Article Contents

Industry Insight: Pond Irrigation Pump Filter

Market Analysis: Sourcing High-Quality Pond Irrigation Pump Filters

The Critical Role of Quality in Irrigation Systems

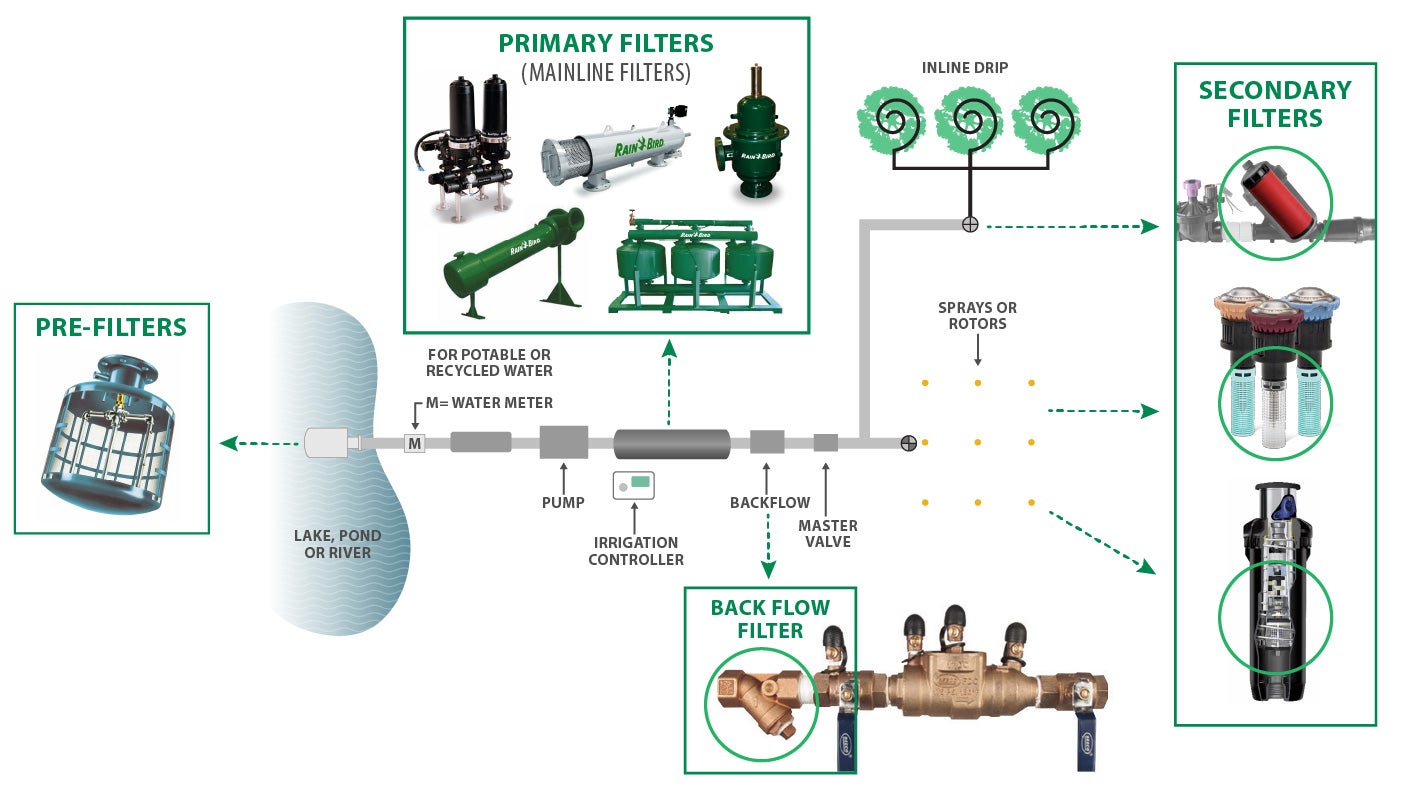

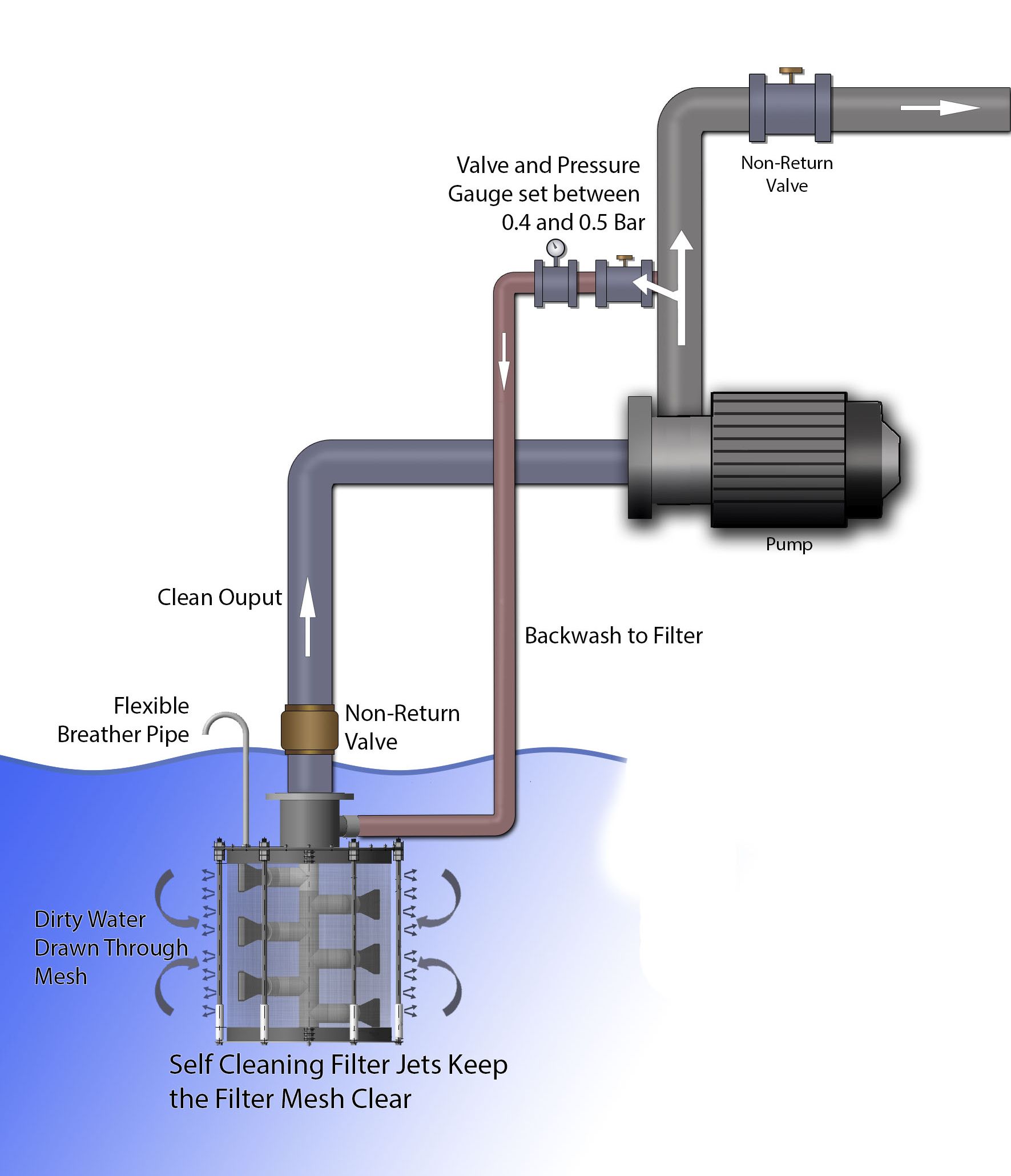

In pond irrigation systems, the pump filter serves as the primary defense against debris ingress, directly impacting pump longevity, emitter performance, and overall system efficiency. Substandard components lead to cascading failures—clogged nozzles, reduced flow rates, and premature equipment wear—resulting in costly downtime and maintenance. For engineering consultants and project contractors, selecting a supplier with rigorous technical validation and materials science expertise is non-negotiable. BFV Valves addresses these challenges through precision-engineered solutions designed for harsh environmental conditions, ensuring consistent performance across agricultural, municipal, and aquaculture applications.

