Introduction: Navigating the Global Market for premade large ram pump for irrigation

In the quest for sustainable and efficient irrigation solutions, sourcing a premade large ram pump for irrigation presents both opportunities and challenges for international B2B buyers. As agricultural demands rise in regions such as Africa, South America, the Middle East, and Europe, understanding the intricacies of these hydraulic pumps becomes crucial. This guide delves into the various types of premade large ram pumps, their applications, and the key considerations for effective supplier vetting.

Navigating the global market requires insight into pump specifications, including flow rates, head pressure, and lift capabilities. With the ability to lift water without relying on electricity or fuel, ram pumps are not only environmentally friendly but also cost-effective in the long run. By examining operational efficiencies and total cost of ownership, buyers can make informed decisions that align with their agricultural needs and sustainability goals.

This comprehensive guide equips B2B buyers with actionable insights, including installation requirements, maintenance tips, and strategies for maximizing the pump’s output. With a clear focus on empowering decision-makers, this resource provides the necessary tools to ensure that sourcing a premade large ram pump is a strategic investment, ultimately enhancing agricultural productivity while promoting eco-friendly practices.

Understanding premade large ram pump for irrigation Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Hydraulic Ram Pump | Fully assembled, requires minimal installation, various sizes available | Agricultural irrigation, livestock watering | Pros: Low maintenance, eco-friendly. Cons: Initial investment can be high. |

| High-Output Ram Pump | Designed for larger flow rates, capable of lifting water to significant heights | Large-scale farming, industrial applications | Pros: Higher efficiency, suitable for extensive operations. Cons: More complex installation. |

| Compact Ram Pump | Smaller footprint, designed for limited space or lower water needs | Residential use, small farms | Pros: Space-saving, lower cost. Cons: Limited output capacity. |

| Customizable Ram Pump | Modular design allows for tailored specifications based on site conditions | Specialized agricultural needs, remote locations | Pros: Flexibility in design, tailored solutions. Cons: Longer lead time for production. |

| Solar-Assisted Ram Pump | Integrates solar technology for enhanced efficiency | Off-grid irrigation, sustainable farming | Pros: Reduces reliance on water flow, eco-friendly. Cons: Higher upfront cost, dependent on sunlight. |

What Are the Characteristics of Standard Hydraulic Ram Pumps?

Standard hydraulic ram pumps are designed for efficiency and ease of use. They are fully assembled and come in various sizes, making them suitable for different applications, particularly in agricultural settings. The installation process is straightforward, requiring only the connection of drive and delivery pipes. B2B buyers should consider their water flow rates and head pressure when selecting this type, as it is ideal for consistent irrigation needs.

How Do High-Output Ram Pumps Benefit Large-Scale Operations?

High-output ram pumps are engineered for high flow rates and significant elevation lifts, making them perfect for large-scale agricultural operations or industrial applications. These pumps can handle more demanding tasks, providing a reliable water source for extensive irrigation systems. Buyers should evaluate their specific water needs and site conditions, as these pumps may require more complex installation and maintenance compared to standard models.

Why Choose Compact Ram Pumps for Limited Spaces?

Compact ram pumps are ideal for businesses with limited space or lower water requirements. Their smaller footprint allows for easier integration into residential or small farm settings. While they come at a lower cost, buyers must be aware of their limited output capacity. This type is best suited for operations that do not require extensive water supply but still want to leverage the efficiency of ram pump technology.

What Are the Advantages of Customizable Ram Pumps?

Customizable ram pumps offer a modular design that can be tailored to specific site conditions and operational needs. This flexibility is particularly beneficial for specialized agricultural applications or remote locations where standard models may not suffice. While they provide a tailored solution, potential buyers should factor in the longer lead times associated with customization, as well as the additional costs that may arise.

How Do Solar-Assisted Ram Pumps Enhance Sustainability?

Solar-assisted ram pumps incorporate solar technology to improve efficiency, especially in off-grid irrigation systems. This innovation reduces reliance on continuous water flow and promotes sustainable farming practices. However, the higher upfront investment and dependence on sunlight are critical considerations for buyers. Organizations focused on long-term sustainability and reduced operational costs may find this option particularly appealing.

Key Industrial Applications of premade large ram pump for irrigation

| Industry/Sector | Specific Application of premade large ram pump for irrigation | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Irrigation of crops in remote areas | Reduces dependency on electricity, lowering operational costs. | Ensure compatibility with local water sources and flow rates. |

| Livestock Farming | Providing water for livestock in hilly terrains | Sustainable water supply without fuel costs, improving animal health. | Verify required lift height and water volume needs for livestock. |

| Aquaculture | Water supply for fish farms | Continuous water circulation enhances fish growth and health. | Assess water quality and source proximity for optimal performance. |

| Construction and Landscaping | Supplying water for landscaping projects | Efficient water delivery to remote sites, reducing manual labor. | Confirm ease of installation and maintenance in specific terrains. |

| Community Water Supply | Supplying water to rural communities | Promotes sustainable development by providing a reliable water source. | Evaluate local water flow rates and community needs for scaling. |

How Can Agriculture Benefit from Premade Large Ram Pumps for Irrigation?

In agriculture, premade large ram pumps are invaluable for irrigating crops, especially in regions with limited electricity access. These pumps utilize the kinetic energy from flowing water to elevate it for irrigation purposes, significantly reducing operational costs. For buyers in Africa and South America, ensuring compatibility with local water sources and flow rates is crucial. The ability to operate without fuel or electricity allows farmers to focus on crop yield rather than energy expenses, making them a sustainable choice.

What Advantages Do Livestock Farmers Gain from Using Ram Pumps?

