Introduction: Navigating the Global Market for irrigation pump size calculator

In the dynamic realm of global agriculture, selecting the right irrigation pump size calculator is crucial for optimizing water efficiency and ensuring robust crop yields. Many B2B buyers face the challenge of accurately determining pump capacity, which can significantly impact the success of irrigation projects. The complexities of flow rates, pressure head, and system specifications can lead to costly miscalculations that compromise performance and profitability. This guide aims to demystify the intricacies of irrigation pump sizing, offering a comprehensive overview of various types, applications, and essential calculations that drive informed decision-making.

International B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Germany—will find valuable insights tailored to their unique agricultural contexts. The guide delves into critical factors such as supplier vetting, cost considerations, and the latest technological advancements in pump systems. By empowering buyers with the knowledge to navigate these complexities, this resource ensures they can make educated purchasing decisions that align with their operational needs and sustainability goals.

Whether you are a seasoned agricultural professional or a newcomer to the sector, understanding how to utilize an irrigation pump size calculator effectively can lead to enhanced efficiency, reduced costs, and ultimately, a more productive agricultural enterprise.

Understanding irrigation pump size calculator Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flow Rate Calculator | Focuses on calculating water flow rates based on emitter types. | Drip irrigation, sprinkler systems | Pros: Easy to use; tailored for specific systems. Cons: May not account for pressure loss adequately. |

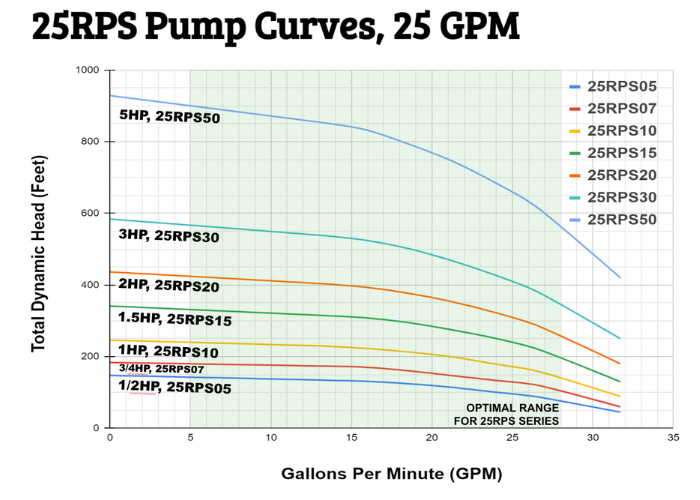

| Total Dynamic Head (TDH) Calculator | Calculates the total dynamic head required for efficient pump operation. | Agricultural and landscape irrigation | Pros: Comprehensive; considers elevation and friction loss. Cons: Requires accurate input data for best results. |

| Submersible Pump Sizer | Designed specifically for submersible pump applications. | Deep well irrigation, ponds, and lakes | Pros: Ideal for deep applications; efficient in water delivery. Cons: Installation can be complex and costly. |

| Pressure Loss Calculator | Estimates pressure loss in pipelines to optimize system design. | Pipeline design, large-scale irrigation | Pros: Critical for efficient system design; prevents over-sizing pumps. Cons: Requires detailed pipeline specs. |

| User-Friendly Sizing Wizard | Simplifies pump selection with a guided interface. | General irrigation, DIY projects | Pros: Intuitive; provides tailored recommendations. Cons: May lack advanced features for complex systems. |

What Are the Characteristics of a Flow Rate Calculator?

A Flow Rate Calculator is a vital tool for B2B buyers focusing on irrigation systems. It allows users to determine the water flow rates required for various emitters, ensuring that the system operates efficiently. This calculator is particularly useful in drip irrigation and sprinkler systems, where precise flow rates are critical for optimal performance. When purchasing, buyers should consider the specific emitter types and the number of emitters in their system to ensure accurate calculations.

How Does a Total Dynamic Head (TDH) Calculator Benefit Buyers?

The Total Dynamic Head (TDH) Calculator is essential for understanding the total energy required to move water through an irrigation system. It factors in elevation changes, suction lift, and friction loss, providing a comprehensive view of what a pump must accomplish. For agricultural and landscape irrigation applications, this tool ensures that the selected pump can meet the system’s demands. Buyers should prioritize accurate input data, as the effectiveness of the TDH calculation hinges on the quality of the information provided.

Why Choose a Submersible Pump Sizer?

