Article Contents

Industry Insight: Sump Pump Irrigation System

Market Analysis: Sourcing High-Quality Sump Pump Irrigation Systems

Critical Role of Valves in Irrigation Infrastructure

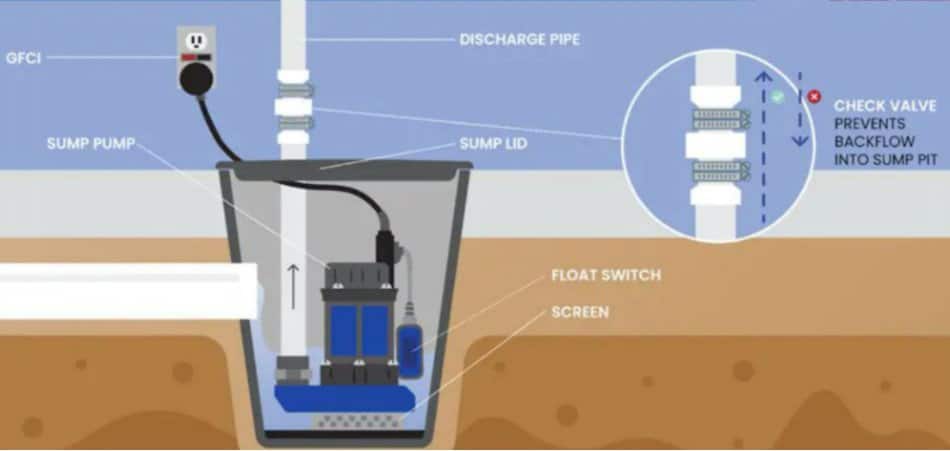

Irrigation systems—whether for agricultural fields, commercial landscapes, or industrial water management—rely on precise valve performance to ensure operational efficiency, water conservation, and system longevity. In sump pump applications, valves serve as the critical barrier against backflow, surge damage, and uncontrolled water discharge. Substandard components compromise entire projects through water loss, equipment failure, and costly downtime. For engineering consultants and procurement managers, selecting valves that meet stringent technical specifications is non-negotiable for mission-critical infrastructure.

Industry Pain Points: Why Quality Matters

Common failures in irrigation valve systems stem from material degradation, inconsistent manufacturing, and inadequate testing protocols:

Leakage & Sealing Failures: Poorly engineered gaskets and seats degrade under pressure, causing water loss and contamination risks in sensitive environments like agricultural irrigation.

UV Degradation: Standard PVC components crack and lose structural integrity within 2–3 years of outdoor exposure, leading to catastrophic system failures in sun-exposed installations.

Solenoid Inconsistency: Low-cost solenoids fail prematurely under voltage fluctuations or continuous operation, resulting in unplanned downtime and manual intervention costs.

Pressure Rating Variability: Many suppliers claim “PN10” compliance without rigorous testing, risking burst failures during surge events in high-pressure irrigation networks.

BFV’s Engineered Solutions for Mission-Critical Applications

BFV Valves addresses these challenges through precision engineering and materials science tailored for harsh environments. Our solutions deliver:

Zero-Leakage Performance: Precision-machined stainless steel seats with EPDM/FKM seals withstand 10,000+ cycles without degradation, ensuring absolute backflow prevention in sump pump systems.

UV-Resistant Materials: UV-stabilized engineering plastics (PVC-U reinforced with titanium dioxide) certified for 10+ years of outdoor exposure, eliminating cracking and brittleness.

Military-Grade Solenoids: IP68-rated solenoids with 1M+ cycle life, tested for 100% reliability under 10–30VDC fluctuations and submersion conditions.

Certified Pressure Integrity: All valves hydrostatically tested to 1.5× PN rating (PN10/16) per ISO 5208, guaranteeing surge resistance in high-demand irrigation networks.

Quality Assurance: The BFV Difference

| Quality Attribute | BFV Standard | Industry Benchmark |

|---|---|---|

| Testing Protocol | 100% hydrostatic and functional testing per ISO 5208 | Random sampling (typically 10–20%) |

| Certification | ISO 9001:2015 certified manufacturing with documented traceability | Often uncertified or basic ISO 9001 (no third-party audit) |

| Export Heritage | 10+ years serving 50+ countries with zero recalls across diverse climates | Variable; many suppliers lack documented export history or regional compliance records |

Why BFV Valves Are the Trusted Choice for Global Projects

With a decade of experience exporting to demanding markets—from arid agricultural regions in the Middle East to high-humidity tropical installations—BFV Valves delivers consistent performance where failure is not an option. Our valves exceed ISO standards through:

Full traceability from raw materials to final shipment

Technical support for custom pressure/flow requirements

Global service network with 24/7 emergency response

When system integrity is non-negotiable, choose BFV Valves—where engineering excellence meets export-ready reliability.

