Introduction: Navigating the Global Market for irrigation valves leaking

In the ever-evolving landscape of global agriculture, the challenge of irrigation valves leaking has emerged as a critical concern for B2B buyers. Sourcing reliable irrigation solutions is essential for maintaining efficient water management systems, particularly in regions such as Africa, South America, the Middle East, and Europe. This guide provides a comprehensive overview of the common causes of leaking valves, from low head drainage to debris obstruction, and outlines practical solutions for each scenario. By addressing these issues, businesses can minimize water waste, reduce operational costs, and enhance the longevity of their irrigation systems.

This guide not only delves into the various types of irrigation valves and their applications but also offers insights into supplier vetting, cost considerations, and maintenance best practices. It empowers international B2B buyers, particularly those in countries like Nigeria and Vietnam, to make informed purchasing decisions tailored to their specific needs. With actionable insights and expert recommendations, this resource aims to equip you with the knowledge necessary to navigate the complexities of sourcing effective irrigation solutions. Ultimately, by understanding the nuances of valve performance and leakage prevention, businesses can optimize their irrigation systems for greater efficiency and sustainability.

Understanding irrigation valves leaking Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Low Head Drainage | Water drains from the lowest point, leading to leaks. | Agricultural fields, golf courses | Pros: Simple fix with check valves. Cons: May require ongoing maintenance. |

| Debris-Induced Leakage | Leaks caused by debris obstructing the valve diaphragm. | Landscaping, residential systems | Pros: Easy to troubleshoot. Cons: Possible frequent cleaning needed. |

| O-Ring Seal Failure | Leaks due to worn or damaged O-rings in valves. | Industrial irrigation systems | Pros: Cost-effective repairs. Cons: Requires regular inspections. |

| Pressure Vacuum Breaker Leak | Leaks from the vacuum breaker due to O-ring issues. | Municipal water systems | Pros: Prevents backflow contamination. Cons: Requires specific replacement parts. |

| Zone Valve Malfunction | Leakage from zone valves due to mechanical failures. | Large-scale agricultural operations | Pros: Comprehensive control over irrigation zones. Cons: Complex repairs may require professional help. |

What Are the Characteristics of Low Head Drainage in Irrigation Systems?

Low head drainage is characterized by water leaking from the lowest point of an irrigation zone when the system is off. This phenomenon occurs when residual water remains in lateral piping and drains out through the lowest sprinkler head. In B2B applications, especially in agriculture and golf courses, this issue can be mitigated by installing check valves, which prevent backflow. Buyers should consider the installation costs and the potential for ongoing maintenance, as low head drainage can lead to water loss and increased operational costs.

How Does Debris-Induced Leakage Affect Irrigation Systems?

Debris-induced leakage arises when foreign materials obstruct the diaphragm of the valve, preventing it from sealing properly. This type of leakage is common in landscaping and residential irrigation systems, where dirt, leaves, and other debris may infiltrate the system. Troubleshooting is typically straightforward, requiring disassembly and cleaning of the valve components. For B2B buyers, the ease of maintenance is a significant advantage, although the need for regular cleaning can add to operational overhead.

What Causes O-Ring Seal Failure in Irrigation Valves?

O-ring seal failure is a prevalent issue that results from wear and tear on rubber seals within valves. This type of leak can occur in various irrigation systems, including industrial setups. The main advantage for buyers is the cost-effectiveness of replacing O-rings compared to replacing entire valves. However, regular inspections are necessary to prevent leaks from escalating, which can lead to water wastage and increased costs.

Why Is Pressure Vacuum Breaker Leakage Significant?

Pressure vacuum breakers are critical for preventing backflow contamination, especially in municipal water systems. Leakage from these devices typically occurs due to worn or damaged O-rings. While the advantages include enhanced safety and compliance with health regulations, the need for specific replacement parts can be a drawback for buyers. Understanding the importance of these devices helps in making informed purchasing decisions regarding irrigation components.

What Are the Implications of Zone Valve Malfunction?

Zone valve malfunctions can lead to significant water leakage, often due to mechanical failures or blockages. This type of leakage is particularly relevant in large-scale agricultural operations where precise irrigation control is essential. While zone valves offer comprehensive management of irrigation zones, their complexity can lead to higher repair costs and the need for specialized technicians. B2B buyers should weigh the benefits of efficient zone management against potential maintenance challenges when considering these systems.

Key Industrial Applications of irrigation valves leaking

| Industry/Sector | Specific Application of Irrigation Valves Leaking | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Leak detection in crop irrigation systems | Prevents water wastage and enhances crop yield | Durability in harsh climates, compatibility with existing systems |

| Landscaping | Maintenance of parks and recreational areas | Ensures aesthetic appeal and water efficiency | Availability of spare parts, ease of installation and repair |

| Golf Course Management | Management of irrigation systems for greens and fairways | Reduces operational costs and improves course quality | Customization options, performance under varying pressure |

| Municipal Water Supply | Control of irrigation for public spaces | Maintains public greenery while conserving water | Compliance with local regulations, reliability of components |

| Horticulture | Precision irrigation for nurseries and greenhouses | Optimizes water usage and enhances plant health | Ability to handle various water pressures, ease of maintenance |

How is Irrigation Valves Leaking Used in Agriculture?

In agriculture, irrigation valves leaking can be pivotal in detecting leaks within crop irrigation systems. When water leaks occur, it can lead to significant water wastage, directly affecting the efficiency of water use. By implementing systems that monitor valve leaks, farmers can ensure that their crops receive adequate hydration without unnecessary expenses. Buyers in this sector should prioritize durable components that can withstand harsh environmental conditions and are compatible with existing irrigation systems.

What Role Do Irrigation Valves Leaking Play in Landscaping?

