Introduction: Navigating the Global Market for irrigation pump sizing calculator

In the intricate world of agricultural innovation, sourcing an effective irrigation pump sizing calculator can be a daunting challenge for international B2B buyers. With varying environmental conditions and crop requirements across regions like Africa, South America, the Middle East, and Europe, selecting the right pump is crucial for optimizing irrigation efficiency and ensuring sustainable water management. This guide serves as a comprehensive resource, delving into the various types of irrigation pumps, their applications, and the critical factors influencing pump selection, such as flow rates, pressure requirements, and energy efficiency.

Navigating the global market necessitates a keen understanding of supplier vetting processes, cost considerations, and the technological advancements available in pump sizing tools. Buyers will find actionable insights into assessing supplier credibility, comparing product specifications, and evaluating total cost of ownership. By empowering decision-makers with robust data and practical frameworks, this guide aims to facilitate informed purchasing decisions that align with the unique needs of diverse agricultural operations.

In a landscape where precision and reliability are paramount, understanding the intricacies of irrigation pump sizing is not just beneficial; it is essential for achieving optimal agricultural productivity. Whether you are a seasoned agribusiness or a startup, this guide will equip you with the knowledge to make strategic investments in irrigation technology that enhance crop yields and support sustainable practices.

Understanding irrigation pump sizing calculator Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flow Rate Calculator | Focuses on calculating the total flow rate required. | Greenhouses, orchards, and large farms. | Pros: Simple to use; helps avoid under/over-sizing. Cons: Doesn’t account for pressure losses. |

| Total Dynamic Head (TDH) Calculator | Considers elevation changes, friction losses, and required pressure. | Large-scale irrigation systems. | Pros: Comprehensive; ensures accurate pump selection. Cons: More complex; requires detailed data input. |

| Friction Loss Calculator | Estimates pressure losses due to friction in pipes. | Pipeline design and installation. | Pros: Critical for optimizing system efficiency. Cons: Requires knowledge of pipe materials and sizes. |

| Pump Performance Curve Tool | Visualizes pump performance over a range of conditions. | System design and pump selection. | Pros: Provides insights into pump efficiency. Cons: May require technical expertise to interpret. |

| Application-Specific Sizing Tools | Tailored calculators for specific applications (e.g., drip irrigation). | Specialty farms, vineyards, and nurseries. | Pros: Highly relevant; designed for specific needs. Cons: Limited to specific scenarios; may not be versatile. |

What are the characteristics of Flow Rate Calculators in irrigation pump sizing?

Flow Rate Calculators are essential tools for determining the total gallons per minute (GPM) required for an irrigation system. They consider the flow rate of individual emitters and the total number of emitters in a zone. B2B buyers, particularly those managing greenhouses or large farms, benefit from these calculators as they help prevent costly mistakes associated with under or over-sizing pumps. However, while they simplify the initial sizing process, they do not account for pressure losses, which can lead to inefficiencies.

How does a Total Dynamic Head (TDH) Calculator enhance irrigation system design?

The Total Dynamic Head Calculator integrates multiple factors, including elevation changes, friction losses, and the pressure required by emitters, to provide a comprehensive overview of pump requirements. This tool is particularly valuable for large-scale irrigation systems where accuracy is paramount. B2B buyers should ensure they have precise data on their system’s layout and specifications, as the complexity of this calculator requires detailed input. While it offers a thorough analysis, the complexity may deter less experienced users.

Why is a Friction Loss Calculator important for irrigation systems?

Friction Loss Calculators are pivotal in estimating the pressure losses that occur as water travels through pipes. They help determine the optimal pipe size and layout, ensuring efficient water delivery. This is especially relevant for B2B buyers involved in pipeline design and installation, where even minor losses can significantly impact system performance. While these calculators are crucial for optimizing efficiency, they require users to have a solid understanding of pipe materials and configurations.

What insights can a Pump Performance Curve Tool provide to buyers?

Pump Performance Curve Tools offer visual representations of how pumps operate under various conditions, including flow rates and head pressures. This aids B2B buyers in selecting pumps that align with their specific operational needs. These tools are invaluable during the system design phase, as they provide insights into potential pump efficiency and longevity. However, interpreting the curves may require technical expertise, which could be a barrier for some buyers.

How do Application-Specific Sizing Tools cater to niche markets?

Application-Specific Sizing Tools are designed to meet the unique needs of particular irrigation applications, such as drip irrigation for vineyards or nurseries. These calculators provide tailored recommendations based on specific parameters, ensuring buyers select the most appropriate pump for their needs. While they offer highly relevant solutions, their focus on niche markets may limit versatility for broader applications, making them less suitable for general irrigation projects.

Key Industrial Applications of irrigation pump sizing calculator

| Industry/Sector | Specific Application of irrigation pump sizing calculator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Crop irrigation systems | Ensures optimal water delivery, enhancing crop yields | Local climate conditions, water availability, pump efficiency |

| Horticulture | Greenhouse irrigation | Provides precise water management for sensitive plants | Type of crops, system design, and emitter requirements |

| Mining | Dust suppression and slurry transport | Reduces operational downtime and improves safety | Pump durability, flow rate requirements, and energy efficiency |

| Municipal Water Supply | Landscape irrigation for public parks | Enhances aesthetic value and community satisfaction | Compliance with regulations, water pressure needs, and system integration |

| Aquaculture | Water circulation in fish farms | Maintains optimal aquatic conditions for fish growth | Water quality parameters, pump size, and energy costs |

How is the Irrigation Pump Sizing Calculator Used in Agriculture?

