Introduction: Navigating the Global Market for orbit irrigation valve box

As the global demand for efficient irrigation systems continues to rise, sourcing high-quality Orbit irrigation valve boxes has become a pivotal challenge for international B2B buyers. From protecting essential irrigation components like valves and meters to ensuring seamless installations, these products play a critical role in agricultural and landscaping applications across diverse climates. However, with varying market standards and supplier reliability, making informed purchasing decisions is more crucial than ever.

This comprehensive guide delves into the essential aspects of the Orbit irrigation valve box market, covering a range of topics including product types, applications, and supplier vetting processes. We will also explore pricing strategies and best practices for negotiating with suppliers, tailored specifically for international buyers operating in regions such as Africa, South America, the Middle East, and Europe, including countries like Vietnam and Saudi Arabia.

By equipping B2B buyers with the knowledge and tools necessary to navigate this market, this guide empowers them to make strategic decisions that enhance their irrigation projects. Whether you are a distributor, contractor, or agricultural business, understanding the nuances of the Orbit irrigation valve box will enable you to optimize your supply chain, reduce costs, and ultimately improve the efficiency of your irrigation systems.

Understanding orbit irrigation valve box Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

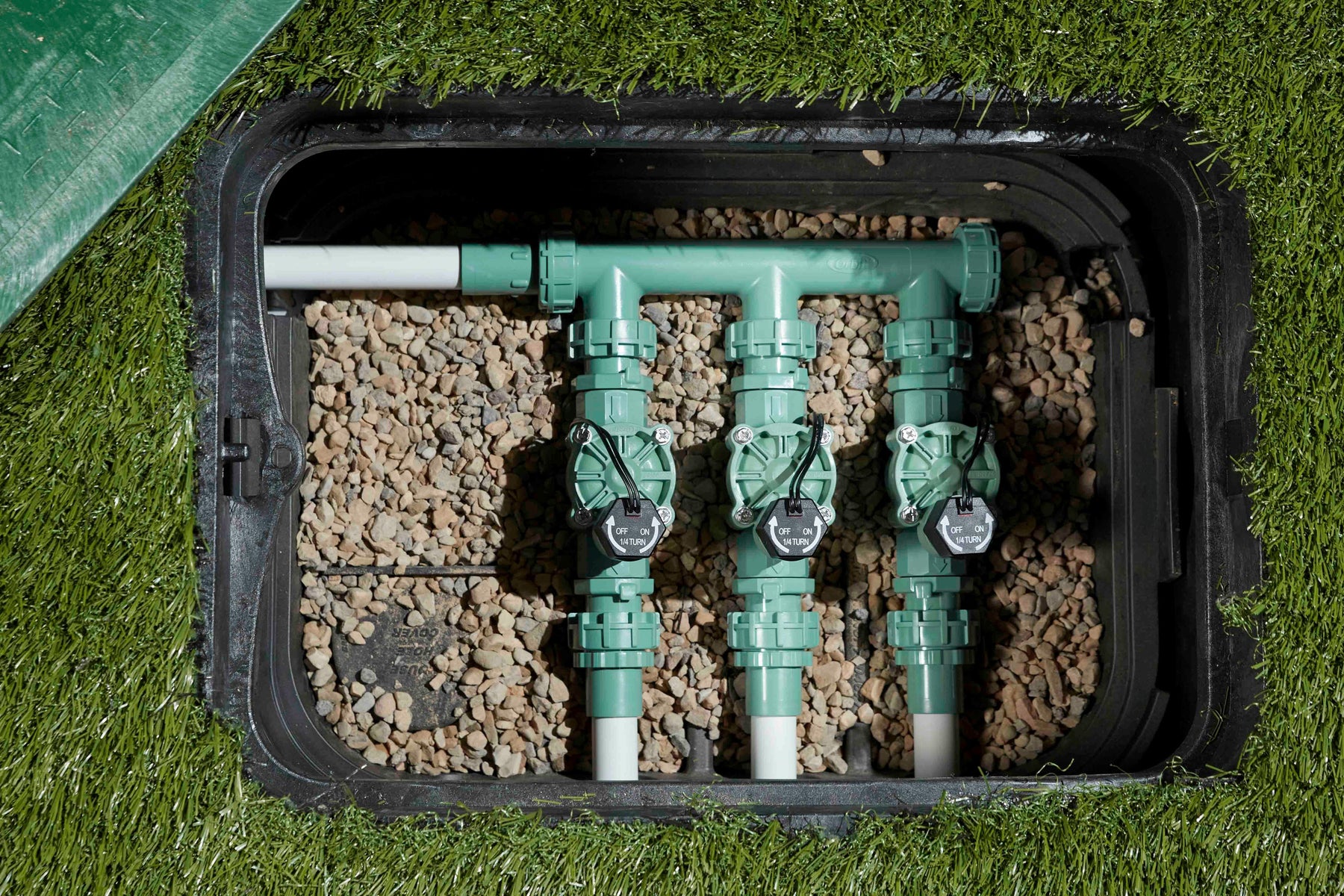

| Rectangular Sprinkler Valve Box | Heavy-duty HDPE, reinforced lid, mousehole openings for pipes | Residential and commercial irrigation | Pros: Durable, compatible with various brands. Cons: Requires gravel for drainage. |

| Valve Box Platform with Removable Windows | Snap-on design, removable slots for easy installation | Complex irrigation setups | Pros: Quick installation, no sawing needed. Cons: Limited to specific valve sizes. |

| Jumbo Valve Box | Larger dimensions, accommodates more equipment | Large-scale irrigation projects | Pros: More space for equipment, robust construction. Cons: Heavier and may require more handling. |

| Standard Valve Box | Compact design, ideal for small systems | Small residential gardens | Pros: Space-efficient, easy to install. Cons: Limited capacity for larger systems. |

| Lockable Valve Box | Security features with optional locking bolt | High-security irrigation installations | Pros: Enhanced security, protects valuable equipment. Cons: Higher cost due to security features. |

What are the Key Characteristics of the Rectangular Sprinkler Valve Box?