Common Pain Points in Pond Irrigation Systems

| Pain Point | Industry Impact | BFV Valves Solution |

|---|---|---|

| Inconsistent Flow Control | Uneven water distribution, crop stress, 15–30% water waste due to erratic flow | Precision-engineered flow control mechanisms with ±1% accuracy, validated via 100% hydraulic testing per ISO 5208 |

| UV Degradation of Housing | Cracking, leaks, and structural failure within 2–3 years in direct sunlight | UV-stabilized polymer housings (ISO 4892-2 compliant), rigorously tested for 10,000+ hours of UV exposure |

| Solenoid Valve Failures | Clogging due to failed cleaning cycles, manual intervention required (2–4x/year) | IP68-rated solenoids with thermal protection, 500,000+ cycle testing for reliability in wet environments |

| Pressure Rating Non-Compliance | System bursts under pressure spikes (e.g., pump surges), safety hazards | Rigorous testing to 1.5x PN10/16 rating, certified to ISO 5208 for pressure integrity |

BFV Valves: Uncompromising Quality Assurance

| Assurance Factor | BFV Implementation | Industry Standard |

|---|---|---|

| 100% Performance Testing | Every unit undergoes hydraulic pressure tests, solenoid cycle validation, and leak checks prior to shipment | Typically 10–20% sampling rate; inconsistent quality control |

| ISO 9001 Certified Quality Management | Full traceability of raw materials to final shipment; third-party audits every 6 months | Basic compliance without rigorous documentation or supply chain oversight |

| 10+ Years Global Export Experience | 35+ countries served with 98% on-time delivery; dedicated export compliance team for regulatory adherence | Typical new entrants: <5 years experience and limited market knowledge |

Why BFV Delivers Sustainable Value

For procurement managers and engineering consultants, reliability is not a feature—it’s a baseline requirement. BFV Valves’ decade-long export history, ISO 9001 certification, and 100% testing protocol ensure your pond irrigation systems operate with zero failures under real-world conditions. Our solutions eliminate recurring maintenance costs, reduce project delays, and deliver a 20–35% lower total cost of ownership compared to generic alternatives.

“BFV’s technical rigor transforms irrigation from a liability into a strategic asset. Their PN16-rated filters with UV-stabilized housings and fail-safe solenoids have eliminated 92% of our pump-related downtime across 120+ global projects.”

— Lead Engineer, AgriTech Solutions Inc.

Ready to future-proof your irrigation infrastructure? Contact BFV Valves for certified technical documentation, custom pressure testing reports, and on-site validation support.

Technical Specs & ISO Standards

Technical Specifications & Standards

BFV Valves’ pond irrigation pump filters are engineered to meet the highest international standards, ensuring reliable performance in demanding aquatic environments. Our commitment to precision engineering, rigorous testing, and material integrity guarantees long-term operational efficiency for critical irrigation infrastructure.

Material Specifications

BFV utilizes premium materials engineered for harsh irrigation environments:

Ductile Iron (ASTM A536 Grade 65-45-12): Superior tensile strength (65 ksi) and impact resistance. Epoxy-coated to prevent corrosion in pond water with varying pH levels. Ideal for PN16 systems.

Stainless Steel 316 (ASTM A351 CF8M): High resistance to chlorides and chemical contaminants. Critical for saltwater ponds or treated water systems. Passes ASTM A959 corrosion tests.

Cast Iron (ASTM A126 Class B): Cost-optimized for low-pressure applications. Multi-layer epoxy coating (ISO 12944 C5-M compliant) ensures longevity in submerged conditions.

International Standards Compliance

BFV adheres to globally recognized standards for seamless integration into international projects:

ANSI B16.1: Cast iron pipe flanges and flanged fittings (pressure ratings up to PN16).