In agriculture, the irrigation pump sizing calculator is essential for determining the appropriate pump specifications for crop irrigation systems. By inputting variables such as flow rate requirements and elevation changes, farmers can ensure that water is delivered efficiently to their crops. This tool addresses common issues like inadequate water supply or excessive energy consumption, which can lead to decreased yields. For international buyers, understanding local water availability and climate conditions is crucial for selecting the right pump.

What Role Does the Irrigation Pump Sizing Calculator Play in Horticulture?

In horticulture, precise water management is critical for the health of sensitive plants in greenhouses. The irrigation pump sizing calculator allows growers to calculate the necessary flow rates and pressures required for their specific watering systems, ensuring optimal irrigation without overwatering. This tool helps solve problems related to plant stress and inefficiencies in water use. Buyers in this sector should consider the type of crops, emitter specifications, and system design when sourcing pumps.

How is the Irrigation Pump Sizing Calculator Applied in Mining?

Mining operations often utilize irrigation pump sizing calculators for applications like dust suppression and slurry transport. By accurately sizing pumps, companies can minimize operational downtime and enhance safety in hazardous environments. The calculator aids in determining the right flow rates and pump durability needed for challenging mining conditions. For international buyers, factors such as energy efficiency and compliance with local regulations are key considerations when sourcing pumps for mining applications.

How Does the Irrigation Pump Sizing Calculator Benefit Municipal Water Supply?

Municipalities can leverage irrigation pump sizing calculators to optimize landscape irrigation systems in public parks. By ensuring that water is distributed evenly and efficiently, these systems enhance the aesthetic value of public spaces, leading to increased community satisfaction. The calculator helps address challenges related to water pressure and regulatory compliance. Municipal buyers should focus on integrating the pump systems with existing infrastructure and understanding local water pressure needs.

What is the Importance of the Irrigation Pump Sizing Calculator in Aquaculture?

In aquaculture, maintaining optimal water conditions is vital for the health and growth of fish. The irrigation pump sizing calculator assists aquaculture operators in determining the right pump size for water circulation systems, ensuring consistent water quality. This tool resolves issues related to inadequate oxygen levels and temperature control in aquatic environments. Buyers in this industry must consider water quality parameters, energy costs, and pump size when sourcing equipment for aquaculture operations.

3 Common User Pain Points for ‘irrigation pump sizing calculator’ & Their Solutions

Scenario 1: Miscalculating Pump Requirements Can Lead to System Failures

The Problem: B2B buyers often struggle with the complexities of calculating the correct pump capacity for their irrigation systems. Misjudging the required flow rate and pressure can result in underperformance or even system failures. For instance, a company in South America may assume a pump’s maximum capacity without considering real-world factors like friction losses in pipes, elevation changes, or the specific needs of their irrigation method. This can lead to wasted resources, increased operational costs, and potential crop damage due to inadequate irrigation.

The Solution: To avoid these pitfalls, buyers should leverage comprehensive irrigation pump sizing calculators that account for all necessary variables, including flow rate, elevation, and friction losses. Start by gathering detailed data about your irrigation system, including the total gallons per minute (GPM) needed and the total dynamic head (TDH), which combines suction lift, elevation change, and pressure requirements. Use the calculator to input these parameters, ensuring that you consider the efficiency ratings of both the pump and the motor. Furthermore, it’s advisable to consult with pump manufacturers or irrigation specialists to validate your calculations and receive tailored recommendations that suit your specific application.

Scenario 2: Selecting the Wrong Pump Type Can Increase Costs

The Problem: Many B2B buyers face the challenge of selecting the wrong type of pump—be it submersible, jet, or centrifugal—leading to inefficiencies and inflated operational costs. For example, a European agricultural company might choose a submersible pump for a shallow well, which could be more expensive and less efficient than a jet pump. This mismatch not only impacts initial investment but also affects long-term energy consumption and maintenance expenses.

The Solution: To select the most suitable pump type, buyers should utilize a pump sizing calculator that categorizes options based on specific applications and performance needs. Begin by defining the application requirements, including the depth of the water source and the total flow rate needed. The calculator can provide a tailored list of pump types that meet these requirements, allowing you to compare their efficiencies and operational costs. Additionally, it is beneficial to engage with suppliers who can offer insights into the latest technologies and pump designs that may provide better performance and cost savings over time.

Scenario 3: Lack of Knowledge on Pressure Losses Can Compromise Efficiency

The Problem: A common pain point for B2B buyers is the insufficient understanding of how pressure losses in pipes can impact the overall efficiency of their irrigation systems. For instance, a buyer in Africa may not account for friction losses due to long pipeline runs, which can significantly reduce the effective pressure at the emitters. This oversight can lead to uneven water distribution and insufficient irrigation, ultimately affecting crop yields and profitability.