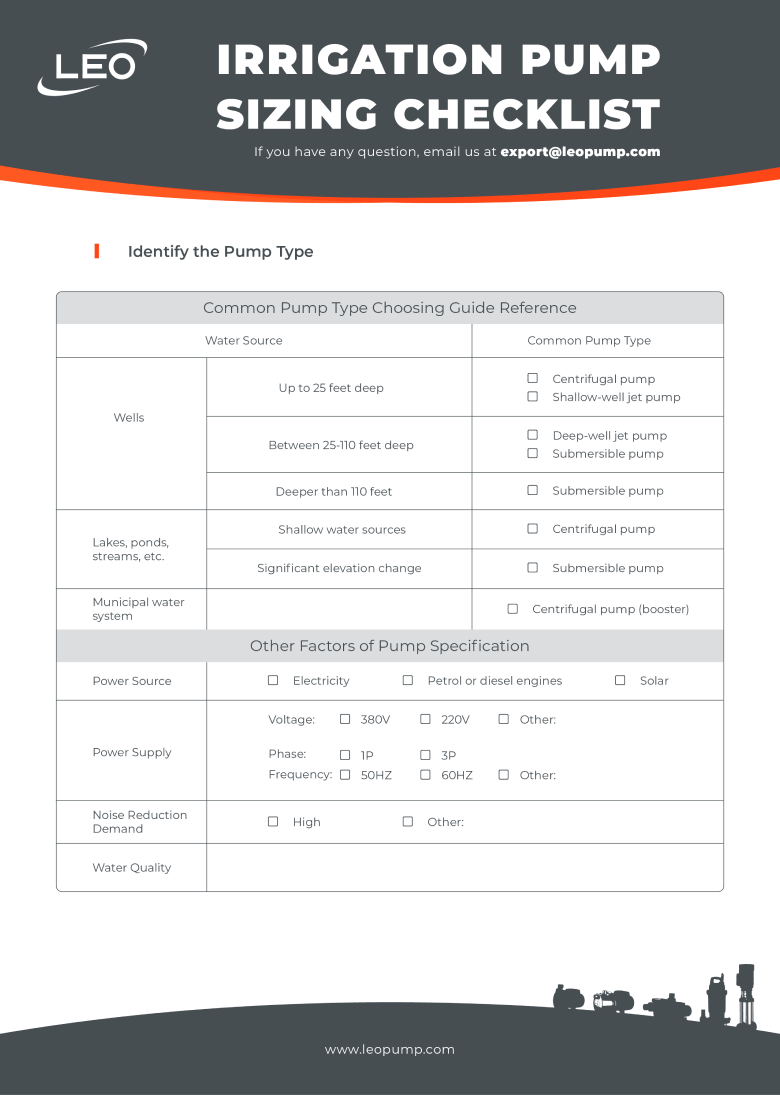

Submersible Pump Sizers are tailored for applications involving deep water sources, such as wells or ponds. These calculators help determine the appropriate pump size based on the depth of the water source and the required flow rate. They are ideal for projects that necessitate efficient water delivery from significant depths. Buyers should weigh the initial installation costs and complexity against the long-term benefits of efficiency and reduced energy consumption.

What Is the Importance of a Pressure Loss Calculator?

A Pressure Loss Calculator is crucial for designing an efficient irrigation system. It helps estimate the pressure loss that occurs in pipelines due to friction, allowing for the selection of appropriately sized pumps. This tool is particularly beneficial in large-scale irrigation projects, where minimizing pressure loss can lead to substantial energy savings. Buyers need to provide detailed specifications of their pipeline to ensure accurate assessments and prevent over-sizing pumps, which can lead to unnecessary costs.

How Does a User-Friendly Sizing Wizard Enhance the Purchasing Process?

A User-Friendly Sizing Wizard simplifies the pump selection process, making it accessible even for those less familiar with technical specifications. By guiding users through a series of questions, it tailors recommendations to specific irrigation needs. This tool is particularly useful for general irrigation and DIY projects, as it reduces the complexity often associated with pump selection. Buyers should consider the level of detail they require, as simpler wizards may not cater to more complex irrigation systems.

Key Industrial Applications of irrigation pump size calculator

| Industry/Sector | Specific Application of irrigation pump size calculator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Crop irrigation system design | Optimizes water use, enhancing crop yield and reducing costs | Local water availability, pump efficiency, and energy costs |

| Horticulture | Greenhouse irrigation management | Ensures consistent water supply, improving plant health | Compatibility with existing systems and emitter specifications |

| Landscaping | Large-scale landscape irrigation | Increases efficiency in water distribution, reducing waste | Local climate conditions and soil types |

| Mining | Dust suppression and dewatering | Enhances operational safety and reduces equipment damage | Pump durability under harsh conditions and flow rate needs |

| Municipal Water Systems | Water supply and distribution systems | Ensures reliable water delivery to communities | Regulatory compliance and environmental impact assessments |

How is the Irrigation Pump Size Calculator Used in Agriculture?

In agriculture, the irrigation pump size calculator is essential for designing efficient crop irrigation systems. By inputting factors like flow rate, pressure requirements, and elevation changes, farmers can determine the optimal pump size to meet their specific irrigation needs. This ensures maximum water efficiency, which is critical in regions facing water scarcity, such as parts of Africa and the Middle East. International buyers must consider local water availability and energy costs when sourcing pumps to ensure sustainable operations.

What Role Does the Irrigation Pump Size Calculator Play in Horticulture?

For horticulture, especially in greenhouse environments, the irrigation pump size calculator helps manage water distribution effectively. By calculating the required flow rate for various emitters, growers can ensure that each plant receives the right amount of water, promoting healthy growth. This application is vital for international buyers who need to align pump specifications with local climate conditions and emitter types to optimize plant health and yield.

How is the Irrigation Pump Size Calculator Beneficial for Landscaping Projects?

In landscaping, particularly for large-scale projects, the irrigation pump size calculator plays a crucial role in ensuring efficient water distribution across extensive areas. By accurately sizing pumps, landscape designers can minimize water waste and enhance the aesthetic appeal of green spaces. Buyers in this sector should consider local climate conditions and soil types to select pumps that can maintain optimal moisture levels in diverse landscaping applications.

Why is the Irrigation Pump Size Calculator Important for Mining Operations?

In the mining industry, the irrigation pump size calculator is vital for applications such as dust suppression and dewatering. By determining the appropriate pump size, mining operations can enhance safety and reduce equipment damage caused by excess water. Buyers in this sector must prioritize pump durability and flow rate capabilities, especially in harsh environments, to ensure reliable performance under demanding conditions.

How Can Municipal Water Systems Benefit from the Irrigation Pump Size Calculator?

Municipal water systems utilize the irrigation pump size calculator to design efficient water supply and distribution networks. This ensures that communities receive a consistent and reliable water supply. International buyers should focus on regulatory compliance and environmental impact assessments when sourcing pumps for municipal applications, ensuring that their systems meet local standards while providing essential services to residents.

3 Common User Pain Points for ‘irrigation pump size calculator’ & Their Solutions

Scenario 1: Inaccurate Pump Sizing Leading to System Failures

The Problem: One of the primary challenges B2B buyers face when using an irrigation pump size calculator is the risk of inaccurate pump sizing. This can occur due to insufficient data regarding flow rates, pressure requirements, and total dynamic head (TDH). A common scenario involves a buyer who underestimates the friction loss in their pipeline or fails to account for elevation changes. As a result, they select a pump that is either too small or too large for their irrigation system, leading to inefficiencies, increased operational costs, and ultimately, system failures.

