Introduction: Navigating the Global Market for berkeley irrigation pumps

In an era where efficient water management is paramount, sourcing reliable Berkeley irrigation pumps poses a significant challenge for international B2B buyers. With the growing demand for sustainable agriculture and effective water distribution systems, understanding the diverse range of pump types and their specific applications is crucial. This guide provides an in-depth exploration of Berkeley irrigation pumps, covering various models, including centrifugal and submersible options, and their suitability for different agricultural and industrial needs.

Navigating the complexities of the global market requires more than just product knowledge; it necessitates a strategic approach to supplier vetting and cost analysis. This comprehensive resource equips buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Vietnam and Nigeria—with the insights needed to make informed purchasing decisions. By detailing essential factors such as performance specifications, maintenance requirements, and potential return on investment, this guide empowers businesses to select the right pumping solutions that align with their operational goals.

Moreover, it highlights key considerations in sourcing, such as identifying reputable suppliers and understanding shipping logistics, ensuring that buyers are well-prepared to tackle the challenges of acquiring high-quality Berkeley irrigation pumps in a competitive marketplace. With this guide, international buyers can confidently navigate their procurement processes, ensuring they secure the best products for their unique needs.

Understanding berkeley irrigation pumps Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Centrifugal Pumps | High flow rates, simple design, and easy maintenance | Agricultural irrigation, water transfer | Pros: Efficient and cost-effective; Cons: Limited suction lift capabilities. |

| Vertical Lineshaft Turbine Pumps | Deep well capability, high efficiency, multi-stage design | Deep well irrigation, municipal water systems | Pros: Excellent for high lift applications; Cons: Higher initial investment. |

| Submersible Turbine Pumps | Compact design, submerged operation, quiet operation | Deep water irrigation, drainage | Pros: Space-saving and energy-efficient; Cons: Requires careful installation. |

| Self-Priming Pumps | Automatic priming capability, versatile applications | Irrigation, dewatering, and firefighting | Pros: Easy to use and install; Cons: May have lower efficiency than non-self-priming models. |

| Booster Pumps | Increases pressure in existing systems, compact design | Pressure boosting in irrigation systems | Pros: Improves system efficiency; Cons: Requires power source and maintenance. |

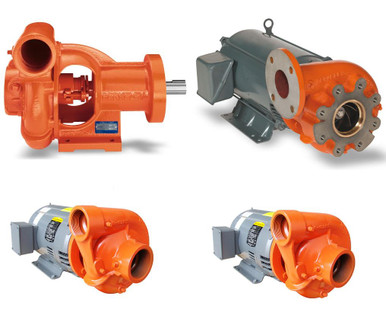

What are the Characteristics and Applications of Centrifugal Pumps?

Centrifugal pumps are among the most widely used irrigation pumps due to their high flow rates and straightforward design. They operate by converting rotational energy from a motor into kinetic energy in the fluid. These pumps are ideal for agricultural irrigation and water transfer projects where large volumes of water need to be moved quickly. However, buyers should consider their limitations regarding suction lift capabilities, which may necessitate additional equipment in certain applications.

How Do Vertical Lineshaft Turbine Pumps Benefit B2B Buyers?

Vertical lineshaft turbine pumps are specifically designed for deep well applications, making them suitable for municipal water systems and agricultural irrigation in areas with limited surface water. Their multi-stage design allows for high efficiency and significant lifting capabilities. While the initial investment may be higher compared to other pump types, their durability and performance in demanding environments make them a valuable long-term investment for businesses focused on sustainable water sourcing.

What Advantages Do Submersible Turbine Pumps Offer?

Submersible turbine pumps are known for their compact design and quiet operation, making them ideal for deep water irrigation and drainage applications. Being submerged, they are less prone to cavitation and can operate efficiently at various depths. For B2B buyers, the space-saving aspect is a critical consideration, especially in urban settings or confined spaces. However, proper installation is crucial to avoid operational issues, which may require specialized expertise.

Why Choose Self-Priming Pumps for Irrigation Needs?

Self-priming pumps are designed to automatically remove air from the system, making them highly versatile for various applications, including irrigation and dewatering. Their ease of use and installation appeals to buyers looking for reliable solutions without complex setup requirements. While they offer convenience, it’s essential to note that self-priming pumps may not be as efficient as their non-self-priming counterparts, potentially impacting long-term operational costs.

How Do Booster Pumps Enhance Irrigation Systems?

Booster pumps are essential for increasing pressure in existing irrigation systems, ensuring that water reaches all areas of the field efficiently. Their compact design allows for easy integration into current setups, making them an attractive option for businesses looking to enhance their water distribution systems. While they improve overall efficiency, buyers must consider the need for a reliable power source and ongoing maintenance to keep the systems running optimally.

Key Industrial Applications of berkeley irrigation pumps

| Industry/Sector | Specific Application of Berkeley Irrigation Pumps | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Crop irrigation in large-scale farms | Enhanced crop yields and water efficiency | Availability of suitable pump models for specific crops; local support and maintenance services. |

| Horticulture | Greenhouse irrigation systems | Consistent moisture levels and reduced labor costs | Ability to customize pump specifications for varying greenhouse sizes and water needs. |

| Mining | Dewatering and water transfer in mining sites | Improved operational efficiency and reduced downtime | Durability in harsh environments; compatibility with existing systems and local regulations. |

| Construction | Water supply for concrete mixing and site dust control | Increased project efficiency and compliance with safety standards | Sourcing pumps that can handle high volumes and provide reliable performance under pressure. |

| Municipal Water Supply | Water distribution for urban irrigation systems | Sustainable water management and enhanced community aesthetics | Adherence to local regulations and standards; energy efficiency to reduce operational costs. |

How Are Berkeley Irrigation Pumps Used in Agriculture?