The Solution: To mitigate pressure loss issues, buyers should make use of advanced irrigation pump sizing calculators that include a pipeline pressure loss component. These tools can help calculate friction losses based on pipe diameter, material, and flow rate. It is crucial to measure the total length of the pipeline and input these details into the calculator to get an accurate estimate of pressure loss. Additionally, consider using larger diameter pipes where feasible to reduce friction losses, and ensure that the selected pump compensates for these losses. Regular maintenance checks on the irrigation system can also help identify and rectify any pressure loss issues that arise over time, ensuring optimal performance and efficiency.

Strategic Material Selection Guide for irrigation pump sizing calculator

When selecting materials for irrigation pump systems, understanding the properties and applications of various materials is crucial for ensuring optimal performance and longevity. Here, we analyze four common materials used in irrigation pump systems, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What are the Key Properties of Cast Iron in Irrigation Pump Systems?

Cast iron is a traditional choice for pump casings and components due to its excellent strength and durability. It typically has a temperature rating of up to 200°C and can withstand high pressures, making it suitable for various irrigation applications. Additionally, cast iron exhibits good wear resistance and can handle abrasive media effectively.

Pros & Cons: The primary advantage of cast iron is its robustness and ability to handle high-stress conditions. However, it is prone to corrosion, especially in aggressive environments, which can lead to premature failure. Moreover, cast iron is heavier than other materials, which may complicate installation and maintenance.

Impact on Application: Cast iron is compatible with a wide range of fluids, including water and some chemical solutions, but its susceptibility to corrosion limits its use in saline or acidic environments.

Considerations for International Buyers: Buyers should be aware of compliance with standards such as ASTM A48 for cast iron. In regions like Africa and South America, where irrigation systems may face harsh conditions, selecting a corrosion-resistant coating can enhance the longevity of cast iron components.

How Does Stainless Steel Compare in Terms of Performance?

Stainless steel is favored for its corrosion resistance and aesthetic appeal. It can withstand temperatures up to 400°C and high pressures, making it ideal for various irrigation applications. Its smooth surface reduces friction loss, improving pump efficiency.

Pros & Cons: The key advantage of stainless steel is its resistance to rust and corrosion, which is essential for applications involving saline or chemically aggressive media. However, stainless steel can be significantly more expensive than cast iron and may require specialized manufacturing processes, increasing lead times.

Impact on Application: Stainless steel is compatible with a wide range of fluids, including potable water, making it suitable for both agricultural and residential irrigation systems.

Considerations for International Buyers: Compliance with standards such as ASTM A240 is crucial. Buyers in regions with stringent regulations, such as Europe, should ensure that the stainless steel used meets local quality standards.

Why is Thermoplastic a Viable Option for Irrigation Pump Components?

Thermoplastic materials, such as PVC and polyethylene, are increasingly used in irrigation systems due to their lightweight and corrosion-resistant properties. They can operate effectively at temperatures up to 60°C and provide good pressure ratings, making them suitable for various applications.

Pros & Cons: The primary advantage of thermoplastics is their resistance to corrosion and chemical damage, which makes them ideal for use in diverse environments. However, they may not withstand high temperatures or pressures as effectively as metals, limiting their application in some high-demand scenarios.

Impact on Application: Thermoplastics are compatible with a variety of fluids, including water and fertilizers, making them suitable for agricultural irrigation systems.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM D1785 for PVC. In regions like the Middle East, where UV exposure can be significant, selecting UV-stabilized materials is crucial for longevity.

What Role Does Ductile Iron Play in Pump Sizing Calculators?

Ductile iron combines the strength of cast iron with improved ductility, making it suitable for high-pressure applications. It can handle temperatures up to 300°C and offers excellent corrosion resistance when properly coated.

Pros & Cons: The key advantage of ductile iron is its ability to withstand higher pressures and impacts compared to cast iron. However, it is heavier and can be more expensive than both cast iron and thermoplastics.

Impact on Application: Ductile iron is suitable for high-pressure irrigation systems and can handle a variety of media, including water and some chemicals.

Considerations for International Buyers: Compliance with standards such as ASTM A536 is important. Buyers in regions with varying climate conditions should consider the impact of temperature fluctuations on ductile iron components.

Summary Table

| Material | Typical Use Case for irrigation pump sizing calculator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cast Iron | Pump casings and components | High strength and durability | Prone to corrosion; heavy | Medium |

| Stainless Steel | High-end pump applications | Excellent corrosion resistance | Higher cost; complex manufacturing | High |

| Thermoplastic | Piping and low-pressure components | Lightweight and corrosion-resistant | Limited temperature and pressure resistance | Low |

| Ductile Iron | High-pressure irrigation systems | High strength and impact resistance | Heavier and more expensive than alternatives | Medium |

This strategic material selection guide provides essential insights for B2B buyers, enabling informed decisions in the context of irrigation pump sizing calculators.

In-depth Look: Manufacturing Processes and Quality Assurance for irrigation pump sizing calculator

What Are the Main Stages of Manufacturing an Irrigation Pump Sizing Calculator?

The manufacturing process for an irrigation pump sizing calculator involves several critical stages to ensure high-quality output. These stages can be broadly categorized into material preparation, forming, assembly, and finishing.

How Is Material Prepared for Pump Sizing Calculators?

