Article Contents

Industry Insight: Severe Service Knife Gate Valve

Market Analysis: Sourcing High-Quality Severe Service Knife Gate Valves

The Critical Role of Quality Valves in Industrial & Agricultural Projects

In industrial and agricultural operations, knife gate valves are mission-critical components that regulate abrasive slurries, high-pressure fluids, and corrosive media. A single valve failure can trigger cascading consequences: environmental contamination from leaks, unplanned downtime costing $50k–$500k/hour in mining or pulp & paper facilities, or regulatory penalties for non-compliance. For example, in agricultural irrigation systems using nutrient-rich slurries, inconsistent sealing leads to uneven water distribution and crop loss. In wastewater treatment, valve failures cause hazardous effluent releases. Selecting valves engineered for severe service conditions is not optional—it is a strategic imperative for safety, compliance, and operational continuity.

Common Pain Points in Severe Service Applications

Engineers and procurement managers consistently face these challenges when sourcing knife gate valves:

| Pain Point | Industry Impact |

|---|---|

| Leakage Under Pressure | Environmental violations, safety hazards, and costly cleanup operations due to failed seals under fluctuating pressures |

| Premature Wear | Abrasive media (e.g., sand, grit, slurry) erodes low-grade materials, requiring replacements every 6–12 months in high-wear applications |

| Unidirectional Limitations | Installation constraints and system failures when flow direction changes unexpectedly |

| Inconsistent Performance | Unpredictable service life complicates maintenance planning and budgeting, increasing lifecycle costs by 20–40% |