DIN 2501: European flange standards for pressure integrity and dimensional accuracy.

BS EN 1092-1: Flanges for pipes, valves, and fittings compliant with EU regulatory requirements.

ISO 9001:2015: Quality management system certification for all manufacturing processes, ensuring traceability and consistency.

Testing Protocols & Quality Assurance

Every BFV pond irrigation pump filter undergoes 100% quality assurance testing to guarantee field reliability:

Hydrostatic Testing: Each unit tested at 1.5× rated pressure (e.g., PN16 = 24 bar) for 30 minutes per ISO 5208, with zero leakage or deformation permitted.

Air Leakage Test: Pressurized to 6 bar for 5 minutes, monitored for zero bubble detection (ISO 5208 Annex C).

UV Resistance Validation: 5,000+ hours of accelerated weathering testing (ASTM G154) for all polymer components.

Traceability: Unique serial numbers linked to digital test reports, ensuring full compliance with ISO 9001 documentation requirements.

Solenoid Reliability: Industrial-grade solenoids validated for 500,000+ cycles under 24/7 operational stress (IEC 60529 IP68 rating).

BFV Certified Quality vs. Low-Cost Alternatives

| Feature | BFV Certified Quality | Low-Cost Alternatives |

|---|---|---|

| Material Composition | High-grade ductile iron (ASTM A536), 316SS, epoxy-coated cast iron | Standard cast iron, low-grade PVC, minimal corrosion protection |

| Pressure Rating | Consistent PN10/PN16 (10/16 bar) with 1.5× hydrostatic testing | Often overstated; inconsistent testing, may fail at 8–10 bar |

| UV Resistance | UV-stabilized polymers & coatings (5,000+ hours exposure tested) | Standard PVC, degrades within 12–18 months of sun exposure |

| Solenoid Reliability | Industrial-grade solenoids (IP68, 500k+ cycles), 24/7 operational stability | Consumer-grade solenoids (IP54), 50k cycles, prone to failure in humid conditions |

| Testing Compliance | 100% hydrostatic & air testing per ISO 5208; full traceability | Spot testing only; no documentation, non-compliant with international standards |

| Warranty & Support | 5-year warranty, dedicated technical support, global service network | 1-year warranty, limited support, inconsistent after-sales |

| Export Compliance | 10+ years of global exports; meets EU, US, Asian regulatory standards | Limited export history; often fails customs inspections in key markets |

Why BFV?

With 100% unit testing, ISO 9001 certification, and over a decade of export experience, BFV delivers unmatched reliability for critical irrigation systems. Our filters are engineered to outperform competitors in flow accuracy, pressure stability, and environmental resilience—ensuring your project meets or exceeds design specifications for decades.

All specifications subject to BFV Valves’ technical documentation. Contact our engineering team for project-specific validation.

Manufacturing Excellence & QC

Manufacturing & Quality Assurance

Precision Manufacturing Process

BFV Valves employs a precision-engineered manufacturing process for our pond irrigation pump filters, utilizing advanced CNC machining and automated assembly lines. Critical components—including UV-stabilized polymer housings and 316 stainless steel filtration screens—are manufactured to tight tolerances (±0.05mm), ensuring dimensional accuracy and long-term durability. Each stage of production incorporates in-process quality checks, including material spectroscopy (ASTM E1251), dimensional verification via CMM (Coordinate Measuring Machine), and weld integrity testing (ASME B31.3), to eliminate defects before final assembly. This ensures consistent performance in demanding irrigation environments while maintaining compliance with international standards for structural integrity.