The Solution: To avoid these pitfalls, it is crucial to gather comprehensive data before using the irrigation pump size calculator. Buyers should meticulously document all relevant parameters, including the total flow rate required by all emitters, the vertical distance from the water source to the pump, and the highest point in the irrigation system. Utilizing a systematic approach, such as the pump sizing worksheet provided by various manufacturers, can help in accurately calculating the necessary TDH. Additionally, considering a safety factor in the calculations can provide a buffer against unexpected changes in system performance. Engaging with pump sizing tools that allow for the input of specific project parameters, combined with expert consultation, can ensure the selection of the right pump size for optimal efficiency.

Scenario 2: Complex System Configurations Confusing Pump Selection

The Problem: B2B buyers often encounter complexities when dealing with intricate irrigation system configurations, such as those with multiple zones, varying emitter types, and diverse elevation levels. These complexities can make it challenging to determine the correct pump size, leading to confusion and potential miscalculations. For instance, a buyer might find themselves unsure how to factor in different emitter flow rates and the cumulative effect on system pressure.

The Solution: To tackle this issue, buyers should leverage advanced irrigation pump sizing calculators that accommodate multi-zone systems. These tools typically guide users through a series of questions to gather detailed information about each zone’s requirements. For instance, a user could input the flow rates for each emitter and the total number of emitters in each zone, along with the elevation changes and friction loss calculations. Furthermore, engaging with technical support or consulting with experienced irrigation specialists can provide clarity on how to approach complex configurations. This collaborative effort can yield accurate pump size recommendations tailored to the specific needs of the irrigation system, ensuring reliable performance across all zones.

Scenario 3: Lack of Understanding of Pump Efficiency Factors

The Problem: Another significant pain point for buyers is the lack of understanding regarding pump efficiency factors, such as motor efficiency and pump performance curves. Many buyers may overlook these critical elements, leading to the selection of pumps that do not perform as expected in real-world applications. For example, a buyer may select a pump based solely on maximum flow rates without considering how actual operational conditions will affect performance, resulting in higher energy costs and reduced lifespan of the equipment.

The Solution: To enhance their understanding of pump efficiency, buyers should prioritize education on key performance indicators, including pump efficiency ratings and the impact of various factors on operational performance. Utilizing resources such as manufacturer performance charts and efficiency calculators can provide valuable insights into how different pump models will perform under actual working conditions. Additionally, buyers should seek to clarify their specific application needs, such as the desired flow rates and pressure requirements, before consulting pump sizing tools. Engaging with knowledgeable sales representatives or technical experts during the selection process can further help buyers make informed decisions that account for efficiency, ultimately leading to improved system performance and cost savings.

Strategic Material Selection Guide for irrigation pump size calculator

What Are the Key Materials Used in Irrigation Pump Size Calculators?

When selecting materials for an irrigation pump size calculator, it’s essential to consider how these materials influence performance, durability, and cost. Here, we analyze four common materials: cast iron, stainless steel, thermoplastics, and aluminum, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Cast Iron Perform in Irrigation Pump Applications?

Cast iron is a traditional material widely used in pump manufacturing due to its excellent strength and durability. It can withstand high pressures and is resistant to wear, making it suitable for heavy-duty applications. However, cast iron is susceptible to corrosion, particularly in environments with high moisture or aggressive chemicals, which can limit its lifespan.

Pros:

– High strength and durability

– Good wear resistance

– Cost-effective for large-scale applications

Cons:

– Prone to corrosion

– Heavier than other materials, increasing transportation costs

– Limited flexibility in design modifications

For international buyers, particularly in regions like Africa and the Middle East, compliance with local standards for corrosion resistance is crucial. Cast iron pumps may require protective coatings or treatments to enhance their longevity in humid or saline environments.

What Advantages Does Stainless Steel Offer for Pump Systems?

Stainless steel is renowned for its corrosion resistance and ability to maintain structural integrity under varying temperatures and pressures. This makes it ideal for applications involving water with high mineral content or chemicals. Its lightweight nature also facilitates easier installation and maintenance.

Pros:

– Excellent corrosion resistance

– High strength-to-weight ratio

– Versatile for various applications

Cons:

– Higher initial cost compared to cast iron

– Requires specialized manufacturing techniques

– Can be prone to pitting in aggressive environments

For B2B buyers in Europe, such as Germany, adherence to DIN standards for material quality is essential. Buyers should also consider the local availability of stainless steel grades suited to their specific applications.

How Do Thermoplastics Compare in Terms of Cost and Performance?

Thermoplastics, such as PVC and polypropylene, are becoming increasingly popular in irrigation applications due to their lightweight nature and resistance to corrosion. They are particularly effective in low-pressure systems and are easy to fabricate into various shapes.

Pros:

– Lightweight and easy to handle

– Resistant to corrosion and chemical damage

– Cost-effective for low-pressure applications

Cons:

– Limited temperature and pressure ratings

– Less durable than metals in high-stress environments

– Potential for UV degradation unless treated

International buyers, especially in regions with high UV exposure like South America, should consider UV-resistant grades of thermoplastics. Compliance with ASTM standards for plastic materials is also a critical factor.

What Role Does Aluminum Play in Pump Manufacturing?

Aluminum is favored for its lightweight and high strength, making it an excellent choice for portable pump applications. It offers good corrosion resistance, especially when anodized, and can handle moderate pressures effectively.