Material preparation is the initial stage where raw materials are sourced and inspected. For an irrigation pump sizing calculator, materials such as plastic, metal, and electronic components are commonly used. Quality control begins at this stage, with suppliers required to provide certifications for their materials, ensuring they meet international standards such as ISO 9001. This step is crucial for B2B buyers in regions like Africa and South America, where material quality can vary significantly.

What Forming Techniques Are Utilized?

Once the materials are prepared, forming techniques come into play. This involves shaping the components of the calculator, typically through processes such as injection molding for plastic parts and machining for metal components. Precision is vital in this stage, as any inaccuracies can affect the calculator’s performance. Manufacturers often utilize Computer Numerical Control (CNC) technology to enhance precision and reduce human error, which is particularly beneficial for international buyers seeking reliable performance.

How Is the Assembly Process Conducted?

The assembly stage combines all formed components into a functional unit. This may involve soldering electronic parts, fastening mechanical components, and integrating software that operates the calculator. Manufacturers often employ lean assembly techniques to streamline this process, reducing waste and improving efficiency. For B2B buyers, understanding the assembly methods used can provide insights into the product’s reliability and longevity.

What Finishing Techniques Are Applied?

Finishing involves final touches that enhance the aesthetic and functional qualities of the irrigation pump sizing calculator. This includes surface treatments like painting, coating, or labeling. Quality control checks at this stage ensure that the finished product meets design specifications and is free from defects. Buyers should inquire about finishing techniques, as these can impact the product’s durability, especially in demanding environments.

How Is Quality Assurance Implemented in the Manufacturing of Pump Sizing Calculators?

Quality assurance (QA) is a vital aspect of the manufacturing process for irrigation pump sizing calculators. It encompasses various international and industry-specific standards to ensure products are reliable and meet customer expectations.

What International Standards Should Buyers Be Aware Of?

For B2B buyers, familiarity with international standards such as ISO 9001 is crucial. This standard outlines the requirements for a quality management system, ensuring consistent product quality and continuous improvement. Other relevant certifications include CE marking for products sold within the European Economic Area and API standards for pumps used in various industries. Understanding these standards helps buyers assess the credibility of suppliers.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints throughout the manufacturing process typically include Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

Incoming Quality Control (IQC): This stage involves inspecting raw materials and components upon arrival. Suppliers must provide documentation proving compliance with quality standards.

In-Process Quality Control (IPQC): Throughout the manufacturing process, periodic checks are conducted to ensure that production is adhering to specified tolerances and quality standards. This includes monitoring machine performance and conducting random sampling of assembled products.

Final Quality Control (FQC): The final stage ensures that the completed calculators meet all design specifications and quality standards before shipment. This may involve functional testing, accuracy verification, and user interface assessments.

Which Testing Methods Are Commonly Used?

Common testing methods for irrigation pump sizing calculators include functional testing, performance testing, and reliability testing. Functional testing ensures that all features work as intended, while performance testing evaluates the calculator’s accuracy under various conditions. Reliability testing simulates long-term use to identify potential failure points. B2B buyers should request test reports to verify the reliability of the products they intend to purchase.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, verifying a supplier’s quality control measures is essential for ensuring product reliability. There are several strategies to accomplish this.

What Audit Options Are Available for Buyers?

Conducting audits of potential suppliers is one of the most effective ways to assess their quality control practices. Buyers can either perform on-site audits or hire third-party auditors to evaluate the supplier’s manufacturing processes and quality management systems. This provides an in-depth understanding of the supplier’s capabilities and adherence to quality standards.

How Can Buyers Obtain Quality Reports?

Buyers should request detailed quality reports that outline the results of IQC, IPQC, and FQC processes. These reports should include data on testing methods, results, and any corrective actions taken in response to quality issues. Having access to this documentation enhances transparency and builds trust between buyers and suppliers.

What Are the Quality Control Nuances for International Buyers?

Quality control nuances can vary based on geographical location. For instance, B2B buyers from Africa and South America may face challenges related to inconsistent quality standards and varying supplier capabilities. It is advisable for buyers in these regions to establish clear quality expectations and conduct thorough due diligence when selecting suppliers.

In contrast, buyers from Europe may benefit from stricter regulatory frameworks that enforce compliance with quality standards. They should leverage these regulations to demand higher quality from suppliers, ensuring that the products meet European market requirements.

Conclusion

Understanding the manufacturing processes and quality assurance practices for irrigation pump sizing calculators is vital for B2B buyers seeking reliable and high-quality products. By familiarizing themselves with the manufacturing stages, quality control measures, and verification methods, buyers can make informed decisions that align with their operational needs and market standards. This knowledge not only aids in selecting the right suppliers but also enhances the overall success of their irrigation projects.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘irrigation pump sizing calculator’

Introduction

Selecting the right irrigation pump sizing calculator is critical for optimizing your irrigation system’s performance and efficiency. This guide provides a practical checklist for B2B buyers, ensuring that you make an informed decision that meets your specific agricultural or landscape management needs.

Step 1: Define Your Technical Specifications

Before sourcing a pump sizing calculator, clearly outline your project requirements. This includes understanding the desired flow rate, pressure requirements, and elevation changes within your irrigation system. Defining these parameters ensures you choose a calculator that can accurately reflect the unique conditions of your project.

