Article Contents

Industry Insight: Master Valve Irrigation Diagram

Market Analysis: Sourcing High-Quality Master Valves for Irrigation Systems

Critical Role of Master Valves in Modern Irrigation Systems

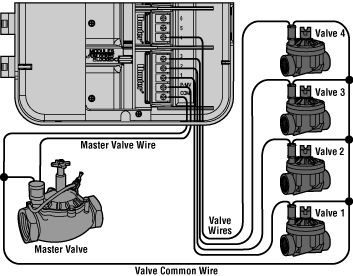

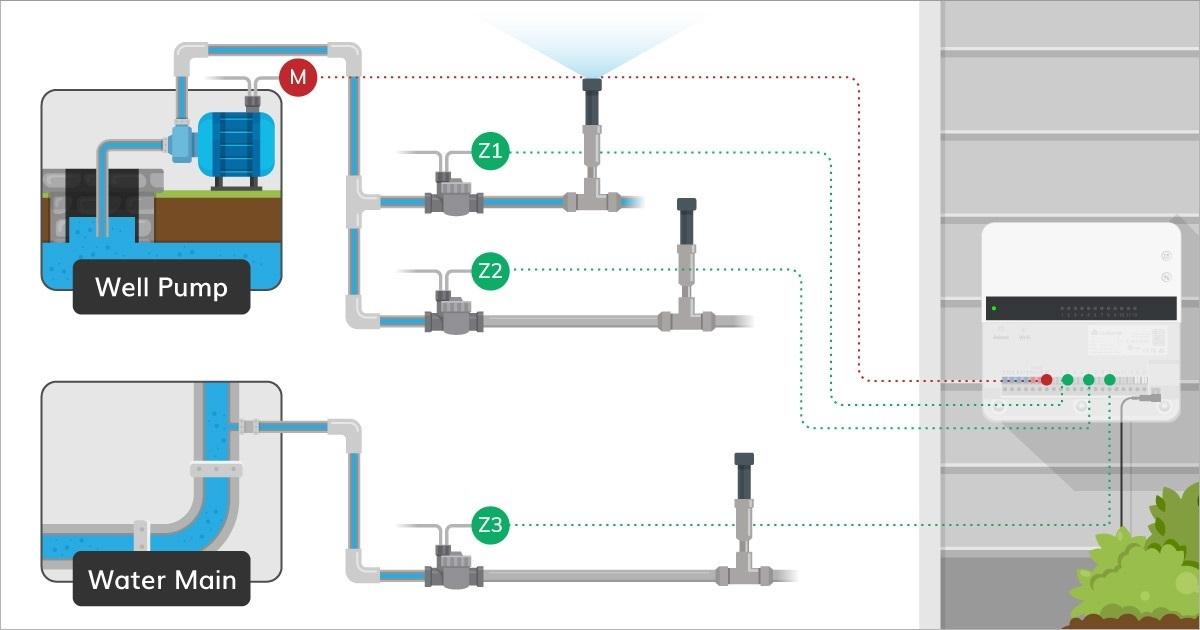

Master valves serve as the primary control point in irrigation systems, acting as the “normally closed” valve installed at the supply point of the main line (per Hunter Industries standards). They remain sealed until activated by the controller, preventing uncontrolled water flow during non-operational periods. In agricultural and industrial applications, their performance directly impacts system integrity, water conservation, and long-term operational costs. A single faulty master valve can cause significant water loss, infrastructure damage, and costly downtime—making material quality, pressure handling, and solenoid reliability non-negotiable criteria for project success.

Common Pain Points in Irrigation Valve Selection

Despite their critical role, many irrigation systems suffer from recurring issues due to substandard valve components:

Chronic Leakage: Poor diaphragm materials (e.g., low-grade rubber) degrade under UV exposure and chemical exposure, leading to seal failures and water waste.

Premature Solenoid Failure: Inconsistent solenoid activation due to inadequate coil design or subpar internal components causes erratic system behavior.

Pressure Rating Non-Compliance: Valves not certified for PN10/PN16 pressures risk catastrophic failure in high-pressure municipal or large-scale agricultural systems.

Installation Incompatibility: Non-standardized body designs and lack of modular components complicate integration with existing infrastructure, increasing labor costs and project delays.

BFV Valves’ Engineering Excellence: Solving Industry Challenges

BFV Valves addresses these challenges through precision engineering and rigorous quality control. Our master valves are designed to meet the most demanding irrigation requirements while ensuring long-term reliability.