In landscaping, the management of irrigation systems is crucial for maintaining parks and recreational areas. Leaking valves can disrupt the water supply, leading to dry patches and negatively impacting the aesthetic appeal of green spaces. By utilizing reliable irrigation valves, landscaping companies can maintain consistent watering schedules, promoting healthy plant growth. When sourcing valves, companies should consider the availability of spare parts and the ease of installation and repair to minimize downtime.

How Do Golf Course Management Teams Benefit from Irrigation Valves Leaking Solutions?

Golf course management relies heavily on effective irrigation to maintain greens and fairways. Leaking valves can lead to increased operational costs and affect the quality of the course. By using advanced irrigation systems that detect and address leaks, golf courses can conserve water and reduce maintenance costs while ensuring the course remains in top condition. Key considerations for buyers include customization options and the ability of the valves to perform effectively under varying pressure conditions.

Why is Managing Irrigation Valves Leaking Important for Municipal Water Supply?

For municipal water supply systems, controlling irrigation in public spaces is essential for maintaining greenery while conserving water. Leaking valves not only waste water but can also lead to higher operational costs for municipalities. Implementing reliable irrigation solutions helps cities maintain their parks and gardens efficiently. Buyers should ensure that the components comply with local regulations and offer a high level of reliability to avoid service interruptions.

How Can Horticulture Professionals Optimize Water Usage with Irrigation Valves Leaking Solutions?

In horticulture, precision irrigation is vital for nurseries and greenhouses, where plant health directly affects profitability. Leaking valves can compromise water delivery, leading to inconsistent moisture levels and impacting plant growth. By sourcing high-quality irrigation valves that minimize leaks, horticulturists can optimize water usage and improve overall plant health. Buyers should look for valves that can handle varying water pressures and are easy to maintain, ensuring long-term efficiency.

3 Common User Pain Points for ‘irrigation valves leaking’ & Their Solutions

Scenario 1: Leaks from Low Head Drainage Impacting Crop Irrigation Efficiency

The Problem: Many agricultural businesses encounter issues with irrigation valves leaking due to low head drainage. This situation arises when the lowest sprinkler head in a zone allows water to drain back into the lateral piping, even when the system is turned off. This not only leads to water wastage but can also contribute to soil saturation, which can harm crop health and reduce yield. For businesses operating in regions with water scarcity, such as parts of Africa and the Middle East, this inefficiency can severely impact both profitability and sustainability.

The Solution: To mitigate low head drainage, B2B buyers should consider installing check valves on sprinkler heads and lateral lines. These devices prevent backflow and ensure that water does not drain from the system when not in operation. When sourcing check valves, it’s crucial to choose high-quality options that are compatible with existing systems. Additionally, consider conducting a thorough assessment of the irrigation layout to identify the lowest points and strategically place check valves. Regular maintenance, including checking for debris or blockages, will ensure that these valves operate effectively and prolong the lifespan of the irrigation system.

Scenario 2: Leaking Valves Caused by Debris Buildup Leading to Increased Maintenance Costs

The Problem: A common issue faced by irrigation system managers is leaking valves caused by debris obstructing the valve diaphragm. In regions with heavy dust or organic material, such as agricultural fields in South America, the accumulation of debris can lead to leaks, requiring frequent repairs and increasing operational costs. This not only disrupts irrigation schedules but also places additional strain on maintenance teams, ultimately affecting productivity and resource allocation.

The Solution: To address this challenge, it is recommended that businesses implement a routine maintenance schedule that includes disassembling and cleaning the valves. This process involves rinsing all valve components with clean water and inspecting for visible damage, particularly to the diaphragm assembly. If wear and tear are evident, replacing the diaphragm can prevent future leaks. Investing in filtration systems upstream can also minimize debris entering the irrigation system, thus reducing the frequency of maintenance required. Additionally, educating staff on proper maintenance techniques will empower them to manage these issues proactively.

Scenario 3: Pressure Vacuum Breaker Leaks Affecting System Reliability

The Problem: In commercial irrigation systems, pressure vacuum breakers (PVBs) are critical for preventing backflow and maintaining system integrity. However, leaks can occur at the top of the PVB, often due to worn-out O-rings or obstructions preventing a good seal. For companies in Europe with extensive irrigation networks, these leaks can lead to non-compliance with water regulations and potential fines, in addition to affecting the overall reliability of the irrigation system.

The Solution: To resolve leaks from pressure vacuum breakers, it’s essential for B2B buyers to conduct regular inspections and maintenance. Begin by turning off the water supply and carefully removing the top of the PVB. Inspect the O-ring for wear and replace it if necessary. It’s advisable to keep a stock of replacement parts, such as O-rings, on hand to facilitate quick repairs. Additionally, implementing a preventive maintenance schedule that includes checking for obstructions, such as debris or insect nests, will enhance the performance of the PVB and reduce the likelihood of leaks. Engaging with reputable suppliers for high-quality parts can also ensure long-lasting solutions, ultimately safeguarding the investment in the irrigation system.

Strategic Material Selection Guide for irrigation valves leaking

What Are the Key Materials Used for Irrigation Valves to Prevent Leaking?

When selecting materials for irrigation valves, particularly in regions prone to leaking, it is essential to consider their properties, advantages, and limitations. Below, we analyze four common materials used in the manufacturing of irrigation valves, focusing on their performance characteristics, cost implications, and suitability for various applications.

How Do Brass Irrigation Valves Perform Against Leaking?

Key Properties: Brass is a copper-zinc alloy known for its excellent corrosion resistance and ability to withstand high pressures and temperatures. It typically has a pressure rating of up to 200 psi and can handle temperatures ranging from -40°F to 200°F.

Pros & Cons: Brass valves are durable and provide a reliable seal, minimizing the risk of leaks. However, they can be more expensive than alternatives like PVC. The manufacturing process is relatively straightforward, but the higher material cost can be a deterrent for budget-conscious projects.