The Rectangular Sprinkler Valve Box is engineered from heavy-duty high-density polyethylene (HDPE), designed to withstand harsh environmental conditions such as UV exposure and freezing temperatures. Its mousehole-shaped openings allow for seamless pipe integration, making it suitable for both residential and commercial irrigation systems. When purchasing, consider compatibility with existing equipment and whether additional drainage measures, such as gravel, are needed for optimal performance.

How Does the Valve Box Platform with Removable Windows Enhance Installation?

This innovative design features removable slots that eliminate the need for cutting or sawing, significantly speeding up the installation process. It’s particularly effective for complex irrigation setups, accommodating multiple header lines. B2B buyers should evaluate the specific dimensions and compatibility with valve sizes to ensure it meets their project requirements. The ease of installation is a key selling point for contractors looking to save time and labor costs.

What Advantages Does the Jumbo Valve Box Offer for Large Projects?

The Jumbo Valve Box is tailored for larger irrigation systems, providing ample space for various components and ensuring robust protection. Its size makes it ideal for large-scale agricultural or commercial applications where multiple valves and filters are used. Buyers should consider the weight and handling requirements, as its larger dimensions may necessitate more careful installation and transport.

Why Choose the Standard Valve Box for Smaller Systems?

The Standard Valve Box is compact and designed for smaller residential gardens, making it an excellent choice for DIY projects or small-scale installations. Its space-efficient design allows for easy installation without compromising functionality. However, buyers should be mindful of its limited capacity for larger systems, ensuring it aligns with their specific irrigation needs.

What Security Benefits Does the Lockable Valve Box Provide?

The Lockable Valve Box incorporates security features, including an optional locking bolt, making it ideal for installations requiring enhanced protection against tampering or theft. This is particularly relevant for high-value irrigation systems in commercial settings. While it may come at a higher price point, the added security can justify the investment for businesses concerned about equipment safety.

Key Industrial Applications of orbit irrigation valve box

| Industry/Sector | Specific Application of Orbit Irrigation Valve Box | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Protecting irrigation control valves in large-scale farming | Ensures uninterrupted water supply, enhancing crop yield | Durability in extreme weather, compatibility with existing systems |

| Landscaping & Turf Management | Securing valves in commercial landscaping projects | Maintains aesthetics while protecting vital irrigation components | Size options, ease of installation, and resistance to UV damage |

| Municipal Water Management | Housing valves and meters in urban irrigation systems | Supports efficient water distribution in urban settings | Compliance with local regulations, availability in bulk, and reliability |

| Sports Facilities | Installation in athletic fields and parks for automated irrigation | Promotes healthy turf and reduces maintenance costs | Customization options, impact resistance, and ease of access for repairs |

| Residential Developments | Integration in residential sprinkler systems | Enhances property value and ensures efficient water usage | Compatibility with various brands, ease of installation, and security features |

How Is the Orbit Irrigation Valve Box Used in Agriculture?

In agriculture, the Orbit irrigation valve box is crucial for protecting irrigation control valves in large-scale farming operations. These boxes ensure that valves remain safe from environmental stresses such as UV rays and freezing temperatures, which can lead to system failures and crop loss. International buyers, particularly from regions with harsh climates, should prioritize sourcing options that emphasize durability and compatibility with existing irrigation systems to ensure seamless integration.

What Role Does the Orbit Irrigation Valve Box Play in Landscaping & Turf Management?

In landscaping and turf management, the Orbit irrigation valve box secures control valves and meters, maintaining the aesthetic appeal of commercial properties. By protecting these components, businesses can avoid costly repairs and ensure efficient water distribution. Buyers in this sector should consider the size and ease of installation when sourcing these boxes, as well as their resistance to UV damage to ensure longevity and performance.

How Does the Orbit Irrigation Valve Box Support Municipal Water Management?

Municipal water management systems benefit from the Orbit irrigation valve box by housing critical components like valves and meters. This application supports efficient water distribution across urban areas, helping municipalities manage resources effectively. Buyers from this sector must ensure compliance with local regulations and consider bulk purchasing options for cost-effectiveness and reliability in high-demand environments.

Why Is the Orbit Irrigation Valve Box Important for Sports Facilities?

In sports facilities, the Orbit irrigation valve box is essential for automated irrigation systems that maintain healthy turf on athletic fields and parks. By protecting valves from damage, these boxes help reduce maintenance costs and ensure consistent water supply. Key sourcing considerations for buyers include customization options to fit specific field layouts, impact resistance for heavy usage, and easy access for maintenance and repairs.

How Does the Orbit Irrigation Valve Box Enhance Residential Developments?

In residential developments, the Orbit irrigation valve box integrates into sprinkler systems, enhancing property value and ensuring efficient water usage. These boxes protect critical irrigation components from environmental damage, promoting sustainable landscaping practices. Buyers in this sector should focus on compatibility with various brands, ease of installation, and security features to safeguard their investments from vandalism or accidental damage.