- Flow Rate: Identify the maximum gallons per minute (GPM) needed for your system.

- Pressure Requirements: Assess the pressure head necessary for your emitters or sprayers to function effectively.

Step 2: Research Available Tools

Conduct thorough research on available irrigation pump sizing calculators. Look for tools that are user-friendly, offer detailed output, and can cater to various irrigation methods, including drip and sprinkler systems. A well-designed calculator will provide you with insights that can lead to better decision-making.

- Online Reviews: Check for testimonials and user experiences to gauge reliability.

- Functionality: Ensure the tool can handle the complexities of your specific irrigation needs.

Step 3: Evaluate Potential Suppliers

Before making a purchase, vet the suppliers of the calculators you are considering. Request company profiles, product demonstrations, and references from other clients in your region or industry. This step is crucial to ensure you are dealing with a reputable provider.

- Case Studies: Look for examples of successful implementations of their calculators.

- Customer Support: Assess the level of technical support they offer post-purchase.

Step 4: Check for Compatibility with Existing Systems

Ensure that the pump sizing calculator you select is compatible with your existing irrigation infrastructure. It should seamlessly integrate with your current systems to avoid unnecessary complications or additional costs.

- Software Integration: If applicable, check if the calculator can work with existing software systems you use.

- Data Export Options: Look for calculators that allow you to export data for further analysis.

Step 5: Verify Supplier Certifications and Compliance

Investigate whether the supplier holds any relevant certifications or complies with industry standards. Certifications can indicate the quality and reliability of the product and the supplier’s commitment to maintaining high standards.

- ISO Certifications: Check for compliance with international standards for quality management.

- Local Regulations: Ensure they adhere to regulations specific to your region, especially in agriculture.

Step 6: Assess Cost vs. Value

Finally, evaluate the cost of the pump sizing calculator against the value it offers. Consider not just the purchase price but also potential savings in efficiency, reduced water usage, and overall system performance improvement.

- Long-Term Savings: Calculate potential savings in energy and water costs over time.

- Return on Investment (ROI): Assess how quickly the investment can pay for itself through improved irrigation efficiency.

By following this checklist, B2B buyers can confidently procure an irrigation pump sizing calculator that aligns with their operational needs and enhances their irrigation systems’ performance.

Comprehensive Cost and Pricing Analysis for irrigation pump sizing calculator Sourcing

What Are the Key Cost Components of Irrigation Pump Sizing Calculators?

When sourcing an irrigation pump sizing calculator, understanding the cost structure is essential. The primary cost components include:

Materials: The quality and type of materials used in the construction of the pump sizing calculator directly affect the cost. High-grade materials that ensure durability and efficiency may incur higher initial costs but can lead to savings over time through reduced maintenance and longer lifespan.

Labor: Labor costs encompass the expenses associated with design, assembly, and quality assurance. Skilled labor can increase costs, but it also enhances the reliability and accuracy of the calculator, which is crucial for effective irrigation management.

Manufacturing Overhead: This includes indirect costs related to production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help minimize overhead costs, which can be passed on to buyers.

Tooling: The setup of production tools and machinery is a one-time cost that can be significant, especially for custom or specialized designs. Investing in high-quality tooling can ensure better precision and efficiency in the production process.

Quality Control (QC): Ensuring that the calculator meets performance specifications requires a rigorous QC process. The associated costs can vary depending on the complexity of the product and the standards required.

Logistics: Transportation and distribution costs play a crucial role in the total cost structure. These can fluctuate based on the distance between the manufacturing facility and the buyer, as well as the chosen shipping method.

Margin: Supplier margins can vary widely based on market conditions and competition. Understanding typical margins in the industry can assist buyers in identifying fair pricing.

How Do Price Influencers Affect Sourcing Decisions for Irrigation Pump Sizing Calculators?

Several factors can influence the pricing of irrigation pump sizing calculators:

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to optimize pricing based on their needs.

Specifications and Customization: Custom features can significantly increase costs. Buyers should weigh the necessity of specific features against the additional expenses they incur.

Material Quality and Certifications: High-quality materials and certifications (e.g., ISO, CE) can elevate costs but ensure reliability and compliance with international standards, which is particularly important for B2B buyers in regulated markets.

Supplier Factors: The reputation and reliability of the supplier can impact costs. Established suppliers may charge more, but they often provide better quality assurance and customer service.

Incoterms: The agreed-upon shipping terms can influence the total landed cost. Understanding Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for buyers to anticipate additional costs related to shipping and insurance.

What Are the Best Buyer Tips for Cost-Efficient Sourcing?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, here are some actionable tips:

Negotiate Effectively: Engage in discussions with suppliers to negotiate terms that can lead to cost reductions. Building a relationship with suppliers can also yield better prices over time.

Focus on Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the long-term costs associated with maintenance, operation, and potential downtime. A cheaper initial cost may lead to higher TCO if the product is less reliable.

Understand Pricing Nuances: Be aware of regional pricing variations and currency fluctuations. This understanding can help in making informed decisions and budgeting appropriately.

Consider Local Suppliers: Sourcing from local suppliers can reduce logistics costs and lead times, making it easier to manage inventory and maintenance.