Impact on Application: Brass is compatible with various media, including potable water, making it suitable for agricultural and residential irrigation systems. However, its susceptibility to dezincification in certain water conditions should be monitored.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local standards, such as ASTM for the USA or DIN for Europe, to guarantee quality and safety.

What Role Does PVC Play in Irrigation Valve Applications?

Key Properties: Polyvinyl chloride (PVC) is a lightweight plastic that is resistant to corrosion and has a pressure rating of about 150 psi. It is effective in handling temperatures up to 140°F.

Pros & Cons: PVC is cost-effective and easy to install, making it a popular choice for irrigation systems. However, it may not be as durable as metals and can become brittle over time, especially in extreme temperatures.

Impact on Application: PVC is suitable for non-potable water applications and is widely used in agricultural irrigation. Its chemical resistance allows it to handle various fertilizers and pesticides without degrading.

Considerations for International Buyers: Compliance with local regulations is crucial, especially in regions with strict environmental standards. Buyers should also consider the availability of compatible fittings and accessories in their local markets.

How Do Stainless Steel Valves Compare for Leak Prevention?

Key Properties: Stainless steel is renowned for its high strength and excellent corrosion resistance, with pressure ratings often exceeding 300 psi. It can withstand temperatures up to 1,500°F, making it suitable for a wide range of applications.

Pros & Cons: The durability and longevity of stainless steel valves make them ideal for harsh environments. However, they are typically more expensive than brass and PVC, and the manufacturing process can be complex, which may lead to higher costs.

Impact on Application: Stainless steel is compatible with various media, including potable water, chemicals, and wastewater, making it versatile for different irrigation systems. Its robust nature reduces the risk of leaks significantly.

Considerations for International Buyers: Buyers should verify that stainless steel valves meet international standards such as JIS in Japan or ISO standards, ensuring quality and compliance in their specific markets.

What Benefits Do Composite Materials Offer for Irrigation Valves?

Key Properties: Composite materials, often a blend of plastics and fiberglass, are lightweight and resistant to corrosion. They generally have a pressure rating of around 150 psi and can handle temperatures similar to PVC.

Pros & Cons: Composites are highly resistant to chemicals and UV light, making them suitable for outdoor applications. However, they may not provide the same level of strength as metals and can be more expensive than PVC.

Impact on Application: These materials are ideal for agricultural irrigation systems where chemical exposure is a concern. Their lightweight nature facilitates easier installation and maintenance.

Considerations for International Buyers: Buyers should assess the availability of composite materials in their regions and ensure compliance with local standards to avoid issues related to quality and performance.

Summary of Material Selection for Irrigation Valves

| Material | Typical Use Case for irrigation valves leaking | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Potable water and residential irrigation | Excellent corrosion resistance | Higher cost than alternatives | High |

| PVC | Non-potable agricultural irrigation | Cost-effective and easy to install | Less durable in extreme conditions | Low |

| Stainless Steel | Harsh environments and chemical applications | High strength and durability | Expensive and complex to manufacture | High |

| Composite | Chemical exposure in agricultural settings | UV and chemical resistance | Weaker than metals | Medium |

This guide provides essential insights for international B2B buyers to make informed decisions regarding material selection for irrigation valves, ensuring optimal performance and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for irrigation valves leaking

What Are the Key Stages in the Manufacturing Process of Irrigation Valves?

The manufacturing of irrigation valves involves several critical stages, each designed to ensure durability and functionality. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in manufacturing irrigation valves is the careful selection and preparation of materials. Common materials include brass, stainless steel, and high-density polyethylene (HDPE), chosen for their corrosion resistance and strength. The materials undergo rigorous testing to confirm they meet necessary specifications. This includes checking for impurities and ensuring that the physical properties align with international standards.

Forming Techniques

Once materials are prepared, they are subjected to various forming techniques. Common methods include casting, machining, and injection molding. Casting is often used for metal valves, allowing for complex shapes and durable products. In contrast, injection molding is prevalent for plastic valves, ensuring precision and consistency. Each technique has its advantages, and manufacturers choose based on the valve’s intended use and required specifications.

Assembly Process

After forming, the components are assembled. This stage is crucial, as improper assembly can lead to leaks or malfunctions. Manufacturers typically employ automated assembly lines for efficiency, though skilled labor is also essential for quality assurance. During this phase, components such as seals, diaphragms, and actuators are integrated. Attention to detail is vital, as any misalignment can compromise the valve’s integrity.

Finishing Touches

The final stage involves finishing processes, which may include surface treatment, painting, or coating to enhance durability and resistance to environmental factors. For instance, applying a protective coating can prevent corrosion and extend the lifespan of the valve. This stage also includes quality checks to ensure that the final product meets the required specifications.

How Is Quality Assurance Implemented in the Manufacturing of Irrigation Valves?

Quality assurance (QA) is a cornerstone of the manufacturing process for irrigation valves, ensuring that each product meets both industry standards and client expectations. Various international and industry-specific standards guide these QA processes.

International Standards for Quality Assurance

ISO 9001 is the most recognized international standard for quality management systems. Adhering to ISO 9001 ensures that manufacturers have a robust process for managing quality throughout their operations, from design to delivery. Other relevant standards may include CE marking for compliance with EU directives, and API standards for valves used in oil and gas applications.

Quality Control Checkpoints

Manufacturers implement several quality control checkpoints throughout the production process. Incoming Quality Control (IQC) assesses raw materials before they enter production. In-Process Quality Control (IPQC) occurs during manufacturing, where operators monitor for defects. Finally, Final Quality Control (FQC) evaluates the finished product against specifications. Each checkpoint helps catch potential issues early, reducing the risk of leaks and ensuring reliability.

Common Testing Methods Used in Quality Assurance

Testing methods are crucial in validating the performance of irrigation valves. Common tests include pressure testing, where valves are subjected to high pressure to check for leaks, and cycle testing, which simulates the operational lifespan of the valve. Other tests may include temperature resistance and flow rate assessments, ensuring the valve performs under various conditions.