3 Common User Pain Points for ‘orbit irrigation valve box’ & Their Solutions

Scenario 1: Incomplete Orders Leading to Project Delays

The Problem: One common issue faced by B2B buyers in the irrigation industry is receiving incomplete orders, particularly with components such as the Orbit irrigation valve box. This can lead to significant project delays, as contractors rely on the timely arrival of all necessary parts to complete installations. For instance, if a buyer orders both the valve box and its compatible base but only receives the box, they may have to halt work while waiting for the missing component. Such delays can increase labor costs, disrupt project timelines, and impact client satisfaction.

The Solution: To mitigate the risk of incomplete orders, B2B buyers should prioritize purchasing from reputable suppliers who have established systems for quality control and order fulfillment. When placing an order, it’s crucial to verify that all components are included, either by reviewing the order confirmation details or reaching out to customer service for clarification. Additionally, buyers can consider ordering a complete system package that includes the valve box, base, and any necessary accessories. This reduces the chances of missing parts and streamlines the procurement process, ensuring that the project remains on schedule.

Scenario 2: Difficulty in Installation and Compatibility Issues

The Problem: Another pain point is the challenge of installing the Orbit irrigation valve box due to compatibility issues with existing systems. Buyers may find themselves with a valve box that does not fit their pre-installed pipes or valves, leading to frustrating installation setbacks. This is particularly prevalent in regions with varying irrigation standards or where multiple brands are used. A buyer might assume compatibility based on product descriptions but later discover that modifications are needed, causing additional costs and labor.

The Solution: To address compatibility concerns, buyers should conduct thorough research before purchasing. This includes confirming the dimensions and specifications of both the Orbit valve box and existing systems. Consulting with suppliers for guidance on which valve box models work best with specific brands or types of pipes can provide clarity. Additionally, opting for Orbit’s integrated systems, which are designed to work seamlessly together, can help ensure compatibility. When planning installations, consider having a flexible design that allows for minor adjustments, such as using adapter fittings that can bridge gaps between different system components.

Scenario 3: Vulnerability to Environmental Damage

The Problem: Irrigation systems are often exposed to harsh environmental conditions, which can lead to damage over time. B2B buyers may experience issues with the durability of the Orbit irrigation valve box, especially in regions facing extreme temperatures or heavy rainfall. For instance, a valve box that is not adequately reinforced can crack under freezing conditions or become dislodged due to flooding, resulting in costly repairs and operational downtime.

The Solution: To combat environmental vulnerabilities, buyers should look for high-quality products specifically designed for resilience. The Orbit irrigation valve boxes made from heavy-duty high-density polyethylene (HDPE) are engineered to withstand UV exposure and freezing temperatures. Buyers should ensure they are selecting models with reinforced lids and consider adding optional locking bolts for enhanced security against impacts. Implementing best practices during installation, such as placing the valve box at grade level and using gravel for drainage, can further protect the system from environmental challenges. Regular maintenance checks are also advisable to identify potential issues before they escalate, ensuring the longevity of the irrigation setup.

Strategic Material Selection Guide for orbit irrigation valve box

What Are the Key Materials Used in Orbit Irrigation Valve Boxes?

When selecting materials for Orbit irrigation valve boxes, several factors must be considered, including durability, environmental resistance, and cost. Below is an analysis of four common materials used in the construction of these valve boxes, focusing on their properties, advantages, disadvantages, and implications for international buyers.

How Does High-Density Polyethylene (HDPE) Perform in Valve Boxes?

Key Properties:

HDPE is known for its excellent resistance to UV radiation, freezing temperatures, and general wear and tear. It has a high tensile strength and can withstand a wide range of temperatures, making it suitable for various climates.

Pros & Cons:

The primary advantage of HDPE is its durability and lightweight nature, which simplifies installation and reduces shipping costs. However, it can be more expensive than other materials, and its manufacturing process can be complex, requiring specialized equipment.

Impact on Application:

HDPE is compatible with cold water applications and is ideal for outdoor use. Its resistance to corrosion ensures that it can handle various irrigation media without degrading.

Considerations for International Buyers:

For buyers in regions like Africa and the Middle East, compliance with local standards such as ASTM or DIN is crucial. HDPE products are generally accepted globally, but verifying certifications can prevent future issues.

What Role Does Polypropylene (PP) Play in Valve Box Construction?

Key Properties:

Polypropylene is a thermoplastic polymer that offers good chemical resistance and a moderate temperature range. It is less robust than HDPE but can still withstand significant impacts.

Pros & Cons:

PP is typically more cost-effective than HDPE, making it an attractive option for budget-conscious buyers. However, its lower durability and susceptibility to UV damage can limit its lifespan in outdoor applications.

Impact on Application:

This material is suitable for environments where chemical exposure is a concern, but its performance may decline in extreme weather conditions.

Considerations for International Buyers:

Buyers from South America and Europe should ensure that PP products meet the necessary safety and environmental regulations. Understanding local preferences for material durability is also essential.

How Does PVC Compare as a Material for Valve Boxes?

Key Properties:

PVC is a rigid plastic known for its excellent chemical resistance and structural integrity. It can handle high-pressure applications and is less prone to degradation from environmental factors compared to other materials.

Pros & Cons:

The advantages of PVC include its affordability and high-performance capabilities. However, it can be brittle in cold temperatures, which may lead to cracking if not handled properly.

Impact on Application:

PVC is ideal for pressurized systems and can be used in various irrigation setups. However, its brittleness may limit its effectiveness in colder climates.