Conclusion

Understanding the cost structure and pricing influencers is vital for making informed sourcing decisions regarding irrigation pump sizing calculators. By leveraging these insights and employing strategic negotiation and purchasing strategies, B2B buyers can optimize their investments and ensure the efficiency of their irrigation systems. Remember that prices are indicative and can vary based on market conditions, supplier relationships, and specific requirements.

Alternatives Analysis: Comparing irrigation pump sizing calculator With Other Solutions

Understanding Alternatives to Irrigation Pump Sizing Calculators

In the agricultural and irrigation sectors, selecting the right pump is crucial for operational efficiency. While irrigation pump sizing calculators are a popular choice for determining pump specifications, there are several alternative solutions that can also achieve effective pump selection. Understanding these alternatives can help B2B buyers make informed decisions tailored to their specific needs.

| Comparison Aspect | Irrigation Pump Sizing Calculator | Flow Rate and Pressure Chart | Consultation with Pump Specialists |

|---|---|---|---|

| Performance | Provides precise calculations based on specific inputs, ensuring optimal pump selection. | Offers general estimates that may not account for unique system variables. | Delivers expert insights tailored to the specific installation and environmental conditions. |

| Cost | Typically low-cost or free to use, especially online. | Minimal costs associated with printing or accessing charts. | Can be expensive, depending on the consultant’s fees and project scope. |

| Ease of Implementation | User-friendly interfaces allow for quick input and results. | Requires manual calculations and understanding of charts, which can be cumbersome. | Involves scheduling consultations and may require detailed project descriptions. |

| Maintenance | No maintenance needed; digital tools are self-updating. | Charts may become outdated if not regularly refreshed. | Ongoing support may be available, but can vary by consultant. |

| Best Use Case | Ideal for straightforward irrigation systems where exact specifications are crucial. | Useful for quick estimates in less complex systems or for initial assessments. | Best for complex projects requiring tailored solutions or expert guidance. |

Exploring Alternative Solutions in Depth

Flow Rate and Pressure Chart

Flow rate and pressure charts provide a comparative overview of pump specifications based on various flow rates and pressure levels. While these charts can serve as a quick reference tool, they may lack the precision required for complex irrigation systems. Users must interpret data and perform manual calculations, which can lead to errors if the unique characteristics of the irrigation setup are not fully considered. However, these charts can be useful in scenarios where quick estimates are needed, or where costs must be minimized.

Consultation with Pump Specialists

Engaging with pump specialists offers the advantage of expert knowledge and tailored solutions. Specialists can analyze the specific requirements of an irrigation project, considering factors such as environmental conditions, system layout, and water source characteristics. Although this option may come with higher costs, the personalized recommendations can significantly reduce the risk of selecting an inappropriate pump. This is particularly beneficial for complex or large-scale irrigation projects where precision is paramount.

Making the Right Choice for Your Irrigation Needs

When selecting the best solution for pump sizing, B2B buyers should consider the complexity of their irrigation system and their specific operational requirements. For straightforward applications, an irrigation pump sizing calculator may suffice, offering cost-effective and user-friendly options. However, for more intricate setups or projects that demand precision, investing in a consultation with a pump specialist could prove invaluable. Ultimately, the choice will depend on the balance between budget constraints, the need for accuracy, and the resources available for implementation. By carefully evaluating these aspects, buyers can ensure they select the most suitable method for their irrigation needs.

Essential Technical Properties and Trade Terminology for irrigation pump sizing calculator

What are the Key Technical Properties for an Irrigation Pump Sizing Calculator?

When selecting an irrigation pump, understanding its technical properties is crucial for ensuring optimal performance and efficiency. Below are some critical specifications to consider:

Flow Rate (GPM or L/min)

The flow rate indicates the volume of water the pump can deliver, measured in gallons per minute (GPM) or liters per minute (L/min). For B2B buyers, knowing the required flow rate helps in selecting a pump that meets specific irrigation needs, avoiding underperformance or excess energy consumption.Total Dynamic Head (TDH)

TDH is the total height that water needs to be pumped, accounting for elevation changes, friction losses, and pressure requirements. Accurately calculating TDH is essential for pump selection as it directly affects pump size and energy efficiency. A mismatch can lead to system inefficiencies and increased operational costs.Efficiency Ratings

Pump efficiency measures how effectively the pump converts electrical energy into hydraulic energy. Higher efficiency ratings mean lower operating costs and reduced energy consumption, making them attractive to B2B buyers focused on sustainability and cost-effectiveness.Material Grade and Durability

The construction materials of the pump (e.g., stainless steel, plastic, or cast iron) influence its lifespan, resistance to corrosion, and suitability for different water types (e.g., saline or acidic water). Buyers must consider the environment in which the pump will operate to ensure longevity and reliability.Motor Power (HP or kW)

The power of the pump’s motor, measured in horsepower (HP) or kilowatts (kW), affects its ability to handle various loads. Selecting the right motor power ensures that the pump can meet the demands of the irrigation system without overheating or failing.Operating Conditions

Understanding the operating conditions, such as temperature, pressure, and water quality, is vital for selecting a compatible pump. B2B buyers should ensure that the pump is rated for the specific conditions it will encounter, which can prevent premature failure and costly repairs.