Pros:

– Lightweight and easy to transport

– Good corrosion resistance when treated

– Cost-effective for smaller applications

Cons:

– Lower strength compared to cast iron and stainless steel

– Can be more expensive than thermoplastics

– Limited performance in high-pressure situations

For buyers in the Middle East, where weight is a significant consideration for transport and installation, aluminum pumps can be particularly advantageous. Compliance with local manufacturing standards is essential to ensure product reliability.

Summary Table of Material Properties for Irrigation Pump Size Calculators

| Material | Typical Use Case for irrigation pump size calculator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cast Iron | Heavy-duty irrigation systems | High strength and durability | Prone to corrosion | Medium |

| Stainless Steel | Chemical and mineral-rich water applications | Excellent corrosion resistance | Higher initial cost | High |

| Thermoplastics | Low-pressure irrigation systems | Lightweight and resistant to corrosion | Limited temperature and pressure ratings | Low |

| Aluminum | Portable irrigation solutions | Lightweight and good corrosion resistance | Lower strength compared to metals | Medium |

This comprehensive analysis of materials provides valuable insights for international B2B buyers, ensuring they make informed decisions based on performance, cost, and application suitability.

In-depth Look: Manufacturing Processes and Quality Assurance for irrigation pump size calculator

What Are the Key Manufacturing Processes for an Irrigation Pump Size Calculator?

The manufacturing process for an irrigation pump size calculator involves several critical stages, each designed to ensure that the final product is both accurate and reliable. Understanding these stages can help B2B buyers assess the quality of the calculators they intend to purchase.

How Is Material Prepared for Pump Size Calculators?

The first step in the manufacturing process involves the preparation of materials. Typically, high-quality electronic components, durable casings, and accurate sensors are selected for the production of these calculators. Materials are chosen based on their ability to withstand various environmental conditions, such as humidity and temperature fluctuations, which are common in agricultural settings.

Before manufacturing, materials undergo rigorous testing to ensure they meet predefined specifications. This includes checking the electrical conductivity of components, the tensile strength of casings, and the accuracy of sensors. Proper material preparation is crucial, as it directly impacts the performance and longevity of the irrigation pump size calculator.

What Techniques Are Used in Forming and Assembling?

Once materials are prepared, the forming stage follows. This may involve molding plastic casings, machining metal components, or assembling circuit boards. Advanced techniques such as injection molding are often employed for casings to ensure precision and durability.

In the assembly phase, components are meticulously put together. This includes integrating the electronic circuitry with the casing, installing sensors, and ensuring that all parts fit securely. Automated assembly lines may be used to enhance speed and efficiency, but manual checks are vital to guarantee that each unit meets quality standards.

How Is Finishing Done to Ensure Quality?

The finishing stage involves several processes aimed at enhancing the aesthetic and functional aspects of the calculator. This may include painting, adding protective coatings, and performing final inspections. The finishing touches not only improve the visual appeal but also provide additional protection against environmental factors.

Quality control during this stage is essential, as it ensures that any defects are identified and rectified before the product reaches the market. This attention to detail can significantly impact customer satisfaction and brand reputation.

What Quality Assurance Practices Are Essential for Pump Size Calculators?

Quality assurance is a critical aspect of the manufacturing process, ensuring that the irrigation pump size calculators meet both international and industry-specific standards. This guarantees that B2B buyers receive reliable, accurate, and durable products.

Which International Standards Should Buyers Be Aware Of?

International standards such as ISO 9001 play a crucial role in the quality assurance process. ISO 9001 focuses on quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements. Compliance with this standard indicates a commitment to quality and continuous improvement.

Additionally, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may also apply, depending on the specific use case of the pump size calculator. These certifications ensure that the product adheres to safety and performance standards relevant to the irrigation sector.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are integral to maintaining product quality throughout the manufacturing process. Common checkpoints include:

Incoming Quality Control (IQC): This stage involves inspecting materials and components upon arrival at the manufacturing facility to ensure they meet specified requirements.

In-Process Quality Control (IPQC): During production, continuous monitoring is conducted to identify defects or deviations from standards in real-time. This can include testing electronic components and verifying assembly accuracy.

Final Quality Control (FQC): Once assembly is complete, the final product undergoes rigorous testing. This may include functionality tests, accuracy assessments, and environmental durability checks.

Each of these checkpoints helps identify issues early in the process, reducing the risk of defective products reaching the market.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must ensure that their suppliers adhere to stringent quality control practices. Here are several methods to verify supplier QC:

What Should Buyers Look for in Supplier Audits and Reports?

Conducting supplier audits is an effective way to assess compliance with quality standards. Buyers should request access to audit reports that detail the supplier’s adherence to ISO 9001 and other relevant standards. These reports should provide insights into the supplier’s quality management practices, including any corrective actions taken in response to previous issues.

How Do Third-Party Inspections Enhance Confidence?

Engaging third-party inspection services can further bolster confidence in a supplier’s quality assurance processes. Independent inspectors can provide unbiased assessments of the manufacturing processes, quality control measures, and product performance. This additional layer of scrutiny can help buyers feel assured that they are sourcing from reputable suppliers.

What Are the Quality Control Nuances for International Buyers?

B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, should be aware of specific quality control nuances that may affect their purchasing decisions.

How Do Regional Standards Impact Quality Assurance?

Different regions may have varying quality standards and regulations. For instance, products intended for the European market must comply with CE certification, while Middle Eastern buyers might need to consider specific local regulations. Understanding these regional standards is crucial for ensuring compliance and avoiding legal issues.

What Should Buyers Consider Regarding After-Sales Support?

Buyers should also consider the after-sales support provided by suppliers. This includes warranties, technical support, and maintenance services. A robust after-sales support system indicates a supplier’s commitment to quality and customer satisfaction, which is particularly important in regions where access to replacement parts and service may be limited.

