Introduction: Navigating the Global Market for irrigation pump covers

As global agricultural demands rise, the need for reliable irrigation solutions has never been more critical. Among these solutions, irrigation pump covers play a pivotal role in protecting vital equipment from harsh environmental conditions, ensuring longevity and efficiency. However, sourcing the right covers can be a daunting challenge for international B2B buyers, particularly those operating in diverse markets across Africa, South America, the Middle East, and Europe, including countries like Vietnam and Germany. This guide aims to demystify the process of selecting high-quality irrigation pump covers by providing comprehensive insights into various types, their applications, and essential criteria for supplier vetting.

Throughout this guide, we will explore the broad spectrum of irrigation pump cover options available on the market, from decorative mock rock designs that blend seamlessly into landscapes to functional, heavy-duty models suited for extreme climates. In addition to examining product features, we will delve into cost considerations, helping buyers understand pricing structures and potential return on investment. By equipping B2B buyers with the knowledge necessary to make informed purchasing decisions, this guide empowers businesses to enhance their irrigation systems, ultimately leading to improved agricultural productivity and sustainability. Whether you are a distributor, a contractor, or a farm manager, navigating the global market for irrigation pump covers has never been easier.

Understanding irrigation pump covers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mock Rock Covers | Made from durable, weather-resistant materials, mimicking natural rock. | Landscaping, residential, and commercial irrigation systems. | Pros: Aesthetic appeal; blends with natural surroundings. Cons: Higher initial cost compared to basic covers. |

| Plastic Utility Covers | Lightweight, easy to install, and often come in various colors. | Agricultural irrigation setups, municipal water systems. | Pros: Cost-effective; versatile use. Cons: Less durable than other materials, may require replacement sooner. |

| Metal Covers | Constructed from galvanized steel or aluminum, offering high durability. | Heavy-duty applications, industrial irrigation systems. | Pros: Long lifespan; excellent protection against physical damage. Cons: Heavier and more expensive; may require professional installation. |

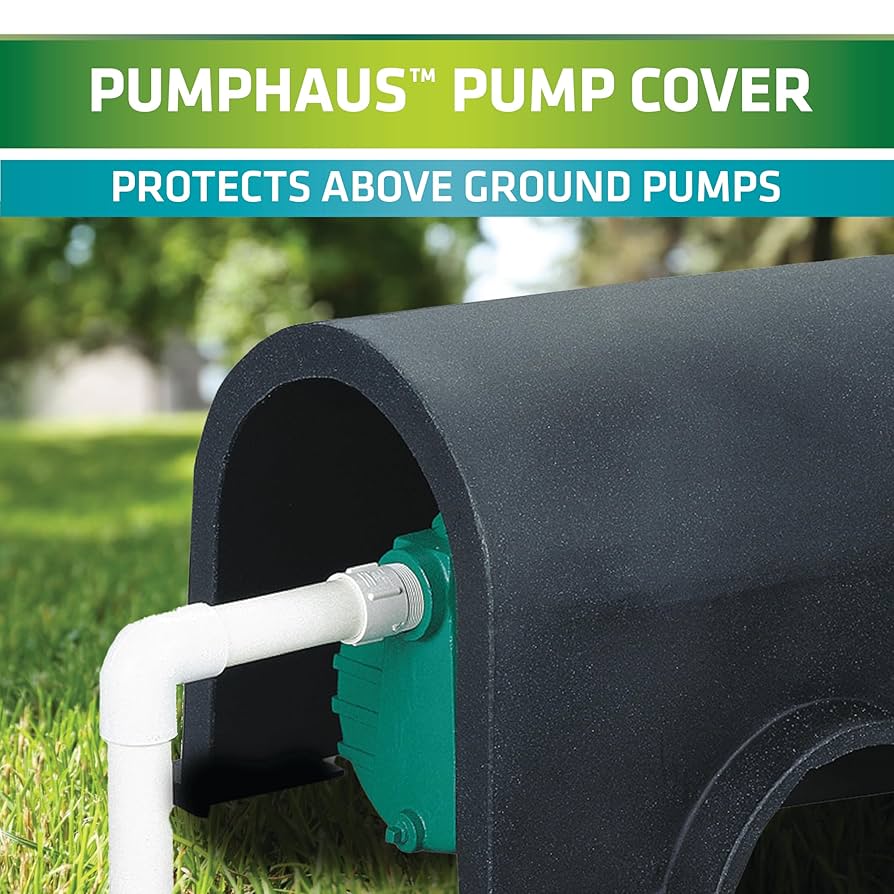

| Insulated Pump Covers | Designed to prevent freezing, often with foam insulation. | Cold climate irrigation systems, winterization processes. | Pros: Protects equipment from extreme temperatures. Cons: More complex design; higher cost. |

| Custom Fabricated Covers | Tailored to specific pump sizes and installations, made from various materials. | Specialized agricultural operations, unique irrigation setups. | Pros: Perfect fit for specific applications; optimal protection. Cons: Longer lead times; potentially higher costs. |

What are Mock Rock Covers and Their Benefits for B2B Buyers?

Mock rock covers are designed to resemble natural stone, providing an aesthetically pleasing solution for concealing pumps and wellheads. These covers are typically made from durable, weather-resistant materials that can withstand harsh environmental conditions. They are especially suitable for landscaping projects, both residential and commercial, as they blend seamlessly into the natural surroundings. B2B buyers should consider the initial investment, as these covers tend to be pricier than standard options, but their long-term durability and visual appeal can justify the cost.