In the agriculture sector, Berkeley irrigation pumps are essential for large-scale crop irrigation. These pumps facilitate the efficient movement of water from sources to fields, ensuring that crops receive adequate moisture, which enhances yield and quality. By utilizing these pumps, farmers can significantly reduce water wastage and optimize their irrigation schedules. Buyers in this sector must consider the specific pump models suitable for their crop types, as well as the availability of local support services for maintenance and repairs.

What Role Do Berkeley Pumps Play in Horticulture?

In horticulture, Berkeley irrigation pumps are commonly used in greenhouse irrigation systems. They help maintain consistent moisture levels, which is crucial for the health of delicate plants. These pumps also reduce labor costs by automating watering processes, allowing growers to focus on plant care rather than manual irrigation. Buyers should ensure that the pumps can be customized to meet the specific water demands of various greenhouse setups, and they should seek suppliers who provide technical support for installation and maintenance.

How Are Berkeley Pumps Beneficial in Mining Operations?

Mining operations often require effective dewatering solutions, where Berkeley irrigation pumps excel. These pumps are utilized to remove excess water from mining sites, ensuring operational efficiency and reducing the risk of equipment damage. By maintaining optimal water levels, mining companies can minimize downtime and adhere to safety regulations. Buyers in this sector should prioritize the durability and reliability of pumps, as well as their compatibility with existing water management systems and compliance with local environmental regulations.

Why Are Berkeley Pumps Important for Construction Projects?

In the construction industry, Berkeley irrigation pumps are vital for supplying water for concrete mixing and controlling dust on job sites. Their ability to provide high volumes of water quickly contributes to project efficiency and helps maintain safety standards. Construction companies must consider the pressure ratings and flow capacities of the pumps to ensure they meet project demands. Additionally, sourcing pumps that can withstand the rigors of construction environments is essential for minimizing downtime and maintenance costs.

How Do Berkeley Pumps Enhance Municipal Water Supply Systems?

Municipal water supply systems benefit significantly from Berkeley irrigation pumps, which are used for urban irrigation and landscape management. These pumps enable sustainable water distribution, enhancing community aesthetics and promoting environmental responsibility. Local governments and municipalities must consider energy-efficient models to reduce operational costs while ensuring compliance with regulatory standards. Buyers should also assess the pumps’ adaptability to varying water demands and their integration capabilities with existing infrastructure.

3 Common User Pain Points for ‘berkeley irrigation pumps’ & Their Solutions

Scenario 1: Inefficient Water Distribution in Agricultural Fields

The Problem:

B2B buyers in agriculture often face the challenge of inefficient water distribution across large fields. This inefficiency can lead to under-irrigated crops, impacting yield and profitability. Factors such as uneven terrain, varying soil types, and outdated irrigation systems can exacerbate this issue. For instance, a buyer managing a large-scale farm may invest in a Berkeley irrigation pump, but if the pump’s capacity and type aren’t matched to their specific needs, it can result in poor water coverage and wasted resources.

The Solution:

To combat this, buyers should conduct a thorough assessment of their irrigation needs before selecting a Berkeley irrigation pump. They should consider factors such as the size of the area to be irrigated, the types of crops grown, and the pump’s flow rate and pressure capabilities. It is advisable to consult with Berkeley’s technical support or a trusted distributor to identify the right model, such as the Vertical Multistage Pumps, which are ideal for high-pressure applications in uneven terrains. Additionally, integrating automated irrigation systems can optimize water usage, ensuring that every part of the field receives adequate moisture.

Scenario 2: Frequent Pump Failures Leading to Downtime

The Problem:

Frequent pump failures can be a significant pain point for B2B buyers, leading to costly downtime and disrupted operations. This issue is particularly pertinent in regions with harsh climates or where pumps are subjected to heavy use. For example, a construction company relying on Berkeley pumps for dewatering might find that their pumps fail unexpectedly due to overheating or improper maintenance, causing project delays and increased labor costs.

The Solution:

To mitigate this risk, regular maintenance and proper operation protocols must be established. Buyers should utilize the maintenance manuals provided by Berkeley and schedule routine inspections to ensure that all components are functioning optimally. Investing in additional monitoring systems, such as pressure gauges and flow meters, can also provide real-time data, allowing operators to detect issues before they escalate. Furthermore, engaging with Berkeley’s customer support for advice on suitable operating conditions and potential upgrades can enhance pump longevity and reliability.

Scenario 3: Difficulty Sourcing Replacement Parts for Pumps

The Problem:

A common frustration among B2B buyers is the difficulty in sourcing replacement parts for Berkeley irrigation pumps, particularly in regions where supply chains are less robust. Delays in obtaining parts can result in extended downtime, which is critical in agricultural and industrial contexts. For example, a buyer operating a greenhouse might face significant losses if a key component of their irrigation system fails and replacement parts are not readily available.

The Solution:

To address this issue, buyers should establish a proactive inventory management system that includes essential spare parts for their specific pump models. Engaging with local distributors or Berkeley’s authorized service centers can ensure that parts are available when needed. Additionally, buyers can take advantage of Berkeley’s comprehensive support resources, including online catalogs and customer service hotlines, to streamline the ordering process. Joining industry forums or networks can also provide insights on alternative suppliers and lead times, further ensuring that operations remain uninterrupted.

Strategic Material Selection Guide for berkeley irrigation pumps

What Are the Key Materials Used in Berkeley Irrigation Pumps?

