Introduction: Navigating the Global Market for nds irrigation control valve cover

The global market for NDS irrigation control valve covers presents a myriad of challenges for B2B buyers, particularly when it comes to sourcing reliable products that ensure the longevity and efficiency of irrigation systems. As agricultural practices evolve and water management becomes increasingly critical, understanding the nuances of valve cover options is essential for those in regions like Africa, South America, the Middle East, and Europe. This guide serves as a comprehensive resource, detailing various types of NDS valve covers, their applications, and the specific needs they address within irrigation systems.

In this guide, we will explore the diverse array of NDS irrigation control valve covers, including their construction materials, durability features, and compatibility with existing systems. Buyers will gain insights into the importance of selecting covers that not only protect vital irrigation components but also withstand harsh environmental conditions. Additionally, we will provide strategies for vetting suppliers, assessing costs, and ensuring compliance with regional standards, all crucial for making informed purchasing decisions.

By leveraging this guide, international B2B buyers can enhance their procurement strategies, ensuring they invest in high-quality, durable valve covers that meet their operational needs. Whether you are in Brazil or Saudi Arabia, this resource empowers you to navigate the complexities of the market with confidence, securing the best solutions for your irrigation management challenges.

Understanding nds irrigation control valve cover Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Series Valve Box Cover | Made of UV-treated polypropylene; overlapping twist-lock design | Residential and commercial irrigation systems | Pros: Durable, easy to remove; Cons: Limited to specific sizes. |

| Pro-Spec Series Valve Box Cover | Engineered for heavy-duty use; thick, corrugated sidewalls | Commercial-grade irrigation and utility systems | Pros: High strength, lightweight; Cons: Higher cost. |

| SureFit™ Universal Valve Box Lid | Compatible with various brands; available in multiple sizes | Replacement for various valve boxes | Pros: Versatile, time-saving; Cons: May not fit all models perfectly. |

| Meter Box Cover | Designed for secure access; protects water system components | Water metering applications | Pros: Reliable protection; Cons: Limited to specific applications. |

| Telecom Box Cover | Heavy-duty design for FTTH applications; optional marker disc | Telecom installations | Pros: Durable and easy to install; Cons: Specialized use may limit market. |

What Are the Characteristics of Standard Series Valve Box Covers?

The Standard Series Valve Box Cover is primarily constructed from UV-treated polypropylene, ensuring longevity and resistance to environmental factors. Its overlapping twist-lock design prevents debris from entering, making maintenance easier. This type is ideal for both residential and commercial irrigation systems, providing a reliable solution for protecting valve components. Buyers should consider the specific size requirements for their projects, as these covers are tailored to fit designated valve box sizes.

How Does the Pro-Spec Series Valve Box Cover Differ from Standard Options?

The Pro-Spec Series Valve Box Cover is designed for heavy-duty applications, featuring thick, corrugated sidewalls that enhance its strength while minimizing weight. This makes it suitable for commercial-grade irrigation and utility systems where durability is crucial. While it offers superior performance, the higher price point may be a consideration for budget-conscious buyers. Companies in sectors requiring robust infrastructure should prioritize this option for its resilience.

What Advantages Do SureFit™ Universal Valve Box Lids Offer?

SureFit™ Universal Valve Box Lids are designed for compatibility with various brands, making them a versatile choice for businesses needing replacement covers. Available in multiple sizes, these lids save time and effort when matching covers to existing valve boxes. However, while they provide flexibility, buyers should ensure a proper fit to avoid potential issues in installation and usage. This option is particularly beneficial for contractors managing diverse projects.

In What Scenarios Are Meter Box Covers Essential?

Meter Box Covers are specifically designed to secure water system components, providing essential protection against environmental damage and unauthorized access. Their robust construction ensures that vital metering equipment remains safe and functional. Ideal for water metering applications, businesses must assess the compatibility of these covers with their existing systems. The investment in meter box covers can lead to long-term savings by preventing costly repairs due to environmental exposure.

Why Choose Telecom Box Covers for Fiber Installations?

Telecom Box Covers are engineered for heavy-duty use, particularly in Fiber to the Home (FTTH) applications, where reliability and ease of installation are paramount. They often come with optional marker discs for enhanced identification, making them suitable for diverse telecom installations. While their specialized design ensures durability, the niche application may limit broader market appeal. Companies focused on telecommunications infrastructure should consider these covers to ensure the protection of essential equipment.

Key Industrial Applications of nds irrigation control valve cover

| Industry/Sector | Specific Application of NDS Irrigation Control Valve Cover | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Protecting irrigation systems in crop production | Enhances system longevity and efficiency, reducing maintenance costs | Sourcing durable materials resistant to UV and extreme weather |

| Landscaping | Concealing irrigation control valves in residential areas | Improves aesthetics while ensuring system accessibility | Availability of various sizes and designs for compatibility |

| Municipal Water Management | Securing access to irrigation controls in public parks | Ensures public safety and protects irrigation infrastructure | Compliance with local regulations and standards |

| Commercial Real Estate | Maintaining irrigation systems in commercial properties | Supports sustainable landscaping practices and reduces water waste | Need for robust, weather-resistant materials for long-term use |

| Sports Facilities | Managing irrigation for athletic fields and golf courses | Promotes healthy turf and reduces operational disruptions | Consideration for high-frequency access and maintenance needs |

How is the NDS Irrigation Control Valve Cover Used in Agriculture?