Livestock farming in hilly terrains can be challenging due to limited access to water sources. Premade large ram pumps can efficiently supply water to these areas, ensuring livestock have a constant water supply. This not only improves animal health but also enhances productivity. Buyers in regions like Saudi Arabia or Nigeria should assess the required lift height and water volume needs to ensure the pump meets their specific livestock requirements, facilitating better herd management.

How Do Aquaculture Operations Utilize Ram Pumps?

In aquaculture, maintaining a steady water supply is critical for the health of fish populations. Large ram pumps can provide a continuous flow of water, which is essential for oxygenation and temperature regulation in fish farms. This sustainable solution eliminates the need for electric pumps, thus reducing operational costs. Buyers should evaluate water quality and the proximity of water sources to ensure optimal performance and fish health, particularly in remote areas of South America and Africa.

What Role Do Ram Pumps Play in Construction and Landscaping?

In construction and landscaping, premade large ram pumps facilitate efficient water delivery to remote sites where traditional water sources may not be readily available. This reduces manual labor and increases the speed of project completion. For B2B buyers, confirming the ease of installation and maintenance in specific terrains is vital, as it impacts project timelines and costs. These pumps can significantly enhance the efficiency of landscape irrigation and construction activities.

How Can Community Water Supply Projects Benefit from Ram Pumps?

For rural communities, premade large ram pumps represent a sustainable solution to water supply challenges. They enable the delivery of water without reliance on external power sources, promoting self-sufficiency. When sourcing these pumps, it’s essential to evaluate local water flow rates and community needs for scaling the system effectively. This approach fosters community development by ensuring access to a reliable and consistent water source, improving overall quality of life.

3 Common User Pain Points for ‘premade large ram pump for irrigation’ & Their Solutions

Scenario 1: Inconsistent Water Supply Disrupts Agricultural Operations

The Problem: Many agricultural businesses rely on a steady water supply for irrigation, but inconsistent access can severely disrupt operations. Buyers in regions with seasonal rainfall or varying water flow often find that traditional pumps fail to meet their needs. The unpredictability of water availability can lead to crop failures, impacting yield and revenue. Furthermore, the reliance on fuel or electricity for conventional pumps can complicate operations, especially in remote areas with limited infrastructure.

The Solution: A premade large ram pump offers a reliable, sustainable solution for these challenges. Since it operates solely on the kinetic energy of flowing water, it doesn’t require electricity or fuel, making it ideal for locations where access is limited. To effectively implement this solution, buyers should first assess their water source to ensure there is adequate flow and head pressure. This can be done by measuring the water flow rate and elevation drop. Once suitable conditions are confirmed, selecting the appropriate ram pump size based on flow and lift requirements is crucial. Additionally, ensuring the installation of the correct drive and delivery pipes will maximize efficiency. Regular maintenance checks will further ensure that the pump operates effectively throughout the irrigation season.

Scenario 2: High Operating Costs from Traditional Pumps

The Problem: Businesses frequently encounter escalating operational costs associated with traditional irrigation pumps. Fuel prices can fluctuate dramatically, and electric pumps often require costly infrastructure and ongoing electricity bills. In regions where budgets are tight, these expenses can threaten the viability of agricultural operations, leaving buyers seeking more cost-effective alternatives.

The Solution: By opting for a premade large ram pump, buyers can significantly reduce ongoing operational costs. Since these pumps do not require fuel or electricity, they eliminate the need for continuous expenditure on energy resources. To maximize savings, buyers should invest in a system that matches their specific water needs and conditions. This includes calculating the daily water requirements and selecting a pump that can efficiently deliver that volume. Additionally, considering the long lifespan and low maintenance needs of ram pumps, businesses can achieve substantial cost savings over time. Buyers should also explore potential grants or subsidies for sustainable irrigation solutions, which can further offset initial investment costs.

Scenario 3: Installation Challenges Leading to Inefficient Systems

The Problem: Many B2B buyers face challenges during the installation of irrigation systems, especially when dealing with complex setups involving traditional pumps. Inadequate installation can lead to inefficiencies, resulting in suboptimal water delivery and wasted resources. This is particularly problematic for buyers who are not well-versed in hydraulic systems, leading to frustration and potential financial losses.

The Solution: To overcome installation challenges, buyers should consider utilizing the comprehensive guidelines provided by manufacturers of premade large ram pumps. These guidelines often include detailed instructions for determining the necessary site conditions, such as measuring flow rates and head pressure. For buyers lacking technical expertise, engaging with experienced local installers or seeking assistance from the manufacturer can ensure proper setup. It’s also advisable to participate in training sessions or workshops that may be offered by suppliers, focusing on effective installation and maintenance practices. By ensuring proper installation, buyers can enhance the efficiency of their irrigation systems, leading to improved water delivery and reduced waste in the long run.

Strategic Material Selection Guide for premade large ram pump for irrigation

What Are the Key Materials for Premade Large Ram Pumps for Irrigation?

When selecting materials for premade large ram pumps, it’s crucial to consider their properties, advantages, and limitations. The choice of materials directly impacts the pump’s performance, durability, and suitability for various applications, especially in regions like Africa, South America, the Middle East, and Europe.

Which Materials Are Commonly Used in Ram Pumps?

1. Lead-Free Brass

Key Properties: Lead-free brass is known for its excellent corrosion resistance, high strength, and ability to withstand moderate temperatures and pressures. It typically has a temperature rating of up to 200°C (392°F) and can handle pressures around 300 psi.

Pros & Cons: This material is durable and has a long lifespan, making it ideal for applications where water quality is a concern. However, it can be more expensive than other materials, and its manufacturing process can be complex due to the need for precise machining.