How Can B2B Buyers Verify Quality Control Practices of Suppliers?

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential. Here are several strategies to ensure that suppliers meet high standards.

Conducting Supplier Audits

One effective way to verify quality control is through supplier audits. These audits can be scheduled or random and should assess the manufacturing process, quality control systems, and adherence to international standards. Buyers should prepare a checklist based on relevant standards to evaluate the supplier comprehensively.

Requesting Quality Control Reports

Buyers should request regular quality control reports from suppliers. These documents should detail the results of IQC, IPQC, and FQC processes, along with any corrective actions taken for non-conformities. Transparent reporting allows buyers to assess the reliability of the supplier’s quality assurance processes.

Utilizing Third-Party Inspections

Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control practices. These agencies can conduct on-site inspections, review quality management systems, and validate compliance with international standards. This external verification can significantly reduce risk for B2B buyers.

What Are the Unique Quality Control Considerations for International Buyers?

International buyers must navigate various nuances in quality control when sourcing irrigation valves. These considerations include understanding regional standards, supply chain challenges, and cultural differences in business practices.

Adherence to Regional Standards

Different regions may have specific standards that suppliers must meet. For instance, valves exported to Europe must comply with CE marking requirements, while those used in the Middle East may need to adhere to local regulations. Buyers should be well-informed about the standards applicable to their target markets.

Supply Chain Considerations

Supply chain logistics can impact quality control. Delays in shipping or sourcing materials can lead to rushed manufacturing processes, increasing the likelihood of defects. Buyers should work closely with suppliers to establish clear timelines and quality expectations throughout the supply chain.

Cultural Differences in Quality Practices

Cultural attitudes toward quality and business practices can vary significantly across regions. Buyers should foster open communication with suppliers to ensure that quality standards are clearly understood and met. Building strong relationships can enhance trust and accountability, leading to improved quality outcomes.

In summary, the manufacturing processes and quality assurance practices for irrigation valves are intricate and vital for ensuring product reliability. By understanding these processes, B2B buyers can make informed decisions, fostering partnerships that enhance operational efficiency and effectiveness in irrigation systems.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘irrigation valves leaking’

To assist B2B buyers in navigating the procurement of irrigation valves, particularly when dealing with leaks, this guide provides a structured checklist. Properly addressing these leaks is crucial for maintaining efficient irrigation systems and preventing potential water loss, which can lead to increased costs and environmental concerns.

Step 1: Identify the Type of Leak

Understanding the nature of the leak is essential. Determine whether it is due to low head drainage or an obstruction in the valve. This initial assessment will guide your procurement decisions, ensuring you select the right products to address the specific issue.

- Low Head Drainage: This occurs when the lowest point in your irrigation system allows water to escape.

- Obstruction Issues: Debris in the valve can lead to leaks even when the system is off, requiring different solutions.

Step 2: Define Your Technical Specifications

Clearly outline the technical requirements for the irrigation valves you need. Consider factors like flow rate, pressure ratings, and compatibility with existing systems.

- Flow Rate: Ensure the valves can handle the expected flow without causing pressure drops.

- Material Specifications: Depending on the environment (e.g., corrosive soils), select materials that will withstand local conditions.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request company profiles, case studies, and references from other businesses in similar sectors or regions.

- Supplier Credentials: Look for certifications or industry recognitions that demonstrate reliability.

- Past Performance: Understanding how suppliers have performed in the past can give insights into their service quality.

Step 4: Request Samples or Demonstrations

Whenever possible, request samples or demonstrations of the valves. This step allows you to assess the quality and functionality firsthand.

- Hands-On Testing: Evaluate the ease of installation and the operational efficiency of the valves.

- Compatibility Checks: Ensure that the samples work seamlessly with your current irrigation setup.

Step 5: Negotiate Terms and Pricing

Engage in negotiations with potential suppliers to secure favorable terms and competitive pricing. A clear understanding of your budget and the value offered by each supplier is essential.

- Bulk Purchase Discounts: Inquire about pricing structures for larger orders, which can significantly reduce costs.

- Warranty and Support: Ensure that the terms include comprehensive warranties and support for repairs or replacements.

Step 6: Plan for Installation and Maintenance

Consider the logistics of installation and ongoing maintenance when selecting your valves. Proper planning can prevent future leaks and ensure longevity.

- Installation Guidelines: Verify that the supplier provides clear installation instructions or offers professional installation services.

- Maintenance Protocols: Understand what maintenance is required to keep the valves functioning optimally, including any seasonal checks.

Step 7: Monitor Performance Post-Purchase

After installation, monitor the performance of the valves regularly. This ongoing assessment will help you identify any potential issues early and maintain system efficiency.

- Performance Metrics: Establish key performance indicators (KPIs) for water usage and system efficiency.

- Feedback Loop: Create a system for collecting feedback from users to address any operational concerns swiftly.

By following these steps, B2B buyers can effectively source irrigation valves that mitigate leakage issues, enhance system performance, and contribute to sustainable water management practices.

Comprehensive Cost and Pricing Analysis for irrigation valves leaking Sourcing

What Are the Key Cost Components for Sourcing Irrigation Valves?

When evaluating the cost structure for sourcing irrigation valves, particularly those prone to leaking, several components come into play. The primary cost components include:

Materials: The choice of materials significantly impacts the overall cost. High-quality materials such as brass, stainless steel, or specialized plastics enhance durability and reduce leak risks but come at a higher price.

Labor: Labor costs can vary based on the region and the complexity of the valve design. Skilled labor is often required for assembly and quality checks, which can increase production costs.

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment maintenance. Efficient production processes can help mitigate these overhead costs.

Tooling: Custom tooling for specific valve designs adds to initial costs. However, investing in quality tooling can lead to better precision and lower defect rates in the long run.