In the agriculture sector, the NDS irrigation control valve cover is crucial for protecting irrigation systems used in crop production. These covers shield vital components from dirt, debris, and harsh weather conditions, ensuring optimal performance and longevity. For international buyers, particularly in regions like Africa and South America, sourcing covers that can withstand extreme temperatures and UV exposure is essential to minimize maintenance costs and enhance system efficiency.

What Role Does the NDS Valve Cover Play in Landscaping?

In landscaping, the NDS irrigation control valve cover serves a dual purpose: it protects essential irrigation components while enhancing the aesthetic appeal of residential properties. By concealing unsightly valves, these covers help maintain a clean and professional appearance. Buyers from Europe and the Middle East should consider the availability of various sizes and designs to ensure compatibility with existing systems and meet local aesthetic preferences.

Why is the NDS Cover Important for Municipal Water Management?

Municipal water management relies on the NDS irrigation control valve cover to secure access to irrigation controls in public parks and recreational areas. These covers prevent unauthorized access and protect critical infrastructure, thereby ensuring public safety. For international buyers, compliance with local regulations and standards is a key consideration when sourcing these products to avoid potential liabilities.

How Does the NDS Valve Cover Benefit Commercial Real Estate?

In the commercial real estate sector, the NDS irrigation control valve cover is vital for maintaining irrigation systems in landscaped areas. It supports sustainable landscaping practices by ensuring efficient water use, thereby reducing operational costs. Buyers need to focus on sourcing robust, weather-resistant materials that can handle the demands of high-traffic environments, especially in regions with diverse climates.

What is the Importance of the NDS Cover in Sports Facilities?

For sports facilities, the NDS irrigation control valve cover is essential for managing irrigation systems that maintain healthy turf on athletic fields and golf courses. These covers allow for easy access while protecting critical components from damage. Buyers should consider high-frequency access needs and maintenance requirements when sourcing, ensuring that the covers can withstand the rigors of frequent use in high-stakes environments.

3 Common User Pain Points for ‘nds irrigation control valve cover’ & Their Solutions

Scenario 1: Inadequate Protection from Environmental Damage

The Problem: B2B buyers often encounter issues with irrigation control valve covers that do not withstand harsh weather conditions. In regions such as Africa and the Middle East, extreme temperatures and intense sunlight can lead to rapid deterioration of standard valve covers, resulting in cracks or complete failure. This not only jeopardizes the integrity of the irrigation system but can also lead to costly repairs and downtime, which is particularly detrimental for agricultural businesses relying on timely irrigation.

The Solution: To combat environmental damage, buyers should specifically look for NDS irrigation control valve covers made from high-density polyethylene (HDPE) with UV inhibitors. These materials are engineered to resist fading and cracking under intense sunlight. When sourcing these covers, it’s crucial to verify that they meet rigorous quality standards. Buyers can enhance their purchasing strategy by consulting NDS’s product specifications and engaging their project specialists for tailored solutions. This proactive approach ensures that the selected covers will last longer, ultimately saving costs associated with frequent replacements.

Scenario 2: Difficulty in Access and Maintenance

The Problem: Another common pain point for B2B buyers is the challenge of accessing irrigation control valve boxes for routine maintenance. Covers that are difficult to open or are not designed for easy removal can lead to time-consuming and frustrating maintenance processes. This issue is particularly pronounced in commercial setups where quick access is crucial for efficient operations, potentially causing delays that impact productivity.

The Solution: Buyers should prioritize NDS valve covers that feature overlapping designs and integrated finger holes for easy removal. These thoughtful design elements make it simple for maintenance teams to access the valves without the need for specialized tools. When purchasing, buyers should also consider opting for the SureFit™ Universal Valve Box Lids, which are compatible with various valve box sizes, reducing inventory complexity and ensuring a perfect fit. By selecting these user-friendly covers, businesses can streamline their maintenance processes, saving time and improving operational efficiency.

Scenario 3: Compatibility Issues with Existing Systems

The Problem: Compatibility is a frequent concern when purchasing irrigation control valve covers, especially for businesses that have existing valve systems from different manufacturers. B2B buyers often face the dilemma of needing to replace covers but finding that new products do not fit older models, leading to wasted resources and additional expenses. This situation can be particularly challenging in regions with a mix of irrigation technology due to varying standards and practices.

The Solution: To mitigate compatibility issues, buyers should conduct thorough assessments of their existing valve box dimensions and specifications before making a purchase. NDS offers a range of sizes and options, including the SureFit™ Universal Valve Box Lids, which are designed to fit most major brands. Additionally, reaching out to NDS’s customer support for personalized assistance can provide valuable insights into which products will seamlessly integrate with existing systems. By taking these steps, buyers can ensure they make informed decisions that will enhance their irrigation setups without incurring unnecessary costs or operational disruptions.

Strategic Material Selection Guide for nds irrigation control valve cover

What Are the Key Materials for NDS Irrigation Control Valve Covers?