How Do Plastic Utility Covers Compare in Practicality?

Plastic utility covers are lightweight and versatile, making them easy to install and transport. Available in various colors, these covers are ideal for agricultural and municipal irrigation systems where cost-effectiveness is a priority. While they offer a lower price point, buyers should be aware that plastic covers may not last as long as more robust materials, potentially leading to more frequent replacements. This trade-off between upfront costs and longevity is an important consideration for B2B purchasers.

What Advantages Do Metal Covers Offer for Heavy-Duty Applications?

Metal covers, typically made from galvanized steel or aluminum, provide exceptional durability and protection for irrigation pumps. Their robust construction makes them suitable for heavy-duty applications, including industrial irrigation systems where physical damage is a concern. While they come with a higher price tag and may require professional installation due to their weight, their long lifespan and ability to withstand harsh conditions make them a worthwhile investment for businesses looking for reliable pump protection.

Why Are Insulated Pump Covers Essential in Cold Climates?

Insulated pump covers are specifically designed to protect irrigation equipment from freezing temperatures, featuring foam insulation to maintain optimal operating conditions. These covers are crucial for businesses operating in colder climates, where the risk of equipment damage due to freezing is significant. While they may involve a higher initial cost and a more complex design, the protection they offer can prevent costly repairs or replacements, making them a smart choice for B2B buyers in relevant regions.

How Do Custom Fabricated Covers Meet Unique Business Needs?

Custom fabricated covers are tailored to fit specific pump sizes and installations, offering an optimal solution for specialized agricultural operations or unique irrigation setups. These covers can be made from various materials, allowing businesses to choose the best fit for their environmental conditions and operational requirements. However, buyers should consider that custom solutions may involve longer lead times and potentially higher costs. Investing in a custom cover can ensure the best protection and efficiency for unique applications.

Key Industrial Applications of irrigation pump covers

| Industry/Sector | Specific Application of Irrigation Pump Covers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Protecting irrigation pumps in crop fields | Enhances pump longevity and reduces maintenance costs | Durability against UV, moisture resistance, and proper sizing |

| Landscaping & Horticulture | Concealing pumps in decorative gardens and landscapes | Improves aesthetic appeal while protecting equipment | Customizable designs and colors to blend with landscape features |

| Water Management | Covering pumps in municipal water supply systems | Prevents contamination and ensures reliable water delivery | Compliance with local regulations and standards for safety |

| Construction | Shielding temporary irrigation setups on construction sites | Reduces equipment theft and damage during project duration | Lightweight materials for easy handling and installation |

| Aquaculture | Protecting pumps in fish farms and aquaculture facilities | Maintains optimal water quality and minimizes operational risks | Corrosion-resistant materials suitable for aquatic environments |

How Are Irrigation Pump Covers Used in Agriculture?

In the agricultural sector, irrigation pump covers are essential for protecting pumps used in crop fields from environmental elements such as UV rays, dust, and moisture. This protection enhances the longevity of the pumps, significantly reducing maintenance costs and downtime. Buyers in this sector should prioritize covers made from durable materials that can withstand harsh weather conditions, particularly in regions like Africa and South America, where extreme climates are prevalent.

What Role Do Irrigation Pump Covers Play in Landscaping & Horticulture?

In landscaping and horticulture, irrigation pump covers serve both functional and aesthetic purposes. They conceal pumps in decorative gardens, ensuring that the visual appeal of the landscape is maintained while protecting the equipment from the elements. Buyers in this industry often seek customizable designs that can blend seamlessly with their landscaping features, making it crucial to source covers that offer both functionality and style.

How Do Irrigation Pump Covers Contribute to Water Management?

Irrigation pump covers are critical in municipal water supply systems, where they help prevent contamination and ensure reliable water delivery. These covers protect pumps from debris and environmental pollutants, which is vital for maintaining water quality. International buyers, especially in the Middle East and Europe, should consider sourcing covers that comply with local safety and regulatory standards to ensure operational integrity and public health.

Why Are Irrigation Pump Covers Important in Construction?

In the construction industry, temporary irrigation setups often require pump covers to shield equipment from theft and damage. These covers provide a layer of security and protection during the project duration, ensuring that the irrigation systems remain operational when needed. Buyers should look for lightweight materials that facilitate easy handling and installation, as construction sites may require frequent adjustments and relocations of equipment.

How Do Irrigation Pump Covers Benefit Aquaculture?

In aquaculture, irrigation pump covers protect pumps used in fish farms and other aquatic facilities from environmental factors that could compromise water quality. This protection is crucial for maintaining optimal conditions for aquatic life, thereby minimizing operational risks. Sourcing corrosion-resistant materials is essential for buyers in this sector, particularly in regions with high humidity or saline conditions, ensuring the longevity and reliability of their equipment.

3 Common User Pain Points for ‘irrigation pump covers’ & Their Solutions

Scenario 1: Inadequate Protection Against Environmental Factors

The Problem:

B2B buyers often face the challenge of selecting irrigation pump covers that effectively shield their equipment from harsh environmental conditions. In regions with extreme weather, such as intense sunlight in Africa or heavy rainfall in South America, inadequate protection can lead to significant wear and tear on pumps. This not only shortens the lifespan of the equipment but can also result in costly repairs or replacements. Additionally, buyers may struggle to find covers that can withstand local climate challenges while still being aesthetically pleasing for landscaping purposes.