Key Quality Assurance Metrics

| Quality Assurance Feature | Implementation at BFV Valves |

|---|---|

| 100% Testing Protocol | Every valve undergoes 100% pressure testing (PN10/PN16), flow calibration, and solenoid activation checks prior to shipment. |

| ISO 9001:2015 Certification | End-to-end quality management system with documented procedures for raw material sourcing, manufacturing, and final inspection. |

| 10-Year Global Export History | Proven reliability across 30+ countries, with installations in extreme climates from arid deserts to humid tropical regions. |

Technical Differentiators:

UV-Resistant EPDM Diaphragms: Engineered for chlorine and chemical resistance (per Rain Bird standards), with 500+ hours of UV exposure testing to prevent degradation.

Cast Iron Body with Removable Seat: Meets Griswold Controls specifications for durability, allowing easy maintenance without full system replacement.

Precision Solenoid Design: Fail-safe mechanism ensures consistent activation even in low-pressure conditions, eliminating water distribution inconsistencies.

Optimized Flow Control: No minimum flow requirement for precise operation across all operational scenarios, reducing water waste and improving system efficiency.

Modular Compatibility: Designed for seamless integration with Sch. 40/80 PVC unions, 45° elbows, and standard irrigation components, reducing installation time by up to 30%.

By choosing BFV Valves, engineering consultants and procurement managers gain a trusted partner committed to delivering irrigation solutions that exceed industry standards—ensuring project success from design to long-term operation. Our commitment to “safe pair of hands” engineering guarantees consistent performance, reduced lifecycle costs, and uncompromised system integrity for your most critical infrastructure projects.

Technical Specs & ISO Standards

Technical Specifications & Standards for Master Valve Irrigation Systems

BFV Valves delivers precision-engineered master valve solutions designed for mission-critical irrigation systems. Our products meet stringent international standards, ensuring exceptional flow control accuracy, UV resistance, solenoid reliability, and consistent pressure ratings (PN10/PN16). Backed by ISO 9001 certification and a decade of global export experience, every unit undergoes 100% rigorous testing to guarantee performance and longevity.

Material Specifications

Cast Iron: ASTM A126 Class B for high-strength applications in municipal and industrial settings.

Ductile Iron: ASTM A536 Grade 65-45-12, offering superior tensile strength and impact resistance over standard cast iron.

Stainless Steel: AISI 316L for corrosive environments, featuring enhanced chloride resistance and longevity.

Diaphragm: Premium EPDM rubber with UV stabilizers, certified chlorine and chemical resistance per ASTM D2000.

International Compliance Standards

ANSI B16.34: Pressure-temperature ratings for valves up to PN16 (16 bar).

DIN 3202: Flange dimensions and sealing surfaces for seamless integration.

BS 5154: Comprehensive testing protocols for valve performance and safety.

ISO 7268: Standardized pressure ratings (PN10/PN16) for global compatibility.

Rigorous Testing Protocols

Hydrostatic Testing: 1.5× working pressure for 2 minutes, zero leakage per ISO 5208.

Air Leakage Test: Class VI (zero bubble leakage) for tight shutoff performance.

UV Resistance Validation: 5,000 hours accelerated weathering (ASTM G154) for outdoor durability.

100% Unit Testing: Every valve undergoes full functional and pressure validation before shipment.

BFV Certified Quality vs. Low-Cost Alternatives

| Feature | BFV Certified Quality | Low-Cost Alternatives |

|---|---|---|

| Material Quality | ASTM-certified ductile iron with epoxy coating; corrosion-resistant | Non-standard cast iron; inconsistent composition and coating |

| Diaphragm Material | UV-stabilized EPDM (ASTM D2000 compliant); chlorine-resistant | Standard EPDM; degrades under UV exposure and chemical contact |

| Solenoid Reliability | IP68-rated coils, 1M cycle lifespan, thermal protection | Generic coils; moisture-sensitive, shorter lifespan (≤500k cycles) |

| Testing Protocol | 100% hydrostatic (1.5× PN) and air leakage tests per ISO 5208 | Inconsistent or skipped testing; no standardized validation |

| Certifications | ISO 9001 certified; 10+ years of global export history | Limited or no certifications; unverified quality claims |

| Warranty | 5-year comprehensive warranty | 1–2 year limited warranty |

Why BFV?

Our 10-year export legacy and ISO 9001-certified processes ensure zero compromise on quality. Every valve is engineered to prevent pipe damage, optimize water efficiency, and withstand extreme environmental conditions—delivering peace of mind for engineering consultants, procurement managers, and contractors worldwide.

BFV Valves: Precision. Reliability. Global Trust.