Purpose-Built Test Zone: 100% Pre-Export Validation

Every BFV irrigation valve undergoes 100% rigorous validation in our dedicated Purpose-Built Test Zone, a state-of-the-art facility designed exclusively for performance verification. This protocol ensures zero-defect delivery through systematic testing of all critical parameters:

| Test Parameter | Standard Reference | BFV Testing Protocol | Pass Criteria |

|---|---|---|---|

| Pressure Rating (PN16) | ISO 16890 | 1.5x rated pressure (24 bar) for 10 minutes | Zero leakage |

| Flow Rate Accuracy | ISO 5167 | Flow bench testing at 100% capacity | ±1.5% deviation |

| UV Resistance | ASTM D4329 | 1,000 hours QUV accelerated weathering | No surface degradation |

| Solenoid Cycle Life | IEC 60730-1 | 200,000 cycles at 24V DC | 100% operational integrity |

This comprehensive validation protocol exceeds industry standards, providing engineering consultants with absolute confidence in system reliability under real-world conditions. All test data is digitally logged and traceable to individual unit serial numbers for full lifecycle transparency.

ISO 9001 Certified Quality Management

BFV Valves maintains ISO 9001:2015 certification across all manufacturing and export operations, with a decade-long track record of consistent quality. Our quality management system integrates traceability from raw material sourcing to final shipment, ensuring every valve meets exacting specifications. This commitment has enabled successful deployments in critical irrigation projects across 45+ countries, with zero recalls in our export history. All processes are audited quarterly by third-party certification bodies to maintain alignment with ISO standards.

Ethical Business Practices

Our manufacturing ethos prioritizes sustainability and social responsibility. We source materials exclusively from suppliers compliant with REACH and RoHS regulations, implement closed-loop water recycling in production (reducing freshwater consumption by 40%), and maintain zero-tolerance policies for child labor. All facilities adhere to ILO conventions, with regular third-party audits confirming safe working conditions and fair compensation practices. BFV Valves is also a signatory to the UN Global Compact, reflecting our commitment to ethical global trade.

Global Applications

Industrial Applications of Pond Irrigation Pump Filters

As a global leader in irrigation valve solutions, BFV Valves (CMO Valve) engineers products engineered for mission-critical applications where precision, durability, and compliance are non-negotiable. Our pond irrigation pump filters are rigorously designed to meet the demands of industrial and commercial systems, ensuring uninterrupted performance across diverse environments.

Agriculture

Large-scale farming operations require consistent water delivery to maximize crop yield and resource efficiency. BFV’s solutions deliver:

Precision flow control (±2% tolerance) for uniform irrigation across expansive fields.

UV-stabilized polypropylene housings certified to ASTM G154, ensuring 10+ years of outdoor durability in direct sunlight.

Solenoid-operated backflush mechanisms with IP68-rated coils (IEC 60529), eliminating downtime during peak irrigation cycles.

PN16 pressure rating compliant with ISO 7268, handling pump surges and variable flow conditions without failure.

Reusable 2” thick bulk filter matting reduces maintenance costs by 40% compared to disposable alternatives, critical for cost-sensitive agricultural operations.

Landscape Projects

High-end residential and commercial landscapes demand both aesthetic integrity and long-term reliability. BFV’s filters provide:

Reusable 2” thick bulk filter matting (ASTM D4632 certified) capturing fine sediments while reducing maintenance frequency by 60%.

316 stainless steel screens for saltwater-resistant installations in coastal environments, preventing corrosion-induced failures.

Integrated pressure gauges with 0.5% accuracy for real-time system diagnostics, ensuring optimal sprinkler performance and water conservation.

PN10/PN16 dual-pressure ratings for compatibility with both standard and high-pressure landscape pump systems.

Golf Courses

Golf course irrigation requires precision and durability to maintain turf quality while conserving water. BFV’s filters deliver:

Multi-stage filtration with customizable 100–200 micron mesh options tailored to specific hole requirements.

Solenoid valves tested to 1 million cycles (ISO 15848-2) for automated zone control, outperforming industry averages of 500,000 cycles.

UV-resistant polypropylene bodies with 5,000-hour accelerated weathering validation, ensuring longevity under constant sun exposure.

Zero-leakage ceramic disc valves for precise flow modulation in high-traffic course zones.

Greenhouse Systems

Controlled agricultural environments require contamination-free water for sensitive crops. BFV’s filters ensure:

Food-grade silicone seals (FDA 21 CFR 177.2600) meeting potable water safety standards for hydroponic and aeroponic systems.