What are the Common Trade Terminologies Relevant to Irrigation Pump Sizing?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are some commonly used terms:

OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products that may be marketed by another company. In the irrigation sector, understanding OEM relationships can help buyers identify reliable suppliers and guarantee product quality.MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is crucial for budget management and inventory planning, particularly when scaling up irrigation projects.RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. Crafting a detailed RFQ can ensure that buyers receive accurate pricing, helping them make informed purchasing decisions.Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for B2B buyers to manage logistics, risk, and costs effectively.Lead Time

Lead time refers to the period between placing an order and receiving the product. For irrigation projects, knowing the lead time is essential for planning and ensuring timely delivery, especially in seasonal markets.Warranty and Support Terms

Warranty refers to the guarantee provided by the manufacturer regarding the performance and longevity of the pump. Understanding warranty terms helps buyers assess the risk of potential failures and the support they can expect from suppliers.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions, ensuring that their irrigation systems are efficient, reliable, and cost-effective.

Navigating Market Dynamics and Sourcing Trends in the irrigation pump sizing calculator Sector

What Are the Key Drivers and Trends Influencing the Irrigation Pump Sizing Calculator Market?

The global market for irrigation pump sizing calculators is experiencing significant growth, fueled by several key drivers. Increasing agricultural productivity demands, water scarcity issues, and the necessity for efficient irrigation practices are pushing B2B buyers to seek precise and reliable pump sizing solutions. In regions like Africa and South America, where agriculture is a crucial economic driver, the need for optimized irrigation systems is paramount. Additionally, the Middle East’s arid climate necessitates advanced irrigation technologies to maximize water use efficiency.

Emerging trends in B2B technology are reshaping the market landscape. The integration of IoT and smart technology into irrigation systems is enabling real-time monitoring and data analytics, enhancing the accuracy of pump sizing calculations. Cloud-based solutions are gaining traction, allowing for easy access to sizing tools and resources from various devices, which is particularly appealing to buyers in remote areas. Furthermore, a growing emphasis on sustainable agricultural practices is leading buyers to prioritize energy-efficient pumps, prompting manufacturers to innovate and offer eco-friendly options.

How Is Sustainability and Ethical Sourcing Shaping the Irrigation Pump Sizing Calculator Sector?

Sustainability has become a cornerstone of the irrigation pump sizing calculator market. As environmental concerns rise, B2B buyers are increasingly focused on the ecological impact of their sourcing decisions. Efficient irrigation not only conserves water but also reduces energy consumption, aligning with global sustainability goals. The use of renewable materials and energy-efficient designs in pump manufacturing is essential for attracting environmentally conscious buyers.

Ethical sourcing practices are also gaining prominence. Buyers are keen on understanding the supply chain, ensuring that manufacturers adhere to responsible labor practices and environmental regulations. Certifications such as ISO 14001 for environmental management and other ‘green’ certifications signal a commitment to sustainability, making products more attractive to B2B buyers. Companies that prioritize ethical sourcing are likely to foster stronger relationships with their clients, enhancing brand loyalty and market share.

What Is the Historical Context of the Irrigation Pump Sizing Calculator Market?

The evolution of irrigation pump sizing calculators can be traced back to the increasing need for efficient agricultural practices amid growing global food demands. Early systems relied heavily on manual calculations, often resulting in errors that led to inefficiencies in water use. Over the years, technological advancements have transformed these processes, introducing digital calculators that streamline the sizing process and improve accuracy.

The introduction of online tools and software has revolutionized the way B2B buyers approach pump sizing. Modern calculators incorporate various parameters such as flow rates, pressure requirements, and elevation changes, providing users with tailored solutions. This transition not only enhances efficiency but also empowers buyers to make informed decisions, reflecting the broader trend towards digitization and automation in agriculture.

In summary, the irrigation pump sizing calculator sector is driven by emerging technologies, sustainability imperatives, and a historical shift towards more efficient agricultural practices. B2B buyers must navigate these dynamics to make informed sourcing decisions that align with their operational needs and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of irrigation pump sizing calculator

How do I determine the right pump size for my irrigation system?

To accurately size a pump for your irrigation system, you need to calculate the total dynamic head (TDH), which includes the elevation change, friction losses in the piping, and the required pressure for your emitters. Start by assessing your total flow rate in gallons per minute (GPM) based on the number and type of emitters. Utilize online pump sizing calculators that allow you to input these parameters for an accurate recommendation tailored to your specific system requirements.What factors should I consider when selecting an irrigation pump?

When selecting an irrigation pump, consider the flow rate, total dynamic head, and the type of irrigation system you are using (e.g., drip, spray). Additionally, evaluate the pump’s efficiency, energy consumption, and compatibility with your existing infrastructure. It’s also essential to take into account local conditions, such as water source availability and elevation changes, to ensure optimal performance and longevity of the pump.What are the common mistakes to avoid in pump sizing for irrigation?

Common mistakes in pump sizing include neglecting to account for friction loss in the pipes, miscalculating the total dynamic head, and choosing a pump based solely on maximum flow rates without considering operational efficiency. Additionally, failing to incorporate a safety factor can lead to underperformance. Always ensure that your calculations are based on realistic operational conditions rather than maximum specifications to avoid system failures.How can I ensure the quality of the irrigation pump I am purchasing?