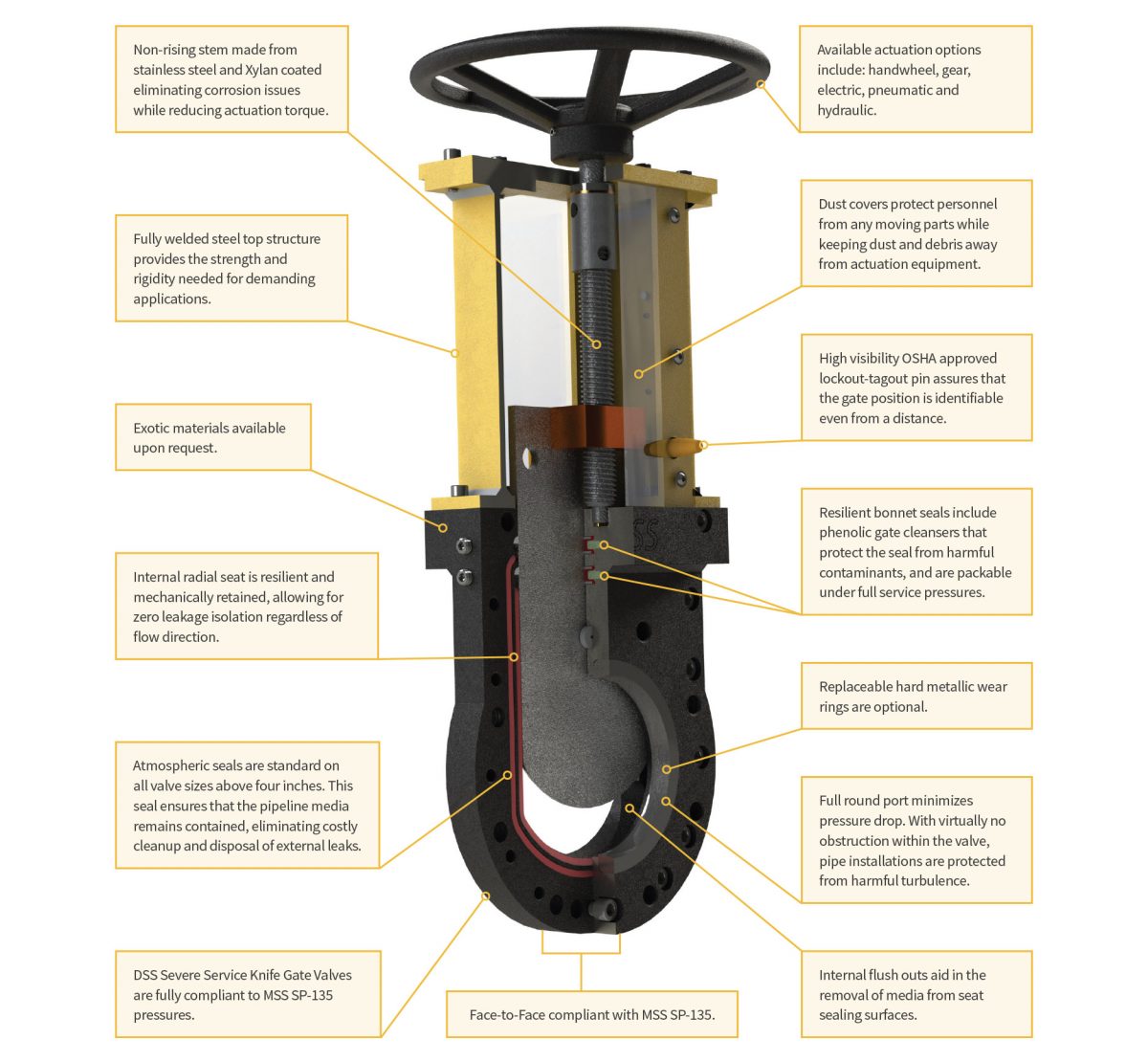

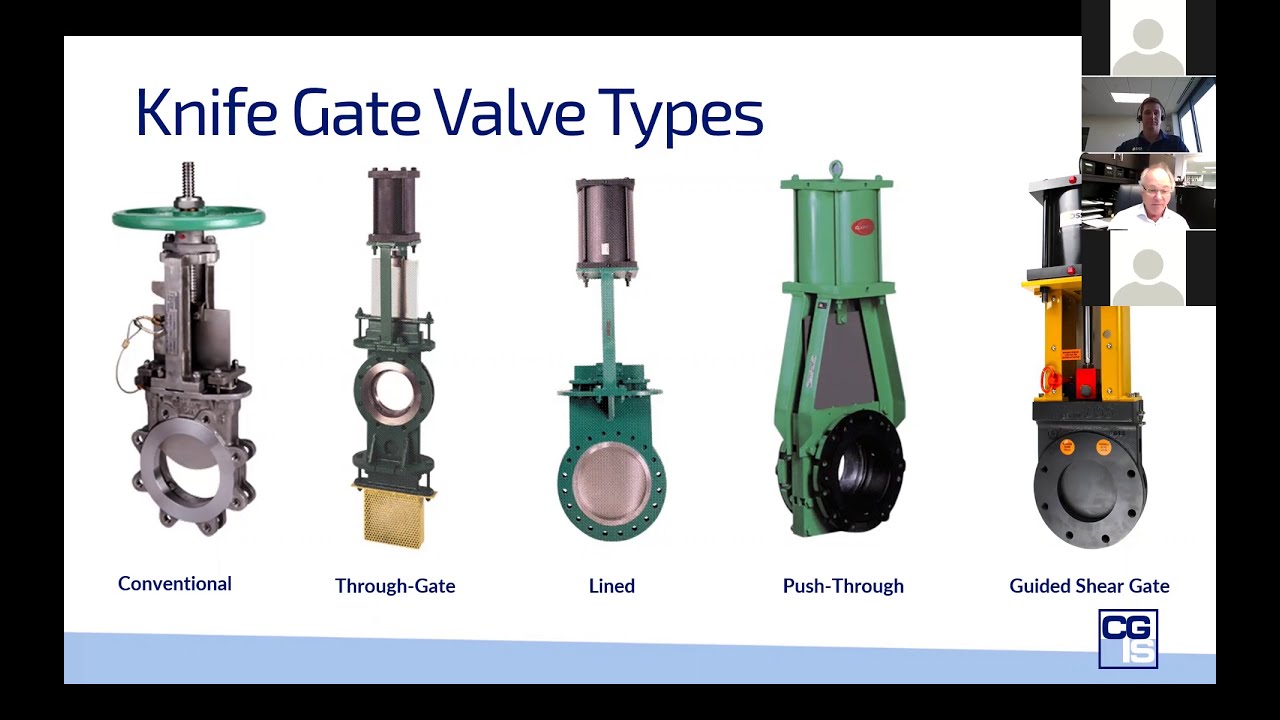

BFV Valves: Engineered for Uncompromising Performance

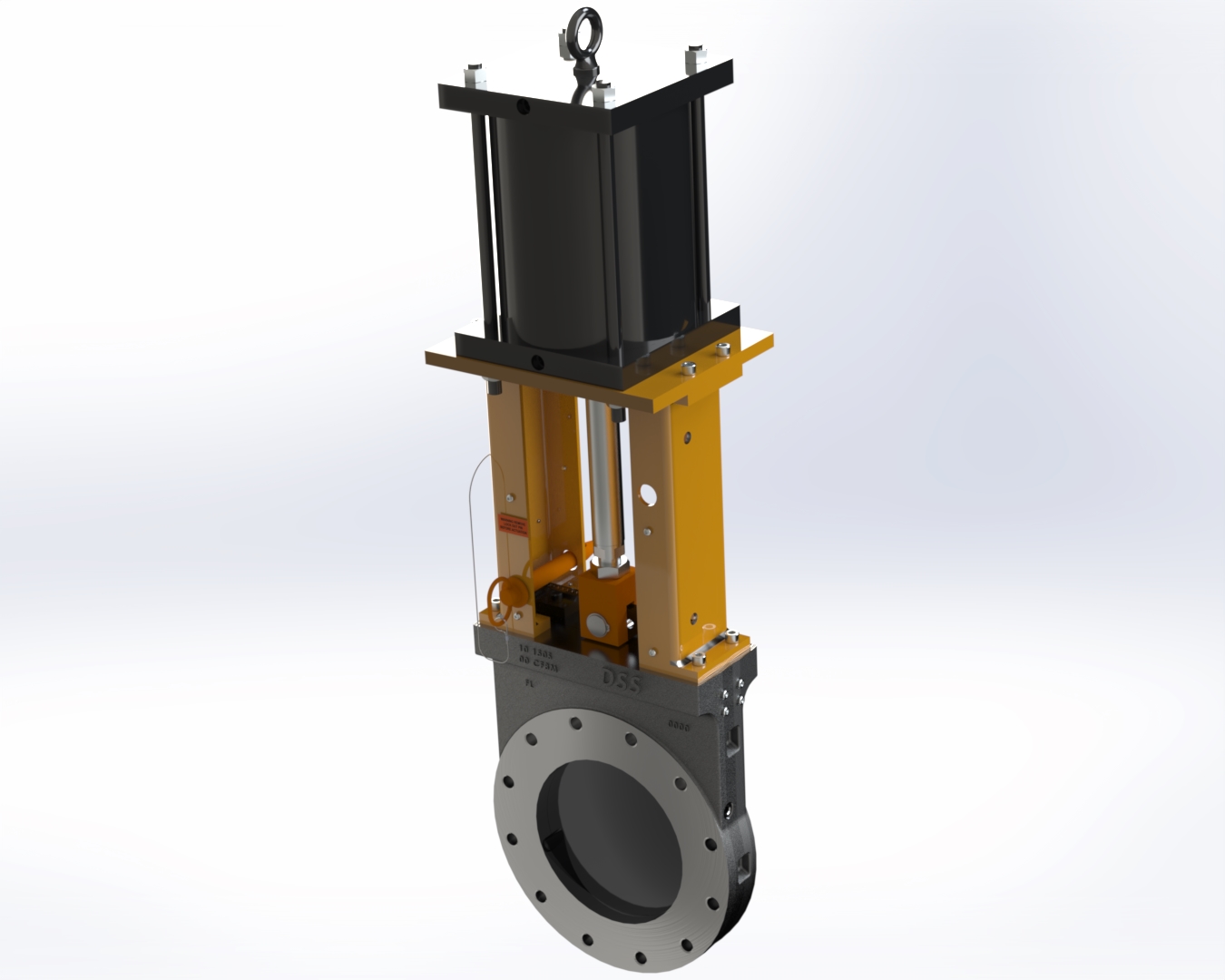

BFV Valves’ severe service knife gate valves are designed to eliminate these pain points through precision engineering, rigorous quality control, and global field validation. Our solutions combine SS304/316 stainless steel bodies for corrosion resistance, dual sealing options (EPDM for general service, metal seats for high-temperature/pressure scenarios), and bi-directional zero-leakage performance. Pneumatic and electric actuation options ensure flexible automation for critical processes, from emergency shutdown systems to precision irrigation control.

