Article Contents

Industry Insight: Underground Irrigation Valves

Market Analysis: Sourcing High-Quality Underground Irrigation Valves

The Critical Role of Quality Valves in Irrigation Systems

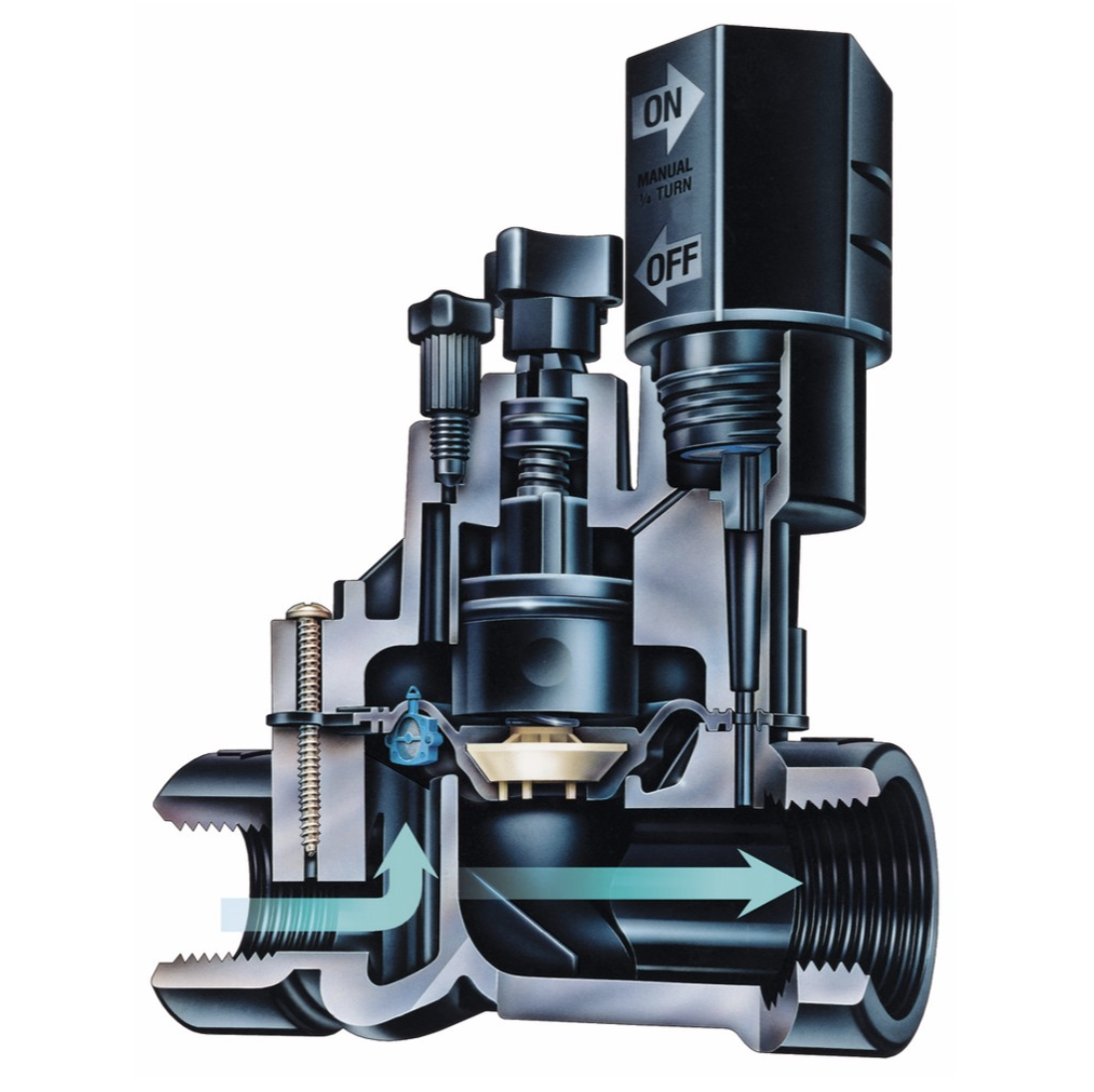

Underground irrigation valves serve as the operational backbone of modern water management systems. In agricultural and industrial applications, these components directly impact system efficiency, water conservation, and long-term infrastructure reliability. A single valve failure can disrupt entire irrigation cycles, leading to crop damage, excessive water waste, and costly emergency repairs. For projects where uptime and precision are non-negotiable—such as large-scale farms, municipal parks, or commercial landscapes—selecting valves engineered for consistent performance under pressure is essential.