Impact on Application: Lead-free brass is suitable for potable water applications, ensuring compliance with health and safety regulations. It is particularly important in regions where water quality standards are stringent.

Considerations for International Buyers: Buyers should ensure that the brass used complies with international standards such as ASTM B584. In markets like Saudi Arabia and Nigeria, where water quality is paramount, lead-free materials are often preferred.

2. PVC (Polyvinyl Chloride)

Key Properties: PVC is lightweight, resistant to corrosion, and has a temperature rating of around 60°C (140°F). It is not suitable for high-pressure applications but performs well under normal irrigation conditions.

Pros & Cons: The primary advantage of PVC is its low cost and ease of installation. However, it can become brittle over time, especially in extreme temperatures, which may lead to failure in harsh environments.

Impact on Application: PVC is suitable for the drive and delivery pipes in ram pump systems. Its compatibility with various water sources makes it a versatile choice for irrigation.

Considerations for International Buyers: Compliance with standards like ASTM D1784 is essential. In regions like South America, where temperature fluctuations can be significant, buyers should consider the potential for PVC degradation.

3. Stainless Steel

Key Properties: Stainless steel offers exceptional strength, corrosion resistance, and durability, with a temperature rating of up to 800°C (1472°F) and high-pressure capabilities.

Pros & Cons: Its longevity and resistance to harsh environments make stainless steel an excellent choice for long-term applications. However, it is significantly more expensive than other materials and can be more challenging to manufacture and install.

Impact on Application: Stainless steel is ideal for applications in corrosive environments or where high pressure is expected, such as in areas with saline water.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM A312. In the Middle East, where corrosion from saltwater is a concern, stainless steel is often the preferred material.

4. Polyethylene (PE)

Key Properties: Polyethylene is known for its flexibility, chemical resistance, and low-temperature performance, with a temperature rating of around 80°C (176°F). It is suitable for low-pressure applications.

Pros & Cons: It is lightweight and easy to install, making it cost-effective. However, it may not be as durable as other materials and can be susceptible to UV degradation if not properly protected.

Impact on Application: Polyethylene is often used for delivery pipes in irrigation systems due to its resistance to various chemicals and ease of handling.

Considerations for International Buyers: Compliance with standards like ASTM D2239 is important. In regions with high UV exposure, such as parts of Africa, UV-resistant grades of polyethylene should be considered.

Summary Table of Material Selection

| Material | Typical Use Case for premade large ram pump for irrigation | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Lead-Free Brass | Components requiring corrosion resistance and potable water | Long lifespan and excellent water quality | Higher cost and complex manufacturing | High |

| PVC | Drive and delivery pipes in irrigation systems | Low cost and easy installation | Brittle over time and limited pressure capacity | Low |

| Stainless Steel | High-pressure applications and corrosive environments | Exceptional durability and strength | High cost and manufacturing complexity | High |

| Polyethylene | Flexible delivery pipes for irrigation | Lightweight and chemical resistance | Susceptible to UV degradation | Medium |

This strategic material selection guide provides critical insights for B2B buyers in various regions, enabling informed decisions that align with both operational needs and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for premade large ram pump for irrigation

What Are the Main Stages of Manufacturing a Premade Large Ram Pump for Irrigation?

The manufacturing process of a premade large ram pump involves several key stages: material preparation, forming, assembly, and finishing. Each stage is crucial in ensuring the final product meets the quality standards expected by international B2B buyers.

Material Preparation

The process begins with sourcing high-quality, lead-free materials that comply with industry regulations. Common materials include brass for valves, PVC or poly pipes for the drive and delivery systems, and steel or aluminum for structural components. Suppliers often perform initial quality checks to ensure the materials are free from defects and meet specifications. This stage may also involve cutting and shaping materials to the required dimensions.Forming Techniques

The forming stage includes various techniques such as machining, welding, and molding. For instance, the pump body may be cast or machined to precise specifications. The forming process must ensure that components fit together seamlessly, which is critical for the pump’s efficiency and longevity. Techniques like CNC machining can enhance precision, while welding techniques ensure strong joints that withstand operational stresses.Assembly Process

Assembly is a critical phase where all components come together. Skilled technicians or automated systems fit the pump’s parts, including valves, air chambers, and seals. Each assembly line should follow a standardized procedure to maintain consistency. During assembly, manufacturers might also conduct in-process quality control (IPQC) to catch defects early on, ensuring that each pump functions correctly before moving on to the next stage.Finishing Touches

The finishing stage involves surface treatment and painting to prevent corrosion and enhance durability. This may include powder coating or galvanization, especially important for pumps exposed to harsh environmental conditions. Final inspections are carried out to ensure aesthetic quality and confirm that no part of the pump is compromised.

How Is Quality Control Implemented in the Manufacturing of Ram Pumps?

Quality assurance is vital in maintaining the integrity and reliability of premade large ram pumps. Manufacturers typically adhere to international standards such as ISO 9001 and industry-specific certifications like CE and API. These standards ensure that products are consistently produced and controlled according to quality management principles.

Quality Control Checkpoints

– Incoming Quality Control (IQC): This initial checkpoint verifies the quality of incoming materials. Suppliers must provide documentation proving that materials meet specified standards. This may include certificates of compliance or material safety data sheets (MSDS).

– In-Process Quality Control (IPQC): During the manufacturing process, IPQC ensures that each stage of production meets quality standards. This can involve regular checks on dimensions, assembly accuracy, and functional testing of components.

– Final Quality Control (FQC): Before shipping, an FQC is conducted to ensure the final product meets all specifications. This may include functional testing, pressure testing, and performance evaluations under simulated operational conditions.Common Testing Methods

Testing methods vary based on the specific requirements of the ram pump. Common methods include:

– Hydraulic Testing: To verify that the pump can handle expected pressures without leaking.