Considerations for International Buyers:

For buyers in colder regions like parts of Europe, understanding the temperature limitations of PVC is crucial. Compliance with local standards, such as JIS in Japan or DIN in Germany, is also a key consideration.

What About Metal Materials for Valve Boxes?

Key Properties:

Metal valve boxes, often made from aluminum or steel, provide exceptional strength and resistance to impact. They can handle high pressures and are less likely to degrade over time.

Pros & Cons:

Metal boxes are extremely durable and can withstand harsh conditions. However, they are heavier and more expensive than plastic alternatives, which can increase shipping costs.

Impact on Application:

Metal is suitable for high-pressure applications and environments where physical impact is a concern. However, corrosion can be an issue unless properly treated.

Considerations for International Buyers:

In regions like the Middle East, where corrosion from saltwater is a concern, buyers should ensure that metal products are treated for corrosion resistance. Compliance with international standards is also essential for quality assurance.

Summary Table of Material Selection for Orbit Irrigation Valve Boxes

| Material | Typical Use Case for orbit irrigation valve box | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High-Density Polyethylene (HDPE) | Outdoor irrigation systems | Excellent UV and temperature resistance | Higher manufacturing complexity | Medium |

| Polypropylene (PP) | Chemical exposure environments | Cost-effective | Less durable, susceptible to UV damage | Low |

| Polyvinyl Chloride (PVC) | Pressurized irrigation systems | Affordable and strong | Brittle in cold temperatures | Low |

| Metal (Aluminum/Steel) | High-pressure and impact-prone applications | Exceptional durability | Heavier and more expensive | High |

In conclusion, selecting the right material for Orbit irrigation valve boxes requires an understanding of the specific application, environmental conditions, and regional compliance standards. By considering these factors, international B2B buyers can make informed decisions that ensure the longevity and effectiveness of their irrigation systems.

In-depth Look: Manufacturing Processes and Quality Assurance for orbit irrigation valve box

What Are the Key Stages in the Manufacturing Process of Orbit Irrigation Valve Boxes?

The manufacturing of Orbit irrigation valve boxes involves several critical stages that ensure the final product meets the high standards expected by international B2B buyers.

1. Material Preparation

The primary material used for Orbit valve boxes is high-density polyethylene (HDPE), known for its durability and resistance to UV rays and freezing temperatures. The first step in the manufacturing process involves sourcing quality HDPE pellets from reputable suppliers. Quality checks on raw materials are crucial to ensure consistency and performance. Suppliers often provide certifications that confirm the material’s compliance with international standards.

2. Forming

Once the HDPE is prepared, it undergoes a forming process. This typically involves techniques such as injection molding or rotational molding, where molten HDPE is shaped into the desired form of the valve box. The choice of method depends on the specific design requirements and production volume. Injection molding is favored for its precision and ability to produce complex shapes, while rotational molding is ideal for larger, hollow structures.

3. Assembly

After forming, the various components of the valve boxes, such as lids and bases, are assembled. This stage may involve mechanical fastening, welding, or snap-fit techniques to ensure that the components fit securely and function effectively. For added security, some models come with optional locking mechanisms. The assembly process is designed to be straightforward, allowing for efficient production while maintaining high quality.

4. Finishing

The final stage involves quality checks and finishing touches. This may include the application of surface treatments to enhance UV resistance or aesthetic appeal. Additionally, the valve boxes are inspected for defects and any necessary adjustments are made. This stage ensures that all products meet the exact specifications and are ready for shipment.

What Quality Assurance Standards Are Relevant for Orbit Irrigation Valve Boxes?

Quality assurance is paramount in the manufacturing of irrigation products, especially for international markets. Orbit valve boxes adhere to several recognized international standards.

ISO 9001 Certification

ISO 9001 is a widely recognized quality management standard that ensures manufacturers maintain consistent quality in their processes. Companies with this certification demonstrate their commitment to continuous improvement and customer satisfaction. This certification is particularly important for B2B buyers seeking reliable suppliers.

CE Marking

For products sold in Europe, CE marking indicates compliance with EU safety, health, and environmental protection standards. This certification assures buyers that the valve boxes meet stringent European regulations, which is crucial for market entry.

API Standards

In specific markets, especially those involving industrial applications, adherence to American Petroleum Institute (API) standards can be critical. While primarily focused on oil and gas, certain API standards may apply to valve boxes used in irrigation systems in industrial contexts.

How Is Quality Control Implemented Throughout the Manufacturing Process?

Quality control is integrated at multiple checkpoints throughout the manufacturing process to ensure that each valve box meets the required standards.

Incoming Quality Control (IQC)

Before production begins, raw materials undergo rigorous inspections. IQC involves checking the quality of HDPE pellets and other components to ensure they meet specified standards. Any subpar materials are rejected to prevent defects in the final products.

In-Process Quality Control (IPQC)

During the manufacturing stages, IPQC is implemented to monitor processes in real-time. This includes regular inspections of the forming and assembly processes. Operators are trained to identify anomalies, and immediate corrective actions can be taken to minimize waste and maintain production efficiency.

Final Quality Control (FQC)

Once the valve boxes are fully assembled, FQC is conducted. This final inspection checks for structural integrity, aesthetic quality, and functionality. Any boxes that do not meet the stringent quality standards are either reworked or scrapped.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers need to ensure their suppliers maintain robust quality control measures. Here are effective ways to verify supplier QC practices:

Supplier Audits

Conducting audits of potential suppliers can provide insight into their manufacturing processes and quality control measures. An on-site visit allows buyers to assess compliance with international standards and to observe the quality management systems in place.

