Pre factory inspection of Teflon butterfly valve products – HB24069 order

When it comes to industrial valves, quality and reliability are key factors to consider. This is why pre-factory inspection plays a crucial role in ensuring that the products meet the required standards and specifications. One such inspection was recently conducted for Teflon butterfly valve products under the HB24069 order.

Teflon butterfly valves are known for their excellent chemical resistance and durability, making them ideal for a wide range of industrial applications. The HB24069 order required a specific set of quality standards to be met, including precise dimensions, material composition, and performance capabilities.

The pre-factory inspection involved a thorough examination of the manufacturing process, from raw material sourcing to final product assembly. Inspectors carefully checked the quality of the Teflon used in the valves, ensuring that it met the required purity levels and had the necessary chemical resistance properties.

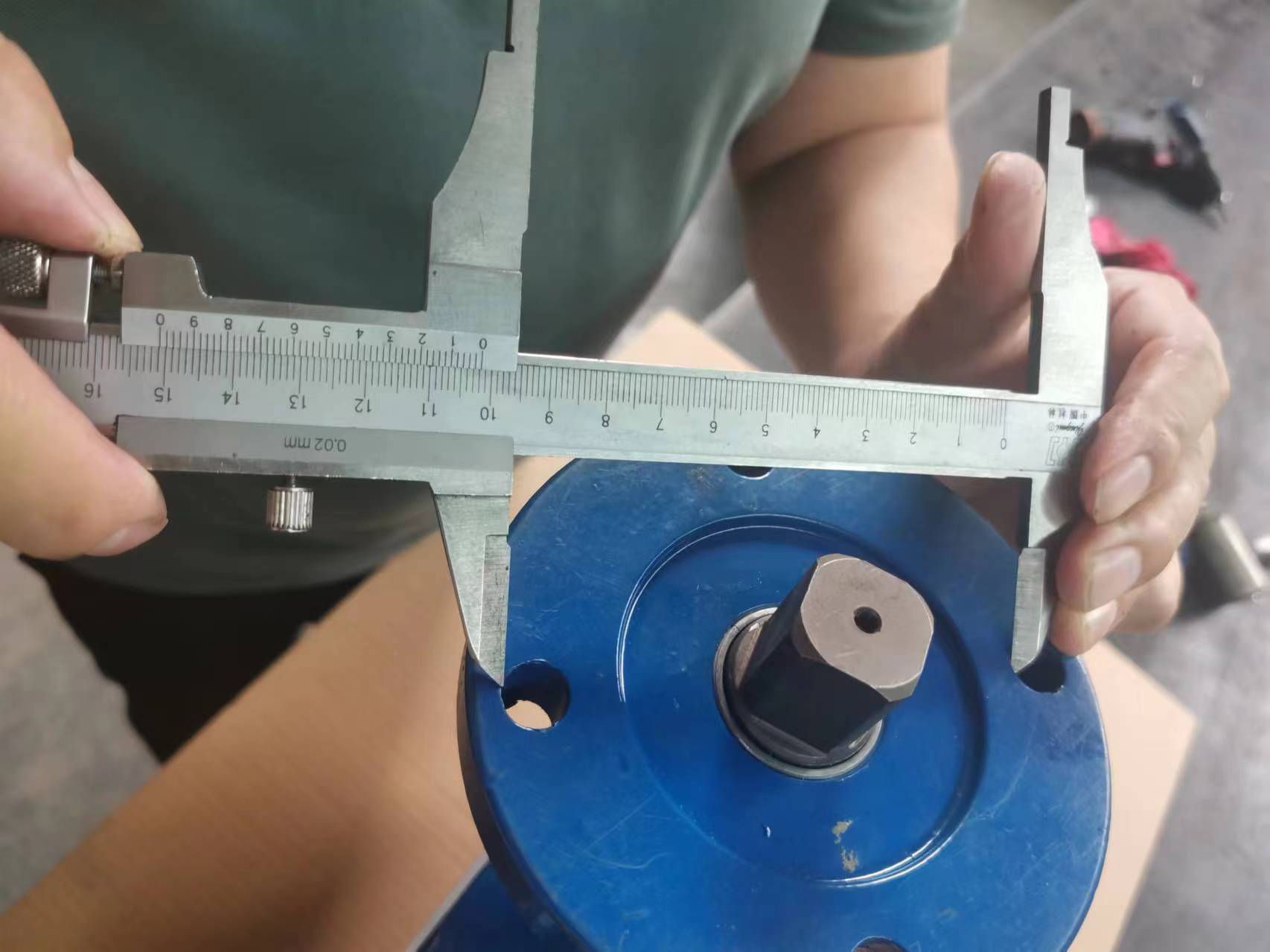

Furthermore, the inspectors tested the valves for proper functioning, including checking for any leaks, pressure drops, or other performance issues. They also verified that the valves met the specified dimensions and tolerances, ensuring a proper fit and seal in industrial applications.

Overall, the pre-factory inspection of the Teflon butterfly valve products under the HB24069 order was a success. The products met all the required quality standards and specifications, ensuring that they would perform reliably in the field.

In conclusion, pre-factory inspections are essential for ensuring the quality and reliability of industrial products like Teflon butterfly valves. By conducting thorough inspections, manufacturers can guarantee that their products meet the necessary standards and specifications, providing customers with peace of mind and confidence in their purchase.