– Flow Rate Testing: To ensure the pump meets the specified output based on its design.

– Durability Testing: Subjecting the pump to various environmental conditions to assess its performance and longevity.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, it’s essential to ensure that suppliers adhere to rigorous quality control processes. Here are several methods to verify supplier QC:

Supplier Audits

Conducting onsite audits can help verify a supplier’s adherence to quality standards. During an audit, buyers can assess the manufacturing processes, check quality control documentation, and observe the conditions under which pumps are produced.Quality Reports

Requesting detailed quality reports from suppliers can provide insights into their QC procedures. These reports should outline the results of IQC, IPQC, and FQC, as well as any corrective actions taken for identified issues.Third-Party Inspections

Engaging third-party inspection services can add an extra layer of assurance. These independent entities can conduct inspections and testing to verify that the products meet the specified standards before shipment.

What Are the Quality Control Nuances for International Buyers?

When sourcing premade large ram pumps, international buyers must be aware of several nuances related to quality control:

Regulatory Compliance

Different regions have specific regulations regarding water pumps, especially concerning lead content and environmental impact. Buyers should ensure that the supplier’s products comply with local regulations in their respective markets.Cultural and Logistical Considerations

Buyers from diverse regions may face challenges in communication and logistics that could impact quality assurance. Establishing clear lines of communication and understanding local practices can help mitigate these challenges.Post-Purchase Support

Quality control doesn’t end at the point of sale. Buyers should inquire about the supplier’s post-purchase support, including warranties, replacement parts availability, and maintenance services. This can significantly affect the long-term performance of the ram pump.

In conclusion, understanding the manufacturing processes and quality assurance protocols for premade large ram pumps is essential for B2B buyers. By focusing on quality control measures and verifying supplier practices, buyers can ensure they are investing in reliable and efficient irrigation solutions that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘premade large ram pump for irrigation’

Introduction

This practical sourcing guide is designed to assist B2B buyers in procuring premade large ram pumps for irrigation. By following this step-by-step checklist, buyers can ensure they make informed decisions that meet their agricultural needs while considering efficiency, sustainability, and long-term value.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for your ram pump before initiating the procurement process. This includes determining the necessary flow rate, head pressure, and lift height based on your specific irrigation needs. Understanding these parameters ensures that you select a pump that can effectively meet the demands of your agricultural operation.

- Flow Rate: Measure the available water source flow using a bucket method to calculate gallons per minute (GPM).

- Head Pressure: Assess the vertical distance from the water source to the pump location, which directly influences the pump’s performance.

Step 2: Research Available Models and Sizes

Explore the various models and sizes of premade ram pumps available on the market. Different sizes correspond to specific flow rates and output capabilities, so it’s essential to match the pump size with your water source and irrigation requirements.

- Standard Sizes: Be aware of common sizes (e.g., 1/2″, 3/4″, 1″, 1-1/4″) and their respective capacities.

- Output Expectations: Review the expected daily output for each model to ensure it aligns with your irrigation needs.

Step 3: Evaluate Potential Suppliers

Conduct thorough evaluations of potential suppliers before making a purchase. This step is critical to ensuring that you partner with reputable manufacturers who provide high-quality products.

- Supplier Background: Investigate the supplier’s history, customer reviews, and product guarantees.

- Certifications: Verify if the supplier holds relevant certifications, which can indicate adherence to quality and safety standards.

Step 4: Request Quotes and Compare Pricing

Once you have identified suitable suppliers, request detailed quotes that include pricing, shipping costs, and lead times. Comparing these factors is crucial to finding the best value for your investment.

- Cost Breakdown: Look for transparency in pricing; ensure that all components, including installation accessories, are included.

- Bulk Discounts: Inquire about discounts for bulk purchases, which can significantly reduce overall costs.

Step 5: Assess Installation Requirements

Understand the installation requirements associated with your selected ram pump model. This knowledge will help you prepare adequately for the setup process, ensuring a smooth installation.

- Installation Complexity: Review whether professional installation is recommended or if it can be done in-house.

- Required Accessories: Identify any additional components needed (e.g., drive pipe, delivery pipe, fittings) to ensure you have everything ready for installation.

Step 6: Plan for Maintenance and Support

Consider the long-term maintenance and support options offered by the supplier. A reliable supplier should provide guidance on maintenance practices and have available spare parts to ensure the longevity of your pump.

- Maintenance Guidelines: Request information on routine maintenance requirements and troubleshooting tips.

- Spare Parts Availability: Confirm that spare parts for the pump are readily available, which can minimize downtime in case of repairs.

Step 7: Finalize Purchase and Document the Agreement

After thorough evaluation and comparison, finalize your purchase by documenting all agreements with the supplier. This should include details on warranties, delivery schedules, and payment terms to protect your investment.

- Contract Clarity: Ensure that the contract clearly outlines all terms, including return policies and warranty coverage.

- Record Keeping: Keep a copy of all correspondence and agreements for future reference.

By following these steps, B2B buyers can confidently navigate the procurement process for premade large ram pumps, ensuring that their investment supports efficient and sustainable irrigation practices.

Comprehensive Cost and Pricing Analysis for premade large ram pump for irrigation Sourcing

What Are the Key Cost Components of Premade Large Ram Pumps for Irrigation?

When sourcing premade large ram pumps for irrigation, understanding the cost structure is essential. The main cost components include:

Materials: This encompasses the cost of lead-free brass for valves, high-density polyethylene or PVC for piping, and other essential components. The choice of materials significantly impacts durability and efficiency, thus influencing overall costs.