Berkeley irrigation pumps are crafted from various materials, each selected for its unique properties and suitability for specific applications. Understanding these materials is crucial for international B2B buyers, especially those operating in diverse environments across Africa, South America, the Middle East, and Europe. Below, we analyze four common materials used in Berkeley irrigation pumps, focusing on their properties, advantages, disadvantages, and implications for specific applications.

How Does Cast Iron Perform in Berkeley Irrigation Pumps?

Cast iron is a popular choice for the construction of pump casings and components due to its excellent durability and strength. It typically has a high-temperature rating, making it suitable for various applications. Cast iron also offers good corrosion resistance when properly coated, which is essential for pumps operating in harsh environments.

Pros: Cast iron is relatively inexpensive, widely available, and easy to machine, making it a cost-effective option for manufacturers. Its durability ensures a long service life, reducing the need for frequent replacements.

Cons: The primary drawback of cast iron is its weight, which can complicate installation and transportation. Additionally, if not adequately protected, it can corrode over time, especially when exposed to aggressive chemicals.

Impact on Application: Cast iron is ideal for handling water and other non-corrosive fluids. However, its compatibility with specific media should be assessed to avoid degradation.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM or DIN for cast iron components. In regions with high humidity or aggressive water conditions, additional protective coatings may be necessary.

What Role Does Stainless Steel Play in Berkeley Irrigation Pumps?

Stainless steel is favored for its exceptional corrosion resistance and strength, making it suitable for applications involving aggressive fluids or environments. It can withstand high temperatures and pressures, which is vital for maintaining performance in demanding conditions.

Pros: Stainless steel is highly durable and requires minimal maintenance. Its resistance to corrosion extends the lifespan of pumps, making it a reliable choice for long-term investments.

Cons: The primary disadvantage is its higher cost compared to other materials like cast iron. Additionally, stainless steel can be more challenging to machine, which may increase manufacturing complexity.

Impact on Application: Stainless steel is particularly suitable for irrigation systems that handle saline or chemically aggressive water, ensuring optimal performance and longevity.

Considerations for International Buyers: Buyers must consider the specific grades of stainless steel that meet their needs and local regulations. Compliance with international standards is crucial, especially in regions with stringent environmental regulations.

How Does Plastic Compare in Berkeley Irrigation Pumps?

Plastic, particularly high-density polyethylene (HDPE) and polypropylene, is increasingly used in pump components due to its lightweight and corrosion-resistant properties. These materials are suitable for non-pressurized applications and environments where chemical exposure is a concern.

Pros: The lightweight nature of plastic simplifies installation and transportation. Additionally, plastic is resistant to corrosion, making it ideal for handling various fluids without degradation.

Cons: Plastic may not withstand high temperatures or pressures as effectively as metals, limiting its application scope. It can also be less durable than metal options, potentially leading to shorter lifespans.

Impact on Application: Plastic is best suited for irrigation systems that deal with non-aggressive fluids and lower pressure scenarios.

Considerations for International Buyers: Buyers should ensure that the selected plastic materials comply with local standards and regulations, particularly in regions where environmental impact is a concern.

What Advantages Does Bronze Offer in Berkeley Irrigation Pumps?

Bronze is another material used in pump components, particularly for fittings and impellers. Its excellent corrosion resistance and strength make it suitable for various applications, especially in marine environments.

Pros: Bronze offers superior corrosion resistance compared to many other metals, making it ideal for applications exposed to saltwater or other corrosive elements. It also has good wear resistance, enhancing performance longevity.

Cons: The cost of bronze can be significantly higher than that of cast iron or plastic, which may deter some buyers. Additionally, its availability may vary by region.

Impact on Application: Bronze is particularly effective for pumps that operate in harsh environments, such as coastal areas or industrial applications with corrosive fluids.

Considerations for International Buyers: Buyers should check for compliance with local standards and consider the cost implications of using bronze in their irrigation systems.

Summary Table of Material Selection for Berkeley Irrigation Pumps

| Material | Typical Use Case for berkeley irrigation pumps | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cast Iron | General irrigation applications | Cost-effective and durable | Heavy and prone to corrosion | Low |

| Stainless Steel | Aggressive fluid handling | Excellent corrosion resistance | Higher cost and machining complexity | High |

| Plastic | Non-pressurized irrigation systems | Lightweight and corrosion-resistant | Limited temperature/pressure tolerance | Med |

| Bronze | Marine and corrosive environments | Superior corrosion resistance | Higher cost and variable availability | High |

This analysis provides a comprehensive overview of the materials used in Berkeley irrigation pumps, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for berkeley irrigation pumps

What Are the Main Stages of Manufacturing Berkeley Irrigation Pumps?

The manufacturing process for Berkeley irrigation pumps involves several critical stages that ensure each product meets the highest quality standards. Understanding these stages can help B2B buyers evaluate the reliability and durability of the pumps they are purchasing.

Material Preparation

The first step in the manufacturing process is material preparation. High-grade materials, typically stainless steel, cast iron, and various alloys, are sourced to ensure longevity and performance. This phase includes rigorous testing of raw materials to confirm they meet specific standards, such as tensile strength and corrosion resistance. Advanced technology and equipment are utilized for precise cutting and shaping of materials, laying the groundwork for consistent quality.

Forming Techniques

Following material preparation, the forming techniques come into play. Common methods include forging, casting, and machining. Forging is often used for components that require high strength, while casting is employed for complex shapes that cannot be easily machined. Machining operations, such as CNC milling and turning, ensure that each part is made to exact specifications. This precision is crucial, as even minor deviations can affect pump performance and efficiency.

