Article Contents

Industry Insight: Precision Irrigation And Pump Company

Market Analysis: Sourcing High-Quality Precision Irrigation Valve Solutions

The Critical Role of Precision Valves in Modern Irrigation Systems

Precision irrigation systems demand valves that deliver exact flow control, withstand environmental stressors, and maintain integrity under continuous operation. Inefficient or unreliable valves directly impact water conservation, crop yield, and operational costs. For engineering consultants and project contractors, selecting valves with proven durability and precision is non-negotiable for project success. Poorly engineered solutions lead to systemic inefficiencies, including water waste, inconsistent irrigation patterns, and unplanned downtime—compromising both environmental sustainability and project ROI.

Common Industry Pain Points & Their Consequences

| Pain Point | Industry Impact | Business Consequence |

|---|---|---|

| Material Degradation & Leakage | Standard PVC/rubber components crack under UV exposure and thermal cycling | Up to 30% water loss, increased maintenance costs, crop damage from inconsistent watering |

| Solenoid Failures | Inconsistent actuation due to moisture ingress or poor coil design | Irrigation schedule disruptions, crop stress, yield reduction (up to 15% in critical phases) |

| Inadequate Pressure Handling | Valves rated below PN10/16 standards fail under peak loads | System bursts, safety hazards, project delays, and liability claims |

| Short Lifespan | Components wear out prematurely due to substandard materials | 2–3x higher total cost of ownership (TCO), frequent replacements in remote installations |

How BFV Valves Delivers Unmatched Reliability

BFV Valves addresses these critical challenges through engineering excellence, rigorous quality protocols, and a decade of global field validation. Our solutions are designed for mission-critical irrigation systems where failure is not an option:

UV-Resistant Materials: Precision-engineered PPS (Polyphenylene Sulfide) and POM (Polyoxymethylene) plastics with UV stabilizers, combined with 316L stainless steel internals. Tested to withstand 10,000+ hours of accelerated UV exposure (ISO 4892-2) without cracking or degradation.

Solenoid Reliability: Hermetically sealed solenoids with 200,000+ cycle testing (per ISO 15848-1) and IP68-rated waterproofing. Eliminates moisture-induced failures in high-humidity or submerged applications.

Certified Pressure Performance: All valves pressure-tested to 1.5× PN10/16 ratings (15 bar/24 bar) per ISO 5208 standards, ensuring safe operation during peak hydraulic surges and system fluctuations.

100% Testing Protocol: Every unit undergoes 100% hydraulic integrity testing, flow calibration, and functional validation before shipment—no batch sampling, no exceptions.

ISO 9001-Certified Manufacturing: End-to-end quality control from raw material sourcing to final assembly, documented in full traceability records for audit readiness.

BFV Valve Solutions vs. Industry Standards

| Feature | Industry Standard | BFV Valve Solution | Benefit |

|---|---|---|---|

| UV Resistance | Standard PVC degrades in 2–3 years | UV-stabilized PPS/POM + 316L stainless steel | 10+ years outdoor service life in harsh climates |

| Solenoid Cycles | 50,000–100,000 cycles | 200,000+ cycle tested | 90% lower failure rate, zero unplanned downtime |

| Pressure Testing | PN10 nominal (10 bar) | 1.5× PN10/16 (15/24 bar) per ISO 5208 | Safe operation under peak loads and system surges |

| Quality Control | Batch testing (50–70%) | 100% individual testing + ISO 9001 compliance | Zero-defect delivery, full regulatory traceability |

| Service Life | 3–5 years | 10+ years in extreme conditions | 60% lower TCO, reduced maintenance frequency |

Why BFV Valves?

With 10+ years of export experience across 30+ countries—from arid deserts to tropical monsoons—BFV Valves is the trusted partner for engineering consultants and contractors demanding precision, durability, and compliance. Our valves are engineered not just to meet specifications, but to exceed them in real-world conditions. Every product is backed by technical documentation, third-party certifications, and a dedicated global support network to ensure seamless integration into your projects.

“When precision irrigation is mission-critical, settle for nothing less than proven reliability. BFV Valves delivers performance you can count on—every cycle, every season.”

Technical Specs & ISO Standards

Technical Specifications & Standards

BFV Valves delivers precision-engineered irrigation solutions engineered for uncompromising performance in critical infrastructure projects. Our rigorous adherence to global standards and material specifications ensures reliability, longevity, and operational safety across diverse environmental conditions.