Labor: Labor costs vary by region and the complexity of assembly. Skilled labor is required to ensure that pumps are assembled correctly, particularly for quality assurance purposes.

Manufacturing Overhead: This includes utilities, facility costs, and indirect labor. Efficient manufacturing processes can reduce overhead, leading to lower prices for buyers.

Tooling: Initial investments in tooling for production can be substantial. However, these costs are amortized over production volumes, affecting the pricing of smaller orders.

Quality Control (QC): Rigorous QC processes ensure product reliability and longevity. Costs related to testing and certification can add to the final price but are crucial for maintaining standards, especially in international markets.

Logistics: Shipping costs can vary widely based on location, volume, and chosen Incoterms. For international buyers, understanding logistics is vital to avoid unexpected expenses.

Margin: Suppliers typically add a margin to cover their costs and profit. This margin may fluctuate based on market demand and competition.

How Do Price Influencers Impact the Cost of Ram Pumps?

Several factors influence the pricing of premade ram pumps, including:

Volume/MOQ: Bulk purchasing often leads to lower per-unit costs. Suppliers may offer discounts for larger orders, making it beneficial for buyers to consolidate their purchases.

Specifications and Customization: Custom features or specific performance requirements can increase costs. Buyers should clearly define their needs to avoid unnecessary expenses.

Materials and Quality Certifications: Higher-quality materials and certifications (like ISO) can raise initial costs but may lead to long-term savings through reduced maintenance and increased lifespan.

Supplier Factors: Established suppliers with a proven track record may charge higher prices but offer better reliability and support. New entrants may offer lower prices to penetrate the market, but this can come at the cost of quality.

Incoterms: Understanding Incoterms is crucial for international transactions. Terms like FOB (Free On Board) and CIF (Cost, Insurance, and Freight) can significantly impact total landed costs.

What Buyer Tips Can Enhance Cost-Efficiency for International Sourcing?

To maximize cost-efficiency when sourcing ram pumps, buyers should consider the following strategies:

Negotiate Wisely: Engage in discussions with suppliers to explore price reductions, especially for larger orders. Being clear about your budget and needs can help in negotiations.

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors like maintenance, operational costs, and longevity of the pump. A higher upfront cost may be justified if it leads to lower TCO.

Research Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of local market conditions and currency fluctuations that can affect pricing. Establishing relationships with local distributors can provide insights into fair pricing.

Understand Import Duties and Taxes: Be aware of any import tariffs or taxes that may apply to your purchase, as these can significantly affect the total cost.

Stay Informed About Market Trends: Keeping abreast of industry developments can provide leverage in negotiations and help buyers make informed purchasing decisions.

In summary, a comprehensive understanding of cost components, pricing influences, and strategic buying practices can empower international B2B buyers to make informed decisions when sourcing premade large ram pumps for irrigation. Always remember that prices can vary, and it’s advisable to obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing premade large ram pump for irrigation With Other Solutions

Introduction to Alternatives for Irrigation Solutions

When considering irrigation solutions, the choice of technology can significantly impact efficiency, cost, and sustainability. Premade large ram pumps are a popular option for many agricultural and irrigation needs, especially in regions where electricity is unreliable or unavailable. However, it is essential to evaluate alternative solutions that may better suit specific requirements, budget constraints, or environmental conditions.

Comparison Table

| Comparison Aspect | Premade Large Ram Pump For Irrigation | Solar-Powered Water Pump | Diesel Water Pump |

|---|---|---|---|

| Performance | 60-80% efficiency, lifts water up to 10 times the height of the fall | Highly efficient, continuous operation, lift varies by solar availability | High flow rate, suitable for large-scale irrigation |

| Cost | Moderate initial investment, low operating costs | Higher initial investment, low operating costs | Low initial cost, high fuel costs |

| Ease of Implementation | Requires minimal setup, needs a water source with adequate fall | Installation can be complex, requires adequate sunlight | Quick setup, requires fuel supply and maintenance |

| Maintenance | Low maintenance, durable design | Low maintenance but requires battery management | High maintenance, fuel logistics required |

| Best Use Case | Ideal for remote areas with flowing water | Best for sunny regions with limited access to power | Suitable for large farms with reliable fuel supply |

Detailed Breakdown of Alternatives

Solar-Powered Water Pump

Solar-powered water pumps harness the sun’s energy to operate, making them an eco-friendly alternative to traditional fuel-based pumps. They are particularly advantageous in regions with abundant sunlight, enabling continuous operation without the need for an external power source. However, the initial investment can be substantial, and the system’s efficiency is highly dependent on solar availability. Additionally, installation may require more planning and expertise compared to ram pumps, which can be set up relatively quickly.

Diesel Water Pump

Diesel water pumps are known for their high flow rates and ability to handle large-scale irrigation needs. They are typically less expensive to purchase initially than solar-powered systems and can operate in various weather conditions. However, the ongoing fuel costs and maintenance requirements can add up over time. Furthermore, reliance on diesel fuel can raise concerns regarding sustainability and environmental impact, especially in regions facing fuel supply challenges.

Conclusion: How to Choose the Right Irrigation Solution

Selecting the appropriate irrigation solution requires a thorough analysis of the specific needs and conditions of the agricultural operation. Factors such as the availability of water sources, regional climate, budget constraints, and long-term sustainability goals should guide the decision-making process. For B2B buyers, understanding the strengths and weaknesses of each option is crucial to making an informed investment that aligns with both operational efficiency and environmental responsibility. The premade large ram pump for irrigation offers a reliable and low-maintenance choice, while alternatives like solar-powered and diesel pumps may provide benefits in specific contexts.