The Solution:

To combat these issues, it is crucial to select irrigation pump covers made from high-quality, durable materials designed for specific environmental conditions. Buyers should prioritize covers that offer UV protection and are waterproof or resistant to moisture. When sourcing, consider manufacturers who provide detailed specifications and climate ratings for their products. It may also be beneficial to look for customizable options that can be tailored to fit specific pump sizes and local aesthetic preferences. Regular maintenance checks and timely replacement of worn covers can further extend the lifespan of the irrigation systems, protecting the investment in the long term.

Scenario 2: Difficulty in Sizing and Compatibility

The Problem:

Another common pain point for B2B buyers is the challenge of ensuring that irrigation pump covers fit properly and are compatible with existing equipment. Many buyers experience frustration when covers do not align with the dimensions or configurations of their pumps, leading to inadequate protection and operational inefficiencies. This issue can arise from a lack of clear sizing information from suppliers or the existence of various pump models with unique specifications across different regions.

The Solution:

To mitigate sizing challenges, buyers should adopt a systematic approach to measuring their pumps before making a purchase. Detailed measurement guides and compatibility charts provided by manufacturers can be extremely helpful. Engaging with suppliers who offer pre-purchase consultations can also ensure that the right cover is selected. Additionally, buyers should consider investing in adjustable or flexible covers that can accommodate minor variations in pump sizes. Implementing a standardized procedure for documenting pump specifications can streamline future purchases, reducing the likelihood of compatibility issues.

Scenario 3: High Costs of Replacement and Maintenance

The Problem:

Cost management is a critical concern for B2B buyers dealing with irrigation pump covers. Buyers often find themselves facing unexpected costs associated with frequent replacements or maintenance of subpar covers. This scenario is particularly prevalent in regions where budget constraints are significant, and the need for cost-effective solutions is paramount. Inadequate covers can lead to higher operational costs due to increased energy consumption or damage to the pumps, ultimately impacting the bottom line.

The Solution:

To address these financial concerns, buyers should consider investing in high-quality, durable covers that may have a higher upfront cost but provide long-term savings through reduced maintenance and replacement needs. Conducting a total cost of ownership analysis can help buyers understand the long-term implications of their purchasing decisions. Additionally, exploring bulk purchasing options or establishing contracts with suppliers can lead to discounts and more favorable pricing structures. Regularly reviewing the performance of existing covers and seeking feedback from maintenance teams can also identify opportunities for cost savings and efficiency improvements.

Strategic Material Selection Guide for irrigation pump covers

What Are the Key Materials Used for Irrigation Pump Covers?

When selecting materials for irrigation pump covers, it is crucial to consider properties that enhance performance and durability under various environmental conditions. Below, we analyze four common materials used in the manufacturing of irrigation pump covers, focusing on their key properties, advantages and disadvantages, and implications for international buyers.

How Does Polyethylene Perform as a Material for Irrigation Pump Covers?

Polyethylene is a widely used thermoplastic known for its excellent chemical resistance and lightweight nature. It can withstand temperatures up to 80°C (176°F) and is resistant to corrosion from various chemicals, making it suitable for many irrigation applications.

Pros: Polyethylene is cost-effective and easy to manufacture, allowing for mass production of covers in various shapes and sizes. Its lightweight nature simplifies installation and transportation.

Cons: While it is durable against chemicals, polyethylene may not perform well under extreme UV exposure, leading to degradation over time. Additionally, it has lower temperature resistance compared to other materials.

Impact on Application: Polyethylene covers are particularly suitable for environments with moderate temperature fluctuations and exposure to chemicals commonly found in irrigation systems.

Considerations for International Buyers: Buyers in regions like Africa and the Middle East should ensure that the polyethylene used meets local environmental standards. Compliance with ASTM D1248 for polyethylene materials is essential for quality assurance.

What Advantages Does Fiberglass Offer for Irrigation Pump Covers?

Fiberglass is a composite material known for its high strength-to-weight ratio and excellent resistance to corrosion and UV light. It can withstand temperatures up to 150°C (302°F), making it suitable for hotter climates.

Pros: Fiberglass is highly durable and can withstand harsh weather conditions, making it ideal for long-term use. Its resistance to corrosion ensures a longer lifespan compared to other materials.

Cons: The manufacturing process for fiberglass can be complex and costly, leading to higher prices. Additionally, it may require specialized installation techniques.

Impact on Application: Fiberglass covers are well-suited for environments with extreme temperatures and UV exposure, providing reliable protection for irrigation pumps.

Considerations for International Buyers: Buyers in Europe, such as Germany, should verify that fiberglass products comply with DIN standards for safety and quality.

Why Choose Metal for Irrigation Pump Covers?

Metal covers, often made from aluminum or galvanized steel, offer robust protection and durability. They can withstand high temperatures and pressures, making them suitable for heavy-duty applications.

Pros: Metal covers are highly durable and resistant to physical impacts. They provide excellent protection against environmental elements and pests.

Cons: Metal can be prone to corrosion if not properly treated, which may lead to maintenance issues. Additionally, metal covers are heavier, making installation more challenging.

Impact on Application: Metal covers are ideal for industrial applications where pumps are subjected to high pressure and temperature variations.

Considerations for International Buyers: Buyers in South America should ensure that metal covers comply with local corrosion resistance standards, such as ISO 9227 for salt spray testing.

What Role Does Concrete Play in Irrigation Pump Covers?

Concrete is a traditional material known for its strength and durability. It offers excellent protection against physical damage and can withstand extreme weather conditions.

Pros: Concrete covers provide superior durability and can be customized to fit specific site requirements. They are resistant to fire and pests.