To ensure quality, source pumps from reputable manufacturers with proven track records. Request product certifications, performance data, and customer testimonials. Conduct thorough supplier vetting by checking for compliance with international quality standards and engaging in discussions about warranty policies and after-sales support. It’s also beneficial to ask for samples or references from previous customers in your region.What are the minimum order quantities (MOQ) for irrigation pumps?

Minimum order quantities (MOQ) for irrigation pumps can vary significantly depending on the manufacturer and product type. Many suppliers set MOQs to balance production costs and inventory management. It’s advisable to discuss MOQs upfront with potential suppliers, particularly if you are looking for customization options, to ensure that your purchasing needs align with their policies.What payment terms are typically offered by suppliers for irrigation pump purchases?

Payment terms can vary widely among suppliers, but common options include net 30, net 60, or cash in advance. Some suppliers may offer financing options or discounts for upfront payments. When negotiating, consider discussing payment milestones based on production or delivery phases to mitigate risk. Always ensure that terms are clearly outlined in the purchase agreement to avoid misunderstandings.How can I manage logistics for importing irrigation pumps?

Effective logistics management involves coordinating shipping methods, understanding customs regulations, and selecting reliable freight forwarders. Research import duties and taxes applicable to your region to factor them into your budget. Establish a timeline for delivery that accounts for potential delays and communicate clearly with your supplier about shipping documentation and requirements to facilitate smooth customs clearance.What should I look for in a supplier’s customer service regarding irrigation pump support?

When evaluating a supplier’s customer service, consider their responsiveness, technical support capabilities, and availability of resources such as user manuals and installation guides. A good supplier should provide ongoing support, including assistance with troubleshooting and maintenance. It’s also beneficial to assess their warranty policies and the ease of reaching their service team for prompt resolutions to any issues that may arise post-purchase.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 Irrigation Pump Sizing Calculator Manufacturers & Suppliers List

1. Driptec – Pump Capacity Calculator

Domain: driptec.com

Registered: 2023 (2 years)

Introduction: Pump calculator for irrigation systems; essential for determining pump capacity based on flow and pressure; considers maximum flow and pressure indices; includes safety factor; calculates operating point; variables include flow rate, pressure, pump efficiency, drive motor efficiency, brake horsepower, total power input requirements, pipeline pressure loss; features calculators for pipeline pressur…

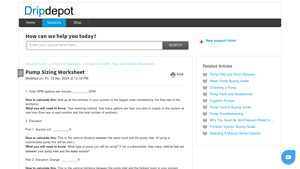

2. Drip Depot – Pump Sizing Worksheet

Domain: help.dripdepot.com

Registered: 2005 (20 years)

Introduction: Pump Sizing Worksheet includes key calculations for determining pump requirements for irrigation systems. Key details include: 1. Total GPM (gallons per minute) based on emitter flow rates. 2. Elevation Part 1: Suction Lift (vertical distance to pump inlet). 3. Elevation Part 2: Elevation Change (vertical distance to highest emitter). 4. Friction Loss (in feet) calculated using flow rate and tubin…

3. RPS Water Pumps – Submersible & Residential Well Pumps

Domain: rpswaterpumps.com

Registered: 2022 (3 years)

Introduction: Water Pump Sizing Wizard, Free Ground Shipping on Orders Over $100, Next Day Air Available, USA Based Sizing & Support, Submersible Well Pumps, Residential Well Pumps, 220V and 110V Pumps, Booster Pumps, Shop by HP (1/2HP to 25HP), Shop by GPM (0-1400 GPM), Shop by Well Depth (Under 100ft to 800-1400ft+), User-Friendly Pump Sizing Calculator, Engineer-reviewed results, Downloadable installation gu…

4. Atlas Copco – Pump Sizing Calculator

Domain: atlascopco.com

Registered: 1995 (30 years)

Introduction: Pump sizing calculator from Atlas Copco USA helps users find the right dewatering submersible pump by comparing models based on application data. The tool provides a performance calculation, product characteristics, performance curve, and power rating. It covers various pump types including High Head Pumps, High Flow Pumps, Weda Submersible Pumps, and Chopper Pumps.

Strategic Sourcing Conclusion and Outlook for irrigation pump sizing calculator

In conclusion, the effective sizing of irrigation pumps is critical for optimizing agricultural productivity and resource management. Key takeaways for B2B buyers include the importance of understanding flow rates, pressure requirements, and friction losses to ensure the selection of the right pump for specific applications. Strategic sourcing not only facilitates the procurement of high-quality pumps but also enables buyers to leverage technological advancements, such as online sizing calculators and expert support, to make informed decisions.

As international markets continue to evolve, particularly in regions such as Africa, South America, the Middle East, and Europe, the demand for efficient irrigation solutions will grow. Buyers are encouraged to engage with suppliers who offer robust pump sizing tools and expert consultations to align product specifications with agricultural needs. By prioritizing strategic sourcing, businesses can enhance operational efficiency and sustainability in their irrigation practices.

The future of irrigation technology is promising, and those who adapt early will be well-positioned to capitalize on emerging opportunities. Take the next step in optimizing your irrigation systems—partner with trusted suppliers and utilize innovative tools to ensure your projects thrive.