The Bidirectional Stainless Steel Knife Valve is designed for reliable shut-off and isolation in demanding flow systems involving slurry, pulp, powder, granular material, or corrosive fluids. Unlike unidirectional types, this bidirectional knife gate valve can seal in both flow directions—minimizing leakage and maximizing operational flexibility.

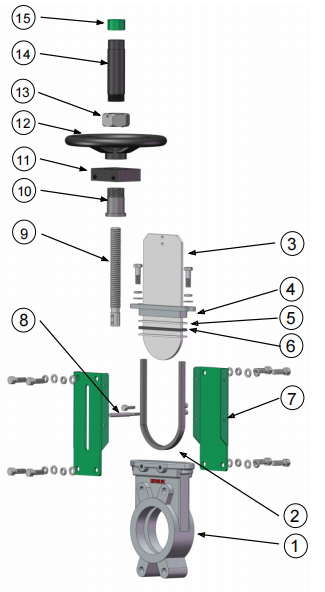

| NO | Part Name | Material |

|---|---|---|

| 1 | Body | Ductile Iron |

| 2 | Seat | EPDM |

| 3 | Gate | Stainless Steel |

| 4 | Packing Gland | Ductile Iron |

| 5 | Packing | Viton+PTFE |

| 6 | O-Ring Seal | EPDM |

| 7 | Support Plates | Steel |

| 8 | Position Indicator | SS304 |

| 9 | Stem | Stainless Steel |

| 10 | Stem Nut | Bronze |

| 11 | Yoke | Ductile Iron |

| 12 | Handwheel | Steel |

| 13 | Nut | Steel |

| 14 | Hood | Steel |

| 15 | Top Cap | Plastic |

Bidirectional stainless steel knife valve specification

| DN | SIZE Inch | HA | HB | L |

|---|---|---|---|---|

| 50 | 2” | 65 | 289 | 40 |

| 65 | 2.5” | 70 | 313 | 40 |

| 80 | 3” | 95 | 335 | 50 |

| 100 | 4” | 108 | 380 | 50 |

| 125 | 5” | 124 | 415 | 50 |

| 150 | 6” | 135 | 470 | 60 |

| 200 | 8” | 165 | 580 | 60 |

| 250 | 10” | 198 | 670 | 70 |

| 300 | 12” | 234 | 768 | 80 |

| 350 | 14” | 256 | 900 | 96 |

| 400 | 16” | 292 | 1014 | 100 |

| 450 | 18” | 308 | 1100 | 106 |

Key Features

Flow Direction: Bidirectional (zero-leakage in both directions)

Valve Size: DN50 – DN1200 (2” – 48”)

Body Material: Full Stainless Steel 304 / 316

Gate Material: SS304 / SS316 / Duplex steel optional

Seat Options: Metal-to-metal, PTFE, EPDM, Viton

Pressure Rating: PN10 / PN16 (custom options up to 25 bar)

Temperature Range: -20°C to +250°C depending on seal material

Face-to-Face: MSS-SP-81 or manufacturer standard

End Connection: Wafer / Lug / Flanged types

Actuation Options

Manual (handwheel or gearbox)

Pneumatic actuator (double-acting or spring return)

Electric actuator with modulating control

Hydraulic actuator (for high force applications)

All actuators can be fitted with position indicators, solenoid valves, limit switches, and manual override upon request.

Advantages

Bidirectional Sealing: Reliable shut-off in either flow direction, reducing the need for valve orientation

Corrosion Resistance: 100% stainless steel body and gate suitable for harsh or hygienic environments

Slurry-Proof Design: Self-cleaning gate and replaceable soft or metal seat minimize clogging and wear

Long Lifespan: Precision-machined components reduce leakage and increase cycle life

Maintenance Friendly: Easy disassembly and replacement of parts without pipeline removal

Typical Applications

Mining and tailings pipelines

Wastewater treatment (abrasive media)

Pulp and paper mills

Chemical and food processing

Power plant ash handling systems

Cement and bulk powder industries

Available Configurations

Pneumatic Bidirectional Knife Gate Valve Stainless Steel

Manual Bidirectional Knife Valve with SS316 Body

Flanged SS Knife Gate Valve with Dual Seal

Air Operated Stainless Steel Slurry Knife Valve

Quality Assurance

Our bidirectional stainless steel knife valves are manufactured under strict quality control standards and tested for:

Pressure seal integrity

Bi-directional leakage performance

Surface finish and dimensional accuracy

Corrosion resistance per ASTM / ISO standards

Request a Quote

Looking for a stainless steel bidirectional knife valve for your critical flow control needs?

Contact us now for model selection, datasheets, and competitive pricing.