Assembly Process

The assembly process is where individual components come together to create the final product. Skilled technicians oversee this stage, ensuring that each part is correctly fitted and aligned. Automated assembly lines may be used for repetitive tasks, while manual assembly allows for greater attention to detail on more complex assemblies. Quality control measures are integrated at this stage to catch any defects before the pumps proceed to the finishing phase.

Finishing Touches

The finishing stage involves surface treatments and coatings to enhance durability and appearance. Techniques such as sandblasting, powder coating, and galvanization are employed to protect against environmental factors. These treatments not only improve aesthetic appeal but also significantly increase the lifespan of the pumps, making them suitable for various applications in diverse climates.

How Is Quality Assurance Implemented in Berkeley Pump Manufacturing?

Quality assurance (QA) is integral to the manufacturing process of Berkeley irrigation pumps. International standards and industry-specific regulations guide the QA protocols, ensuring that each product is reliable and safe for use.

What International Standards Are Followed?

Berkeley adheres to several international quality standards, most notably ISO 9001. This standard ensures a consistent quality management system is in place, focusing on continuous improvement and customer satisfaction. Additionally, certifications such as CE (European Conformity) and API (American Petroleum Institute) are crucial for specific markets, demonstrating compliance with safety and performance standards.

Key Quality Control Checkpoints

Quality control is conducted at multiple checkpoints throughout the manufacturing process:

Incoming Quality Control (IQC): This initial phase involves the inspection of raw materials and components upon arrival. Testing for specifications and compliance ensures that only high-quality inputs enter the manufacturing process.

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor critical processes. This step helps identify potential issues early, minimizing waste and rework.

Final Quality Control (FQC): Once assembly is complete, a thorough inspection of the finished product occurs. Testing includes performance assessments and safety checks, ensuring that the pumps operate efficiently and meet all regulatory requirements.

What Testing Methods Are Commonly Used?

Various testing methods are employed to validate the quality and performance of Berkeley irrigation pumps. These may include:

Hydraulic Testing: Pumps are subjected to pressure tests to ensure they can handle operational demands without failure.

Leak Testing: This method checks for potential leaks in seals and joints, crucial for maintaining efficiency and safety.

Vibration Analysis: Monitoring vibrations during operation helps identify imbalances or mechanical issues that could lead to premature failure.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential for ensuring product reliability.

What Audits and Reports Should Be Requested?

Buyers should request access to quality audits and reports from suppliers. These documents should detail the quality management systems in place and provide evidence of compliance with international standards. Regular internal audits and third-party inspections can also validate the effectiveness of the supplier’s quality control processes.

How Important Are Third-Party Inspections?

Engaging third-party inspectors can provide an unbiased assessment of a supplier’s quality control measures. These inspections often include a comprehensive review of manufacturing processes, material quality, and testing protocols. Third-party certifications can serve as a significant assurance of product quality, particularly for buyers concerned about compliance and reliability.

What Are the Quality Control Nuances for International Buyers?

International buyers should be aware of specific nuances in quality control that may vary by region. For example, certain certifications may hold more weight in specific markets, while local regulations could impose additional compliance requirements. Understanding these factors is crucial for navigating international procurement processes effectively.

How Do Regional Regulations Affect Quality Standards?

In regions like Africa and South America, local regulations may dictate additional testing or certification requirements that differ from international standards. Buyers should familiarize themselves with these regulations to ensure that the products they import comply with local laws and standards.

Conclusion

A comprehensive understanding of the manufacturing processes and quality assurance measures for Berkeley irrigation pumps equips B2B buyers with the insights necessary to make informed purchasing decisions. By focusing on material preparation, forming techniques, assembly processes, and stringent quality controls, Berkeley ensures that their pumps meet the rigorous demands of various applications. Buyers are encouraged to engage in due diligence by verifying supplier quality control practices and understanding regional nuances in quality standards. This proactive approach will lead to more reliable partnerships and successful procurement outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘berkeley irrigation pumps’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure Berkeley irrigation pumps. By following these steps, you can ensure that you make informed decisions, select the right products for your needs, and establish successful supplier relationships.

Step 1: Define Your Technical Specifications

Begin by clarifying the specific requirements for your irrigation system. This includes understanding the flow rate, pressure requirements, and the type of pump best suited for your application, whether it’s centrifugal, vertical lineshaft, or submersible. Knowing these specifications will help you narrow down your options and communicate effectively with suppliers.

Step 2: Research Available Product Lines

Familiarize yourself with the various Berkeley pump models and their features. Explore product lines such as the B-Series, C-Series, and submersible turbine pumps. Pay attention to the advantages each series offers, such as energy efficiency or adaptability to different irrigation methods, as this knowledge will guide your selection process.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers. Request company profiles, case studies, and references from other buyers in similar industries or regions. Look for suppliers with a solid reputation, proven track record, and extensive inventory to ensure they can meet your needs promptly.

- Check for certifications: Ensure that suppliers adhere to international quality standards and certifications relevant to your region.

- Inquire about support services: Reliable suppliers should offer after-sales support, including installation guidance and maintenance services.

Step 4: Request Quotes and Compare Pricing

Once you have a shortlist of potential suppliers, request quotes for the specific Berkeley pump models you’re interested in. Compare pricing not only on the pumps but also consider additional costs such as shipping, installation, and warranty terms. A thorough comparison will help you identify the best overall value rather than just the lowest price.

Step 5: Assess Delivery and Lead Times

Understanding the delivery timelines is crucial for planning your irrigation projects. Inquire about the expected lead times for your chosen pumps and any potential delays that could arise. Reliable suppliers should provide clear timelines, enabling you to schedule your operations effectively.