When selecting materials for NDS irrigation control valve covers, several options stand out due to their unique properties and performance characteristics. This analysis focuses on four common materials: High-Density Polyethylene (HDPE), Polypropylene (PP), Structural Foam Polyolefin, and Reinforced Composite Materials. Each material has its own set of advantages and disadvantages that can significantly impact product performance and suitability for various applications.

High-Density Polyethylene (HDPE)

Key Properties: HDPE is known for its excellent chemical resistance, high tensile strength, and ability to withstand a wide temperature range. It can typically handle temperatures from -40°F to 120°F (-40°C to 49°C) and is resistant to corrosion from various chemicals.

Pros & Cons: The durability of HDPE makes it a popular choice for outdoor applications, as it can resist impact and UV degradation. However, it can be more expensive than other materials, which may affect overall project costs. The manufacturing complexity is moderate, as HDPE can be molded into various shapes but requires specific machinery.

Impact on Application: HDPE is suitable for use in environments with exposure to harsh chemicals or extreme weather, making it ideal for regions with varying climates, such as parts of Africa and South America.

Considerations for International Buyers: Buyers should ensure that HDPE products meet local compliance standards, such as ASTM or DIN, particularly in the Middle East and Europe where regulations may vary.

Polypropylene (PP)

Key Properties: Polypropylene is lightweight, flexible, and has a high melting point, making it suitable for applications requiring thermal stability. It also has good chemical resistance, particularly against acids and bases.

Pros & Cons: The low cost of polypropylene makes it an attractive option for budget-conscious projects. However, it is less durable than HDPE and may suffer from UV degradation if not treated with inhibitors. Its manufacturing process is relatively straightforward, allowing for efficient production.

Impact on Application: PP is ideal for less demanding applications where cost savings are a priority, but it may not be suitable for high-stress environments.

Considerations for International Buyers: Buyers should consider the availability of UV-treated polypropylene options to ensure longevity in sunny regions, such as Brazil and Saudi Arabia.

Structural Foam Polyolefin

Key Properties: This material combines the benefits of lightweight foam with structural integrity. It offers excellent insulation properties and is resistant to moisture, making it suitable for outdoor applications.

Pros & Cons: The primary advantage of structural foam polyolefin is its strength-to-weight ratio, which allows for easier handling and installation. However, it can be more expensive than traditional plastics, and its manufacturing process can be complex due to the need for specialized equipment.

Impact on Application: This material is particularly effective in applications requiring insulation from temperature fluctuations, making it suitable for various climates.

Considerations for International Buyers: Buyers should verify that the foam polyolefin meets local environmental regulations, as some regions may have restrictions on certain materials.

Reinforced Composite Materials

Key Properties: Reinforced composites are engineered to provide superior strength and durability. They can withstand high loads and are resistant to a wide range of chemicals.

Pros & Cons: These materials offer exceptional performance in demanding environments, but they come at a higher cost and can involve complex manufacturing processes. The weight of reinforced composites can also be a consideration during transportation and installation.

Impact on Application: Ideal for heavy-duty applications, reinforced composites are suitable for commercial projects where reliability is critical.

Considerations for International Buyers: Compliance with international standards is crucial, especially for large-scale projects in Europe and the Middle East, where regulations may dictate material specifications.

Summary Table of Material Selection

| Material | Typical Use Case for NDS Irrigation Control Valve Cover | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High-Density Polyethylene (HDPE) | Outdoor irrigation systems in harsh climates | Excellent chemical resistance and durability | Higher cost compared to other materials | High |

| Polypropylene (PP) | Budget-sensitive projects with moderate requirements | Cost-effective and lightweight | Less durable and UV sensitive | Low |

| Structural Foam Polyolefin | Applications needing insulation and moisture resistance | Strong yet lightweight | More complex manufacturing and higher cost | Medium |

| Reinforced Composite Materials | Heavy-duty commercial irrigation systems | Superior strength and load-bearing capacity | Higher cost and complex manufacturing | High |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions based on performance requirements, cost considerations, and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for nds irrigation control valve cover

What Are the Key Stages in the Manufacturing Process of NDS Irrigation Control Valve Covers?

The manufacturing of NDS irrigation control valve covers involves a series of well-defined stages that ensure the product meets durability and quality standards essential for irrigation systems. Understanding these stages is crucial for B2B buyers looking for reliable suppliers.

1. Material Preparation: What Materials Are Used?

The primary material used for NDS irrigation control valve covers is high-density polyethylene (HDPE) or polypropylene (PP), which are chosen for their resistance to UV radiation, moisture, and chemical exposure. The manufacturing process begins with the careful selection and preparation of raw materials, which includes sourcing recycled content to meet sustainability goals.

In this stage, the materials undergo quality checks to ensure they meet specifications. This can involve testing for tensile strength, impact resistance, and UV stability, ensuring the covers will withstand harsh environmental conditions.

2. Forming: How Are the Covers Shaped?

Once the materials are prepared, the forming process begins. This typically involves injection molding, a technique that allows for precise shaping of the valve covers. During this process, heated plastic is injected into molds, forming the desired shapes and sizes.

Key techniques include:

- Injection Molding: This process allows for high-volume production with consistency in quality and dimensions. The use of molds designed for specific cover sizes (e.g., 6-inch or 10-inch) ensures that the covers fit perfectly onto the valve boxes.