Conclusion: Ensuring Quality in Irrigation Pump Size Calculators

For B2B buyers, understanding the manufacturing processes and quality assurance practices surrounding irrigation pump size calculators is essential. By focusing on material preparation, assembly techniques, international standards, and verification methods, buyers can make informed decisions. Quality assurance not only ensures product reliability but also fosters long-term partnerships with suppliers who prioritize excellence.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘irrigation pump size calculator’

In the realm of irrigation, selecting the correct pump size is crucial for optimal system performance. This guide serves as a practical checklist for B2B buyers looking to procure an irrigation pump size calculator, ensuring that all necessary factors are considered for effective and efficient irrigation solutions.

Step 1: Define Your Technical Specifications

Establishing your technical requirements is the first step in selecting an irrigation pump size calculator. Consider the flow rate, pressure head, and the specific characteristics of your irrigation system. This foundational knowledge ensures that the calculator can provide accurate pump sizing tailored to your unique operational needs.

- Flow Rate: Identify the total gallons per minute (GPM) needed for your system.

- Pressure Requirements: Determine the required pressure for effective irrigation, factoring in elevation changes and friction losses.

Step 2: Research Available Calculator Tools

Not all pump size calculators are created equal. Investigate various tools available online or from suppliers, focusing on features such as user-friendliness, accuracy, and support resources. A well-designed calculator will streamline your pump selection process and reduce the risk of errors.

- User Interface: Look for calculators that offer a straightforward input method.

- Technical Support: Check if the supplier provides assistance or guidance for using their tool effectively.

Step 3: Evaluate Potential Suppliers

Before making a procurement decision, thoroughly vet potential suppliers. Request company profiles, case studies, and references from clients in similar regions or industries to gain insights into their reliability and service quality.

- Supplier Reputation: Investigate online reviews and testimonials.

- Experience: Choose suppliers with a proven track record in the irrigation sector.

Step 4: Verify Compliance and Certifications

Ensure that the calculators you consider comply with relevant industry standards and regulations. This is particularly important in international markets, where compliance with local regulations can significantly impact your project’s success.

- Certifications: Look for certifications from recognized organizations.

- Regulatory Compliance: Verify that the tool adheres to local irrigation and environmental standards.

Step 5: Test the Calculator

Once you have shortlisted a few options, test the calculators with sample data to evaluate their accuracy and functionality. This hands-on approach will help you understand how well the tool meets your specific needs.

- Input Scenarios: Use different flow rates and pressure requirements to see how the calculator performs.

- Output Validation: Cross-check the results with known pump specifications to ensure reliability.

Step 6: Assess Customer Support and Training

Evaluate the level of customer support offered by the supplier. A responsive support team can be invaluable, especially if issues arise during the calculation process or if you need additional training on using the tool effectively.

- Availability of Support: Ensure that the supplier offers various channels for support, such as phone, email, or live chat.

- Training Resources: Look for tutorials, webinars, or documentation that can help you maximize the tool’s potential.

Step 7: Finalize Your Purchase Decision

After thorough research and evaluation, make an informed decision on which irrigation pump size calculator to procure. Consider all factors, including cost, features, and supplier reliability, before finalizing your purchase.

- Cost vs. Benefit: Weigh the price against the functionality and support offered.

- Long-term Partnership: Consider if the supplier can be a long-term partner for future needs, including upgrades or additional tools.

By following this structured checklist, B2B buyers can confidently select an irrigation pump size calculator that meets their operational requirements, ensuring the success of their irrigation projects.

Comprehensive Cost and Pricing Analysis for irrigation pump size calculator Sourcing

What Are the Key Cost Components for Sourcing an Irrigation Pump Size Calculator?

When analyzing the cost structure for sourcing an irrigation pump size calculator, several critical components must be considered. These include:

Materials: The raw materials used in manufacturing the pump calculators, such as high-grade plastics or metals for the casing, electronic components for sensors, and software development costs for digital calculators, significantly influence the overall cost. Quality materials can enhance durability and accuracy, which can justify a higher price.

Labor: Labor costs encompass not only the wages of workers involved in the manufacturing process but also the salaries of engineers and designers who develop the calculator’s functionalities. In regions with higher labor costs, such as parts of Europe, these expenses can be substantial.

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, maintenance, and administrative costs. Efficient production processes can help mitigate these costs, making it essential for suppliers to optimize their manufacturing operations.

Tooling: Investment in specialized tools and equipment for the production of pump size calculators can be significant, especially for customized solutions. The cost of tooling is often amortized over the production volume, influencing the price per unit.

Quality Control (QC): Ensuring that the irrigation pump size calculators meet international standards requires rigorous quality control processes. This adds to the cost but is essential for maintaining reliability and customer satisfaction.

Logistics: Transportation costs, including shipping and handling, can vary widely based on the origin of the product, destination, and chosen Incoterms. International shipping often incurs additional fees, which should be factored into the total cost.

Margin: Suppliers typically add a margin to cover their expenses and generate profit. Understanding the average industry margin can help buyers gauge whether a price is competitive.

How Do Price Influencers Impact the Cost of Irrigation Pump Size Calculators?

Several factors can influence the pricing of irrigation pump size calculators:

Volume and Minimum Order Quantity (MOQ): Higher order volumes generally lead to lower unit prices due to economies of scale. Buyers should negotiate MOQs to optimize cost efficiency.

Specifications and Customization: Custom features, such as specific flow rate calculations or integration with existing systems, can increase costs. Buyers should clarify their requirements early to avoid unexpected expenses.

Materials and Quality Certifications: The choice of materials directly impacts durability and functionality. Additionally, products certified for quality standards (e.g., ISO certifications) may command higher prices but offer greater reliability.

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record of quality may charge more but can provide better after-sales support and warranty services.

Incoterms: Understanding the implications of Incoterms is crucial for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost of the product.

What Tips Can Buyers Use to Negotiate Better Prices for Pump Size Calculators?

Conduct Thorough Market Research: Understanding the market landscape and average pricing can provide leverage in negotiations. Buyers should compare multiple suppliers to identify competitive rates.