Quality Reports

Requesting detailed quality reports from suppliers can also help verify their commitment to quality. These reports should include information on IQC, IPQC, and FQC processes, as well as statistical data on defect rates and corrective actions taken.

Third-Party Inspections

Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control practices. These agencies can perform inspections at various stages of production and provide certifications that verify compliance with international standards.

What Are the QC and Certification Nuances for International B2B Buyers?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, understanding QC and certification nuances is essential.

Regional Compliance

Each region may have specific compliance requirements. For instance, products sold in the EU must meet CE standards, while buyers in the Middle East may require compliance with local regulations. Understanding these nuances is crucial for successful market entry.

Supply Chain Transparency

Buyers should seek suppliers who offer transparency in their supply chains. This includes traceability of materials and adherence to ethical sourcing practices. Suppliers that openly share their quality control processes and certifications build trust and credibility.

Cultural Considerations

Cultural differences can impact business negotiations and expectations regarding quality. Buyers should be aware of these factors and establish clear communication regarding quality standards and certifications needed for their specific markets.

In conclusion, Orbit irrigation valve boxes are manufactured through a rigorous process that emphasizes quality at every stage. By understanding the manufacturing techniques and quality assurance standards, B2B buyers can make informed decisions and ensure they partner with reliable suppliers who meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘orbit irrigation valve box’

In today’s competitive landscape, sourcing high-quality irrigation components like the Orbit irrigation valve box is essential for achieving efficient water management in agricultural and landscaping projects. This guide provides a systematic approach to help B2B buyers make informed procurement decisions.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clarify the technical requirements for the Orbit irrigation valve box. Consider factors such as size, material, and compatibility with existing systems. For instance, whether you need a standard 12-inch box or a jumbo 20-inch version will significantly impact your choices.

Step 2: Research Reliable Suppliers

Identifying trustworthy suppliers is crucial for ensuring product quality and reliable delivery. Look for suppliers with a strong track record in the irrigation industry, particularly those that specialize in products compatible with Orbit systems. Utilize platforms like trade shows, industry forums, and online marketplaces to gather potential options.

Step 3: Evaluate Supplier Certifications

Verify that your chosen suppliers possess the necessary certifications and compliance with international standards. This includes ISO certifications or other relevant quality assurance certifications. Such credentials are indicators of a supplier’s commitment to quality and can reduce risks associated with procurement.

Step 4: Request Detailed Product Information

Engage with suppliers to obtain comprehensive product specifications, including material composition and performance ratings. For example, ensure that the valve boxes are made from heavy-duty HDPE to withstand environmental stressors like UV exposure and freezing temperatures. This information is vital to ascertain the longevity and reliability of the products.

Step 5: Compare Pricing and Terms of Sale

Price should not be the only determining factor, but it is essential to compare costs among different suppliers. Look for transparent pricing models that include shipping and handling fees. Additionally, inquire about payment terms, bulk purchase discounts, and return policies, as these can significantly impact your overall costs.

Step 6: Check Customer Reviews and Testimonials

Investigate customer feedback on potential suppliers and their products. Look for reviews that discuss the durability and performance of the Orbit irrigation valve boxes in various applications. Testimonials from businesses in similar regions or industries can provide insights into the supplier’s reliability and product quality.

Step 7: Finalize Your Order and Establish Communication

Once you have selected a supplier, finalize your order while ensuring clear communication regarding delivery timelines and product specifications. Establish a point of contact for any queries or issues that may arise during the transaction. This proactive approach can help mitigate potential challenges and foster a long-term business relationship.

By following this checklist, B2B buyers can navigate the complexities of sourcing Orbit irrigation valve boxes effectively, ensuring they secure high-quality products that meet their operational needs.

Comprehensive Cost and Pricing Analysis for orbit irrigation valve box Sourcing

What are the Key Cost Components in Sourcing Orbit Irrigation Valve Boxes?

Understanding the cost structure of Orbit irrigation valve boxes is essential for B2B buyers looking to make informed purchasing decisions. The primary cost components include:

Materials: The primary material used for these valve boxes is high-density polyethylene (HDPE), known for its durability and resistance to UV light and freezing temperatures. The quality of materials can significantly impact costs, especially if sourcing from suppliers that prioritize eco-friendly production.

Labor: Labor costs can vary widely depending on the manufacturing location. For instance, labor rates in Southeast Asia may differ from those in Europe or Africa. This variability affects not just direct labor costs, but also the overall pricing strategy of manufacturers.

Manufacturing Overhead: This includes utilities, rent, and other operational costs associated with production facilities. Efficient manufacturing processes can help reduce overhead, which is beneficial in competitive pricing.

Tooling: Initial costs for molds and other manufacturing tools can be significant, especially for customized valve boxes. Buyers should consider these costs when evaluating pricing, as they can be amortized over larger production runs.

Quality Control (QC): Ensuring that each valve box meets international quality standards incurs additional costs. However, investing in quality control can reduce returns and enhance customer satisfaction, translating to long-term savings.

Logistics: Shipping costs can vary based on the destination, mode of transport, and freight terms. International buyers must account for these factors, as logistics can significantly influence the total cost.

Margin: Manufacturers typically include a profit margin in their pricing. Understanding the standard margins in the industry can provide leverage during negotiations.

What Influences Pricing for Orbit Irrigation Valve Boxes?