Cons: The weight of concrete makes it difficult to handle and install. Additionally, it can be more expensive due to the need for specialized equipment and labor for installation.

Impact on Application: Concrete covers are best suited for permanent installations in areas where extreme weather conditions are prevalent.

Considerations for International Buyers: Buyers in regions with seismic activity, such as parts of South America, should ensure that concrete covers meet local building codes and standards.

Summary Table of Material Selection for Irrigation Pump Covers

| Material | Typical Use Case for irrigation pump covers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene | Light-duty applications in moderate climates | Cost-effective and lightweight | UV degradation over time | Low |

| Fiberglass | Harsh environments with extreme conditions | Highly durable and UV resistant | Higher manufacturing cost | High |

| Metal | Heavy-duty industrial applications | Robust protection against impacts | Prone to corrosion if untreated | Medium |

| Concrete | Permanent installations in extreme climates | Superior durability | Difficult to handle and install | High |

In-depth Look: Manufacturing Processes and Quality Assurance for irrigation pump covers

What Are the Key Manufacturing Processes for Irrigation Pump Covers?

The manufacturing of irrigation pump covers involves a series of well-defined stages that ensure the final product meets industry standards and customer expectations. Understanding these processes is crucial for B2B buyers looking to source high-quality irrigation pump covers.

How Is Material Prepared for Manufacturing?

The first step in the manufacturing process is material preparation, which typically involves selecting high-quality materials suited for the intended application. Common materials include high-density polyethylene (HDPE), fiberglass, and reinforced plastics, chosen for their durability, weather resistance, and UV stability.

Once the materials are selected, they undergo treatment to enhance their performance. For instance, UV stabilizers may be added to prevent degradation from sun exposure. The raw materials are then cut into the required dimensions, ensuring they are ready for the forming stage.

What Techniques Are Used in Forming Irrigation Pump Covers?

Forming is a critical stage that shapes the prepared materials into the desired configurations. Various techniques are employed, including:

Injection Molding: This method is widely used for producing plastic covers. The thermoplastic material is heated until molten and then injected into a mold. Once cooled, the mold is removed, and the cover is ready for further processing.

Rotational Molding: Ideal for creating hollow covers, this technique involves heating the material in a mold that rotates along two axes. This ensures even distribution and thickness of the material.

Vacuum Forming: A less common method, vacuum forming involves heating a sheet of plastic until pliable and then drawing it over a mold using vacuum pressure. This technique is often used for smaller covers.

Each technique offers unique advantages in terms of cost, scalability, and finish quality, allowing manufacturers to select the most suitable method based on order size and specifications.

How Are Irrigation Pump Covers Assembled and Finished?

After forming, the next stage is assembly, where components, if any, are joined together. For instance, covers that require additional features like vents or locks will undergo assembly at this stage.

Finishing processes enhance the aesthetic appeal and functionality of the covers. This may include:

Surface Treatment: Processes like sanding, painting, or coating are applied to improve the surface finish and add protective layers against environmental factors.

Quality Coatings: Special coatings can be applied for enhanced durability, such as anti-fungal or anti-corrosive treatments, particularly important in humid or saline environments.

Labeling and Branding: Final touches often include the application of labels for branding and compliance information.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is paramount in ensuring that irrigation pump covers meet both local and international standards. B2B buyers should be aware of relevant certifications and quality control processes.

Which International Standards Are Relevant for Irrigation Pump Covers?

Manufacturers often adhere to international standards such as ISO 9001, which outlines the requirements for a quality management system. This certification demonstrates a commitment to consistent quality and customer satisfaction.

In addition to ISO standards, industry-specific certifications may apply, such as:

CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

API Certification: Relevant for products used in oil and gas applications, ensuring safety and reliability.

These certifications not only enhance product credibility but also facilitate smoother international trade.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) is integrated throughout the manufacturing process, with several key checkpoints established:

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

In-Process Quality Control (IPQC): Ongoing checks during production help identify and rectify issues in real-time, ensuring consistent quality throughout the manufacturing process.

Final Quality Control (FQC): The last stage of quality assurance, where finished products are inspected for defects and compliance with specifications before they are shipped to customers.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, ensuring that suppliers maintain high-quality standards is essential. Here are several strategies to verify supplier QC:

What Steps Can Buyers Take to Conduct Supplier Audits?

Conducting thorough supplier audits is one of the most effective ways to assess quality control processes. Buyers should consider:

On-site Visits: Direct visits to manufacturing facilities can provide insights into production practices, equipment, and overall operations.

Documentation Review: Requesting quality assurance documentation, including QC reports, test results, and certification copies, allows buyers to evaluate a supplier’s commitment to quality.

What Are the Benefits of Third-Party Inspections?

Engaging third-party inspection services can add an extra layer of assurance. These independent organizations can conduct comprehensive audits and testing, providing unbiased assessments of product quality and compliance with standards.

What Nuances Should International Buyers Be Aware Of?

When sourcing irrigation pump covers from different regions, B2B buyers must be mindful of regional regulations and standards that may vary significantly.

For example, buyers from Africa and South America may encounter different compliance requirements compared to those in Europe or the Middle East. Additionally, understanding local market demands, climate conditions, and cultural preferences can inform better purchasing decisions.

Conclusion

By grasping the intricacies of the manufacturing processes and quality assurance measures for irrigation pump covers, B2B buyers can make informed decisions. Understanding these factors not only aids in selecting reliable suppliers but also ensures that the products meet the necessary standards for performance and durability in various environments. Investing time in due diligence can yield significant long-term benefits, leading to successful partnerships and high-quality irrigation solutions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘irrigation pump covers’

Introduction

Navigating the procurement of irrigation pump covers can be complex, especially for international B2B buyers. This guide provides a structured checklist to help you source high-quality, durable covers that meet your irrigation needs. By following these steps, you can ensure that your investment is sound, and your operational efficiency is maximized.