Quality Control (QC): Implementing rigorous QC measures ensures that the valves meet industry standards, which can prevent costly leaks and failures. This involves both testing and inspection processes that contribute to overall costs.

Logistics: Transportation and storage costs vary based on the distance from the manufacturer to the buyer. International shipping can further complicate logistics, especially with tariffs and customs duties.

Margin: Suppliers generally build in a profit margin, which can vary based on market demand, competition, and the perceived value of the product.

How Do Price Influencers Affect the Cost of Irrigation Valves?

Several factors influence pricing in the irrigation valve market:

Volume/MOQ: Larger orders often lead to reduced per-unit costs due to economies of scale. Negotiating minimum order quantities (MOQs) can yield better pricing.

Specifications and Customization: Custom-designed valves tailored to specific applications may incur higher costs. Buyers should balance customization needs against budget constraints.

Materials: As previously mentioned, the choice of materials directly affects pricing. Opting for more economical materials can lower costs, but this may compromise durability and performance.

Quality and Certifications: Valves that comply with international standards and certifications (such as ISO) typically command higher prices. Buyers should assess whether these certifications are necessary for their applications.

Supplier Factors: The reputation, location, and reliability of suppliers can influence pricing. Established suppliers may charge more but offer better quality assurance and service.

Incoterms: Understanding Incoterms is crucial for international buyers as they define the responsibilities of buyers and sellers in shipping and logistics, affecting overall costs.

What Tips Can Help Buyers Negotiate Better Prices for Irrigation Valves?

B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, can adopt several strategies to enhance cost-efficiency:

Negotiate Effectively: Engage suppliers in discussions about pricing, especially when placing large orders. Highlighting long-term partnership potential can incentivize suppliers to offer better rates.

Consider Total Cost of Ownership (TCO): Evaluate the long-term costs associated with sourcing valves, including maintenance, replacement, and water loss due to leaks. A slightly higher upfront cost may lead to significant savings over time.

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, import duties, and local market conditions that can affect pricing. This knowledge can be leveraged during negotiations.

Build Relationships with Suppliers: Establishing strong relationships can lead to better pricing, priority service, and access to new products. Suppliers are often more willing to negotiate with trusted clients.

Final Considerations for Buyers

While indicative prices for irrigation valves can vary widely based on the aforementioned factors, potential buyers should conduct thorough market research and supplier assessments to ensure they are making informed decisions. By understanding the nuances of costs and pricing, buyers can secure the best value for their investments in irrigation systems.

Alternatives Analysis: Comparing irrigation valves leaking With Other Solutions

Introduction to Alternative Solutions for Irrigation Management

In the realm of irrigation systems, managing leaks from valves is a common challenge that can lead to inefficiencies and increased operational costs. While addressing the issue of irrigation valve leaks is essential, it is equally important for B2B buyers to explore alternative solutions that can achieve similar objectives in water management. This section compares the traditional approach of dealing with irrigation valves that leak against other viable alternatives, providing insights into their performance, costs, and usability.

Comparison Table

| Comparison Aspect | Irrigation Valves Leaking | Check Valves | Pressure Regulating Valves |

|---|---|---|---|

| Performance | Moderate effectiveness; leaks can disrupt flow | High effectiveness; prevents backflow and drainage | High effectiveness; maintains consistent pressure |

| Cost | Generally low, but can incur high maintenance costs | Moderate initial investment, low maintenance | Higher initial investment, but reduced long-term costs |

| Ease of Implementation | Requires regular checks and maintenance | Easy to install; minimal adjustments needed | Requires professional installation for optimal performance |

| Maintenance | High; frequent repairs needed due to wear and debris | Low; infrequent cleaning required | Moderate; occasional checks for pressure settings |

| Best Use Case | Small to medium irrigation systems | Areas prone to backflow or low head drainage | Systems requiring consistent pressure across varying elevations |

Detailed Breakdown of Alternatives

Check Valves

Check valves are designed to prevent backflow and drainage in irrigation systems, making them a reliable alternative to traditional valves that may leak. They are particularly effective in systems where low head drainage is a concern, as they can help maintain water within the system when the irrigation is off. The installation process is straightforward, which makes it accessible for most irrigation setups. However, while check valves have a moderate initial cost, they require minimal maintenance, making them an economically viable option in the long run.

Pressure Regulating Valves

Pressure regulating valves (PRVs) serve to maintain a consistent water pressure throughout an irrigation system, which can mitigate the risks associated with leaking valves. By controlling pressure fluctuations, PRVs help prevent leaks that may occur due to excessive pressure. Although the initial investment for PRVs is higher compared to other solutions, the long-term savings achieved through reduced water waste and lower maintenance needs can justify the cost. These valves typically require professional installation to ensure they are set correctly, which may be a consideration for buyers looking at DIY options.

Conclusion: Choosing the Right Solution for Your Irrigation Needs

When considering the best solution for managing irrigation systems, B2B buyers should evaluate their specific needs, including system size, water pressure requirements, and budget constraints. While traditional irrigation valves leaking can be addressed through regular maintenance, alternatives such as check valves and pressure regulating valves offer effective strategies for reducing leaks and improving overall system performance. By weighing the pros and cons of each option, buyers can make informed decisions that align with their operational goals and ensure efficient water management in their agricultural or landscape projects.

Essential Technical Properties and Trade Terminology for irrigation valves leaking

What Are the Key Technical Properties of Irrigation Valves That Are Leaking?