Several factors can affect the pricing of Orbit irrigation valve boxes:

Volume/MOQ: Higher order volumes often lead to lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) to achieve better pricing.

Specifications and Customization: Customized valve boxes with specific dimensions or features may incur additional costs. Buyers should clearly define their requirements to avoid unexpected charges.

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (like ISO) can affect pricing. Buyers seeking higher quality or eco-friendly options should be prepared for increased costs.

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but offer better quality assurance and customer support.

Incoterms: The terms of shipping and delivery (e.g., FOB, CIF) can impact the final cost. Buyers should understand these terms to evaluate total landed costs effectively.

What Tips Can Help Buyers Negotiate Better Prices?

Leverage Volume Discounts: Always inquire about discounts for bulk purchases. If a buyer can consolidate orders, they may unlock significant savings.

Assess Total Cost of Ownership: Consider not just the purchase price but also installation, maintenance, and potential replacement costs. A slightly higher upfront cost may lead to lower long-term expenses if the product is of superior quality.

Research Pricing Nuances in International Markets: Pricing strategies can vary by region. Buyers in Africa, South America, the Middle East, and Europe should familiarize themselves with local market conditions to negotiate effectively.

Build Strong Supplier Relationships: Establishing long-term relationships with suppliers can lead to better pricing, exclusive deals, and priority service.

Be Aware of Currency Fluctuations: For international purchases, currency exchange rates can impact pricing. Buyers should consider locking in rates or negotiating terms that account for fluctuations.

Disclaimer on Indicative Prices

Prices for Orbit irrigation valve boxes can vary based on multiple factors, including market conditions, supplier agreements, and specific buyer requirements. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing orbit irrigation valve box With Other Solutions

Exploring Alternatives to the Orbit Irrigation Valve Box

In the irrigation industry, selecting the right valve box is crucial for ensuring the longevity and efficiency of your irrigation system. While the Orbit irrigation valve box offers a robust solution, it’s important for B2B buyers to consider alternative products that might better suit specific needs or budgets. This section compares the Orbit irrigation valve box with two viable alternatives: the Rain Bird Valve Box and the Hunter Industries Valve Box.

Comparison Table

| Comparison Aspect | Orbit Irrigation Valve Box | Rain Bird Valve Box | Hunter Industries Valve Box |

|---|---|---|---|

| Performance | Durable HDPE, UV & frost resistant | Strong, weather-resistant polymer | UV-resistant, designed for heavy-duty use |

| Cost | $39.99 | $35.00 | $40.00 |

| Ease of Implementation | Simple installation, mousehole openings for pipes | Requires basic tools but straightforward | Quick installation, fits standard sizes |

| Maintenance | Low maintenance, easy access | Low maintenance, accessible design | Low maintenance, durable structure |

| Best Use Case | Residential and light commercial use | Suitable for residential and commercial applications | Ideal for commercial and agricultural settings |

In-Depth Analysis of Alternatives

Rain Bird Valve Box

The Rain Bird Valve Box is a strong competitor in the irrigation market, offering a weather-resistant polymer construction that ensures durability. It is priced at approximately $35.00, making it a budget-friendly alternative to the Orbit valve box. Installation is straightforward, though it requires basic tools. This valve box is particularly effective for both residential and commercial applications, providing reliable protection for irrigation components. However, some users have reported that while it is durable, it may not withstand extreme conditions as well as the Orbit box.

Hunter Industries Valve Box

Hunter Industries offers a valve box priced at around $40.00, known for its UV-resistant materials and heavy-duty construction. It is designed for quick installation and fits standard sizes, which makes it a convenient option for many irrigation setups. This box is well-suited for commercial and agricultural environments, where robustness is crucial. One downside is that its cost is slightly higher than the Orbit and Rain Bird options, which may be a consideration for budget-conscious buyers. Additionally, while its durability is an asset, the weight of the material can make it slightly more challenging to handle during installation.

Conclusion: How to Choose the Right Valve Box for Your Needs

When selecting the right valve box, B2B buyers should evaluate their specific requirements, including budget, installation environment, and the expected durability of the product. The Orbit irrigation valve box excels in residential applications with its user-friendly design and robust construction. However, for buyers focused on cost-effectiveness or specific environmental conditions, the Rain Bird or Hunter Industries valve boxes may offer better alternatives. Ultimately, the decision should be guided by a thorough assessment of performance, cost, and maintenance needs to ensure the chosen solution aligns with operational objectives and project demands.

Essential Technical Properties and Trade Terminology for orbit irrigation valve box

What Are the Key Technical Properties of Orbit Irrigation Valve Boxes?

When considering the purchase of Orbit irrigation valve boxes, understanding their technical specifications is crucial for ensuring compatibility and durability in various irrigation systems. Here are several essential properties:

Material Grade (HDPE)

High-Density Polyethylene (HDPE) is the primary material used in Orbit valve boxes. This material is chosen for its exceptional strength and resistance to environmental factors like UV rays and freezing temperatures. For B2B buyers, opting for HDPE ensures longevity and reduces replacement frequency, contributing to lower overall operational costs.Size Specifications

Orbit offers various sizes, such as the 12-inch standard and the 20-inch jumbo valve boxes. The size directly impacts the amount and type of equipment that can be housed within the box. Selecting the appropriate size is crucial for accommodating specific valves, meters, and filters, which ensures efficient irrigation management.Load Capacity

The reinforced lids of Orbit valve boxes are designed to withstand significant impact forces. This load capacity is essential for locations with heavy foot or vehicular traffic. Understanding this property helps buyers assess whether the valve box will maintain its integrity in high-traffic areas, thereby preventing damage to the internal components.Pipe Accommodation (Mousehole Openings)

The mousehole-shaped openings at the bottom of the valve boxes allow for the passage of pipes up to 2 inches in diameter without cutting. This feature simplifies installation and reduces labor time, making it a vital consideration for B2B buyers who prioritize efficiency and ease of use in their operations.Installation Compatibility

Compatibility with other major brands, such as Hydro-Rain, is a significant property. This ensures that the Orbit valve boxes can integrate seamlessly into existing systems without requiring extensive modifications. For international buyers, this versatility is important for maintaining existing infrastructure while upgrading components.