Explore Total Cost of Ownership (TCO): Rather than focusing solely on initial purchase price, consider the TCO, which includes maintenance, operational costs, and potential downtime. This holistic view can justify higher upfront costs if long-term savings are evident.

Leverage Volume Discounts: If planning to make repeat purchases, negotiating for volume discounts can lead to significant savings. Suppliers often have tiered pricing structures based on order sizes.

Seek Long-term Partnerships: Establishing a long-term relationship with suppliers can lead to better pricing and terms. Suppliers value repeat business and may offer loyalty discounts or flexible payment terms.

Be Aware of Pricing Nuances for International Purchases: When sourcing from different regions, consider currency fluctuations, import duties, and regional pricing strategies. These factors can significantly impact the overall cost.

Disclaimer

The prices and cost structures discussed are indicative and can vary based on market conditions, supplier practices, and specific project requirements. Buyers should conduct their due diligence and obtain quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing irrigation pump size calculator With Other Solutions

Understanding Alternative Solutions to the Irrigation Pump Size Calculator

In the realm of irrigation systems, selecting the right pump size is critical for optimizing water flow and pressure. While the irrigation pump size calculator provides a straightforward approach for determining the required pump specifications, other viable methods and technologies can also achieve similar goals. This analysis compares the irrigation pump size calculator with alternative solutions, including the use of manual calculation techniques and consulting with irrigation professionals.

Comparison Table

| Comparison Aspect | Irrigation Pump Size Calculator | Manual Calculation Methods | Consulting with Irrigation Professionals |

|---|---|---|---|

| Performance | High accuracy with correct inputs; provides tailored results | Varies greatly based on user knowledge; potential for errors | Highly accurate, leveraging expert knowledge and experience |

| Cost | Generally low to free; minimal software investment | No direct costs, but time-consuming | Can be expensive; costs vary by consultancy and project scope |

| Ease of Implementation | User-friendly, often web-based tools | Requires thorough understanding of formulas and principles | Dependent on the consultant’s availability and scheduling |

| Maintenance | No ongoing maintenance; requires updates for software | No maintenance needed; requires periodic skill refresh | Ongoing relationship may lead to regular updates and maintenance recommendations |

| Best Use Case | Ideal for DIY users and small-scale projects | Suitable for experienced users with specific project knowledge | Best for large-scale projects or complex systems requiring nuanced solutions |

Detailed Breakdown of Alternatives

Manual Calculation Methods

Manual calculation methods involve using formulas and charts to determine pump requirements based on flow rate, pressure head, and system friction losses. The main advantage of this approach is that it incurs no direct costs and can be performed independently. However, the effectiveness of this method heavily relies on the user’s expertise and understanding of hydraulic principles. Errors in calculations can lead to inadequate or excessive pump sizing, potentially compromising system efficiency.

Consulting with Irrigation Professionals

Engaging with irrigation professionals provides a high level of accuracy in pump sizing, as these experts can draw upon their extensive knowledge and experience in the field. This method is particularly advantageous for large-scale or complex irrigation systems, where many variables must be considered. However, the downside is the associated costs, which can be significant depending on the project’s size and the consultant’s fees. Additionally, reliance on external expertise may lead to longer timelines for project initiation.

Conclusion

For B2B buyers, the choice between an irrigation pump size calculator, manual calculations, and consulting with professionals hinges on several factors, including project complexity, budget, and available expertise. The irrigation pump size calculator is an excellent choice for straightforward applications, especially for those with limited resources or time. Manual methods may appeal to experienced users seeking cost-effective solutions, while consulting professionals is ideal for larger projects requiring detailed analysis and tailored recommendations. Ultimately, understanding the specific needs and capabilities of each option will enable buyers to make informed decisions that align with their irrigation objectives.

Essential Technical Properties and Trade Terminology for irrigation pump size calculator

What Are the Essential Technical Properties of an Irrigation Pump Size Calculator?

Understanding the critical specifications of an irrigation pump size calculator is vital for B2B buyers looking to optimize their irrigation systems. Here are several key properties to consider:

1. Flow Rate (GPM or L/min)

Flow rate is the volume of water that the pump can deliver per minute, measured in gallons per minute (GPM) or liters per minute (L/min). This parameter is crucial because it directly affects the irrigation coverage and efficiency. Businesses must assess the total flow required for all emitters in the system to ensure that the selected pump meets the demand without overloading.

2. Total Dynamic Head (TDH)

TDH represents the total height to which the pump must raise the water, factoring in elevation changes, friction losses, and the required pressure at the emitters. Accurately calculating TDH is essential to prevent pump failure and ensure optimal performance. Buyers should include a safety margin in their calculations to accommodate unexpected pressure losses.

3. Pump Efficiency

Pump efficiency is typically expressed as a percentage and indicates how effectively the pump converts mechanical energy into hydraulic energy. Higher efficiency means lower operational costs and reduced energy consumption, making it a critical factor for B2B buyers focused on sustainability and cost-effectiveness in their irrigation systems.

4. Material Grade

The material grade of the pump components impacts durability and resistance to corrosion, especially in environments with aggressive water chemistry. Common materials include stainless steel, cast iron, and thermoplastics. Choosing the right material is vital for longevity and minimizing maintenance costs, particularly in diverse climates across Africa, South America, the Middle East, and Europe.

5. Motor Power Rating

Motor power rating, typically measured in horsepower (HP) or kilowatts (kW), indicates the pump’s capacity to perform under specific conditions. Selecting a motor with the appropriate power rating ensures that the pump can handle peak demand without overheating or failing. B2B buyers should also consider the power supply infrastructure in their region when selecting a pump.

6. Suction Lift

Suction lift refers to the vertical distance from the water source to the pump inlet. This measurement is crucial for determining whether a particular pump type (e.g., submersible vs. surface) is suitable for the application. Accurate assessment of suction lift helps avoid cavitation issues and ensures reliable water delivery.