When assessing irrigation valves, particularly those that are leaking, several technical properties are critical to understanding their functionality and ensuring long-term reliability. Here are some essential specifications:

Material Grade

The material used in manufacturing irrigation valves affects their durability and resistance to corrosion. Common materials include brass, stainless steel, and PVC. For example, brass valves are favored for their strength and longevity, especially in regions with high salinity or corrosive water. Understanding material grades can help buyers choose valves that will withstand local environmental conditions, reducing maintenance costs over time.Pressure Rating

This specification indicates the maximum pressure the valve can handle without failing. Typical ratings for irrigation valves range from 150 to 300 psi. Selecting a valve with an appropriate pressure rating is vital for preventing leaks under operational conditions, particularly in high-pressure irrigation systems.Tolerance Levels

Tolerance refers to the allowable variation in the dimensions of the valve components. Tight tolerances ensure a better seal and reduce the risk of leaks. For example, a tolerance of ±0.01 inches in the valve seat can significantly enhance performance. Understanding tolerance levels is essential for ensuring compatibility with existing systems and preventing future leaks.Flow Rate

This property measures the amount of water that can pass through the valve, typically expressed in gallons per minute (GPM). An adequate flow rate is critical for optimizing irrigation efficiency. Buyers should consider their specific irrigation needs and select valves that can accommodate the required flow rates without causing backpressure or leaks.Diaphragm Design

The diaphragm is a crucial component in controlling flow and preventing leaks. Different designs, such as flat or dome-shaped diaphragms, can affect the valve’s performance under various conditions. Understanding diaphragm design can help buyers identify the best option for their specific application, particularly in areas prone to debris or sediment.

What Are Common Trade Terms Related to Irrigation Valve Leaks?

Familiarity with industry jargon is essential for effective communication in the B2B market. Here are some common terms related to irrigation valve leaks:

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of irrigation valves, OEM parts are often of higher quality and compatibility, which can be crucial for maintaining system integrity and reducing leaks.MOQ (Minimum Order Quantity)

This term indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers, as it can impact budgeting and inventory management, particularly when sourcing replacement valves to address leaks.RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other relevant details for specific products. This is particularly useful for buyers looking to procure irrigation valves at competitive rates while ensuring they meet the necessary specifications to prevent leakage issues.Incoterms (International Commercial Terms)

These are standardized terms used in international trade to clarify the responsibilities of buyers and sellers. Understanding Incoterms is essential for B2B buyers to ensure that all parties are aware of their obligations regarding shipping, insurance, and risk management, particularly when sourcing valves from different regions.Backpressure

This term describes the pressure exerted on the upstream side of a valve when fluid is unable to flow freely downstream. Backpressure can lead to leaks if valves are not rated to handle such conditions. Recognizing this concept is vital for selecting the right valves for specific irrigation applications.Check Valve

A type of valve that allows fluid to flow in one direction only, preventing backflow. In irrigation systems, check valves can help mitigate leaks caused by low head drainage and ensure that water does not flow back into the system when it is turned off. Understanding the role of check valves is crucial for buyers looking to enhance system reliability.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing irrigation valves, ultimately leading to more efficient and reliable irrigation systems.

Navigating Market Dynamics and Sourcing Trends in the irrigation valves leaking Sector

What Are the Current Market Dynamics and Key Trends in the Irrigation Valves Leaking Sector?

The global market for irrigation valves is influenced by several key drivers, including the rising need for efficient water management systems due to climate change and water scarcity, particularly in regions like Africa, South America, the Middle East, and Europe. In these areas, there is a growing emphasis on sustainable agricultural practices, which has led to increased investments in irrigation infrastructure. Additionally, advancements in technology, such as IoT-enabled irrigation systems and smart sensors, are emerging trends that provide real-time monitoring and control, reducing the likelihood of leaks and improving water conservation efforts.

International B2B buyers are increasingly focusing on sourcing high-quality valves that minimize leakage and enhance system reliability. This trend is driven by the need to lower operational costs and enhance productivity. Furthermore, the demand for customizable solutions is on the rise, allowing businesses to tailor their irrigation systems to specific agricultural needs. As competition intensifies, suppliers that offer innovative products and efficient customer service are likely to gain a competitive edge in this dynamic market.

How Is Sustainability and Ethical Sourcing Influencing B2B Practices in the Irrigation Valves Sector?

Sustainability is becoming a non-negotiable requirement in the irrigation valves sector, with businesses increasingly aware of their environmental impact. The production and operation of irrigation systems can contribute significantly to water wastage if not managed properly. Ethical sourcing practices, which ensure that materials are sourced responsibly, are gaining traction among international buyers. This includes the adoption of ‘green’ certifications and the use of sustainable materials, which not only enhance the brand’s reputation but also align with global sustainability goals.

For B2B buyers, investing in environmentally friendly products can result in long-term cost savings and compliance with regulatory standards. Suppliers that demonstrate a commitment to sustainability by offering eco-friendly materials and processes are likely to attract more buyers who are looking to enhance their corporate social responsibility initiatives. Additionally, the shift towards sustainable practices can lead to innovations in product design and functionality, providing further opportunities for growth and collaboration in the market.

What Is the Brief Evolution and History of Irrigation Valves and Their Leakage Issues?

The evolution of irrigation valves dates back to ancient civilizations that relied on rudimentary methods to control water flow for agriculture. Over time, the development of more sophisticated valve technologies has significantly improved water management practices. In the 20th century, advancements in materials and design led to the production of more durable and efficient valves, reducing the frequency of leaks.

However, despite these advancements, issues such as valve leakage continue to pose challenges. Common causes include debris obstruction and wear on critical components like O-rings and diaphragms. Today, the industry is focusing on addressing these challenges through innovative solutions, such as the integration of smart technology that allows for real-time diagnostics and proactive maintenance. This ongoing evolution not only highlights the importance of quality in valve manufacturing but also underscores the need for continuous improvement in irrigation practices to ensure sustainability and efficiency in agricultural water use.

Frequently Asked Questions (FAQs) for B2B Buyers of irrigation valves leaking

How do I solve a leaking irrigation valve issue?