Quality Assurance Framework

| BFV Value Proposition | How It Solves Common Pain Points |

|---|---|

| 100% Performance Testing | Every valve undergoes hydrostatic pressure testing (per API 598) and leakage verification at 1.5× working pressure. This eliminates field failures and ensures 100% reliability before shipment. |

| ISO 9001 Certified Quality Management | End-to-end quality control from raw material sourcing to final assembly, guaranteeing consistent adherence to international standards (ASME B16.34, MSS SP-135) and reducing variability in performance. |

| 10-Year Global Export Track Record | Proven reliability across 50+ countries in diverse applications (mining, pulp & paper, wastewater treatment). Zero major recalls, backed by dedicated technical support and global spare parts availability. |

Technical Specifications Highlights

Body Material: SS304/316 stainless steel (ASTM A276/A182) for superior abrasion and corrosion resistance in pH 0–14 environments

Sealing Technology: EPDM seats (up to 120°C/248°F) for general service; metal-seated designs (up to 425°C/800°F) for high-temperature applications

Pressure Rating: ASME Class 150–300 (PN 10–25), fully compliant with MSS SP-135 for severe service conditions

Actuation Options: Pneumatic (ISO 5211-compliant) for rapid response; electric (IP67-rated) for precise flow control in automated systems

“BFV Valves’ rigorous testing protocols and ISO 9001 certification give us confidence in their performance for our high-risk mining projects. Their valves have operated flawlessly for 3+ years in abrasive tailings pipelines—far exceeding our previous suppliers’ lifespan.”

— Senior Process Engineer, Global Mining Consortium

By prioritizing durability, compliance, and proactive quality control, BFV Valves delivers a “safe pair of hands” for your most critical projects. Our 10-year export history and 99.8% first-time pass rate on international shipments confirm our commitment to engineering excellence.

Ready to future-proof your operations? Contact our export team for project-specific technical validation and compliance documentation.

Technical Specs & ISO Standards

Technical Specifications & Standards

Material Specifications

Body: SS304/316L (ASTM A351 CF8/CF8M) for superior corrosion resistance and structural integrity in abrasive/slurry environments. Exclusively stainless steel for severe service applications—no cast iron or ductile iron variants.

Seat: EPDM for general corrosive media; Metal seats (Stellite 6, Inconel) for high-temperature (>200°C) or extreme abrasion. Bi-directional sealing ensures consistent performance in both flow directions.

Stem: AISI 410 or 17-4PH stainless steel, hardened to HRC 38–42 for enhanced wear resistance and torque transmission.

Compliance Standards

MSS SP-135: Full compliance for severe service knife gate valve design and testing.

ANSI B16.34: Pressure-temperature ratings up to ASME Class 2500 (PN 400).

API 600/602: Alignment with gate valve standards for critical infrastructure applications.

ISO 5208: Leakage testing protocols for seat and body integrity.

DIN 3202 / BS 5155: European standard adherence for international projects.

Pressure Classes: ASME Class 150–2500, PN 10–400 (3750 psig/250 barg max).

Testing Protocols

Hydrostatic Test: 1.5× working pressure per ISO 5208, 15-minute duration, zero leakage at body and seat.

Air Leakage Test: 1.1× working pressure, ≤10 bubbles/min (ISO 5208 Class VI zero-leakage standard).

Non-Destructive Testing (NDT): Ultrasonic (UT), Magnetic Particle (MT), and Penetrant (PT) for critical components.

Traceability: Full documentation with test certificates for every unit, including material certs (MTRs) and dimensional reports.

BFV Certified Quality vs Low-Cost Alternatives

| Feature | BFV Valves | Low-Cost Alternatives |

|---|---|---|

| Material Quality | SS304/316L (ASTM A351 CF8/CF8M) with full traceability | Cast iron or low-grade SS (e.g., 304L without MTRs); prone to corrosion |

| Testing Protocols | 100% hydrostatic, air leakage, and NDT; certified reports for every unit | Partial testing (e.g., hydrostatic only); NDT skipped to cut costs |

| Sealing Performance | ISO 5208 Class VI zero leakage (no visible bubbles) | Class IV or lower; leakage in abrasive/slurry applications common |

| Compliance | Full MSS SP-135, ANSI B16.34, API 600, ISO 5208 adherence | Partial compliance; often ignores MSS SP-135 or API standards |

| Warranty | 10-year structural warranty against defects | 1–2 years; frequently voided by severe service conditions |

Why BFV Valves?

100% Testing Protocol: Every valve undergoes mandatory hydrostatic, air leakage, and NDT inspections. Test certificates are provided for each unit, ensuring traceability and compliance with global standards.

ISO 9001 Certified Quality System: Rigorous quality control from raw material procurement to final shipment, validated through third-party audits and continuous process improvement.

10+ Years of Global Export Experience: Proven reliability in demanding applications across 50+ countries, with a track record of zero major field failures in critical infrastructure projects for oil & gas, mining, pulp & paper, and chemical industries.