- Structural Reinforcement: Molds are designed with structural reinforcing ribs to enhance durability and load-bearing capacity. This is particularly important for commercial-grade applications where the covers may be subjected to heavier loads.

3. Assembly: Are There Additional Components?

In most cases, the covers are a single piece; however, if multiple components are involved (such as locking mechanisms), they will be assembled during this stage. For valve covers with overlapping designs, features like finger holes for easy removal may be integrated at this point.

Quality control measures are in place during assembly to ensure that all components fit correctly and function as intended, maintaining the integrity of the product.

4. Finishing: What Final Touches Are Applied?

The finishing stage includes any additional treatments that enhance the product’s performance. For NDS valve covers, this often involves:

- UV Protection: Additional additives may be applied to enhance UV resistance, extending the product’s lifespan and maintaining its aesthetic appeal over time.

- Coloring and Marking: Covers may be colored (often in green) for visibility and branding, with specific markings (like ICV for irrigation control valves) added for identification.

Final inspections are conducted to ensure that all products meet aesthetic and functional standards before packaging.

What Quality Assurance Practices Are Essential for NDS Valve Covers?

Quality assurance is critical in manufacturing, particularly for products that play a vital role in irrigation systems. NDS irrigation control valve covers undergo stringent quality checks throughout the manufacturing process.

Relevant International Standards: Which Certifications Matter?

B2B buyers should look for manufacturers that comply with international quality standards. Key certifications include:

- ISO 9001: This standard outlines requirements for a quality management system and demonstrates a manufacturer’s ability to consistently provide products that meet customer and regulatory requirements.

- CE Marking: Particularly relevant for European markets, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: Although primarily focused on the petroleum and natural gas industries, compliance with API standards may be beneficial for buyers involved in irrigation systems linked to these sectors.

Quality Control Checkpoints: What Are the Key Stages?

Quality control involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This step ensures that raw materials meet specified standards before production begins. Tests can include material composition analysis and physical property evaluations.

- In-Process Quality Control (IPQC): During manufacturing, ongoing inspections and measurements are conducted to monitor the production process. This can include dimensional checks and visual inspections for defects.

Final Quality Control (FQC): After production, covers undergo comprehensive testing, which may include:

Functional Testing: Ensuring that covers fit properly and function as intended.

- Durability Testing: Simulating environmental conditions to assess the longevity and resilience of the product.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is crucial for ensuring product reliability.

Supplier Audits: What to Look For?

Conducting supplier audits can provide insight into their quality management practices. Key areas to evaluate include:

- Manufacturing Facilities: Assessing the cleanliness, organization, and technology used in the production process.

- Quality Management Systems: Reviewing documentation related to quality processes and certifications.

Reports and Documentation: How to Ensure Transparency?

B2B buyers should request quality control reports, including:

- Test Reports: Documentation of tests performed during IQC, IPQC, and FQC stages.

- Certifications: Copies of relevant certifications that validate compliance with international standards.

Third-Party Inspections: Are They Necessary?

Engaging third-party inspection services can provide an unbiased assessment of a manufacturer’s quality practices. These inspections can offer additional reassurance regarding product quality and compliance with industry standards.

What Are the Unique Quality Control Nuances for International B2B Buyers?

International buyers must be aware of specific nuances when it comes to quality control. Understanding local regulations, cultural practices, and logistical challenges is essential for successful procurement.

- Regulatory Compliance: Familiarize yourself with the regulations specific to your region, as they may differ significantly from those in the manufacturer’s country.

- Logistics and Shipping: Ensure that quality assurance measures are maintained throughout the shipping process to prevent damage or degradation of the products before reaching the final destination.

By understanding the manufacturing processes and quality assurance protocols for NDS irrigation control valve covers, B2B buyers can make informed decisions, ensuring they select reliable suppliers that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘nds irrigation control valve cover’

In this guide, we provide a practical checklist for B2B buyers seeking to procure NDS irrigation control valve covers. This essential component protects irrigation system elements and ensures efficient water management. By following these steps, you can make informed purchasing decisions that align with your operational needs and budget.

Step 1: Define Your Technical Specifications

Before initiating your sourcing process, clearly outline the technical specifications required for the irrigation control valve cover. Consider factors such as size, material, and compatibility with existing systems. For instance, the NDS 6″ round valve box cover is designed for specific dimensions and must fit securely to prevent debris infiltration.

Step 2: Research Supplier Options

Conduct comprehensive research to identify potential suppliers who specialize in irrigation control valve covers. Utilize industry directories, trade shows, and online platforms to compile a list of manufacturers. Look for suppliers that offer a diverse range of products, including different sizes and materials, to ensure you can find the best match for your needs.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify the certifications and quality standards of your shortlisted suppliers. This step is crucial as it reflects the reliability and durability of the products you intend to purchase. Check for certifications such as ISO or compliance with local regulations in your region, which can impact product performance and acceptance.

Step 4: Request Product Samples

It’s advisable to request samples of the NDS irrigation control valve covers from potential suppliers. Evaluating physical samples allows you to assess quality, material durability, and compatibility with your existing systems. Look for features such as UV inhibitors and structural reinforcements that enhance the longevity of the covers.