Step 1: Define Your Technical Specifications

Before initiating your search, clearly outline the technical specifications required for your irrigation pump covers. This includes dimensions, material preferences (e.g., plastic, metal), and any specific features such as UV resistance or insulation properties. Defining these parameters will help streamline your options and ensure compatibility with your existing systems.

Step 2: Research Market Trends and Requirements

Understand the current market trends in the regions you are targeting, such as Africa, South America, the Middle East, and Europe. Look for insights on preferred materials and designs, as well as any regional compliance standards. This knowledge will help you make informed decisions and avoid potential regulatory issues.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure reliability and quality. Request company profiles, case studies, and references from buyers in similar industries or regions. Check for certifications that validate their compliance with international quality standards, which can significantly impact the longevity and performance of the covers.

Step 4: Request Samples for Quality Assessment

Before finalizing an order, request samples of the irrigation pump covers. Evaluate these samples for durability, aesthetics, and functionality. This hands-on assessment can reveal whether the product truly meets your specifications and expectations, reducing the risk of costly mistakes later on.

Step 5: Compare Pricing and Terms

Gather quotes from multiple suppliers to compare pricing structures and terms of sale. Pay attention not just to the price but also to the delivery timelines, payment terms, and warranty conditions. A lower price may not always equate to better value if it comes with unfavorable terms or long lead times.

Step 6: Check for After-Sales Support and Warranty

Evaluate the after-sales support offered by suppliers, including warranty conditions and customer service responsiveness. A solid warranty and reliable support can provide peace of mind and protect your investment in the long run. Ensure that you understand the procedures for claims and returns, as this will be crucial should any issues arise.

Step 7: Finalize Your Order and Monitor Delivery

Once you have selected a supplier, finalize your order with clear communication regarding specifications, quantities, and delivery expectations. Monitor the delivery process to ensure timelines are met and that the products received match your initial specifications. Establishing a good relationship with the supplier can facilitate smoother transactions in future orders.

By following this checklist, you can effectively navigate the complexities of sourcing irrigation pump covers, ensuring that your procurement process is efficient and your investment is secure.

Comprehensive Cost and Pricing Analysis for irrigation pump covers Sourcing

When sourcing irrigation pump covers, understanding the comprehensive cost structure is crucial for effective budgeting and negotiation. The cost components involved in the manufacturing of these products typically include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

What Are the Key Cost Components in Irrigation Pump Covers?

Materials: The choice of materials significantly affects cost. Common materials include high-density polyethylene (HDPE), polypropylene, and various composite materials designed for durability and weather resistance. Prices can vary based on the quality and availability of these materials, often influenced by regional supply chains.

Labor: Labor costs can fluctuate based on the location of manufacturing. Regions with lower labor costs may offer more competitive pricing but could compromise on quality if not managed properly. It’s essential to consider the skill level of the workforce, which can affect production efficiency and quality.

Manufacturing Overhead: This includes utilities, rent, and equipment maintenance. A well-optimized facility can reduce overhead costs, which directly impacts the final price of the covers.

Tooling: Custom tooling for specific designs or features can be a significant upfront investment. However, this cost can be amortized over larger production runs, making it essential to balance tooling costs with anticipated order volumes.

Quality Control (QC): Implementing robust QC processes can increase initial costs but ultimately ensures product reliability. Certifications such as ISO 9001 can add to costs but are often necessary for international markets.

Logistics: Transportation and shipping costs can vary widely depending on the supplier’s location and the buyer’s destination. Factors such as customs duties and local taxes should also be factored into the logistics budget.

Margin: Suppliers will include a profit margin, which can vary based on their market position, competition, and overall demand for their products.

How Do Price Influencers Affect Sourcing Decisions?

Several factors influence the pricing of irrigation pump covers:

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Higher volumes typically lead to lower per-unit costs due to economies of scale. Negotiating favorable MOQs can yield better pricing structures.

Specifications/Customization: Custom designs or specific technical requirements can raise costs. Buyers should assess whether customization is necessary or if standard models can meet their needs.

Materials and Quality Certifications: The selection of materials and the presence of quality certifications can impact pricing. Higher-quality materials and certifications may lead to higher upfront costs but can reduce maintenance and replacement expenses over time.

Supplier Factors: Supplier reliability, reputation, and financial stability should influence purchasing decisions. Established suppliers may charge a premium but often provide better service and product quality.

Incoterms: Understanding Incoterms is vital for international transactions. Different terms can affect the total cost of ownership by altering responsibilities for shipping, insurance, and risk.

What Are the Best Practices for B2B Buyers in Negotiating Prices?

For international buyers, especially in regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

Negotiate Terms: Don’t hesitate to negotiate payment terms, MOQs, and shipping costs. Building a good relationship with suppliers can lead to better pricing and terms in future transactions.

Consider Total Cost of Ownership (TCO): Evaluate the TCO, including purchase price, shipping, installation, and maintenance costs. Sometimes a higher upfront cost may result in lower overall expenses due to durability and lower maintenance needs.

Be Aware of Pricing Nuances: Currency fluctuations, local market conditions, and geopolitical factors can all affect pricing. Keeping abreast of these elements can aid in making informed purchasing decisions.