Essential Technical Properties and Trade Terminology for premade large ram pump for irrigation

What Are the Key Technical Properties of a Premade Large Ram Pump for Irrigation?

When selecting a premade large ram pump for irrigation, understanding its technical properties is crucial for ensuring optimal performance and compatibility with your specific needs. Here are several essential specifications to consider:

Material Grade

The materials used in the construction of ram pumps, such as lead-free brass for valves and high-grade PVC for pipes, are vital for longevity and safety. Lead-free materials prevent contamination of water sources, making the pump suitable for agricultural and potable water applications. Buyers should prioritize pumps made from corrosion-resistant materials to withstand harsh environmental conditions, particularly in tropical or arid climates.Flow Rate

Flow rate, measured in gallons per minute (GPM), indicates the volume of water the pump can handle. Different sizes of ram pumps have varying minimum flow rate requirements to operate effectively. For instance, a 1/2″ ram pump requires a minimum of 2 GPM, while a 1-1/4″ pump requires 8 GPM. Understanding flow rates helps buyers select the right pump size based on the available water source, ensuring efficient irrigation.Head Pressure

This refers to the height from which water must fall to the pump, expressed in feet. The pump operates on a 1:7 ratio of input head pressure to lift, meaning that for every foot of head pressure, the pump can lift water up to seven feet. Assessing head pressure is crucial for determining the pump’s effectiveness and the height to which it can deliver water.Output Capacity

Output capacity measures the total amount of water the pump can deliver over a specified period, typically expressed in gallons per day (GPD). For example, a 1″ ram pump can output up to 1,080 gallons per day under ideal conditions. Knowing the output capacity allows buyers to match the pump’s capabilities with their irrigation needs, ensuring sufficient water supply for agricultural activities.Operational Efficiency

The efficiency of a ram pump, generally ranging from 60-80%, indicates how well it converts input energy into usable output. Higher efficiency means lower operational costs and reduced wear on components. Buyers should inquire about the efficiency ratings to ensure they are investing in a pump that maximizes water delivery while minimizing resource consumption.

What Are Common Trade Terminology and Jargon in the Ram Pump Industry?

Familiarity with industry-specific terminology can greatly enhance communication and decision-making in the procurement process. Here are several key terms relevant to the ram pump market:

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of ram pumps, OEMs can provide specialized components that ensure compatibility and reliability, making it essential for buyers to source from reputable manufacturers.MOQ (Minimum Order Quantity)

MOQ represents the smallest number of units a supplier is willing to sell. Understanding MOQs is critical for buyers, especially in B2B transactions, as it affects budgeting and inventory management. Buyers should negotiate MOQs to align with their operational needs while ensuring they do not overcommit financially.RFQ (Request for Quotation)

An RFQ is a formal document issued by a buyer requesting price quotes from suppliers for specific products or services. Submitting an RFQ for ram pumps allows buyers to compare prices, terms, and specifications, facilitating informed purchasing decisions.Incoterms

Short for International Commercial Terms, Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is vital for understanding shipping costs, risk transfer, and delivery obligations, which can significantly impact the total cost of acquiring ram pumps.Lead Time

Lead time refers to the period between placing an order and receiving the product. In the ram pump market, lead times can vary based on manufacturing capabilities and shipping logistics. Buyers should account for lead times in project planning to avoid delays in irrigation setup.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing premade large ram pumps for irrigation, ultimately enhancing their operational efficiency and sustainability.

Navigating Market Dynamics and Sourcing Trends in the premade large ram pump for irrigation Sector

What Are the Current Market Dynamics Influencing Premade Large Ram Pumps for Irrigation?

The global market for premade large ram pumps is experiencing notable growth, driven by increasing agricultural demands, especially in regions like Africa, South America, the Middle East, and Europe. The need for sustainable irrigation solutions, coupled with the growing awareness of water scarcity, has intensified the focus on hydraulic ram pumps that operate without external power sources. As these pumps utilize the energy from flowing water, they present an economical and eco-friendly alternative to traditional electric and diesel pumps.

Emerging trends in B2B sourcing highlight the adoption of technology that enhances the efficiency and reliability of ram pumps. Innovations such as smart monitoring systems, which enable remote management and performance tracking, are becoming increasingly popular. Additionally, the rise of e-commerce platforms has simplified procurement processes, allowing international buyers to access a broader range of suppliers and products. Buyers are also seeking suppliers who can provide comprehensive technical support and installation services, ensuring optimal performance of the ram pumps.

How Is Sustainability Shaping the Sourcing of Premade Large Ram Pumps?

Sustainability has become a cornerstone of sourcing strategies in the irrigation sector. The environmental impact of traditional water pumping methods, characterized by high energy consumption and carbon emissions, has prompted buyers to seek out greener alternatives. Premade large ram pumps are inherently sustainable, as they do not rely on fossil fuels or electricity, thus minimizing their carbon footprint.

Moreover, ethical sourcing practices are increasingly important for B2B buyers. Ensuring that suppliers adhere to responsible manufacturing processes and provide transparent supply chains is essential. Buyers are encouraged to look for certifications that indicate the use of lead-free materials and other environmentally friendly components in ram pumps. By prioritizing suppliers who commit to sustainability, businesses can enhance their corporate social responsibility profiles and meet the growing consumer demand for eco-friendly products.

What Is the Historical Context of Hydraulic Ram Pumps in the B2B Market?

Hydraulic ram pumps date back to the late 18th century and were developed to harness the energy of flowing water for irrigation and other applications. The original designs have remained largely unchanged due to their efficiency and reliability. While the popularity of hydraulic ram pumps has fluctuated over the years, a resurgence is now evident as agricultural stakeholders recognize their long-term cost benefits and minimal maintenance requirements compared to conventional pumps.