Step 6: Review Warranty and Service Agreements

Before finalizing your purchase, carefully review the warranty and service agreements offered by the supplier. A robust warranty can provide peace of mind regarding the durability and reliability of your investment. Additionally, understand the terms for service and repairs, as this will be vital for maintaining your pumps in the long run.

Step 7: Finalize Purchase and Establish Communication

Once you have selected a supplier and agreed on terms, finalize the purchase. Establish clear lines of communication with your supplier for any future needs, including inquiries about spare parts, maintenance, or upgrades. A strong partnership can facilitate smoother transactions and enhance the efficiency of your irrigation system in the future.

By following this checklist, B2B buyers can navigate the sourcing process with confidence, ensuring they select the right Berkeley irrigation pumps for their specific needs.

Comprehensive Cost and Pricing Analysis for berkeley irrigation pumps Sourcing

What Are the Key Cost Components of Berkeley Irrigation Pumps?

When sourcing Berkeley irrigation pumps, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

Materials: The quality and type of materials used significantly impact the overall cost. Pumps constructed from stainless steel or specialized alloys for corrosion resistance may incur higher material costs compared to those made from standard metals.

Labor: Labor costs vary based on the region where the pumps are manufactured. Countries with higher labor costs will naturally reflect this in the pricing. Additionally, skilled labor involved in assembly or customization can add to the expenses.

Manufacturing Overhead: This includes costs related to factory operations, such as utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help reduce these costs, which may be passed on to buyers.

Tooling: Custom tooling for specific pump designs can be a significant upfront investment. This is particularly relevant for buyers needing specialized features or customizations, which can influence pricing.

Quality Control (QC): Rigorous QC processes ensure that pumps meet industry standards and specifications. The costs associated with testing and certification can add to the final price but are vital for ensuring product reliability.

Logistics: Shipping and handling costs are critical, especially for international buyers. Factors such as distance, shipping method, and freight rates can influence the overall logistics expenses.

Margin: Suppliers will include their profit margin in the pricing structure. Understanding the typical margins in the industry can help buyers negotiate effectively.

How Do Price Influencers Affect Berkeley Irrigation Pump Costs?

Several factors can influence the pricing of Berkeley irrigation pumps:

Volume/MOQ: Larger orders often result in lower per-unit costs due to economies of scale. Buyers should evaluate their needs and consider bulk purchases to optimize costs.

Specifications and Customization: Custom features, such as specific flow rates or sizes, can lead to higher costs. Buyers should clearly define their requirements to avoid unexpected charges.

Materials and Quality Certifications: Pumps with higher-grade materials or certifications (e.g., ISO, CE) typically command higher prices. Buyers must assess the trade-off between cost and quality based on their operational needs.

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium due to their proven track record, while newer entrants might offer lower prices to gain market share.

Incoterms: The terms of shipping and delivery (e.g., FOB, CIF) can significantly impact overall costs. Buyers should understand these terms to avoid hidden fees and ensure clarity in negotiations.

What Are Essential Buyer Tips for Sourcing Berkeley Irrigation Pumps?

To maximize value when sourcing Berkeley irrigation pumps, consider the following tips:

Negotiation: Engage suppliers in discussions about pricing, especially for bulk orders. Leverage your purchasing power to negotiate better terms and conditions.

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which encompasses initial purchase price, maintenance, operational costs, and potential downtime. A lower upfront cost may not always equate to a better value in the long term.

Pricing Nuances for International Buyers: Understand the local market dynamics, including currency fluctuations, tariffs, and import duties, particularly when sourcing from regions such as Africa, South America, and the Middle East. These factors can significantly affect the final price.

Research Local Regulations: Ensure compliance with local regulations and standards, as failure to meet these can lead to increased costs and delays.

In conclusion, a comprehensive understanding of the cost structure, price influencers, and effective sourcing strategies can empower international B2B buyers to make informed decisions when sourcing Berkeley irrigation pumps. Always seek to balance cost with quality to achieve the best outcomes for your operations.

Alternatives Analysis: Comparing berkeley irrigation pumps With Other Solutions

In the competitive landscape of agricultural irrigation, selecting the right pump system is crucial for maximizing efficiency and productivity. While Berkeley irrigation pumps are renowned for their reliability and performance, it’s essential to explore alternative solutions that may better suit specific needs, particularly in diverse international markets. This analysis compares Berkeley pumps with two viable alternatives: submersible pumps and solar-powered irrigation systems.

Comparison Table

| Comparison Aspect | Berkeley Irrigation Pumps | Submersible Pumps | Solar-Powered Irrigation Systems |

|---|---|---|---|

| Performance | High efficiency in various applications; suitable for deep water extraction | Effective for shallow water sources; limited by depth | Variable performance based on sunlight availability; effective in remote areas |

| Cost | Moderate to high initial investment; long lifespan reduces overall cost | Generally lower upfront costs; may require more frequent replacement | Higher initial costs; potential savings on energy bills over time |

| Ease of Implementation | Requires professional installation; user-friendly with available support | Easier installation; can be DIY for skilled users | Installation can be complex; may require professional setup for optimal performance |

| Maintenance | Low maintenance; durable construction | Moderate maintenance; susceptible to clogging | Minimal maintenance; solar panels require cleaning |

| Best Use Case | Large-scale agricultural operations; high water demand | Residential or small-scale irrigation; shallow water sources | Remote areas with no electricity; sustainable farming practices |

What Are the Advantages and Disadvantages of Submersible Pumps?