What Are Common Trade Terms Related to Irrigation Pump Sizing?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are several commonly used terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of irrigation pumps, working with OEMs ensures that buyers receive high-quality, compatible components that meet industry standards.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for B2B buyers to manage inventory costs effectively and negotiate better pricing terms.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price offers from suppliers for specific products or services. Including detailed specifications in an RFQ for irrigation pumps can lead to more accurate quotes and better decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are predefined commercial terms published by the International Chamber of Commerce, used in international trade to clarify the responsibilities of buyers and sellers. Understanding Incoterms helps B2B buyers navigate logistics and shipping costs effectively.

5. Hydraulic Gradient

The hydraulic gradient is the slope of the energy line in a fluid system, representing the potential energy available to move water. This concept is important for understanding the energy requirements of an irrigation system and ensuring efficient pump selection.

6. Pressure Head

Pressure head indicates the height of water that a pump can generate under pressure. It’s expressed in feet or meters and is critical for ensuring that the water reaches the desired elevation in an irrigation system. Understanding pressure head helps buyers evaluate pump performance against their specific needs.

These technical properties and trade terms are essential for B2B buyers aiming to make informed decisions when utilizing an irrigation pump size calculator, ensuring their systems operate efficiently and effectively.

Navigating Market Dynamics and Sourcing Trends in the irrigation pump size calculator Sector

What are the Global Drivers and Key Trends Influencing the Irrigation Pump Size Calculator Market?

The irrigation pump size calculator market is experiencing significant growth, driven by various global factors. The increasing demand for efficient agricultural practices, particularly in regions such as Africa and South America, is one of the primary drivers. These regions are heavily reliant on irrigation to maximize crop yields, which necessitates precise pump sizing to optimize water usage and reduce operational costs. Furthermore, the Middle East’s arid climate and Germany’s focus on sustainability in farming practices underscore the need for advanced pump sizing solutions.

Emerging technologies are reshaping how B2B buyers approach pump selection. The integration of IoT (Internet of Things) and AI (Artificial Intelligence) into irrigation systems allows for real-time monitoring and data analytics, enhancing decision-making processes. Buyers are now looking for tools that not only calculate pump sizes but also offer predictive analytics to foresee potential issues and maintenance needs. Additionally, the rise of online platforms providing user-friendly pump sizing calculators is making the procurement process more accessible, reducing reliance on traditional supply chains.

International B2B buyers are increasingly focusing on suppliers that offer comprehensive support, including installation guidance and after-sales service. This trend reflects a shift toward long-term partnerships rather than one-off transactions, with buyers valuing expertise and reliability in their sourcing decisions.

How Does Sustainability and Ethical Sourcing Impact the Irrigation Pump Size Calculator Market?

Sustainability has become a cornerstone of procurement strategies in the irrigation sector, influencing the sourcing of irrigation pump size calculators. The environmental impact of irrigation practices is under scrutiny, with a growing emphasis on reducing water waste and improving energy efficiency. B2B buyers are now prioritizing suppliers who offer pumps designed with energy-efficient technologies that align with sustainable practices.

Ethical sourcing is equally critical, as buyers seek transparency within their supply chains. This includes understanding the materials used in pump manufacturing and the environmental impact of their production processes. Certifications such as ISO 14001 (Environmental Management) and other ‘green’ certifications are becoming essential criteria for supplier selection. Buyers are increasingly favoring suppliers that utilize recyclable materials and have robust sustainability policies in place, thereby ensuring their operations contribute positively to the environment.

As global awareness of climate change intensifies, the demand for ‘green’ products is expected to rise. Suppliers that can demonstrate their commitment to sustainability and ethical sourcing will be better positioned to capture the attention of discerning B2B buyers across various regions.

What is the Brief Evolution of the Irrigation Pump Size Calculator Market?

The evolution of the irrigation pump size calculator market reflects broader technological advancements and changing agricultural practices. Initially, pump sizing relied heavily on manual calculations, often leading to inefficiencies and errors in pump selection. Over time, the introduction of basic calculators and charts facilitated better decision-making, but these tools still required a significant level of expertise to interpret.

The past decade has seen a notable shift towards digital solutions. Online calculators and sophisticated software programs now enable users to input specific parameters and receive tailored pump size recommendations almost instantaneously. These advancements not only improve accuracy but also democratize access to critical information, empowering farmers and agricultural businesses in emerging markets.

As the market continues to evolve, the integration of AI and machine learning is set to transform pump sizing further, allowing for even more precise calculations and predictive maintenance. This evolution underscores the importance of innovation in meeting the challenges of modern agriculture and reflects the growing need for sustainable and efficient irrigation solutions globally.

Frequently Asked Questions (FAQs) for B2B Buyers of irrigation pump size calculator

1. How do I accurately size an irrigation pump for my system?

To accurately size an irrigation pump, you need to calculate the Total Dynamic Head (TDH) and the required flow rate. TDH includes the vertical lift (suction lift and elevation change), friction loss in the pipes, and the pressure required by the emitters. Use these parameters to consult pump performance curves from manufacturers to identify a suitable pump. Utilizing an irrigation pump size calculator can streamline this process, ensuring you select a pump that meets both flow and pressure requirements for optimal irrigation efficiency.2. What is the best irrigation pump size calculator for international use?

The best irrigation pump size calculator for international use is one that accommodates various metrics and local requirements. Look for calculators that allow input in both metric and imperial units, and consider those that provide options for different water types and soil conditions. Furthermore, ensure that the calculator is backed by a reputable manufacturer or supplier who offers support and guidance tailored to your specific region, such as Africa or Europe.3. What factors should I consider when sourcing a pump size calculator supplier?