Conduct Supplier Audits: Regularly assess suppliers for quality, reliability, and pricing competitiveness. This practice ensures that you are getting the best value for your investment.

Conclusion

In summary, a comprehensive understanding of the cost structure and pricing dynamics of irrigation pump covers is essential for effective sourcing. By analyzing cost components, recognizing price influencers, and employing strategic negotiation tactics, B2B buyers can optimize their procurement processes and ensure favorable outcomes. Always remember to consider the indicative nature of prices, as they may vary based on market conditions and supplier negotiations.

Alternatives Analysis: Comparing irrigation pump covers With Other Solutions

Understanding Alternatives to Irrigation Pump Covers

In the realm of agricultural and landscape irrigation, protecting vital components such as pumps is essential for ensuring system longevity and efficiency. While irrigation pump covers serve this purpose effectively, buyers may also consider alternative solutions that can provide similar or enhanced benefits. This section explores three viable alternatives, enabling B2B buyers to make informed decisions based on their unique operational needs.

Comparison of Irrigation Pump Covers with Alternative Solutions

| Comparison Aspect | Irrigation Pump Covers | Concrete Enclosures | Protective Shrubs and Landscaping |

|---|---|---|---|

| Performance | Excellent weather resistance and UV protection for pumps. | Very durable; provides robust physical protection against impact and environmental factors. | Offers a natural barrier; can deter pests but less effective against severe weather. |

| Cost | Moderate ($40 – $600 depending on size and material). | Higher upfront costs due to material and labor ($300 – $1,500). | Low to moderate; costs vary based on plant type and landscaping design. |

| Ease of Implementation | Simple installation; often requires minimal tools. | Requires professional installation and site preparation. | Requires planning and maintenance; takes time to establish growth. |

| Maintenance | Low maintenance; occasional cleaning may be needed. | Minimal maintenance once installed; may require occasional repairs. | Regular maintenance needed for plant health (watering, pruning). |

| Best Use Case | Ideal for residential and commercial irrigation systems needing quick protection. | Best for high-value installations where maximum protection is crucial. | Suitable for integrated landscape designs, offering aesthetic and functional benefits. |

In-Depth Look at Alternative Solutions

1. Concrete Enclosures

Concrete enclosures provide a sturdy alternative to irrigation pump covers. They offer superior durability, shielding pumps from physical damage and harsh weather conditions. However, the installation process can be labor-intensive and costly, often requiring professional services. While these enclosures are excellent for high-value installations, they may not be the best choice for projects with budget constraints or where quick access to the pump is necessary.

2. Protective Shrubs and Landscaping

Using shrubs and landscaping as a protective measure is another viable alternative. This method integrates aesthetics with functionality, creating a natural barrier around irrigation pumps. While it can deter pests and provide some protection from the elements, it may not offer the robust coverage that dedicated pump covers do. Additionally, this approach requires ongoing maintenance to ensure plant health, which may not be feasible for all buyers.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right protective solution for irrigation pumps depends on several factors, including budget, installation preferences, and the level of protection required. For quick and effective coverage, irrigation pump covers are often the best choice. However, for projects demanding maximum durability and security, concrete enclosures may be worth the investment. Alternatively, for buyers interested in integrating natural elements into their landscape, protective shrubs can provide a dual benefit. Ultimately, evaluating these alternatives in the context of specific operational needs will guide B2B buyers toward the most suitable solution.

Essential Technical Properties and Trade Terminology for irrigation pump covers

What Are the Key Technical Properties of Irrigation Pump Covers?

When selecting irrigation pump covers, understanding their technical properties is crucial for ensuring durability, functionality, and compliance with industry standards. Here are some essential specifications to consider:

Material Grade: The material used in pump covers, such as high-density polyethylene (HDPE) or fiberglass, affects strength, UV resistance, and longevity. For B2B buyers, selecting the right material can minimize maintenance costs and enhance the lifespan of the cover, making it a critical factor in procurement decisions.

Dimensions and Tolerances: Accurate dimensions and tolerances are vital for ensuring that the cover fits properly over the pump without gaps or excessive pressure. This aspect is particularly important in regions with fluctuating temperatures, as improper fit can lead to damage from thermal expansion or contraction. Buyers should specify their requirements to ensure compatibility with existing installations.

Weight and Portability: The weight of the pump cover can impact installation and maintenance. Lighter covers may be easier to handle but could compromise durability. B2B buyers must evaluate the balance between ease of use and the robustness of the cover, particularly in commercial applications where frequent access may be required.

Weather Resistance: Covers should be designed to withstand extreme weather conditions, including high winds, heavy rain, and intense sunlight. This property is particularly important in regions such as Africa and South America, where environmental conditions can vary significantly. Buyers should look for products that offer warranties against weather-related damages.

Aesthetic Design: While functionality is key, the visual appeal of a pump cover can also be significant, especially in residential or landscaped areas. Products that mimic natural materials, like stone or rock, can blend seamlessly into outdoor environments. This consideration may influence purchasing decisions in markets focusing on aesthetic value.

Which Trade Terminology Is Important for B2B Buyers of Irrigation Pump Covers?

Understanding industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms related to irrigation pump covers:

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. B2B buyers should be aware of OEM offerings to ensure they are purchasing high-quality, compatible products for their irrigation systems.

MOQ (Minimum Order Quantity): MOQ is the smallest number of units a supplier is willing to sell. This term is crucial for B2B buyers to understand, as it can impact budgeting and inventory management. Knowing the MOQ helps in planning purchases and avoiding excess inventory.