Submersible pumps are designed to operate underwater, making them ideal for shallow water sources. They are generally more affordable upfront and easier to install, appealing to small-scale farmers and residential users. However, their efficiency diminishes in deeper applications, limiting their versatility. Maintenance can be moderate, as these pumps may clog with debris, requiring regular checks.

How Do Solar-Powered Irrigation Systems Compare?

Solar-powered irrigation systems offer a sustainable alternative, harnessing renewable energy to pump water. This approach is particularly beneficial in remote areas without electricity, reducing reliance on fossil fuels and minimizing operating costs. However, the initial investment for solar panels and installation can be significant. Performance is heavily influenced by weather conditions, which may lead to variability in water supply during cloudy periods. Maintenance is generally low, with the main focus being on keeping solar panels clean and operational.

Making the Right Choice for Your Irrigation Needs

When choosing between Berkeley irrigation pumps and alternatives like submersible pumps or solar-powered systems, B2B buyers must consider their specific operational requirements. Factors such as the scale of irrigation, water source depth, budget constraints, and sustainability goals are crucial in making an informed decision. For large agricultural operations requiring high performance and reliability, Berkeley pumps may be the best fit. Conversely, small-scale users or those in remote areas might find submersible pumps or solar systems more advantageous. Ultimately, aligning the choice with operational needs will ensure optimal efficiency and cost-effectiveness in irrigation practices.

Essential Technical Properties and Trade Terminology for berkeley irrigation pumps

What Are the Key Technical Properties of Berkeley Irrigation Pumps?

When selecting Berkeley irrigation pumps, several critical specifications need to be considered to ensure optimal performance and reliability. Here are some essential technical properties:

Material Grade

The material used in pump construction, typically stainless steel or cast iron, is crucial. Stainless steel pumps are resistant to corrosion, making them ideal for environments with aggressive fluids, while cast iron provides strength and durability. The choice of material impacts not only the pump’s longevity but also maintenance costs and operational efficiency.Flow Rate

Measured in gallons per minute (GPM), the flow rate determines how much water the pump can move in a given time. Understanding the required flow rate is essential for matching the pump to the specific irrigation needs, whether for agriculture or landscaping. An inadequate flow rate can lead to insufficient irrigation, while an overly powerful pump can waste energy and resources.Horsepower (HP)

This specification indicates the power of the pump motor. Higher horsepower allows for the handling of larger volumes of water and greater elevation changes. Buyers must assess the horsepower needed based on the system’s requirements to ensure efficient operation without overloading the motor.Pump Efficiency

Efficiency ratings express how well a pump converts input energy into hydraulic energy. Higher efficiency means lower operational costs and reduced energy consumption. For B2B buyers, selecting an efficient pump can lead to significant savings over time, particularly in large-scale agricultural applications.Self-Priming Capability

Pumps that can self-prime are able to remove air from the suction line automatically, facilitating easier operation. This feature is particularly beneficial in applications where the pump may be located above the water source, reducing the need for manual priming and minimizing downtime.Tolerance Levels

Tolerance refers to the permissible limits of variation in pump dimensions and performance specifications. Maintaining tight tolerances is crucial for ensuring compatibility with existing systems and for achieving consistent performance. For B2B buyers, understanding tolerance levels can prevent costly operational issues and ensure system reliability.

What Are Common Trade Terms Used in the Berkeley Pump Industry?

Navigating the purchasing process requires familiarity with specific industry jargon. Here are some key trade terms:

OEM (Original Equipment Manufacturer)

Refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of Berkeley pumps, understanding OEM relationships can help buyers identify reliable suppliers and parts compatibility.MOQ (Minimum Order Quantity)

This term indicates the smallest number of units a supplier is willing to sell. Knowing the MOQ is crucial for budget planning and inventory management, particularly for international buyers who may need to balance shipping costs with order sizes.RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to request pricing and terms from suppliers. This process is essential for obtaining competitive bids and understanding the market landscape. Buyers should prepare detailed RFQs to ensure they receive accurate quotes tailored to their needs.Incoterms (International Commercial Terms)

These are a set of predefined international rules that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for managing shipping logistics, costs, and risk, especially for B2B buyers involved in cross-border procurement.Lead Time

This term refers to the time it takes from placing an order to the delivery of the product. Understanding lead times helps buyers plan their irrigation projects effectively and manage expectations regarding equipment availability.Warranty

A warranty is a promise from the manufacturer regarding the condition of the product and the terms under which repairs or replacements will occur. Knowing the warranty details can provide peace of mind and protect against unforeseen costs associated with pump failures.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing Berkeley irrigation pumps, ensuring that they select the right equipment for their specific needs while navigating the complexities of international procurement.

Navigating Market Dynamics and Sourcing Trends in the berkeley irrigation pumps Sector

What Are the Current Market Trends Influencing Berkeley Irrigation Pumps?

The global irrigation pump market is experiencing robust growth, driven by several key factors. The increasing need for efficient water management in agriculture, particularly in developing regions of Africa and South America, is a primary driver. As climate variability impacts water availability, farmers are turning to advanced irrigation solutions, such as Berkeley pumps, to optimize their water usage and improve crop yields. Furthermore, the rise of precision agriculture technologies is pushing the demand for high-performance pumps that can integrate seamlessly with smart irrigation systems.

Emerging trends include the adoption of electric and hybrid-powered pumps, which are becoming more prevalent due to their lower operational costs and environmental benefits. B2B buyers are increasingly looking for pumps that offer energy efficiency and reduced carbon footprints, aligning with global sustainability goals. In addition, technological advancements in pump design, such as variable frequency drives (VFDs) and IoT-enabled monitoring systems, are revolutionizing the industry, offering enhanced performance and reliability.