When sourcing a pump size calculator supplier, consider their expertise in irrigation systems, the accuracy of their calculators, and customer reviews. Evaluate their technological capabilities, such as online tools and support, and assess their responsiveness to inquiries. Additionally, check their experience in international trade, particularly in your region, to ensure they understand local regulations and requirements.4. How can I verify the quality of the irrigation pump size calculator?

To verify the quality of an irrigation pump size calculator, seek out user testimonials and case studies that demonstrate its effectiveness in real-world applications. Additionally, check if the calculator is developed or endorsed by recognized industry experts or organizations. Request a demonstration or trial period to test the calculator’s accuracy and ease of use before making a commitment.5. Are there customization options available for irrigation pump calculators?

Many suppliers offer customization options for irrigation pump calculators to better suit specific agricultural needs. Custom features may include integration with local weather data, soil moisture sensors, or compatibility with existing irrigation systems. When negotiating with suppliers, inquire about their ability to tailor the calculator for specific crops, geographic conditions, or regional water regulations to enhance its applicability for your operations.6. What are the typical payment terms for purchasing an irrigation pump size calculator?

Payment terms for purchasing an irrigation pump size calculator can vary widely by supplier. Common terms include full payment upfront, a deposit followed by balance upon delivery, or installment payments for larger purchases. Always clarify payment methods accepted (credit card, bank transfer, etc.) and check for any additional fees, such as currency conversion or international transaction charges, especially when dealing with suppliers from different regions.7. What is the minimum order quantity (MOQ) for irrigation pump size calculators?

The minimum order quantity (MOQ) for irrigation pump size calculators can differ depending on the supplier and the specific product. Some suppliers may offer single units for individual use, while others may have a MOQ for bulk purchases, especially if the calculator is part of a larger software suite or hardware package. Always confirm the MOQ before proceeding to ensure it aligns with your purchasing needs and budget.8. How do logistics impact the procurement of irrigation pump calculators?

Logistics play a crucial role in the procurement of irrigation pump calculators, particularly for international buyers. Consider factors such as shipping times, customs regulations, and potential tariffs. It’s essential to choose suppliers with experience in exporting to your region, as they can provide guidance on the best shipping methods and ensure compliance with local regulations. Additionally, inquire about after-sales support and availability of technical assistance once the product is received.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Irrigation Pump Size Calculator Manufacturers & Suppliers List

1. Drip Depot – Pump Sizing Worksheet

Domain: help.dripdepot.com

Registered: 2005 (20 years)

Introduction: Pump Sizing Worksheet includes key calculations for determining pump requirements for irrigation systems. Key details include: 1. Total GPM (gallons per minute) – calculated by adding up all emitters or the largest zone multiplied by the emitter flow rate. 2. Elevation Part 1: Suction Lift – vertical distance between water level and pump inlet (zero for submersible pumps). 3. Elevation Part 2: Ele…

2. RPS Water Pumps – Pump Sizing Wizard

Domain: rpswaterpumps.com

Registered: 2022 (3 years)

Introduction: Water Pump Sizing Wizard – RPS Water Pumps offers a user-friendly online tool for estimating the right pump based on specific project data such as desired flow rate, well depth, and system configuration. The service includes free ground shipping on orders over $100, next day air available, and a $25 discount on the next order after using the sizing tool. The sizing wizard provides engineer-reviewe…

3. Atlas Copco – Pump Sizing Calculator

Domain: atlascopco.com

Registered: 1995 (30 years)

Introduction: Pump sizing calculator from Atlas Copco USA helps users find the right dewatering submersible pump through a simple three-step process. It provides a performance calculation based on application data, comparing models within the WEDA range. The calculator offers insights into product characteristics, performance curves, and power ratings. It supports various applications including drainage, sludge…

4. Floraflex – Efficient Pump Sizing for Hemp Irrigation

Domain: floraflex.com

Registered: 2010 (15 years)

Introduction: The text discusses the importance of proper pump sizing for efficient irrigation in Hemp/Cannabis crops. Key points include: 1) Total horsepower requirement should be 10% higher than the GPM needed to achieve 20 PSI at the farthest nozzle. For example, if 12 GPM is needed, a pump with 14 GPM or more is recommended. 2) For systems requiring over 100 PSI, pumps should be sized at 25% higher GPM than…

5. Jain Irrigation – Drip Irrigation Products

Domain: jains.com

Registered: 1997 (28 years)

Introduction: Jain Irrigation Systems Ltd. offers a wide range of products including: Drip Irrigation products (Drip Line, Drip Tapes, Drip Tubes, Emitters/Drippers, Drip Kits, Polyfittings & Accessories, Valves & Accessories, Micro & Mini Sprinklers, Under Tree Irrigation Systems, Micro Sprinklers & Assemblies, Jets & Assemblies, Misters & Assemblies, Foggers & Assemblies, Bubblers), Sprinkler Irrigation produ…

Strategic Sourcing Conclusion and Outlook for irrigation pump size calculator

In today’s rapidly evolving agricultural landscape, the importance of effective irrigation cannot be overstated. An accurate irrigation pump size calculator is pivotal in ensuring that water resources are utilized efficiently, ultimately leading to improved crop yields and reduced operational costs. By leveraging precise calculations that account for flow rates, pressure needs, and system losses, businesses can avoid common pitfalls associated with pump selection, such as underperformance or over-investment in equipment.

Strategic sourcing plays a crucial role in this process, enabling international B2B buyers to identify reliable suppliers and innovative technologies tailored to their specific irrigation challenges. This is particularly vital for regions like Africa, South America, the Middle East, and Europe, where diverse climatic conditions and agricultural practices necessitate customized solutions.

As we look to the future, embracing advanced tools and methodologies for pump sizing will empower businesses to enhance their irrigation strategies significantly. We encourage B2B buyers to engage with suppliers offering sophisticated pump sizing calculators and expert consultations. By doing so, you will not only optimize your irrigation systems but also contribute to sustainable agricultural practices that can withstand the test of time.