Step 5: Compare Pricing and Payment Terms

Gather quotes from multiple suppliers and compare their pricing structures. Ensure you understand the payment terms and any discounts available for bulk orders. Keep in mind that while a lower price might be appealing, it’s essential to consider the overall value, including product quality and supplier reliability.

Step 6: Assess Lead Times and Logistics

Inquire about lead times for delivery and the logistics involved in shipping the products to your location. Timely delivery is critical to maintaining your project schedules, especially in regions where irrigation is seasonal. Ensure that the supplier can meet your deadlines and discuss any potential delays that may arise.

Step 7: Review Warranty and After-Sales Support

Finally, review the warranty offered by the supplier and the availability of after-sales support. A robust warranty can provide peace of mind regarding product performance over time. Additionally, reliable customer support is essential for addressing any issues or questions that may arise post-purchase.

By following this step-by-step checklist, you can confidently navigate the procurement process for NDS irrigation control valve covers, ensuring that you select a high-quality product that meets your operational requirements.

Comprehensive Cost and Pricing Analysis for nds irrigation control valve cover Sourcing

What Are the Key Cost Components for Sourcing NDS Irrigation Control Valve Covers?

When sourcing NDS irrigation control valve covers, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

Materials: The use of high-density polyethylene (HDPE) or polypropylene (PP) treated with UV inhibitors significantly affects the cost. These materials ensure durability and resistance to environmental factors, making them ideal for irrigation applications.

Labor: Labor costs can vary by region. In countries with a skilled workforce, labor costs may be higher, impacting the overall price of the product. Conversely, regions with lower labor costs may offer competitive pricing.

Manufacturing Overhead: This encompasses utilities, rent, and administrative expenses related to production. Efficient manufacturing processes can help mitigate these costs, reflecting on the final product price.

Tooling: The initial setup costs for molds and tooling can be substantial, especially for custom designs. Buyers should inquire about tooling costs when considering unique specifications.

Quality Control (QC): Ensuring product quality involves additional costs related to testing and compliance with international standards. Certifications may add to the price but are essential for ensuring reliability.

Logistics: Transportation and handling costs are significant, especially for international shipments. Incoterms play a vital role in determining who bears these costs, impacting the total price.

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary depending on the supplier’s market positioning and the competitive landscape.

How Do Price Influencers Impact the Cost of NDS Irrigation Control Valve Covers?

Several factors can influence the pricing of NDS irrigation control valve covers:

Volume/MOQ (Minimum Order Quantity): Bulk orders often lead to discounts, making it essential for buyers to assess their purchasing strategy. Understanding the MOQ can help negotiate better pricing.

Specifications and Customization: Customized products or specific design requirements may incur additional costs. Buyers should evaluate whether the added expense aligns with their project needs.

Material Quality and Certifications: Higher quality materials and recognized certifications can increase costs but provide long-term value through enhanced durability and performance.

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their proven track record and service quality.

Incoterms: Different shipping terms can alter the final price. Familiarity with Incoterms can help buyers understand who is responsible for shipping costs, insurance, and duties.

What Tips Can Help Buyers Negotiate Better Prices for NDS Irrigation Control Valve Covers?

To enhance cost-efficiency when sourcing NDS irrigation control valve covers, consider the following buyer tips:

Negotiate: Engage in discussions about pricing, especially if purchasing in bulk. Suppliers may offer discounts for larger orders or long-term contracts.

Assess Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, durability, and replacement. A higher upfront cost may lead to lower TCO if the product lasts longer.

Understand Pricing Nuances for International Markets: Familiarize yourself with local market conditions in regions like Africa, South America, the Middle East, and Europe. Currency fluctuations, import duties, and regional demand can significantly impact prices.

Leverage Relationships: Building a rapport with suppliers can lead to better pricing and terms. Long-term partnerships often yield more favorable conditions.

Request Quotes from Multiple Suppliers: Comparing prices from different suppliers can provide insights into market rates and help in negotiations.

Disclaimer on Indicative Prices

Prices for NDS irrigation control valve covers can vary widely based on the factors discussed above. The figures mentioned in this analysis are indicative and may change due to market dynamics, supplier policies, and regional economic conditions. Always request updated quotes and conduct thorough market research before finalizing any purchase.

Alternatives Analysis: Comparing nds irrigation control valve cover With Other Solutions

Understanding Alternatives in Irrigation Control Valve Covers

In the realm of irrigation management, selecting the right valve cover is crucial for ensuring system efficiency, longevity, and ease of maintenance. While the NDS irrigation control valve cover offers robust features, it is important for B2B buyers to explore viable alternatives that may align better with specific project requirements or budget constraints. This section will compare the NDS irrigation control valve cover with two notable alternatives, providing insights into their performance, cost, implementation ease, maintenance requirements, and best use cases.

| Comparison Aspect | NDS Irrigation Control Valve Cover | Alternative 1: SureFit™ Universal Valve Box Lid | Alternative 2: Pro-Spec® Series Valve Box Lid |

|---|---|---|---|

| Performance | Durable, UV-resistant, prevents debris ingress | Compatible with various brands, versatile | Engineered for heavy-duty use, reinforced cover |

| Cost | $4.35 – $14.84 | $10.00 – $15.00 | $20.00 – $30.00 |

| Ease of Implementation | Simple twist-lock design | Universal fit saves time in selection | Requires specific installation protocols |

| Maintenance | Low maintenance, easily removable | Low maintenance, easy to replace | Requires more rigorous maintenance checks |

| Best Use Case | Residential and commercial applications | Ideal for mixed-brand environments | Commercial-grade projects with heavy loads |