International buyers, especially from regions like the Middle East and Europe, are also increasingly prioritizing supplier partnerships that can provide timely delivery and robust after-sales support. This trend emphasizes the importance of selecting suppliers with a comprehensive inventory and rapid service capabilities, ensuring that businesses can maintain operational continuity.

How Can Sustainability and Ethical Sourcing Impact Your Sourcing Decisions for Berkeley Irrigation Pumps?

Sustainability is now a central theme in the procurement strategies of B2B buyers in the irrigation sector. The environmental impact of pump manufacturing and operation is under scrutiny, pushing companies to seek solutions that minimize their ecological footprint. For buyers in regions with strict environmental regulations, such as Europe, choosing Berkeley pumps that are designed with sustainable materials and efficient energy usage is not just a preference but a necessity.

Ethical sourcing practices are becoming increasingly important in the global supply chain. B2B buyers should seek out suppliers who demonstrate a commitment to ethical labor practices and transparency in their sourcing processes. Certifications such as ISO 14001 for environmental management and other ‘green’ certifications can serve as indicators of a supplier’s commitment to sustainability.

Furthermore, the use of recyclable materials and eco-friendly manufacturing processes in the production of Berkeley irrigation pumps can significantly reduce environmental impact. By prioritizing suppliers who adhere to these principles, businesses can enhance their brand reputation and appeal to a growing base of environmentally conscious consumers.

What Is the Historical Context of Berkeley Irrigation Pumps?

Berkeley pumps have a rich history that dates back to 1937 when they were first introduced to meet the irrigation needs of California’s fertile San Joaquin Valley. This legacy of quality and reliability has established Berkeley as a trusted name in the irrigation pump industry. Over the decades, Berkeley has expanded its product line to include a variety of pump types, including centrifugal, vertical multistage, and submersible pumps, catering to diverse irrigation and water management applications.

The evolution of Berkeley pumps reflects broader trends in the industry, including technological advancements and a growing emphasis on sustainability. This historical context not only showcases Berkeley’s resilience and adaptability but also reinforces its reputation as a leader in innovative irrigation solutions. For international B2B buyers, understanding this legacy can inform their sourcing decisions, as it highlights the brand’s commitment to quality and performance that has stood the test of time.

Frequently Asked Questions (FAQs) for B2B Buyers of berkeley irrigation pumps

How do I determine the right Berkeley irrigation pump for my agricultural needs?

To select the appropriate Berkeley irrigation pump, assess your specific water flow requirements, the type of crops, and the area to be irrigated. Consider factors such as the total dynamic head (TDH), flow rate needed (measured in gallons per minute), and the pump’s efficiency. Consulting with a Berkeley distributor can provide insights into the best model for your application, ensuring you choose a pump that meets both performance and budgetary constraints.What is the best type of Berkeley pump for high-pressure irrigation systems?

For high-pressure irrigation systems, the Berkeley MGP/MGPS series high-pressure booster pumps are ideal. These pumps are designed to deliver substantial pressure and flow rates necessary for effective irrigation over large areas. They are particularly well-suited for applications requiring consistent water delivery under varying demands, making them a preferred choice for agricultural operations in diverse climates.How can I ensure the quality of Berkeley pumps when sourcing internationally?

To ensure the quality of Berkeley pumps, it is essential to partner with authorized distributors or certified dealers. Request certifications, warranties, and product specifications to verify authenticity. Additionally, consider visiting the supplier’s facility or seeking references from other customers to gauge their reputation. Quality assurance measures, including inspection of products before shipment, can further mitigate risks associated with international sourcing.What are the minimum order quantities (MOQs) for Berkeley irrigation pumps?

MOQs for Berkeley irrigation pumps can vary depending on the distributor and the specific model. Generally, larger distributors may have lower MOQs due to their inventory capabilities, while smaller suppliers may require larger orders to justify shipping costs. Always confirm the MOQ with your supplier before placing an order to ensure it aligns with your purchasing needs and operational capacity.What payment terms should I expect when sourcing Berkeley pumps?

Payment terms for sourcing Berkeley pumps can vary significantly based on the supplier and your location. Common arrangements include payment in advance, net 30/60 terms, or letters of credit, especially for international transactions. It is advisable to discuss and negotiate these terms upfront, ensuring they suit your financial situation and cash flow requirements while also understanding any potential fees for international transactions.What shipping options are available for Berkeley irrigation pumps?

Shipping options for Berkeley irrigation pumps typically include air freight for urgent deliveries or ocean freight for cost-effective transport over long distances. The choice of shipping method can impact delivery times and costs. Ensure to discuss logistics with your supplier, considering factors such as customs clearance, delivery timelines, and potential duties or tariffs that may apply to your specific region.Can I customize my order of Berkeley pumps to meet specific requirements?

Yes, many suppliers offer customization options for Berkeley pumps to meet specific operational needs. Customizations may include modifications to pump size, material specifications, or additional features such as variable speed drives. It’s best to communicate your specific requirements to your supplier early in the process to ensure they can accommodate your needs and provide accurate lead times.What after-sales support is available for Berkeley irrigation pumps?