RFQ (Request for Quotation): An RFQ is a standard business process where a buyer requests pricing and terms from suppliers. This is particularly useful for B2B buyers looking to compare offers from multiple manufacturers to secure the best deal on irrigation pump covers.

Incoterms (International Commercial Terms): These terms define the responsibilities of buyers and sellers in international shipping. Understanding Incoterms is essential for B2B transactions, as they clarify who is responsible for costs and risks at various stages of the shipping process.

Lead Time: This term refers to the amount of time between placing an order and receiving the product. For B2B buyers, understanding lead times is crucial for project planning and ensuring that irrigation systems are operational when needed.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and align with their business objectives.

Navigating Market Dynamics and Sourcing Trends in the irrigation pump covers Sector

What Are the Key Market Trends Influencing the Irrigation Pump Covers Sector?

The irrigation pump covers market is experiencing significant growth driven by the increasing demand for efficient water management systems globally. This is particularly evident in regions such as Africa, South America, the Middle East, and Europe, where agricultural practices rely heavily on reliable irrigation solutions. B2B buyers are increasingly seeking innovative products that not only protect pump systems but also enhance the aesthetic appeal of landscapes.

Emerging technologies such as smart irrigation systems are influencing sourcing trends, prompting manufacturers to integrate advanced materials and designs into their products. For instance, the introduction of lightweight, durable materials that can withstand harsh environmental conditions is becoming a priority. Additionally, the rise of e-commerce platforms has streamlined the purchasing process, enabling international buyers to access a broader range of products and suppliers.

Market dynamics are also shifting as buyers become more discerning, placing emphasis on quality, pricing, and supplier reliability. With the global supply chain disruptions witnessed in recent years, there is an increasing focus on local sourcing and partnerships with regional manufacturers to mitigate risks and ensure timely delivery. This trend is particularly vital for buyers in Africa and South America, where logistics can pose significant challenges.

How Are Sustainability and Ethical Sourcing Shaping the Irrigation Pump Covers Market?

Sustainability is increasingly becoming a cornerstone of the irrigation pump covers sector. B2B buyers are now prioritizing products that minimize environmental impact, leading to a surge in demand for eco-friendly materials and manufacturing processes. Sustainable practices not only reduce the carbon footprint but also appeal to a growing demographic of environmentally conscious consumers and businesses.

Ethical sourcing is equally important, as buyers seek to ensure that their supply chains align with social responsibility standards. Companies that adopt transparent sourcing practices and prioritize fair labor conditions are gaining competitive advantages in the market. Certifications such as ISO 14001 for environmental management and Fair Trade can enhance brand reputation and trust among buyers.

Moreover, the use of recycled materials in the production of irrigation pump covers is a trend gaining traction. This not only supports sustainability goals but also resonates with buyers looking to reduce waste and promote circular economy practices. As the market evolves, suppliers that can demonstrate a commitment to sustainability and ethical sourcing will likely capture a larger share of the B2B market.

How Has the Irrigation Pump Covers Sector Evolved Over Time?

Historically, irrigation pump covers were primarily functional, designed to protect pumps from environmental elements. However, as the agricultural sector has evolved, so too has the demand for more sophisticated and aesthetically pleasing solutions. The introduction of decorative and lightweight materials has transformed pump covers into design elements that complement landscaping.

In recent years, the focus has shifted to not only functionality and aesthetics but also sustainability and ethical production. Manufacturers are increasingly adopting advanced technologies and eco-friendly materials, responding to the demands of a more environmentally conscious market. This evolution reflects broader trends within the agricultural and landscaping industries, highlighting the need for innovation in product development to meet changing consumer preferences.

In summary, the irrigation pump covers market is navigating through dynamic changes driven by global trends in sustainability, technology, and shifting buyer expectations. Understanding these factors is essential for B2B buyers seeking to make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of irrigation pump covers

How do I choose the right irrigation pump cover for my needs?

Choosing the right irrigation pump cover involves several factors. First, assess the dimensions of your pump and select a cover that fits snugly to ensure maximum protection from environmental elements. Consider the material as well; high-quality plastic or composite materials are often more durable and weather-resistant. Additionally, evaluate the design—some covers mimic natural rock formations, which can enhance the aesthetic of your landscape. Finally, check for features like UV resistance and insulation, which are critical for areas with extreme temperatures.What are the benefits of using custom irrigation pump covers?

Custom irrigation pump covers offer several advantages, particularly in terms of fit and functionality. Tailored covers ensure complete protection against debris, moisture, and temperature fluctuations. Customization also allows for branding opportunities, as you can incorporate logos or specific colors that align with your company’s identity. Additionally, customized designs can enhance user convenience, such as easier access to the pump or integrated ventilation. This investment can lead to prolonged equipment life and reduced maintenance costs.What should I consider when vetting suppliers for irrigation pump covers?

When vetting suppliers, assess their industry experience and reputation. Look for suppliers with proven track records in providing durable and reliable pump covers. Request samples to evaluate the quality of materials and construction. Additionally, inquire about their production capabilities, lead times, and minimum order quantities (MOQs). It’s also essential to review customer testimonials and case studies to understand their service levels and responsiveness. Finally, ensure they comply with international quality standards relevant to your market.What are the typical minimum order quantities (MOQs) for irrigation pump covers?

Minimum order quantities for irrigation pump covers can vary significantly based on the supplier and the type of cover. Generally, MOQs range from 50 to 500 units, depending on the materials and customization options. Suppliers may offer lower MOQs for standard designs but higher MOQs for custom or specialized covers. It’s advisable to discuss your specific needs with potential suppliers, as many are willing to negotiate MOQs, especially for long-term partnerships or bulk orders.What payment terms should I expect when ordering irrigation pump covers internationally?