To address a leaking irrigation valve, start by identifying the source of the leak. Common causes include debris obstructing the valve diaphragm or low head drainage, where water drains from the lowest point in the system. For debris, disassemble the valve, clean all components with clean water, and reassemble. If the leak persists, consider replacing the diaphragm assembly. Installing check valves on sprinklers and lateral lines can also prevent low head drainage issues. Regular maintenance is crucial to prevent leaks from developing.What is the best type of irrigation valve for agricultural use?

The best type of irrigation valve for agricultural applications typically depends on the specific requirements of the system, such as flow rate and pressure. Generally, electric solenoid valves are favored for their precision and remote operation capabilities, while manual valves are cost-effective for smaller systems. Consider using durable materials like PVC or brass for longevity, especially in regions with extreme weather conditions. Consulting with local experts can also help you choose the most suitable valve for your unique agricultural needs.What should I consider when sourcing irrigation valves internationally?

When sourcing irrigation valves internationally, consider several factors: quality standards, supplier reliability, and compliance with local regulations. Ensure that the valves meet international quality certifications to avoid costly failures. Evaluate suppliers based on their production capabilities, past client feedback, and their ability to provide after-sales support. Additionally, understanding trade agreements and tariffs between your country and the supplier’s location can help in planning your budget and logistics.How can I vet suppliers for irrigation valves?

To vet suppliers for irrigation valves, start by researching their reputation through reviews and testimonials from previous clients. Request samples to assess the quality of their products. Verify their certifications and compliance with international standards. Establish communication to gauge their responsiveness and customer service. Visiting their facility, if feasible, can provide insight into their production processes and capacity. Additionally, consider third-party audits or certifications that verify supplier credibility.What are typical payment terms for purchasing irrigation valves?

Payment terms for purchasing irrigation valves can vary widely based on the supplier and the order size. Common terms include net 30 or net 60 days after delivery, but upfront deposits (e.g., 30-50%) are often required for larger orders. It’s crucial to negotiate terms that align with your cash flow and project timelines. Additionally, consider using letters of credit or escrow services for added security, especially in international transactions.What is the minimum order quantity (MOQ) for irrigation valves?

Minimum order quantities (MOQs) for irrigation valves can vary by supplier and product type. Typically, MOQs range from 50 to 500 units, depending on the manufacturing process and material costs. Some suppliers may offer lower MOQs for specific products or during promotional periods. It’s advisable to discuss your needs with the supplier to see if they can accommodate smaller orders or if they offer bulk pricing for larger quantities.How do I ensure quality assurance for irrigation valves?

To ensure quality assurance for irrigation valves, implement a thorough inspection process both pre- and post-manufacturing. Request quality certifications from suppliers, such as ISO 9001, which demonstrates adherence to quality management standards. Consider third-party inspections during production and before shipment to verify compliance with your specifications. Establish clear acceptance criteria and conduct random sampling during delivery to assess product quality.What logistics considerations should I be aware of when importing irrigation valves?

When importing irrigation valves, consider logistics factors such as shipping methods, customs clearance, and lead times. Choose a reliable freight forwarder experienced in handling agricultural equipment to navigate international shipping efficiently. Understand customs regulations and duties in your country to avoid unexpected costs. Additionally, factor in potential delays caused by weather or geopolitical issues. Planning ahead and maintaining open communication with your logistics partners can help mitigate risks and ensure timely delivery.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 10 Irrigation Valves Leaking Manufacturers & Suppliers List

1. Reddit – Sprinkler Valve Solutions

Domain: reddit.com

Registered: 2005 (20 years)