After-sales support for Berkeley irrigation pumps typically includes warranty services, technical assistance, and access to spare parts. Authorized distributors often provide maintenance services and troubleshooting support to ensure optimal pump performance. When sourcing your pumps, inquire about the specific after-sales services offered, including response times for repairs and availability of replacement parts, to ensure ongoing operational efficiency.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Berkeley Irrigation Pumps Manufacturers & Suppliers List

1. Berkeley – Water Truck & Frame Mount Pumps

Domain: berkeleypumpcatalog.com

Registered: 2006 (19 years)

Introduction: Berkeley Pumps Water Truck Pump, Frame Mount Pumps, Motor Driven Pumps, Stainless Steel Centrifugal Pumps, Vertical Multi-Stage Pumps, SSCX Series, Type B Close Coupled Motor Drive, CP / CB Cast Iron Centrifugals, MGS Stainless Steel 4″ Submersible, BSD Frame-Mount Solids Handling, C Type Straight Centrifugal, Type B Self-Priming, MGP / MGPS High Pressure Booster, Vertical Multi-Stage (BVM) Series…

2. Berkeley – Engine Driven Water Pumps

Domain: absolutewaterpumps.com

Registered: 2012 (13 years)

Introduction: Manufacturer: Berkeley

Product Type: Engine Driven Water Pumps

Pump Styles: Centrifugal Pumps, SAE Centrifugal Pumps, Water Truck Pumps

Inlet Diameter Options: 1.25″, 2″, 2.5″, 3″, 4″, 5″, 6″, 8″, 10″, 12″

Outlet Diameter Options: 1″, 1.5″, 2″, 2.5″, 3″, 4″, 5″, 6″, 8″, 10″

Max Gallon Per Minute (GPM): Ranges from 44 GPM to 295 GPM depending on model

Max Pressure (PSI): Ranges from 33 PSI to 222 P…

3. Berkeley Pumps – B54652 Centrifugal Water Pump

Domain: pumpbiz.com

Registered: 2000 (25 years)

Introduction: Berkeley Pumps are designed for various applications including irrigation, waterfalls, well pumps, and fire pumping needs. They are powered by electric motors or gas-driven engines and are made in Delevan, Wisconsin, USA. Key products include: 1. B54652 Centrifugal Water Pump – 10HP, $11,120.00, used for commercial swimming pools, irrigation, and fountains. 2. B58055 Centrifugal Water Pump – 50HP,…

4. Berkeley Pumps – Key Product Range

Domain: pfcequip.com

Registered: 1998 (27 years)

Introduction: Berkeley Pumps offer a wide range of industrial and commercial pumps designed for reliability and performance in demanding environments. Key product types include:

1. **Centrifugal Pumps**

2. **Sub-Turbine Pumps**

3. **Line Shaft and Propeller Pumps**

4. **Sewage and Solids Handling Pumps**

5. **Engine Drive Pumps**

6. **Vertical Multi-Stage Pumps**

7. **4″ Submersible Pumps**

8. **Jet Pum…

5. Berkeley – 20LTHH Pump

Domain: supremewatersales.com

Registered: 2006 (19 years)

Introduction: {“Manufacturer”:”Berkeley”,”Model”:”20LTHH”,”Motor HP”:”2 HP”,”Voltage”:”115/230 Volt”,”Pipe Tapping Sizes”:”2\” Suction, 2\” Discharge”,”Motor Phase”:”1ph”,”Construction”:”Close-grained cast iron body, specially treated for corrosion resistance”,”Impeller”:”Noryl, precision-molded for perfect balance and ultra-smooth performance”,”Diffuser”:”Precision-molded, reinforced polypropylene, multi-port …

6. A&H – B Series Centrifugal Pumps

Domain: ahturf.com

Registered: 2000 (25 years)

Introduction: This company, A&H – B Series Centrifugal Pumps, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Nebraska Irrigation – Berkeley P.T.O. Pumps

Domain: nebraskairrigation.com

Registered: 1999 (26 years)

Introduction: This company, Nebraska Irrigation – Berkeley P.T.O. Pumps, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Berkeley – Centrifugal Pumps

Domain: pumpproducts.com

Registered: 2003 (22 years)

Introduction: Berkeley Centrifugal Pumps are designed for residential, commercial, and agricultural applications. They are known for their efficiency and durability, offering a variety of options for power outputs, voltages, impeller sizes and materials, suction/discharge connection types and sizes, and seal types. Key models include:

– B Irrigation Frame Mount: Ideal for pivot irrigation and water transfer.

…

9. Berkeley Pumps – Key Product Series

Domain: pumpcatalog.com

Registered: 2000 (25 years)

Introduction: Berkeley Pumps are known for their quality and reliability since 1937, particularly in irrigation and water transfer applications. Key product series include: B3ZRM Frame Mount Centrifugal (Water Truck Pumps), Close-Coupled Motor Drive Series, SAE Centrifugal Series, Vertical Multi-Stage BVM Series, Self-Prime Centrifugal Series, and more. Popular models include B66161, B66168, B66895, and B66899….

Strategic Sourcing Conclusion and Outlook for berkeley irrigation pumps

In summary, strategic sourcing of Berkeley irrigation pumps offers significant advantages for international B2B buyers. With a legacy of reliability and innovation dating back to 1937, Berkeley provides a diverse range of irrigation solutions tailored to meet the unique demands of various markets. Their extensive product lineup, including centrifugal, submersible, and vertical multi-stage pumps, ensures that buyers can find solutions suited for diverse agricultural and industrial applications.

Investing in Berkeley pumps not only guarantees quality but also enhances operational efficiency, ultimately leading to cost savings and improved productivity. As global agricultural sectors in regions like Africa, South America, the Middle East, and Europe continue to evolve, the need for reliable water management solutions becomes increasingly critical.

Looking ahead, B2B buyers are encouraged to leverage the strategic sourcing of Berkeley irrigation pumps to optimize their operations. By partnering with trusted suppliers and utilizing advanced pump technologies, businesses can secure their water supply needs while fostering sustainable growth. Make the proactive choice today—explore Berkeley’s offerings and secure your competitive edge in the marketplace.