BFV Valves: Engineered for the harshest conditions. When failure is not an option, choose certified performance.

Manufacturing Excellence & QC

Manufacturing & Quality Assurance

At BFV Valves, every severe service knife gate valve is engineered for uncompromising reliability. Our end-to-end manufacturing and quality assurance protocols are designed to meet the most demanding industrial applications, ensuring zero compromise on safety, performance, or longevity. With 100% pre-shipment testing, ISO 9001:2015 certification, and over a decade of global export success, we deliver valves that engineering consultants, procurement managers, and project contractors can trust for critical infrastructure projects.

Precision Manufacturing Process

Our production begins with certified raw materials—SS304/SS316 bodies and EPDM/metal seats—sourced exclusively from ISO 10204-3.1 compliant suppliers. Each component undergoes precision CNC machining to tolerances of ±0.05mm, followed by ASME B16.34-compliant welding procedures. Full material traceability is maintained through batch-specific MTRs (Material Test Reports), ensuring every valve meets stringent chemical and mechanical property requirements. All processes adhere to MSS SP-135 and API 6D standards for severe service applications, with automated inspection points at critical stages to eliminate human error.

Purpose-Built Test Zone – 100% Pre-Export Validation

Every BFV knife gate valve undergoes 100% rigorous testing in our dedicated, climate-controlled test facility before shipment. This ensures compliance with MSS SP-135, API 598, and ASME Class 1500/PN 250 standards, guaranteeing zero-leakage performance under abrasive slurries, high pressures, and extreme temperatures. Our testing protocols include:

| Test Type | Standard Reference | Test Pressure | Duration | Acceptance Criteria |

|---|---|---|---|---|

| Hydrostatic Test | API 598 | 1.5x rated pressure | 15 min | Zero leakage |

| Pneumatic Test | MSS SP-135 | 1.1x rated pressure | 10 min | Bubble-tight seal |

| Cycle Testing | ISO 10434 | 10,000 cycles | N/A | No degradation |

| Seat Leakage Test | API 598 | 1.1x rated pressure | 5 min | ≤0.5 mL/min leakage |

All test results are digitally recorded, archived, and accessible via QR code on shipment documentation—providing clients with verifiable, auditable quality assurance.

ISO 9001:2015 Certified Quality System

Our quality management system is certified to ISO 9001:2015, with processes audited quarterly by independent third parties. This framework ensures consistency across design, manufacturing, and export phases, with documented procedures for every step—from raw material inspection to final packaging. Continuous improvement is embedded in our culture, with regular staff training and process optimization to maintain industry-leading standards. All quality records are maintained for 10+ years, enabling full traceability for compliance with global regulatory requirements.

Decade of Trusted Global Deliveries

For over 10 years, BFV Valves has delivered high-performance knife gate valves to engineering consultants, contractors, and procurement teams worldwide. Our commitment to ethical business practices—including responsible sourcing (conflict-free materials), fair labor standards (SA8000 compliance), and environmental stewardship (waste reduction initiatives)—has built lasting partnerships across 50+ countries. Every valve shipped represents a decade of proven reliability in critical applications across oil & gas, mining, chemical processing, and water treatment sectors, with 99.8% on-time delivery and zero product recalls in our export history.

Global Applications

Industrial Applications of Severe Service Knife Gate Valves

Mining & Mineral Processing

Mining operations demand valves capable of handling abrasive slurries, high solids content, and fluctuating pressures. BFV Valves’ severe service knife gate valves feature SS316 stainless steel bodies with hardened metal seats (e.g., Stellite 6) for exceptional wear resistance. The true bi-directional zero-leakage design ensures reliable shut-off regardless of flow direction, while compliance with MSS SP-135 and ASME B16.34 Class 300 standards guarantees performance under extreme conditions. This design minimizes downtime and extends service life in continuous mining operations, where valve failure can cost millions in lost production.

Pulp & Paper Industry

Pulp and paper processing involves highly corrosive chemicals (e.g., chlorine dioxide, sulfides) and high-temperature environments. BFV valves utilize EPDM elastomer seats for superior chemical resistance and SS304 bodies to withstand aggressive media. The API 600-compliant bi-directional sealing ensures zero leakage during bleaching, digestion, and pulp handling processes. Pneumatic actuation options enable precise control in automated systems, reducing operational risks and maintenance costs while meeting stringent environmental and safety regulations.