Exploring Alternative 1: SureFit™ Universal Valve Box Lid

The SureFit™ Universal Valve Box Lid stands out for its adaptability, designed to fit multiple valve box brands. This product simplifies the process for contractors working in diverse environments, as it eliminates the need to stock various sizes and models. However, while it offers versatility, its performance may not match the NDS cover’s durability and UV resistance, potentially leading to shorter lifespan in harsh conditions. The price point is competitive, making it an attractive option for budget-conscious buyers.

Analyzing Alternative 2: Pro-Spec® Series Valve Box Lid

For those requiring heavy-duty solutions, the Pro-Spec® Series Valve Box Lid is engineered to withstand significant loads, making it suitable for commercial applications. Its reinforced design provides added strength and longevity, particularly in high-traffic areas. However, this added durability comes at a higher cost, and the installation may require additional expertise, which could be a consideration for smaller operations or projects with limited budgets. Maintenance can also be more rigorous due to the specifications required for commercial-grade products.

Conclusion: How to Choose the Right Valve Cover Solution

Selecting the appropriate irrigation control valve cover hinges on understanding the specific needs of your project. The NDS irrigation control valve cover offers excellent durability and ease of use, making it a solid choice for both residential and commercial applications. However, alternatives like the SureFit™ lid provide flexibility for varied environments, while the Pro-Spec® lid caters to heavy-duty demands. B2B buyers should assess factors such as performance requirements, budget, ease of installation, and maintenance needs to make an informed decision that aligns with their operational goals. By carefully evaluating these aspects, businesses can enhance their irrigation systems’ efficiency and reliability.

Essential Technical Properties and Trade Terminology for nds irrigation control valve cover

What Are the Key Technical Properties of NDS Irrigation Control Valve Covers?

Understanding the technical specifications of NDS irrigation control valve covers is crucial for B2B buyers. Here are some of the essential properties:

Material Grade

NDS valve covers are typically made from high-density polyethylene (HDPE) or polypropylene (PP) that has been treated with UV inhibitors. This ensures durability and resistance to environmental degradation. High-quality materials are vital as they enhance the longevity of the cover, reducing replacement frequency and associated costs.Dimensions and Tolerances

Standard sizes include 6-inch round and other rectangular configurations, with specific tolerances for fitting. Accurate dimensions ensure that the cover fits securely on the valve box, preventing debris from entering and maintaining the integrity of the irrigation system. This is particularly important in commercial applications where system reliability is paramount.Overlapping Design

The overlapping design of the valve covers prevents dirt and grass from settling between the cover and the valve box. This feature enhances ease of removal and access for maintenance, which is especially beneficial for irrigation systems that require regular checks. B2B buyers should consider this when evaluating the operational efficiency of their irrigation setups.Load Capacity

Many NDS valve covers are designed to support significant weight, particularly in commercial applications. The Pro-Spec series, for instance, includes reinforced covers for heavy-duty use. Understanding the load capacity is essential for buyers to ensure that the covers can withstand local environmental conditions and traffic loads without failing.Resistance to Chemicals and UV Rays

The materials used in NDS valve covers are resistant to various chemicals and UV rays, which is crucial for maintaining functionality in different climates. This resistance prevents cracking and discoloration over time, ensuring that the covers remain effective and aesthetically pleasing.Compliance and Certifications

Many NDS products are ADA compliant and manufactured in the USA, which can be important for buyers in regulated markets. Compliance with local regulations can affect procurement decisions, making it essential for buyers to verify certification and compliance with relevant standards.

What Are Common Trade Terms Related to NDS Irrigation Control Valve Covers?

Familiarity with industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are some common terms:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding whether a valve cover is an OEM product can inform buyers about compatibility and quality standards.MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. Knowing the MOQ helps buyers plan their purchases effectively and manage inventory costs, particularly in international markets where shipping costs can be significant.RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other terms for specific products. This process is vital for buyers to gather competitive pricing and evaluate options before making a purchasing decision.Incoterms (International Commercial Terms)

These are predefined commercial terms that dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms can help buyers avoid misunderstandings in international transactions.Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. Understanding lead times is crucial for planning project timelines and ensuring that irrigation systems are installed or repaired without unnecessary delays.Warranty

A warranty provides assurance from the manufacturer regarding the quality and durability of the product. Buyers should always inquire about warranty terms to protect their investments and ensure recourse in case of defects.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, ensuring that their investments in NDS irrigation control valve covers meet their operational needs and budget considerations.

Navigating Market Dynamics and Sourcing Trends in the nds irrigation control valve cover Sector

What Are the Current Market Dynamics and Key Trends in the NDS Irrigation Control Valve Cover Sector?

The NDS irrigation control valve cover market is experiencing notable growth, driven by increasing global demand for efficient water management solutions. Key factors influencing this trend include urbanization, agricultural expansion, and the necessity to conserve water resources amid climate change challenges. In regions such as Africa, South America, the Middle East, and Europe, particularly in countries like Brazil and Saudi Arabia, the push for sustainable agricultural practices has heightened the focus on robust irrigation systems. These regions are investing in advanced irrigation technologies, including durable valve covers that ensure long-lasting performance.