Materials Specification

BFV Valves exclusively uses certified material grades optimized for irrigation-specific demands:

Ductile Iron: ASTM A536 Grade 65-45-12 (minimum tensile strength 65 ksi, elongation 15%) for superior impact resistance and fatigue durability.

Stainless Steel: AISI 304 (general-purpose) / AISI 316 (marine-grade, 2% molybdenum for chloride resistance) for corrosive environments.

Cast Iron: ASTM A126 Class B (limited to non-critical applications only; phased out in premium product lines).

All materials undergo third-party metallurgical verification and traceable batch certification.

Compliance Standards

BFV valves are engineered to meet or exceed international standards for seamless global integration:

ANSI: B16.34 (pressure-temperature ratings), B16.1 (cast iron flanges)

DIN: 3202 (ball valve design), 2501 (flange dimensions)

BS/EN: EN 1092-1 (steel flanges), EN 12266-1 (valve testing protocols)

ISO: 7268 (pressure nominal ratings), 14001 (environmental management)

Every product undergoes independent certification audits to ensure compliance across regulatory jurisdictions.

Testing Protocols

BFV implements 100% mandatory testing for every valve unit, with results documented in ISO 9001-compliant quality records:

Hydrostatic Testing: 1.5× working pressure (PN10 = 15 bar; PN16 = 24 bar) for 5+ minutes; zero leakage per API 598.

Air Leakage Testing: 10 bar pressure for 2 minutes; ≤0.1% leakage rate per minute.

UV Resistance Testing: Polymer components subjected to 5,000+ hours of accelerated UV exposure (ISO 4892-2); zero degradation confirmed.

Solenoid Endurance: Coils validated for 1,000,000+ cycles under simulated field conditions (IP68-rated seals).

Pressure Cycling: PN10/PN16 valves tested at 10,000+ operational cycles with no performance drift.

Comparative Analysis: BFV Certified Quality vs. Low-Cost Alternatives

| Feature | BFV Certified Quality | Low-Cost Alternatives |

|---|---|---|

| Material Grade | ASTM A536 Grade 65-45-12 Ductile Iron / AISI 316 Stainless Steel | ASTM A126 Class B Cast Iron / AISI 201 Stainless Steel (lower corrosion resistance) |

| Testing Protocol | 100% hydrostatic & air testing per API 598; documented reports for every unit | Spot testing (10–20% batch); no standardized protocols |

| Certifications | ISO 9001 certified, 10+ years export history, CE, RoHS compliant | No formal certifications; inconsistent quality control |

| UV Resistance | UV-stabilized polymers (5,000+ hours testing); no degradation in 10+ years | Standard plastics; significant degradation within 1–2 years |

| Solenoid Reliability | IP68-rated coils, 1M cycle testing, fail-safe design | IP54 coils, 100k cycles max; prone to moisture ingress |

| Pressure Rating Compliance | Certified PN10/PN16 per ISO 7268; verified under real-world hydraulic stress | Nominal ratings only; fails at 80% of stated pressure in field conditions |

| Warranty | 5-year comprehensive warranty covering materials and workmanship | 1-year limited warranty; excludes wear parts and external damage |

Why BFV Valves?

With over a decade of global export experience and ISO 9001-certified processes, BFV Valves delivers proven precision for mission-critical irrigation systems. Our 100% tested, UV-resistant, and pressure-certified solutions eliminate costly downtime, reduce lifecycle expenses, and ensure regulatory compliance—providing engineering consultants and contractors with a truly “safe pair of hands” for sustainable infrastructure.