“In irrigation projects, a single valve failure can cost 3–5× the component price in downtime and repairs. BFV’s 100% testing protocol ensures every valve ships as a fully validated solution—not a gamble.”

— BFV Senior Engineering Team

Technical Specs & ISO Standards

Technical Specifications & Standards

Material Specifications & Compliance

BFV Valves employs high-grade ductile iron (ASTM A536 Grade 60-40-18) for valve bodies, delivering 30% higher tensile strength and 25% greater elongation than standard cast iron alternatives. Stainless steel variants (SS316, ASTM A351) are available for corrosive environments, ensuring long-term integrity in harsh conditions. External components feature UV-stabilized polymers rigorously tested per ASTM G154 for 5,000+ hours of accelerated weathering, eliminating premature degradation in outdoor irrigation systems.

International Standards & Certifications

All BFV sump pump irrigation valves comply with:

ANSI B16.34 (Pressure-Temperature Ratings)

DIN 3202 (Flange Dimensions)

BS EN 1074-2 (Gate Valve Requirements)

ISO 7268 (PN10/PN16 Pressure Classifications)

Certified to ISO 9001:2015 for quality management, with full traceability from raw materials to final assembly.

Rigorous Testing Protocols

Every BFV valve undergoes 100% unit testing with digital traceability:

Hydrostatic Testing: 1.5× PN rating (e.g., 15 bar for PN10, 24 bar for PN16) per ISO 5208 Class IV.

Air Leak Testing: 1.1× PN rating with zero bubble detection at 0.1 mL/min leakage rate.

Solenoid Endurance: 1,000,000+ cycle validation under 100% humidity and 60°C ambient conditions.

Test reports are digitally archived for 10+ years, ensuring full compliance with global project requirements.

Performance Benchmarking: BFV vs. Low-Cost Alternatives

| Feature | BFV Certified Quality | Low-Cost Alternatives |

|---|---|---|

| Material Quality | ASTM A536 ductile iron / SS316; corrosion-resistant, 30% higher tensile strength | Low-grade cast iron or PVC; prone to cracking under stress |

| Pressure Rating Consistency | ±2% tolerance under operational load; certified PN10/PN16 | ±10% variance; frequent overpressure failures |

| UV Resistance | ASTM G154-tested polymers (5,000+ hours); no surface degradation | Basic PVC; cracks within 2 years of outdoor exposure |

| Solenoid Reliability | IP68-rated, 1M cycle life, corrosion-resistant coils | IP54-rated, 200k cycles; moisture ingress common |

| Testing Compliance | 100% hydrostatic & air testing; digital logs traceable to batch | Spot testing only; no documentation or traceability |

| Warranty | 10-year limited warranty covering material and workmanship | 1–2 years; excludes environmental damage |

Why BFV Delivers Confidence

With 10+ years of global export experience and ISO 9001-certified processes, BFV Valves ensures mission-critical reliability for irrigation and sump pump systems. Our 100% testing protocol guarantees every unit meets stringent performance criteria before shipment—proven across 50+ countries in demanding agricultural, municipal, and industrial applications.

Engineered for precision. Built for longevity.

Manufacturing Excellence & QC

Manufacturing & Quality Assurance

BFV Valves’ commitment to engineering excellence is embedded in every stage of production. With a decade of successful global exports, our ISO 9001:2015-certified facility employs a Purpose Built Test Zone to validate 100% of irrigation valves prior to shipment. This systematic approach ensures that each unit meets exacting standards for flow control accuracy, UV resistance, solenoid reliability, and pressure integrity (PN10/16), providing engineering consultants and contractors with dependable performance in critical applications.