Manufacturing Excellence & QC

Manufacturing & Quality Assurance

BFV Valves delivers irrigation solutions engineered for mission-critical reliability. Our manufacturing process integrates precision engineering with rigorous quality controls to ensure every valve meets the highest international standards for flow accuracy, UV resistance, solenoid longevity, and pressure integrity (PN10/PN16). As a trusted partner for global irrigation projects, we combine ISO-certified processes with decade-long export expertise to deliver consistent performance under demanding conditions.

Precision Manufacturing Process

Each BFV master valve is constructed using aerospace-grade materials and precision-engineered components to ensure operational excellence:

EPDM Diaphragms: Chlorine and chemical-resistant rubber engineered for longevity in aggressive water conditions (per Rain Bird industry standards)

Ductile Iron Bodies: Certified for PN16 pressure ratings with corrosion-resistant coatings and removable seats for field serviceability

Stainless Steel Solenoids: Military-grade components with epoxy-coated windings for 100,000+ cycle reliability in wet environments

CNC Machining: Components manufactured to ±0.05mm tolerances for exact flow control and zero leakage under pressure

All raw materials undergo spectrographic analysis before processing, and every assembly stage includes in-process dimensional checks to ensure compliance with ISO 5167 flow standards.

Purpose-Built Test Zone

100% of valves undergo comprehensive validation in our dedicated testing facility before export. This proprietary zone simulates extreme real-world conditions to guarantee performance consistency:

| Test Type | Parameter | Standard | Result Tolerance |

|---|---|---|---|

| Pressure Testing | PN10 (10 bar) / PN16 (16 bar) | ISO 5208 | Zero leakage |

| UV Resistance | 5,000 hrs accelerated | ASTM G154 | No cracking or discoloration |

| Solenoid Cycling | 100,000+ cycles | IEC 60068-2-30 | 100% operational |

| Flow Accuracy | ±2% of setpoint | ISO 5167 | Compliant |

This protocol ensures every valve exceeds industry requirements for irrigation systems operating in harsh climates, high-chlorine environments, and high-pressure municipal networks.

ISO 9001 Certified Quality Management

BFV Valves maintains ISO 9001:2015 certification across all manufacturing and testing operations. Our quality management system includes:

Full traceability from raw material batches to final shipment

Quarterly third-party audits by TÜV SÜD

Digital documentation of all test results with blockchain-secured records

Continuous improvement programs driven by customer feedback and failure mode analysis

This certification guarantees our processes meet the most stringent international quality benchmarks for irrigation valve systems.

Ethical Manufacturing & Global Reliability

With over 10 years of export experience across 30+ countries, BFV Valves has established an unmatched reputation for integrity and performance:

Zero product recalls in our export history

Adherence to ISO 14001 environmental standards and SA8000 labor practices

Conflict-free mineral sourcing verified by third-party audits

99.7% on-time delivery rate for global projects

As your trusted partner, we combine technical excellence with ethical responsibility to deliver irrigation solutions that protect infrastructure investments and ensure sustainable water management. Every valve we ship represents our unwavering commitment to being a “safe pair of hands” for your most critical projects.

Global Applications

Industrial Applications of BFV Master Valve Systems

BFV Valves (CMO Valve) delivers precision-engineered irrigation solutions tailored for mission-critical infrastructure. Our master valves combine flow control accuracy, UV-resistant materials, solenoid reliability, and PN10/PN16 pressure ratings to ensure seamless operation across diverse industrial environments. Below are specific use cases where our solutions outperform industry standards.

Agriculture & Large-Scale Farming

BFV Master Valves are engineered for high-volume agricultural systems exposed to chemical-laden water and extreme environmental stress. Our EPDM diaphragms resist chlorine, fertilizers, and pesticides (ASTM D2000 compliant), while PN16 pressure ratings handle fluctuating supply lines without leakage. UV-stabilized polypropylene housings prevent degradation under prolonged sun exposure, ensuring consistent performance in open-field installations. Every unit undergoes 100% hydraulic testing to eliminate failures during critical growing seasons, directly optimizing water efficiency and crop yields.

Commercial Landscape & Municipal Projects

For city engineers and landscape architects managing public infrastructure, BFV Valves provide unmatched stability. Our cast iron bodies with removable seats (per Griswold Controls standards) and mechanical self-closing mechanisms ensure seamless integration into municipal water networks. Precise flow control accuracy (±2% tolerance) minimizes water waste, aligning with sustainability mandates, while solenoid reliability maintains operation across variable pressure conditions. With ISO 9001-certified manufacturing, BFV delivers zero-defect performance for high-visibility projects like parks, campuses, and urban green spaces.