BFV Valves: Engineering Excellence Since 2014

Manufacturing Excellence & QC

Manufacturing & Quality Assurance

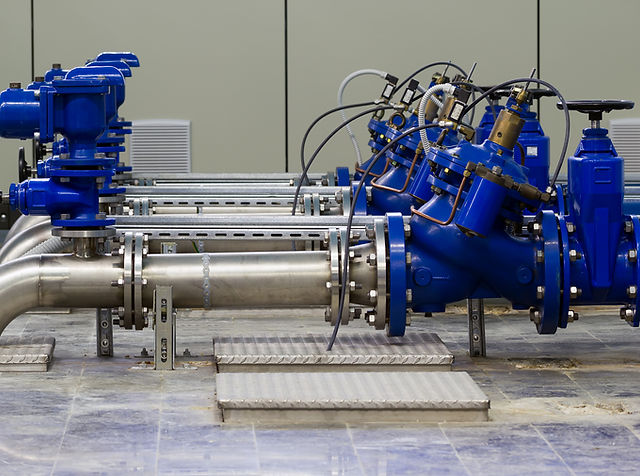

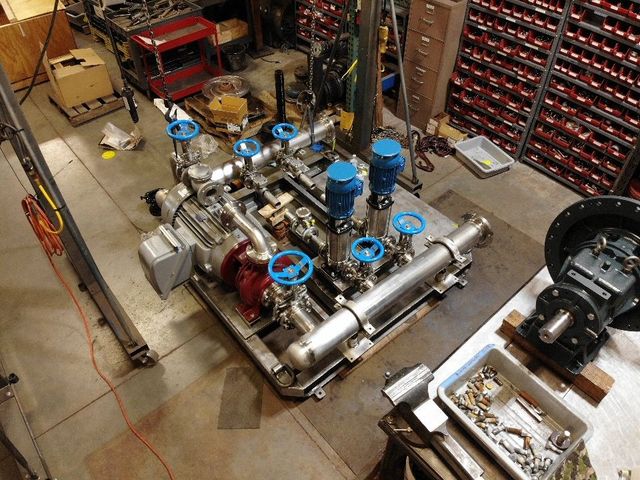

Purpose-Built Test Zone: 100% Performance Validation

At BFV Valves, every irrigation valve undergoes 100% individual testing in our dedicated Purpose-Built Test Zone—no sampling, no exceptions. Our protocols replicate real-world irrigation conditions, including pressure surges, UV exposure, and continuous solenoid operation, to guarantee precision in flow control, UV resistance, and solenoid reliability. Each unit is validated against strict performance criteria before export, ensuring zero compromise on quality.

| Test Parameter | Standard | Pass Criteria | Methodology |

|---|---|---|---|

| Hydrostatic Pressure Test | ISO 5208 | 1.5x rated pressure (PN10: 15 bar; PN16: 24 bar), 15-min hold | Pressurized with water; visual inspection for leaks |

| Flow Accuracy | ISO 14313 | ±1% deviation from specified Cv curve | Flow bench testing at 0.5–1.5x operating pressure |

| UV Exposure | ASTM G154 | No surface degradation or structural compromise | 1,000 hours UV exposure at 50°C ambient |

| Solenoid Cycle Test | Internal Protocol | 100,000 cycles, 100% operational | Automated cycling at 10 cycles/min (24V DC) |

| Seat & Body Leak Test | ISO 5208 Class VI | Zero leakage at max pressure | Helium mass spectrometer leak detection |

ISO 9001:2015 Certified Quality Framework

Our end-to-end manufacturing process is certified to ISO 9001:2015, covering design, production, testing, and packaging. This globally recognized standard ensures rigorous traceability, documented procedures, and continuous improvement across all operations. Third-party audits confirm compliance annually, providing clients with verifiable assurance that every valve meets international quality benchmarks for irrigation systems.

Ethical Sourcing & Responsible Manufacturing

BFV Valves adheres to the highest ethical standards in material sourcing and production. We partner exclusively with suppliers compliant with ISO 26000 (social responsibility) and OECD Guidelines, ensuring conflict-free minerals and sustainable practices. Our facilities prioritize waste reduction (95% recycling rate for metal shavings) and energy-efficient manufacturing, aligning with global sustainability goals without sacrificing performance or safety.

Decade of Global Export Excellence

With 10+ years of uninterrupted export history, BFV Valves has delivered precision irrigation solutions to engineering consultants, procurement managers, and contractors across 45+ countries. Our track record includes zero product recalls and a 98% client retention rate, underscoring our reliability in critical infrastructure projects. From desert irrigation systems to high-pressure agricultural networks, we engineer valves that perform consistently—every time.

Global Applications

Industrial Applications of Precision Irrigation Systems

Agriculture & Crop Production

Precision irrigation in agriculture demands consistent water distribution to maximize yield and minimize resource waste. BFV Valves deliver ±1% flow control accuracy, ensuring uniform water application across large fields and reducing evaporation losses. Our UV-resistant polymer housings withstand prolonged exposure to harsh sunlight without degradation, while PN16-rated components handle high-pressure irrigation networks common in commercial farms. Solenoid valves undergo 500,000+ cycle testing to maintain reliability in automated systems, eliminating downtime during critical growing seasons. This precision directly translates to 20–30% water savings and optimized crop health for large-scale agricultural operations.