The historical context of ram pumps provides valuable insights for B2B buyers, emphasizing the importance of investing in durable, sustainable solutions that align with modern agricultural practices. As the market continues to evolve, understanding the legacy of hydraulic ram pumps can guide buyers in making informed decisions that balance performance, cost, and environmental stewardship.

Frequently Asked Questions (FAQs) for B2B Buyers of premade large ram pump for irrigation

1. How do I solve water supply issues in remote areas without electricity?

Using a premade large ram pump for irrigation is an effective solution for remote locations lacking electricity. These pumps operate solely on the kinetic energy of flowing water, making them ideal for rural areas. To implement this, first assess your water source’s flow rate and head pressure, ensuring they meet the pump’s requirements. Once installed, the ram pump can continuously lift water to higher elevations, facilitating irrigation without ongoing operational costs associated with electric or fuel-powered pumps.2. What is the best size ram pump for large-scale irrigation?

The best size for a ram pump largely depends on your specific water flow rate and the height you need to lift the water. For larger irrigation needs, consider a pump size of 1-1/4″ which can lift up to 1,400 gallons per day, assuming ideal conditions. Make sure to measure your water flow accurately and assess the head pressure to determine the appropriate size. This ensures optimal performance and efficiency, thereby meeting the demands of your irrigation system effectively.3. How do I vet suppliers for premade ram pumps?

When vetting suppliers for premade ram pumps, start by assessing their reputation and experience in the industry. Look for reviews or testimonials from previous customers, and check if they comply with international quality standards. Request samples or product specifications to evaluate the quality of the materials used. Additionally, inquire about their warranty and support services, as reputable suppliers will provide comprehensive after-sales assistance and spare parts availability.4. What are the minimum order quantities (MOQ) for ram pumps?

Minimum order quantities for ram pumps can vary significantly depending on the supplier and the specific pump model. Generally, suppliers may have an MOQ ranging from 5 to 20 units for bulk purchases. It’s advisable to discuss your requirements directly with the supplier to negotiate favorable terms, especially if you are looking to test the market with a smaller initial order. Establishing a relationship with the supplier may also lead to more flexible terms in future orders.5. What payment terms should I expect when purchasing ram pumps internationally?

Payment terms for international purchases of ram pumps can differ based on the supplier’s policies and your negotiation. Common terms include a 30% deposit upon order confirmation, with the balance due before shipping. Some suppliers may also offer letters of credit or escrow services to secure transactions. It’s crucial to clarify these terms upfront to avoid any misunderstandings and to ensure a smooth transaction process.6. How can I ensure quality assurance (QA) for my ram pump order?

To ensure quality assurance for your ram pump order, request detailed product specifications and certifications from your supplier. Inquire if they have a quality control process in place, including testing procedures for each pump before shipment. You may also consider hiring a third-party inspection service to verify the quality of the pumps during production or prior to shipping. This proactive approach minimizes the risk of receiving substandard products.7. What logistics considerations should I keep in mind for importing ram pumps?

When importing ram pumps, consider logistics aspects such as shipping methods, lead times, and customs regulations. Depending on your location, sea freight is often the most cost-effective option, while air freight is faster but more expensive. Ensure you are familiar with import duties and taxes applicable in your country. Collaborating with a logistics partner who has experience in international shipping can help streamline the process and mitigate potential delays.8. Can ram pumps be customized for specific irrigation needs?

Yes, many suppliers offer customization options for ram pumps to cater to specific irrigation requirements. This can include adjustments to size, materials, or additional features like enhanced waste valves or pressure gauges. Discuss your particular needs with the supplier to explore available customization options. Keep in mind that custom orders may have longer lead times and possibly higher costs, so plan accordingly.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Premade Large Ram Pump For Irrigation Manufacturers & Suppliers List