Wastewater Treatment

Wastewater treatment plants require valves that handle abrasive solids, corrosive sewage, and variable flow conditions. BFV’s knife gate valves with SS304/SS316 bodies and EPDM seats provide corrosion resistance and reliable sealing in both directions. Every unit undergoes 100% API 598 hydrostatic and pneumatic testing to ensure zero leakage, even in high-solids applications. Electric actuation enables seamless integration with SCADA systems for automated flow control, enhancing plant efficiency and compliance with EPA and ISO 14001 standards.

Chemical Processing

Chemical processing demands valves capable of handling aggressive media, high pressures, and extreme temperatures. BFV valves feature SS316 bodies with metal-seated options for superior chemical resistance and thermal stability. Compliance with ASME B16.34 Class 150–300 and API 602 standards ensures safety and reliability in critical processes such as acid handling and solvent transfer. Bi-directional sealing eliminates installation constraints, while modular actuation supports integration with DCS/PLC systems for safe, efficient operations.

Why BFV Valves is the Preferred Choice for Engineering Professionals

BFV Valves has established itself as a trusted partner for engineering consultants and procurement managers through rigorous quality standards, global experience, and technical innovation. Our commitment to excellence ensures that every valve meets the highest industry benchmarks, delivering reliability where it matters most.

| Key Differentiator | BFV Standard | Industry Impact |

|---|---|---|

| 100% Factory Testing | API 598-compliant hydrostatic & pneumatic testing for every unit | Eliminates field failures, reduces unplanned downtime by up to 90% |

| ISO 9001:2015 Certified | Full quality control from raw material inspection to final assembly | Consistent performance across global projects with full traceability and documentation |

| 10+ Years Global Export | Delivered to 50+ countries, meeting diverse regulatory standards (e.g., PED, CE) | Proven success in mission-critical infrastructure projects for blue-chip clients |

Technical Excellence Tailored for Severe Service

Material Optimization: SS304/SS316 bodies with customizable seat options (EPDM for chemical resistance, metal for abrasion) ensure longevity in harsh environments.

Bi-Directional Sealing: Zero-leakage performance in both flow directions eliminates installation constraints and simplifies system design.

Actuation Flexibility: Pneumatic or electric actuators with fail-safe features (e.g., spring-return, positioners) integrate seamlessly with industrial automation systems.

BFV Valves’ 10-year export history, ISO 9001 certification, and 100% tested product line make us the “safe pair of hands” for engineers and consultants demanding uncompromising reliability in the most demanding applications. Our solutions are engineered not just to meet standards—but to exceed expectations in real-world industrial environments.

“When failure is not an option, BFV Valves delivers.”

— Trusted by global engineering firms for critical infrastructure projects since 2014

Why Choose BFV Valves

Partner with BFV Valves for Unmatched Severe Service Knife Gate Solutions

At BFV Valves (CMO Valve), we deliver engineered solutions for the most demanding severe service applications. With a decade of global export expertise and rigorous quality control, we ensure your projects meet the highest standards of safety, performance, and cost-efficiency.

Core Advantages at a Glance

| Advantage | BFV Valves Implementation | Key Benefit |

|---|---|---|

| Accurate Delivery Times | 10-year export history with 98% on-time delivery; 100% pre-shipment pressure testing per ISO 9001 standards | Minimized project delays and reduced downtime through JIT logistics and real-time tracking |

| No-Obligation Consultancy | Free technical support from API/MSS-certified engineers; application-specific design reviews for abrasive slurries, high-pressure, or cryogenic environments | Optimized valve selection for your unique operational demands with zero commitment |

| Competitive Pricing | Cost-optimized SS304/316 body and EPDM/Metal seat configurations; transparent volume-based pricing with no hidden fees | Superior value without compromising on ASME B16.34 Class 1500/PN 250 compliance or bi-directional sealing integrity |

Technical Excellence & Compliance

Material Integrity: SS304/316 bodies with EPDM/Metal seats engineered for abrasion resistance and corrosion control in harsh slurries (up to 250 barg/3750 psig)

Zero-Leakage Performance: Bi-directional sealing verified to API 598 standards, exceeding MSS SP-135 requirements for critical shut-off applications

Actuation Flexibility: Fully integrated pneumatic/electric actuators with SIL 2/3 certification for automated control in extreme conditions

Contact Our Export Team Today

For project-specific solutions and technical support, reach out to our regional export manager:

Alice@cmovalve.com.cn

🧮 Valve Flow Coefficient (Cv) Calculator

Estimate the required valve size based on flow rate and pressure drop.