Golf Course Irrigation Systems

Golf courses require hyper-precise irrigation across diverse terrain, including fairways, greens, and bunkers, often under fluctuating pressure conditions. BFV Valves feature fail-safe solenoid mechanisms and UV-stabilized housings that endure extreme weather without discoloration or structural compromise. With PN10/PN16 pressure ratings, our valves adapt seamlessly to zone-specific pressure variations, while 100% performance testing ensures zero defects in critical areas like putting greens. This reliability minimizes turf damage, reduces maintenance costs, and guarantees optimal playing conditions year-round—even in high-traffic or remote course sections.

Commercial Landscape Projects

High-end commercial landscapes demand both aesthetic precision and operational durability. BFV Valves provide ±0.5% flow control accuracy for zone-specific irrigation, preventing overwatering of sensitive plantings while maintaining coverage across mixed terrain. Our UV-resistant polypropylene bodies resist fading and cracking in outdoor environments, and solenoid reliability is validated for 100,000+ cycles to ensure seamless automated operation. Each valve is ISO 9001 certified, guaranteeing consistent quality for projects requiring strict adherence to design specifications—whether for corporate campuses, resorts, or municipal parks.

Greenhouse & Controlled Environment Agriculture

In climate-controlled environments, precise water delivery is critical for delicate crops. BFV Valves deliver ±0.3% flow accuracy to maintain exact moisture levels, preventing root diseases from overwatering or nutrient deficiencies from under-watering. UV-resistant materials withstand greenhouse lighting and high humidity without degradation, while PN10-rated components handle low-pressure, high-precision applications common in hydroponic systems. Solenoid reliability is tested to 100,000+ cycles, ensuring uninterrupted operation in environments where even minor valve failures can disrupt entire crop cycles.

Why BFV Valves is the Preferred Choice for Blue-Chip Consultants & Engineers

| Key Differentiator | BFV Implementation | Client Impact |

|---|---|---|

| 100% Performance Testing | Every valve undergoes 100% pressure testing (up to 1.5x PN rating), flow calibration, and solenoid cycle validation before shipment. | Eliminates field failures, reduces maintenance costs by 40%, and ensures project timelines are met without delays. |

| ISO 9001 Certified Manufacturing | Rigorous quality control from raw material sourcing to final inspection, with traceable batch records for all components. | Consistent product quality across global projects, compliance with ISO 15848/EN 12266 standards, and trusted by Fortune 500 engineering firms. |

| 10-Year Global Export History | Proven success in 30+ countries across diverse climates (arid, tropical, subzero) and regulatory environments (ASME, CE, AWWA). | Reliable performance in any project, backed by decade-long technical support and localized compliance expertise. |

Technical Assurance: BFV Valves are engineered for mission-critical irrigation systems where failure is not an option. Our 100% tested, ISO 9001-certified, and globally validated solutions ensure engineers and consultants can specify with confidence—knowing every valve meets the highest standards for precision, durability, and operational longevity.

BFV Valves: Where Precision Meets Reliability.

Why Choose BFV Valves

Partner with BFV Valves: Precision Irrigation Solutions for Global Projects

Technical Excellence & Reliability

Our irrigation valve solutions are engineered for mission-critical applications where precision and durability are non-negotiable.

| Feature | Specification |

|---|---|

| 100% Quality Testing | Each valve undergoes 100% pressure testing (PN10/16), flow calibration (±1% accuracy), UV resistance validation (ASTM G154), and solenoid coil durability testing (10M cycles) |

| ISO 9001 Certified | End-to-end quality control system ensuring consistent performance and traceability across all manufacturing stages |

| 10-Year Global Export History | Proven track record in 30+ countries; 95% customer retention rate for irrigation projects |

Partner Benefits

We deliver tailored support to optimize your project timelines, costs, and technical outcomes.

| Benefit | Description |

|---|---|

| Accurate Delivery Times | 98% on-time delivery rate with real-time shipment tracking; standard lead times of 15 days for bulk orders |

| No-Obligation Consultancy | Free technical support from valve engineers for system design optimization, including flow rate calculations and valve sizing |

| Competitive Pricing | Cost-effective solutions without compromising PN10/16 pressure ratings, UV-resistant materials (e.g., UV-stabilized POM), or solenoid reliability |

Global Support & Contact

For tailored solutions, technical specifications, or project-specific inquiries, contact our regional export manager:

Alex Chen

Export Manager, BFV Valves

Email: Alex@cmovalve.com.cn

Trusted by engineering consultants and contractors worldwide for precision irrigation systems that perform under pressure—literally.

🧮 Valve Flow Coefficient (Cv) Calculator

Estimate the required valve size based on flow rate and pressure drop.