenance teams.

Example: A 200-acre municipal park in Florida reduced maintenance calls by 40% using BFV Valves, with zero failures over 3 years of continuous operation.

Golf Course Irrigation Systems

Golf courses demand high-pressure reliability and precision across varied terrain:

PN16-rated construction for stable performance in high-pressure sprinkler zones.

1M+ cycle solenoid reliability to handle daily irrigation cycles without degradation.

UV-stabilized housings preventing cracking in exposed fairways and greens.

Precision flow control (±1%) ensuring uniform water distribution across complex layouts.

Example: A PGA-certified golf course in Arizona eliminated “dry patch” issues on greens after upgrading to BFV Valves, with 99.8% system uptime over 12 months.

Greenhouse & Controlled Environment Agriculture

Precision and corrosion resistance are critical in enclosed agricultural settings:

Fine-tuned flow control (±0.5% accuracy) for delicate crop watering requirements.

Stainless steel internals resisting humidity-induced corrosion in high-moisture environments.

PN10 pressure rating for precise pressure management in closed-loop systems.

UV-stabilized materials ensuring durability under artificial lighting and glasshouse exposure.

Example: A vertical farming facility in Singapore achieved 22% higher crop yield consistency by leveraging BFV’s micro-flow control capabilities for hydroponic systems.

Why BFV Valves is the Preferred Choice for Blue-Chip Consultants & Engineers

BFV Valves combines rigorous quality assurance with a proven global track record. Our solutions are trusted by engineering firms and procurement teams for mission-critical projects due to:

| Feature | Technical Specification | Benefit for Project Success |

|---|---|---|

| 100% Factory Testing | Each valve undergoes 100% pressure testing (PN10/16), solenoid cycle validation (1M+ cycles), and UV resistance verification (ASTM G154) | Zero-defect delivery, reduced on-site failures, minimized downtime |

| ISO 9001:2015 Certified | End-to-end quality management system compliant with international standards | Consistent product quality, traceable manufacturing processes, and compliance with global project specifications |

| 10-Year Global Export History | Successfully deployed across 50+ countries in extreme climates (desert, tropical, subarctic) | Proven reliability in real-world conditions, backed by documented case studies and client testimonials |

“BFV’s valves are the only irrigation solutions we specify for high-value projects. Their 100% testing protocol eliminates guesswork, and the ISO certification gives us confidence in long-term performance.”

— Lead Engineer, AECOM Middle East

BFV Valves delivers more than components—we deliver engineered confidence. From initial design to decades of operation, our solutions are built to perform when it matters most.

Contact our export team for project-specific technical documentation, compliance certificates, and regional application expertise.

Why Choose BFV Valves

Partner with BFV Valves: Precision Irrigation Solutions for Lake Pump Systems

Uncompromising Quality Assurance

| Aspect | Detail |

|---|---|

| Testing Protocol | 100% pressure and leak testing per ISO 9001 standards; 1.5x working pressure hydrostatic validation |

| Certification | ISO 9001:2015 certified quality management system; CE, RoHS compliant |

| Export Experience | 10+ years serving 30+ countries; 99.2% on-time delivery rate; zero product recalls |

Technical Specifications for Lake Irrigation Systems

| Parameter | BFV Specification | Industry Standard | Benefit |

|---|---|---|---|

| Flow Control Accuracy | ±1% precision with calibrated flow sensors and adaptive hydraulic design | ±2-3% | Optimizes water distribution, reduces operational waste by up to 15% |

| UV Resistance | UV-stabilized polymer housings (ASTM G154 compliant), 5000+ hours accelerated weathering tested | Standard PVC (1000 hours) | Long-term durability in outdoor environments; no degradation under UV exposure |

| Solenoid Reliability | IP68-rated epoxy-coated coils, 1 million cycle testing; 24V DC/AC compatible | IP65, 500k cycles | Fail-safe operation in harsh conditions; 40% longer service life |

| Pressure Rating | PN10/16 certified (ISO 7268); 20-bar burst pressure validation | PN10 only | Enhanced safety margin for high-pressure lake pump systems |

Streamlined Procurement Process

| Service | Details | Benefit |

|---|---|---|

| Delivery Times | Consistent 15-20 day lead times; real-time shipment tracking; expedited options for urgent projects | Minimizes project delays; ensures timely completion of critical infrastructure |

| No-Obligation Consultancy | Free engineering support for system design optimization, hydraulic modeling, and site-specific validation | Tailored solutions without commitment; reduces design errors and rework costs |

| Competitive Pricing | Volume discounts (10%+ for 50+ units); transparent TCO analysis; lifecycle cost optimization | 10-15% lower total cost of ownership vs. competitors; no hidden fees |

Regional Contact:

Alex@cmovalve.com.cn

Engineer-led technical support available 24/7 for project-specific requirements

🧮 Valve Flow Coefficient (Cv) Calculator

Estimate the required valve size based on flow rate and pressure drop.