What Are Common Trade Terms in the Irrigation Industry?

Understanding trade terminology is essential for effective communication and negotiation in the irrigation industry. Here are several key terms relevant to Orbit irrigation valve boxes:

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of Orbit products, knowing the OEM can help buyers ensure they are sourcing high-quality components that meet industry standards.MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers as it impacts inventory management and upfront costs. Buyers should negotiate MOQs that align with their operational needs and storage capabilities.RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products. For B2B buyers, submitting an RFQ can lead to better pricing and terms, especially when purchasing large quantities of Orbit valve boxes.Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, particularly concerning shipping and delivery. Familiarity with Incoterms helps B2B buyers understand their obligations and rights, ensuring clarity in the procurement process.Lead Time

Lead time refers to the time taken from placing an order to its delivery. For irrigation systems that rely on timely installations, understanding lead times can help B2B buyers plan projects effectively and avoid operational delays.Warranty Period

The warranty period specifies the duration during which the manufacturer will repair or replace defective products. This term is critical for B2B buyers as it reflects the manufacturer’s confidence in product quality and provides assurance against potential failures.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make informed decisions that enhance the efficiency and reliability of their irrigation systems.

Navigating Market Dynamics and Sourcing Trends in the orbit irrigation valve box Sector

What Are the Current Market Dynamics and Key Trends in the Orbit Irrigation Valve Box Sector?

The global market for irrigation products, including the Orbit irrigation valve box, is being shaped by several key drivers. Increasing agricultural demands, particularly in regions such as Africa and South America, are pushing the need for efficient water management systems. Technological advancements in irrigation technology, such as smart controllers and automation, are gaining traction. This trend is particularly relevant for international B2B buyers looking for integrated solutions that enhance efficiency and reduce water wastage.

Emerging B2B sourcing trends are also influencing the market landscape. E-commerce platforms are streamlining procurement processes, allowing buyers to access a wider range of products and suppliers, thereby enhancing competition. Additionally, the shift towards just-in-time inventory management is prompting manufacturers to maintain higher levels of stock and quicker shipping options. Buyers from the Middle East and Europe are increasingly seeking products that offer durability and ease of installation, such as those made from high-density polyethylene (HDPE), which is known for its resistance to UV rays and extreme temperatures.

In summary, international B2B buyers should prioritize suppliers that offer innovative, durable products and emphasize quick delivery and strong customer support. Understanding local market dynamics, such as regulatory requirements and environmental considerations, will also be crucial for successful sourcing.

How Important Is Sustainability and Ethical Sourcing in the Orbit Irrigation Valve Box Sector?

Sustainability is becoming a focal point for B2B buyers in the irrigation sector. The environmental impact of manufacturing processes, particularly in the production of plastic components like the Orbit irrigation valve box, is under scrutiny. Buyers are increasingly prioritizing suppliers who adopt eco-friendly practices, including the use of recycled materials and energy-efficient manufacturing processes.

The importance of ethical supply chains cannot be overstated. International buyers are looking for manufacturers who are transparent about their sourcing practices and labor conditions. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming significant factors in the decision-making process, as they provide assurance of a supplier’s commitment to sustainability.

In addition, the demand for “green” certifications is growing among consumers and businesses alike. Suppliers who offer products made from sustainable materials, such as biodegradable plastics or recycled HDPE, are more likely to attract environmentally conscious buyers. Therefore, B2B buyers should evaluate potential suppliers based on their sustainability credentials, as this can enhance their own brand reputation and align with corporate social responsibility goals.

What Is the Brief Evolution and History of the Orbit Irrigation Valve Box Sector?

The Orbit irrigation valve box sector has seen significant evolution since its inception. Initially designed to protect manual irrigation controls, these valve boxes have transformed to accommodate advanced irrigation technologies, including automated systems. The introduction of materials like HDPE has revolutionized the durability and functionality of valve boxes, enabling them to withstand harsh weather conditions and extend the lifespan of irrigation systems.

As demand for efficient water management solutions has grown, the design of valve boxes has also advanced. Innovations such as removable pipe windows and mousehole-shaped openings have simplified installation processes, making it easier for contractors and end-users to set up complex irrigation systems. This adaptability has solidified Orbit’s position as a leader in the sector, catering to the diverse needs of international markets, particularly in regions facing water scarcity challenges.

Frequently Asked Questions (FAQs) for B2B Buyers of orbit irrigation valve box

How do I choose the right size of Orbit irrigation valve box for my project?

Choosing the correct size of an Orbit irrigation valve box is essential for optimal system performance. Start by assessing the dimensions of your valves and other components that need protection. The standard 12-inch and jumbo 20-inch options cater to different requirements. Ensure that the selected box accommodates all necessary equipment, including pipes and fittings, while allowing for proper drainage and installation ease. Additionally, consider the environment—areas prone to heavy rainfall may require a larger size for effective water management.What materials are used in Orbit irrigation valve boxes, and why are they important?