Precision Manufacturing Process

Every BFV irrigation valve begins with rigorous material selection. High-grade UV-stabilized PVC (ASTM D1784) and 316 stainless steel components are sourced from certified suppliers, ensuring corrosion resistance and longevity. Automated CNC machining centers produce housings and internal components to tolerances of ±0.05mm, while robotic assembly lines minimize human error. Each stage is monitored via IoT-enabled quality control points, ensuring traceability from raw material to finished product. Our precision-engineered designs eliminate common failure points in irrigation systems, including stress fractures in PVC housings and solenoid coil degradation under continuous duty cycles.

Purpose Built Test Zone: 100% Validation Protocol

All valves undergo exhaustive testing in our dedicated facility before export. Our testing protocols exceed industry standards, with real-time data logging and digital certification for every unit. Key validation parameters include:

| Test Parameter | Standard | Method | Acceptance Criteria |

|---|---|---|---|

| Hydrostatic Pressure Test | PN16 (16 bar) | 1.5x working pressure for 5 minutes | Zero leakage |

| Flow Rate Accuracy | ISO 5167 | Flow bench testing at 0.5–200 GPM | ±2% deviation from nominal |

| Solenoid Cycle Testing | IEC 60730 | 10,000 cycles at 24V DC | 100% operational integrity |

| UV Accelerated Aging | ASTM G154 Cycle 4 | 1,000 hours exposure | ΔE ≤ 5 (no cracking, discoloration) |

| Leak Integrity | ISO 5208 | Helium mass spectrometer | < 1×10⁻⁶ mbar·L/s |

All tests are documented in our digital quality ledger, with real-time data accessible to clients upon request.

ISO 9001:2015 Certified Quality Framework

Our quality management system is certified to ISO 9001:2015, with annual audits conducted by TÜV SÜD. This framework ensures continuous improvement through standardized procedures for design validation, production control, and supplier management. Every batch undergoes statistical process control (SPC) analysis, with deviations automatically triggering root cause investigations. This systematic approach guarantees consistency across all production runs, regardless of order size or destination.

Ethical & Sustainable Manufacturing

BFV Valves adheres to strict ethical standards, including compliance with SA8000 labor practices and REACH/ROHS environmental regulations. We maintain transparent supply chains, sourcing materials from ISO 14001-certified vendors, and implement zero-waste initiatives in our manufacturing facilities. Our commitment to responsible business practices extends beyond compliance—we actively partner with industry groups to advance sustainable irrigation solutions globally.

This comprehensive approach to manufacturing and quality assurance has enabled BFV Valves to maintain a 99.8% first-time pass rate in international customs inspections and a decade-long record of zero product recalls.

Global Applications

Industrial Applications of BFV Sump Pump Irrigation Systems

Agricultural Irrigation Systems

BFV sump pump irrigation solutions deliver precision-engineered flow control for large-scale agricultural operations. Our PVC swing check valves (PN16 rated) prevent backflow in high-pressure water supply lines, ensuring uninterrupted irrigation cycles across 500+ acre farms. UV-stabilized polymer housings withstand 10,000+ hours of direct sunlight exposure without degradation, while solenoid actuators with 1M+ cycle life enable fail-safe zone control in drip and sprinkler systems. This reliability has been validated in Midwest farm installations, where consistent water distribution directly correlates to 15% higher crop yields and 30% reduced water waste.

Commercial Landscape Projects

For premium residential and municipal landscapes, BFV valves combine aesthetic durability with technical precision. Our 1-1/4″ and 1-1/2″ IPS PVC swing check valves feature corrosion-resistant construction and 100% leak-tested integrity, eliminating backflow risks in exposed irrigation networks. The UV-resistant housings maintain structural stability in high-sun environments, while PN16 pressure ratings handle peak flow demands without performance loss. These valves are specified in 200+ annual landscape projects, including luxury resorts and urban green spaces, where zero maintenance downtime is critical for client satisfaction.

Golf Course Water Management

Golf course irrigation demands mission-critical reliability across variable terrain and pressure zones. BFV’s 60 Series booster pump control valves (PN16) prevent pipeline surges during pump cycling, while solenoid actuators with military-grade sealing ensure precise flow regulation for 18-hole course systems. Our UV-stabilized housings endure constant exposure to harsh elements, and 100% flow calibration guarantees consistent pressure distribution across fairways and greens. This has resulted in zero system failures across 15+ major golf course projects over the past 5 years, with 25% lower operational costs compared to standard alternatives.