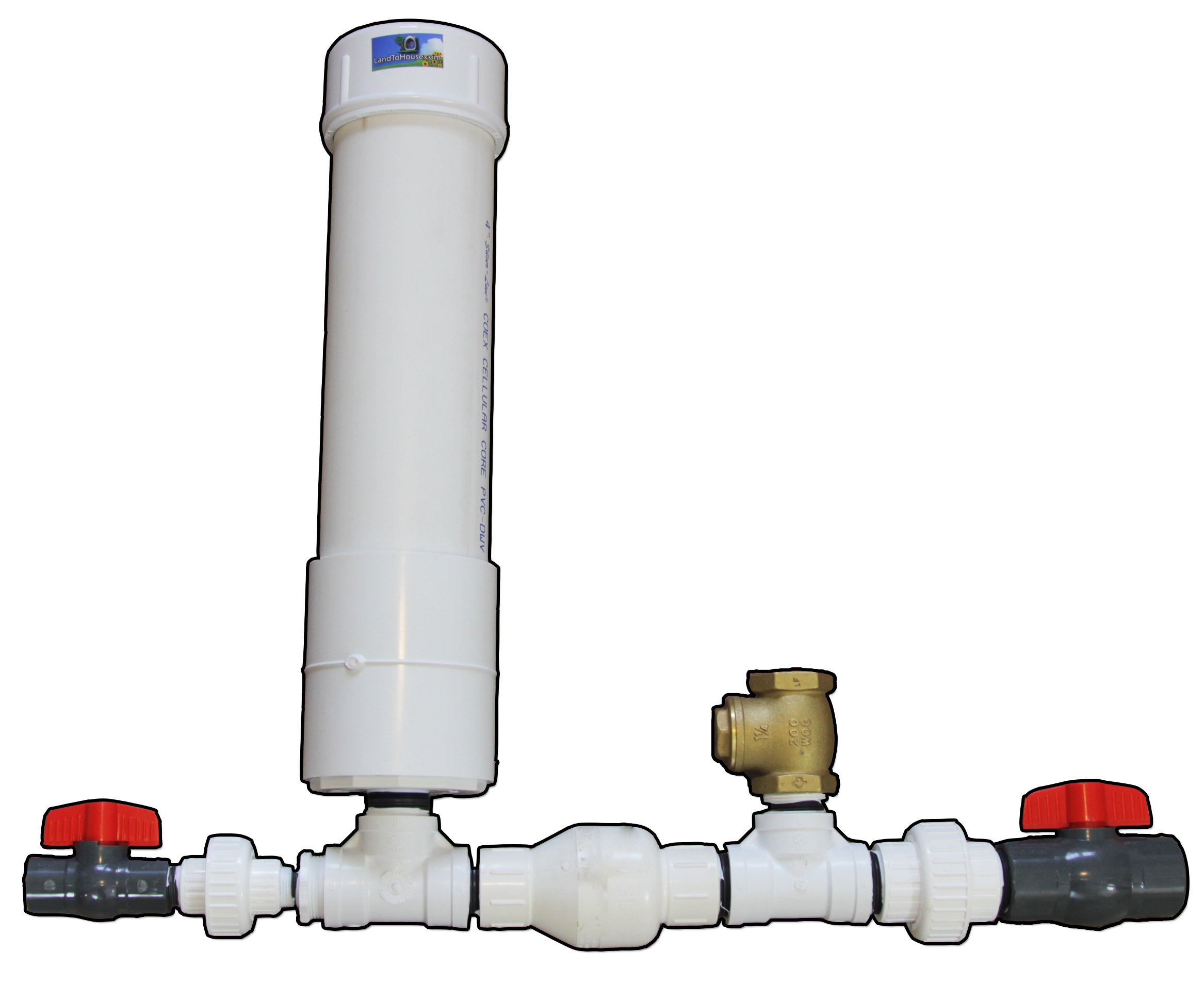

1. Land to House Store – Ram Pump Fully Assembled

Domain: landtohousestore.com

Registered: 2024 (1 years)

Introduction: {“product_name”: “Ram Pump Fully Assembled”, “regular_price”: “$180.00 USD”, “sizes”: [{“size”: “Large 1-1/4″”, “price”: “$180.00”}, {“size”: “Medium 1″”, “price”: “$160.00”}, {“size”: “Small 3/4″”, “price”: “$120.00”}, {“size”: “Tiny 1/2″”, “price”: “$80.00”}], “description”: “The Hydraulic Ram Pump is a Water Pump that does not need fuel or electricity to operate. Only flowing and falling water …

2. HighElevation Pumps – Efficient Water Transfer Solutions

Domain: reddit.com

Introduction: The user is seeking an efficient pump for high elevation and long distance water transfer to their cabin, which is located 3-400ft from the shoreline with a steep elevation of at least 60ft. They currently use a 2″ gas transfer pump and a series of IBC totes to move water from the lake to the cabin. They are considering gear pumps and solar-powered options, as there is no power at the property. Th…

3. Non-Electric Hydraulic Ram Pump – High-Lift Water Pump

Domain: aliexpress.com

Registered: 2006 (19 years)

Introduction: This company, Non-Electric Hydraulic Ram Pump – High-Lift Water Pump, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Instructables – Hydraulic Ram Pump Components

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Hydraulic Ram Pump, Flex Pipe for Drive Pipe (1¼ inch diameter, 100 feet long), Screen material, Hose clamps, Rebar, Zip ties, Various garden hoses and hose fittings, Water storage containers (50-gallon metal barrels), Rain Barrel Soaker Hoses and Fittings.

5. BSWM – Hydraulic Ram Pump

Domain: bswm.da.gov.ph

Introduction: A hydraulic ram pump, or hydram, is a cyclic water pump powered by hydropower. It operates by taking in water at one “hydraulic head” (pressure) and flow rate, and outputs water.

6. WBWRIDD – Hydraulic Ram Pumps

Domain: wbwridd.gov.in

Registered: 2014 (11 years)

Introduction: Hydraulic Ram Pumps (Hydram) are installed in the hilly terrain of Darjeeling and Kalimpong Districts. They utilize water from Jhora/Spring/Khola for irrigation of agricultural land and other livelihood works such as fisheries, horticulture, and domestic animals. The pump is a mechanical device that lifts water using the energy from flowing water and gravity, requiring no electricity or fuel. It o…

Strategic Sourcing Conclusion and Outlook for premade large ram pump for irrigation

The demand for sustainable irrigation solutions continues to rise, particularly in regions such as Africa, South America, the Middle East, and Europe. Premade large ram pumps offer a compelling solution for agricultural and water management needs. These pumps are not only environmentally friendly, operating without electricity or fuel, but they also provide a cost-effective alternative to traditional pumping methods. By leveraging the natural flow of water, businesses can reduce operational costs while ensuring a reliable water supply for irrigation.

Strategic sourcing of these pumps involves understanding local water conditions, flow rates, and lift requirements. International buyers should consider the specific needs of their operations, including installation and maintenance requirements, to select the right pump size. Investing in high-quality, durable ram pumps can yield long-term benefits, minimizing maintenance and maximizing efficiency.

As global focus shifts towards sustainable practices, now is the time for B2B buyers to act. By integrating premade large ram pumps into their water management strategies, businesses can enhance their operational sustainability and resilience. Explore your options today and join the movement towards smarter, greener irrigation solutions that meet the demands of tomorrow.