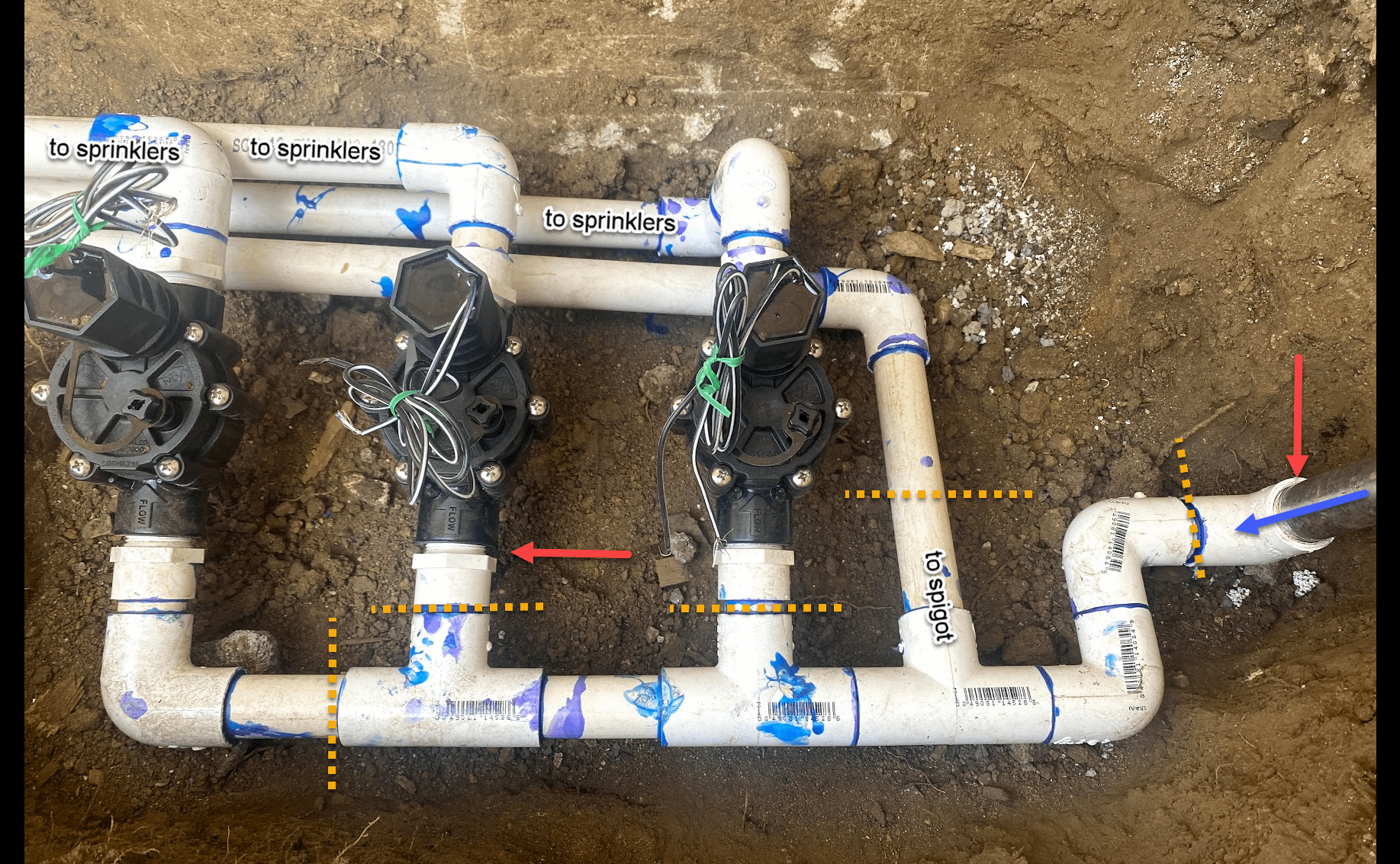

Introduction: Leaking sprinkler valve; replaced top of valve and entire assembly; leak stops when main valve is shut off; potential issues include too much pressure in the system; constant low flow from sprinkler at lowest point; suggestion to install a check valve.

2. Hunter Irrigation – HCV Check Valves

Domain: hunterirrigation.com

Registered: 2001 (24 years)

Introduction: The text discusses issues related to valves weeping or leaking when they are supposed to be off. It identifies two main causes: 1) Low Head Drainage, where water drains from the lateral piping out of the sprinkler, which can be resolved by installing check valves like the HCV on sprinklers and lateral lines. 2) Water leaking through the zone valve due to debris obstructing the valve’s diaphragm, w…

3. Pressure Vacuum Breaker – O-Ring #39

Domain: diy.stackexchange.com

Registered: 2009 (16 years)

Introduction: Pressure vacuum breaker, O-ring, #39 O-Ring Bag, Part Number: 9D0035753B, #6 Union O-Ring

4. Sprinkler Warehouse – Key Rotors and Angle Valves

Domain: school.sprinklerwarehouse.com

Registered: 1999 (26 years)

Introduction: Rain Bird 1804 SAM with built-in check valve; Hunter Adjustable Arc CV Rotor with built-in check valve; Irritrol Rotor 5 in. | 550R; Hydro-Rain Pop-Up Rotor 4 in. | HRX-075; Angle valves with a 90-degree angle between their inlet and outlet pipes.

5. Facebook – Solenoid Leak Solutions

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Solenoid Leak Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Irrigreen – Smart Sprinkler Head

Domain: irrigreen.com

Registered: 2013 (12 years)

Introduction: Irrigreen Smart Sprinkler Head, flexible irrigation line, PVC supply line, compression couplings, Teflon tape, CableLock.

7. Rain Bird – Sprinkler Valve Leak Solutions

Domain: justanswer.com

Registered: 2004 (21 years)

Introduction: Rain Bird Sprinkler System; Valve Leak Troubleshooting; Common Issues: Cracked valve body, loose or broken fitting, failed PVC pipe connection, worn O-ring or seal; Repair Steps: Turn off water, inspect valve connection, tighten connection if threaded, replace valve if broken; Replacement valve size: usually 3/4″ or 1″; Additional notes: Check for dirt or debris, consider using an end cap for repa…

8. Angi – Replacement Sprinkler Valves

Domain: angi.com

Registered: 1996 (29 years)

Introduction: Replacement sprinkler valve or part price ranges from $13 to $150. Common causes of leaks include low head drainage, rubber diaphragm seal breaks, damaged or dirty O-rings, excessive water pressure, dirty sprinkler heads, clogged lines, and debris in the valve.

9. Terry Love – Brass Irrigation Valves

Domain: terrylove.com

Registered: 1996 (29 years)

Introduction: Irrigation valve, potential issues with O ring seal, recommendation to upgrade to brass valves (Armstrong or Champion, USA made), suggestion to avoid using glue on the cap.

10. Rain Bird – Pop Up 180 Spray Heads

Domain: thelawnforum.com

Registered: 2017 (8 years)

Introduction: Rain Bird pop up 180 spray heads, Hunter SS-530 heads, check valves.

Strategic Sourcing Conclusion and Outlook for irrigation valves leaking

How Can Strategic Sourcing Mitigate Issues with Irrigation Valves Leaking?

In conclusion, addressing the challenges posed by leaking irrigation valves is crucial for optimizing water management and reducing operational costs. Key takeaways emphasize the importance of understanding the underlying causes of leaks, such as low head drainage and debris obstruction, which can significantly impact irrigation efficiency. By strategically sourcing high-quality valves and components, businesses can enhance the reliability of their irrigation systems and minimize maintenance disruptions.

International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, should prioritize partnerships with reputable suppliers who offer advanced solutions, including check valves and maintenance services. This proactive approach not only ensures the longevity of irrigation infrastructure but also supports sustainable agricultural practices.

Looking ahead, the demand for efficient irrigation solutions will continue to grow as global water scarcity intensifies. Now is the time to invest in strategic sourcing practices that prioritize quality and reliability. By doing so, businesses can position themselves as leaders in sustainable irrigation, ensuring that they meet both current and future agricultural challenges effectively. Engage with suppliers today to enhance your irrigation systems and secure a more sustainable future for your operations.