Orbit irrigation valve boxes are constructed from heavy-duty high-density polyethylene (HDPE), which offers superior durability and resistance to UV rays, freezing temperatures, and impact. This material is crucial for maintaining the integrity of the box over time, especially in harsh climates typical in regions like Africa or the Middle East. The robust nature of HDPE ensures that your irrigation components remain protected, ultimately extending the lifespan of your irrigation system and reducing maintenance costs.What are the benefits of using a reinforced lid with an optional locking bolt?

The reinforced lid of Orbit valve boxes enhances impact resistance, ensuring that the internal components are protected from accidental damage. The optional locking bolt adds an extra layer of security, which is particularly beneficial for commercial installations in areas prone to vandalism or theft. This feature not only safeguards your investment but also provides peace of mind that your irrigation system is secure, even in less monitored environments.What payment terms should I expect when sourcing Orbit irrigation valve boxes internationally?

Payment terms can vary significantly depending on the supplier and the scale of your order. Common practices include upfront payment, partial payment upon order confirmation, and balance payment before shipment. For larger orders, you might negotiate terms such as net 30 or net 60 days post-delivery. Always clarify these terms upfront and consider using secure payment methods that offer buyer protection to mitigate risks associated with international transactions.What is the minimum order quantity (MOQ) for Orbit irrigation valve boxes?

The minimum order quantity (MOQ) for Orbit irrigation valve boxes typically depends on the supplier and the specific product line. Generally, MOQs can range from a few units to several dozen. It’s advisable to discuss your needs with potential suppliers to negotiate favorable terms, especially if you are a smaller business or just starting in the irrigation sector. Establishing a good relationship with suppliers can also lead to more flexible MOQ arrangements in the future.How can I ensure the quality of the Orbit irrigation valve boxes I source?

To ensure the quality of Orbit irrigation valve boxes, request product samples before placing a larger order. Verify that the boxes meet international quality standards, and check for certifications that indicate compliance with industry regulations. Additionally, consider conducting supplier audits or checking reviews and testimonials from other buyers. Establishing a clear quality assurance process, including inspection upon delivery, can help mitigate potential issues before they impact your operations.What logistics considerations should I keep in mind when importing Orbit irrigation valve boxes?

When importing Orbit irrigation valve boxes, consider factors such as shipping costs, customs duties, and delivery timelines. Work with a reliable logistics partner who understands the complexities of international shipping, especially in regions with varying import regulations. Be aware of potential delays at customs and ensure all necessary documentation is prepared in advance. Planning for these logistics challenges can help streamline the process and avoid disruptions to your supply chain.Can I customize the Orbit irrigation valve boxes for my specific needs?

Customization options for Orbit irrigation valve boxes depend on the supplier. Many manufacturers offer branding options, specific sizes, or modifications to fit unique installation requirements. If you have special needs, communicate them clearly to the supplier during the initial discussions. Custom orders might involve additional costs and longer lead times, so be sure to factor these elements into your project planning to ensure timely delivery and satisfaction with the final product.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 3 Orbit Irrigation Valve Box Manufacturers & Suppliers List

1. Orbit – Valve Box

Domain: plumbersstock.com

Registered: 2007 (18 years)

Introduction: {“Manufacturer”: “Orbit”, “Product”: “Valve Box”, “Color”: “Black”, “Material”: “HDPE”, “Shape”: “Rectangle”, “Width”: “16-3/4\””, “Height”: “3-3/4\””, “Weight”: “1 LB”, “SKU”: “67592”, “MPN”: “53230”, “Shipping Dimensions”: “22.5 \” x 17.0 \” x 4.0 \””, “Shipping Weight”: “1.00 lbs.”, “Shipping Dimensional Weight”: “8.68 lbs.”, “Availability”: “In Stock and Ready to Ship”, “Price”: “$23.60 / ea”,…

2. Big Frog Supply – Valve Boxes & Covers

Domain: bigfrogsupply.com

Registered: 2014 (11 years)

Introduction: This company, Big Frog Supply – Valve Boxes & Covers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Verdian Power – Valve Box Installation Guide

Domain: verdianpower.com

Registered: 2023 (2 years)

Introduction: This company, Verdian Power – Valve Box Installation Guide, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for orbit irrigation valve box

In the competitive landscape of irrigation solutions, the Orbit irrigation valve box stands out as a robust choice for international B2B buyers. Engineered from high-density polyethylene (HDPE), these valve boxes offer unmatched durability, protecting vital irrigation components from environmental stresses such as UV exposure and freezing temperatures. The strategic sourcing of these products not only ensures quality but also optimizes operational efficiency, making installation seamless and reliable.

For businesses in regions such as Africa, South America, the Middle East, and Europe, choosing the right irrigation infrastructure is critical. By leveraging the benefits of the Orbit valve box, companies can enhance their irrigation systems, reducing maintenance costs and increasing the longevity of their equipment. Moreover, the compatibility with various brands facilitates a flexible approach to sourcing, allowing businesses to tailor solutions to specific project needs.

As the global demand for efficient irrigation solutions continues to grow, now is the time for international buyers to invest in high-quality products like the Orbit irrigation valve box. Embrace the future of irrigation management and ensure your projects are equipped with the best technology available. Reach out today to explore your sourcing options and elevate your irrigation systems to new heights.