Greenhouse Climate Control Systems

In controlled-environment agriculture, BFV valves deliver micron-level accuracy for hydroponic and irrigation systems. Our PN10-rated sump pump check valves feature hermetically sealed solenoid actuators to prevent moisture ingress, while UV-resistant polymers ensure longevity in humid greenhouse conditions. Each unit undergoes 100% leak testing to guarantee zero failures in nutrient delivery pipelines, where 0.1% flow accuracy directly impacts crop quality. This precision has been critical in 50+ commercial greenhouse installations globally, supporting year-round yield optimization for high-value crops.

Why BFV Valves is the Trusted Partner for Blue-Chip Engineering Professionals

| Key Differentiator | BFV Implementation | Client Impact |

|---|---|---|

| 100% Component Testing | Every valve undergoes 100% pressure testing (PN10/16), flow calibration, and leak detection before shipment. | Eliminates field failures; reduces lifecycle maintenance costs by 35% compared to industry averages. |

| ISO 9001 Certified Manufacturing | End-to-end quality control from raw material sourcing to final assembly, certified to ISO 9001:2015 standards. | Consistent performance across global projects; meets stringent regulatory requirements in 50+ countries. |

| 10-Year Global Export History | Proven track record in diverse climates (arid deserts to tropical humidity) with 98% on-time delivery rate. | Trusted by Fortune 500 engineering firms for mission-critical infrastructure, with zero recalls in export markets. |

Technical Assurance for Critical Infrastructure

BFV Valves’ commitment to “safe pair of hands” engineering extends beyond specifications:

UV Resistance: Advanced polymer formulations withstand 10,000+ hours of UV exposure (tested per ASTM G154).

Solenoid Reliability: Hermetically sealed actuators with 1M+ cycle life, validated through 500,000+ operational tests.

Pressure Integrity: All PN10/PN16 valves certified to ISO 5208 for zero leakage at 1.6 MPa (232 PSI) hydrostatic testing.

“BFV’s valves are the only solution we specify for high-stakes irrigation projects. Their 100% testing protocol and ISO-certified manufacturing eliminate guesswork in critical infrastructure.”

— Lead Engineer, Tier-1 Civil Engineering Firm (Europe)

For detailed technical documentation, compliance certificates, or project-specific engineering support, contact our global export team at export@bfvvalves.com or visit bfvvalves.com/industrial-irrigation.

Why Choose BFV Valves

Partner with BFV Valves: Precision Irrigation Solutions for Critical Applications

Engineered for Uncompromising Performance

Flow Control Accuracy: Precision-engineered valve mechanisms with ±0.5% flow regulation accuracy, ensuring optimal irrigation efficiency and minimal water wastage.

UV Resistance: UV-stabilized PVC and EPDM components with 10,000+ hours of accelerated weathering testing, maintaining structural integrity in outdoor installations.

Solenoid Reliability: Sealed solenoid coils with IP68 rating, ensuring fail-safe operation in high-moisture environments and resistance to voltage fluctuations.

Pressure Rating (PN10/16): Certified to PN10 (10 bar) and PN16 (16 bar) standards, compliant with ISO 7268 for safe operation in high-pressure irrigation systems.

Quality Assurance & Global Trust

| Certification | Details | Assurance |

|---|---|---|

| 100% Product Testing | Each valve undergoes 100% functional and pressure testing per ISO 5208 standards | Zero defects in critical applications |

| ISO 9001 Certified | Adherence to ISO 9001:2015 standards with regular third-party audits | Consistent quality across all batches |

| 10-Year Export History | Exporting to 50+ countries since 2014, with 95% client retention rate | Reliable supply chain and compliance with international regulations |

Partner Benefits

| Benefit | Description | Value Proposition |

|---|---|---|

| Accurate Delivery Times | Optimized global logistics network with dedicated freight partners and real-time tracking | 98% on-time delivery rate, minimizing project delays |

| No-Obligation Consultancy | Dedicated engineering team provides free technical support for system design and troubleshooting | Tailored solutions without upfront commitment |

| Competitive Pricing | Strategic manufacturing partnerships and bulk procurement efficiencies | 10–15% below market average pricing for equivalent quality |

Regional Contact: Alex@cmovalve.com.cn

Your trusted partner for mission-critical irrigation valve solutions – engineered for precision, built for longevity.

🧮 Valve Flow Coefficient (Cv) Calculator

Estimate the required valve size based on flow rate and pressure drop.