Emerging B2B technology trends in this sector include the integration of IoT (Internet of Things) capabilities into irrigation systems, enabling real-time monitoring and management. Buyers are increasingly looking for valve covers and boxes that not only meet traditional standards but also offer compatibility with smart irrigation systems. This shift is prompting manufacturers to innovate, creating products that are not only functional but also technologically advanced.

Furthermore, sourcing trends indicate a growing emphasis on local suppliers and manufacturers, particularly in emerging markets. This strategy reduces lead times, lowers transportation costs, and aligns with sustainability goals. International buyers should also be aware of the increasing availability of customized solutions, allowing them to better address specific operational needs in their respective markets.

How Is Sustainability and Ethical Sourcing Influencing the NDS Irrigation Control Valve Cover Market?

Sustainability is becoming a cornerstone of the NDS irrigation control valve cover market. As environmental awareness grows, buyers are increasingly prioritizing products that minimize ecological impact. This includes selecting valve covers made from recycled or eco-friendly materials, such as high-density polyethylene (HDPE) and polypropylene (PP) treated with UV inhibitors. These materials not only enhance durability but also contribute to reducing waste in landfills.

Ethical sourcing practices are also gaining traction. Buyers are now more inclined to partner with manufacturers who demonstrate a commitment to fair labor practices and responsible supply chain management. This trend is particularly relevant in regions like Africa and South America, where local economic development is essential. Suppliers that can provide transparency in their sourcing processes and certifications for environmental standards are likely to gain a competitive edge.

Green certifications and labels are increasingly important in the procurement process. Buyers should actively seek out products with recognized certifications that validate their sustainability claims. This not only assures compliance with local regulations but also appeals to environmentally conscious consumers and stakeholders.

What Is the Evolution of the NDS Irrigation Control Valve Cover Sector?

The NDS irrigation control valve cover sector has evolved significantly over the past few decades. Initially, valve covers were primarily functional, focusing on protecting irrigation components from debris and environmental elements. However, as the agricultural and landscaping industries have advanced, so too have the materials and technologies used in these products.

In the early stages, traditional materials such as metal were prevalent, but they often suffered from corrosion and durability issues. The introduction of modern materials like high-density polyethylene and polypropylene marked a pivotal shift, enhancing both longevity and performance. The designs have also transformed, with overlapping covers that prevent dirt accumulation and improve accessibility.

Today, the sector is witnessing a blend of functionality and technology, with smart irrigation systems becoming more commonplace. This evolution reflects the industry’s response to both environmental challenges and the growing demand for efficient water management solutions in a rapidly changing global landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of nds irrigation control valve cover

How do I ensure the NDS irrigation control valve cover is compatible with my existing valve box?

To ensure compatibility, verify the dimensions and specifications of your valve box against the NDS irrigation control valve cover you intend to purchase. NDS covers are designed to fit specific models, such as the 6 in. round valve box. Always consult product documentation or contact the supplier for assistance in matching your valve box model with the appropriate cover. Additionally, consider the type of lid (overlapping or snap-in) to ensure it meets your installation requirements.What is the best material for irrigation control valve covers in harsh climates?

For harsh climates, opt for covers made of high-density polyethylene (HDPE) or polypropylene (PP) with UV inhibitors. These materials are engineered to withstand extreme temperatures, resist cracking, and prevent discoloration. NDS covers are designed with structural reinforcing ribs, ensuring durability against environmental stressors. Always evaluate your specific climate conditions, such as temperature fluctuations and exposure to sunlight, when selecting materials for long-lasting performance.What are the benefits of using overlapping lids on NDS valve covers?

Overlapping lids provide a superior seal against dirt, grass, and debris, ensuring that the internal components of the valve box remain protected and accessible. This design feature facilitates easier removal and replacement of the lid over time, as it prevents buildup between the cover and the box. Additionally, overlapping lids enhance structural integrity and can accommodate various weather conditions, making them an ideal choice for both residential and commercial applications.What is the minimum order quantity (MOQ) for NDS irrigation control valve covers?

The minimum order quantity (MOQ) may vary depending on the supplier and your specific location. Typically, suppliers establish MOQs to ensure cost-effectiveness and efficient shipping logistics. It’s advisable to directly contact your chosen supplier to inquire about their specific MOQ for NDS irrigation control valve covers, as some may offer flexibility for larger orders or specialized projects.How do I vet suppliers for NDS irrigation control valve covers?

When vetting suppliers, consider their reputation, industry experience, and customer reviews. Verify their certifications and compliance with international quality standards, particularly if you are sourcing from different regions such as Africa, South America, or the Middle East. Request references from previous customers and assess their responsiveness and support services. Additionally, evaluate their product range and ability to provide customized solutions to meet your specific irrigation needs.What payment terms should I expect when sourcing NDS irrigation control valve covers?

Payment terms can differ significantly between suppliers. Common arrangements include upfront payment, 30- or 60-day payment terms, or payment upon delivery. Ensure to clarify these terms before finalizing your order. It’s also advisable to explore secure payment options, such as letters of credit or escrow services, especially for international transactions to protect both parties involved.What quality assurance measures should I consider when purchasing NDS valve covers?