Payment terms can differ based on the supplier’s policies and the nature of the order. Common arrangements include upfront payment, a deposit followed by the balance upon shipment, or net terms (e.g., net 30 or net 60 days) after delivery. For international transactions, consider using secure payment methods like letters of credit, PayPal, or escrow services to protect your investment. Always clarify payment terms before finalizing the order to avoid any misunderstandings.How can I ensure quality assurance (QA) for irrigation pump covers?

To ensure quality assurance, establish clear specifications and standards with your supplier before production begins. Request detailed documentation of the materials used, including certifications of compliance with relevant industry standards. Implement a quality control process that includes pre-production samples and random inspections during manufacturing. Additionally, consider third-party inspection services to verify product quality before shipment. This proactive approach helps mitigate risks associated with defective products and ensures you receive reliable covers.What logistics considerations should I keep in mind when importing irrigation pump covers?

When importing irrigation pump covers, consider shipping methods, customs regulations, and delivery timelines. Choose between air freight for faster delivery or ocean freight for cost-effectiveness, depending on your urgency and budget. Familiarize yourself with import duties, taxes, and necessary documentation to avoid delays at customs. Establish a reliable logistics partner who can manage these complexities and ensure timely delivery to your location. Also, factor in warehousing needs if you’re ordering in bulk.Are there eco-friendly options available for irrigation pump covers?

Yes, many suppliers now offer eco-friendly options for irrigation pump covers made from recycled or sustainable materials. These covers not only provide the same level of protection as traditional options but also help reduce environmental impact. When sourcing, inquire specifically about the materials used and any certifications (e.g., ISO 14001) that indicate a commitment to sustainable practices. Choosing eco-friendly products can enhance your company’s reputation and appeal to environmentally conscious customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Irrigation Pump Covers Manufacturers & Suppliers List

1. Irrigation Outlet – Mock Rock Pump Covers

Domain: irrigationoutlet.com

Registered: 2012 (13 years)

Introduction: This company, Irrigation Outlet – Mock Rock Pump Covers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Munro Pump – Outdoor Motor Covers

Domain: munropump.com

Registered: 1996 (29 years)

Introduction: Pump Covers protect outdoor electric motors from sun and rain. They are suitable for various industries including Industrial, Irrigation, Mining, MRO, Municipal, OEM, Oil & Gas, and Wastewater. Applications include Ag irrigation, Domestic or potable water, and Turf Irrigation.

3. Sprinkler Savers – High-Quality Sprinkler Protectors

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Sprinkler Savers: High-quality alternative to concrete Sprinkler Donuts & Sprinkler Head Protectors, designed to keep sprinkler systems functioning properly. Patented in 2003 and made in the USA. DIY Sprinkler Valve Cover: Custom cover made from reclaimed wood to protect valves and pipes from sun damage. Decorative rocks for grinder pump stations: Lightweight and durable rocks to disguise grinder …

4. Landworks Depot – Pump Covers & Enclosures

Domain: landworksdepot.com

Registered: 2010 (15 years)

Introduction: This company, Landworks Depot – Pump Covers & Enclosures, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Safe-T Cover – Pump Covers and Enclosures

Domain: safe-t-cover.com

Registered: 1998 (27 years)

Introduction: Pump Covers and Enclosures provide maximum protection and easy access for various types of pumps including domestic booster pumps, fire pump systems, sewage and wastewater pumps, and municipal pump stations. Key features include:

– Superior protection against vandalism, theft, and harsh weather conditions.

– Easy access with lockable panels and hinged roofs for maintenance.

– Temperature regulati…

6. Zoro – Irrigation Pump Covers

Domain: zoro.com

Registered: 1995 (30 years)

Introduction: Irrigation Pump Covers available on Zoro.com include various models and prices. Key products include: 1. Nds 10 Irrig Valve Cover – Zoro # G108109121, Price: $6.29 /ea (sold in multiples of 2 for $12.58). 2. Danner Cover-Care 360 GPH Automatic Pump – Zoro # G2575451, Price: $89.81 /ea. 3. Eco-Flo Pool Cover Pump – Zoro # G7344198, Price: $175.99 /ea. 4. Jed Pool Tools Cover Pump – Zoro # G60821279…

Strategic Sourcing Conclusion and Outlook for irrigation pump covers

In conclusion, strategic sourcing for irrigation pump covers is critical for optimizing operational efficiency and ensuring the longevity of irrigation systems. Buyers must prioritize quality, durability, and compatibility with their existing infrastructure when selecting covers, as these factors significantly impact performance and maintenance costs. Additionally, understanding regional market trends and supplier capabilities can enhance procurement strategies, enabling organizations to secure the best value and minimize supply chain risks.

As international buyers, particularly from Africa, South America, the Middle East, and Europe, it is essential to stay informed about innovations and advancements in pump cover technologies. Emphasizing sustainability and eco-friendly materials will not only align with global standards but also appeal to increasingly environmentally-conscious consumers.

Looking ahead, now is the time to engage with reliable suppliers and invest in high-quality irrigation pump covers that meet both current and future needs. By leveraging strategic sourcing practices, businesses can enhance their operational resilience and drive growth in an ever-evolving agricultural landscape. Take the next step in your sourcing journey today—explore diverse options and connect with trusted manufacturers to elevate your irrigation solutions.