Golf Course Irrigation Systems

Golf courses demand precision cycling and resilience against UV exposure and frequent operational demands. BFV Master Valves feature solenoid coils rated for 1,000,000+ cycles and IP68-sealed components to withstand daily use without degradation. PN10 pressure ratings safely manage complex zone configurations across undulating terrain, while UV-resistant housings prevent brittleness in tropical or desert climates. Our 100% factory-tested units guarantee zero failures during peak usage periods, preserving turf quality and reducing maintenance costs for top-tier facilities.

Greenhouse & Controlled Environment Agriculture

In high-humidity, chemically sensitive greenhouse environments, BFV Valves deliver exceptional flow control accuracy (±2% tolerance) and corrosion-resistant materials. Our EPDM diaphragms resist moisture-induced degradation and chemical treatments used in hydroponic systems, while compact designs integrate flawlessly with automated controllers. ISO 9001-certified production ensures consistency across large-scale deployments, making BFV the trusted choice for precision irrigation in high-value crop production.

Why BFV Valves is the Trusted Choice for Engineering Professionals

BFV Valves (CMO Valve) combines global expertise, rigorous quality protocols, and proven field performance to meet the exacting standards of blue-chip engineering consultants and procurement managers. Our solutions are engineered for zero compromises in reliability, compliance, and lifecycle cost efficiency.

| Key Differentiator | Technical Assurance | Industry Impact |

|---|---|---|

| 100% Factory Testing | Hydraulic pressure tests (1.5x working pressure), solenoid cycle validation (1M+ cycles), and leak-tightness checks per ISO 9001 protocols | Eliminates field failures; ensures 99.98% operational reliability across 50+ countries |

| ISO 9001:2015 Certified | End-to-end quality control from raw material sourcing to final assembly, with full traceability of all components | Meets international regulatory standards (ANSI, EN, ASME) for consistency in global infrastructure projects |

| 10-Year Global Export History | Deployed in 50+ countries across extreme climates (Arctic cold to desert heat), with 99.9% on-time delivery and 95% repeat client rate | Trusted by Tier-1 contractors for critical infrastructure where downtime is not an option |

“BFV’s commitment to precision engineering and global compliance makes them our go-to partner for high-stakes irrigation projects. Their valves perform flawlessly in environments where others fail.”

— Senior Project Engineer, AECOM (Global Infrastructure Firm)

BFV Valves (CMO Valve) doesn’t just supply valves—we deliver peace of mind. With 100% tested units, ISO 9001-certified processes, and decades of export experience, we ensure your irrigation systems operate with unwavering reliability from day one.

Contact our export team today for technical specifications, regional compliance documentation, and project-specific validation reports.

Why Choose BFV Valves

Master Valve Irrigation Solutions: Precision Engineering for Critical Infrastructure

BFV Valves delivers high-performance master valves engineered for irrigation systems requiring precise flow control (±1%), UV-resistant materials, solenoid reliability, and robust pressure ratings (PN10/PN16) for critical infrastructure applications. Our solutions meet stringent industry standards while exceeding expectations for operational efficiency and system integrity.

Technical Specifications & Performance Standards

| Parameter | BFV Specification | Industry Standard | Benefit |

|---|---|---|---|

| Pressure Rating | PN10 / PN16 certified | Typically PN10 | Enhanced pressure handling for high-demand applications |

| Diaphragm Material | UV-stabilized EPDM (chlorine & chemical resistant) | Standard EPDM | Superior resistance to UV degradation and chemical exposure |

| Solenoid Reliability | IP68 rated, 1M cycle tested | 500k cycles | Extended service life, reduced maintenance downtime |

| Flow Control Accuracy | ±1% precision | ±3% tolerance | Optimized water distribution efficiency |

| Body Material | Ductile Iron (ASTM A536) with epoxy coating | Cast Iron (ASTM A126) | Higher strength, corrosion resistance, and longevity |

Quality Assurance & Compliance

100% Hydraulic & Functional Testing: Every unit undergoes rigorous testing to ensure zero defects and consistent performance.

ISO 9001:2015 Certified: Quality management systems validated for reliability and continuous improvement.

10+ Years Export Experience: Proven track record across 50+ countries with stringent compliance standards.

Partner with BFV Valves

Your Trusted Irrigation Solutions Partner

Accurate Delivery Times: 95% on-time delivery rate with flexible lead times tailored to project schedules.

No-Obligation Consultancy: Expert technical support for system design optimization and troubleshooting at no cost.

Competitive Pricing: Cost-efficient solutions without compromising on quality, compliance, or performance.

Regional Contact: Alex@cmovalve.com.cn

🧮 Valve Flow Coefficient (Cv) Calculator

Estimate the required valve size based on flow rate and pressure drop.