Quality assurance measures are crucial to ensure the reliability and durability of NDS valve covers. Look for suppliers that conduct rigorous testing on their products, including stress tests and environmental simulations. Request information about their quality control processes and certifications. It’s also beneficial to inquire about warranties or guarantees that the supplier offers, which can provide additional peace of mind regarding product performance.How should I handle logistics and shipping when sourcing NDS irrigation control valve covers internationally?

When sourcing internationally, coordinate with your supplier to understand the shipping options available, including freight costs, delivery times, and customs clearance processes. Choose a reputable logistics provider experienced in handling international shipments to mitigate delays and complications. Also, ensure that you have all necessary documentation for customs, such as invoices and certificates of origin, to facilitate smooth importation. Regular communication with your supplier and logistics partner will help address any potential issues promptly.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Nds Irrigation Control Valve Cover Manufacturers & Suppliers List

1. NORMA Group – 6 in. Round Standard Series Valve Box Cover

Domain: ndspro.com

Registered: 1996 (29 years)

Introduction: {“Product Name”: “6 in. Round Standard Series Valve Box Cover, Green ICV”, “Brand”: “NORMA Group”, “SKU”: “107C”, “Compatibility”: “Compatible with the 107B box and other 6 in. round Standard Series valve boxes”, “Material”: “High-density polyethylene (HDPE) treated with UV inhibitors”, “Features”: [“Durable with structural reinforcing ribs”, “Overlapping lid prevents dirt and debris from entering…

2. NDS – Valve Boxes

Domain: sprinklersupplystore.com

Registered: 2010 (15 years)

Introduction: NDS Valve Boxes are manufactured in Lindsay, CA, and come in various sizes from 6″ round to 17″ x 30″ rectangular. They feature black, green, purple, gray, and sand covers with designations for irrigation control valve, water, sewer, electric, reclaimed water, cable TV, and telephone. All boxes and lids include UV inhibitors for durability in direct sunlight. Specific products include: 1. NDS – 11…

3. NDS – 6 Round Cover ICV

Domain: drainageconnect.com

Registered: 2016 (9 years)

Introduction: {“Product Name”: “NDS 6″ Round Cover ICV”, “Price”: “$4.35”, “SKU”: “107C”, “Dimensions”: {“Length”: “6-1/2″”, “Width”: “6-1/2″”, “Height”: “3/4″”}, “Material”: “UV Protected High-Density Polyethylene (HDPE)”, “Top Diameter”: “6-1/2″”, “Bottom Diameter”: “5-3/4″”, “Load Rating”: “Class A (01-60 PSI / 3,800 lbs per foot)”, “Features”: [“ADA Compliant”, “Made in the USA”, “Overlapping covers prevent…

4. NDS – Round Valve Box Cover

Domain: acehardware.com

Registered: 1995 (30 years)

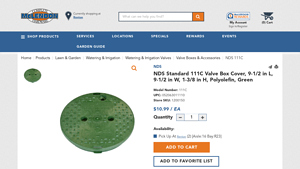

Introduction: NDS 9.5 in. W X 1-3/8 in. H Round Valve Box Cover Green, Mfr# 111C, Price: $7.99, Item # 4537122

5. The Drainage Source – NDS Standard Series Valve Boxes

Domain: thedrainagesource.com

Registered: 2013 (12 years)

Introduction: This company, The Drainage Source – NDS Standard Series Valve Boxes, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Mclendon’s – 10 in Round Valve Box Cover

Domain: mclendons.com

Registered: 1996 (29 years)

Introduction: {“Model Number”:”111C”,”UPC”:”052063011110″,”Store SKU”:””,”Customer Part Number”:””,”Length”:”9-1/2 in”,”Width”:”9-1/2 in”,”Height”:”1-3/8 in”,”Material”:”Polyolefin”,”Color”:”Green”,”Suitable for”:”10 in Round Valve Box”,”Shape”:”Round”}

Strategic Sourcing Conclusion and Outlook for nds irrigation control valve cover

How Can Strategic Sourcing Enhance Your Procurement of NDS Irrigation Control Valve Covers?

In today’s competitive landscape, strategic sourcing of NDS irrigation control valve covers offers significant advantages for B2B buyers. By focusing on high-quality, durable materials such as UV-protected polypropylene and structural foam, organizations can ensure the longevity of their irrigation systems while minimizing maintenance costs. The overlapping design of these covers not only protects critical components from environmental damage but also simplifies access for routine checks, enhancing operational efficiency.

Emphasizing the importance of sourcing from reputable manufacturers like NDS can lead to better pricing strategies and supply chain reliability. With options tailored to various applications—from residential to commercial—buyers can select the perfect fit for their needs, ensuring optimal performance.

Looking ahead, the demand for efficient irrigation solutions in emerging markets across Africa, South America, the Middle East, and Europe presents a unique opportunity. By investing in strategic sourcing now, international buyers can secure competitive advantages, foster sustainable practices, and contribute to the global push for responsible water management. Engage with trusted suppliers today to explore customized solutions that meet your specific needs and enhance your irrigation infrastructure.