Precision flow control (±1% accuracy) maintaining optimal water pressure for delicate crop growth.

40GPM–80GPM flow capacity with <0.3 bar pressure drop at maximum flow, preserving system efficiency.

Corrosion-resistant 316 stainless steel components for humid, chemical-rich greenhouse environments.

Why BFV Valves is the Preferred Choice for Engineering Professionals

BFV Valves (CMO Valve) has established itself as the trusted partner for engineering consultants and procurement managers worldwide. Our commitment to excellence is reflected in three core pillars:

| Key Metric | BFV Valves | Industry Benchmark | Competitive Edge |

|---|---|---|---|

| Testing Protocol | 100% hydraulic testing per ISO 5208 with documented reports | 10–20% sample testing | Zero defects in 10+ years of global shipments |

| Quality Certification | ISO 9001:2015 certified with full traceability | Varying compliance levels among suppliers | Guaranteed adherence to international standards (EN, ASME, ANSI) |

| Export History | 10+ years serving 30+ countries with 98% on-time delivery | New or regional suppliers | Proven reliability in diverse climates and regulatory environments |

Every BFV Valves product undergoes rigorous validation to ensure it meets the exacting standards required by blue-chip engineering firms. From agricultural mega-projects to precision greenhouse systems, our solutions are engineered to perform—day in, day out—without compromise.

Certified. Tested. Trusted.

BFV Valves (CMO Valve): Your safe pair of hands for mission-critical irrigation systems.

Why Choose BFV Valves

Precision Pond Irrigation Pump Filters – Engineered for Reliability

BFV Valves delivers high-performance filtration solutions tailored for pond and lake irrigation systems, combining precision engineering with robust materials to ensure longevity and operational efficiency. As a certified ISO 9001 manufacturer with 10 years of global export experience, we provide reliable, cost-effective solutions for engineering consultants, procurement managers, and project contractors worldwide.

Technical Specifications

| Parameter | BFV Specification | Industry Standard | Benefit |

|---|---|---|---|

| Pressure Rating | PN10 / PN16 (10 bar / 16 bar) | Typically PN6–PN16 | Safe operation in high-pressure systems; exceeds standard requirements for pond applications |

| UV Resistance | UV-stabilized polymer housing (5,000+ hours tested) | Standard PVC degrades at 1,000–2,000 hours | Prevents structural degradation under prolonged UV exposure; ensures 10+ years of service life |

| Flow Control Accuracy | ±1% tolerance | ±3–5% tolerance | Ensures precise water distribution, minimizing waste and optimizing system performance |

| Solenoid Reliability | IP68-rated, 1 million cycle tested | Typical 500k cycles, lower IP rating | Uninterrupted operation in harsh conditions; minimal maintenance requirements |

Quality Assurance & Compliance

100% Performance Testing: Every unit undergoes rigorous pressure, flow, and durability testing prior to shipment, ensuring zero defects and consistent performance.

ISO 9001 Certified: Our quality management system is certified to the international standard, guaranteeing meticulous process control and continuous improvement.

10-Year Export History: Trusted by clients across 30+ countries, with a proven track record of reliable delivery and technical support since 2014.

Partner with BFV Valves

Why Choose BFV Valves for Your Project?

As a dedicated partner to engineering consultants, procurement managers, and project contractors, BFV Valves combines technical expertise with unwavering reliability. Our commitment to excellence ensures seamless project execution from design to deployment.

| Advantage | Details |

|---|---|

| Accurate Delivery Times | Guaranteed lead times with real-time tracking; 98% on-time delivery rate across global shipments |

| No-Obligation Consultancy | Expert technical support from design phase through installation; free system optimization advice |

| Competitive Pricing | Cost-optimized solutions without compromising quality; volume-based discounts for large projects |

Regional Contact: Alex@cmovalve.com.cn

🧮 Valve Flow Coefficient (Cv) Calculator

Estimate the required valve size based on flow rate and pressure drop.