Common Industry Pain Points & Their Impact

Despite their critical role, substandard valves often introduce significant operational risks:

Leakage from Substandard Seals: Poorly manufactured valve bodies or inferior elastomer seals frequently result in chronic leakage, wasting thousands of liters of water annually and increasing operational costs.

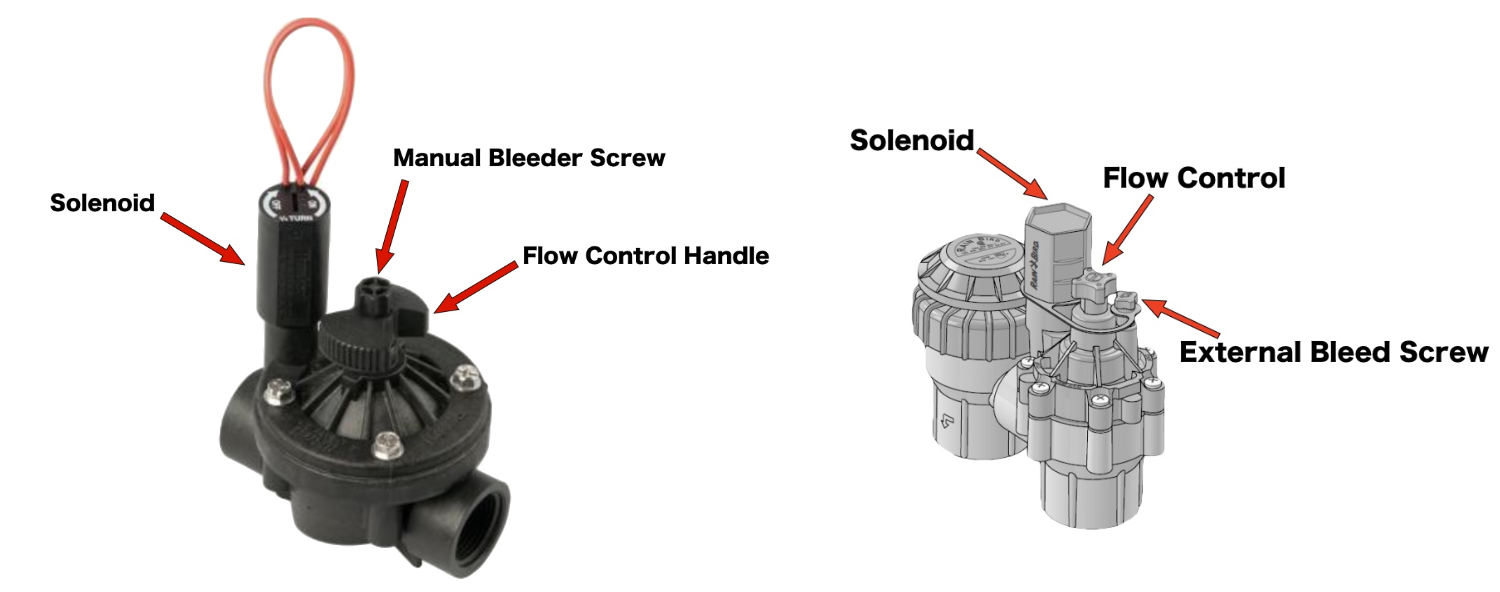

Solenoid Coil Failures: Inconsistent solenoid performance—such as erratic current draw or premature coil burnout—can disrupt automated irrigation schedules, leading to over/under-watering and crop damage.

Pressure Rating Mismatches: Valves rated below system requirements (e.g., PN6 instead of PN16) may burst under peak pressure, causing catastrophic system failures and safety hazards.

Material Degradation: Exposure to soil chemicals, saline water, or fluctuating temperatures accelerates corrosion and material fatigue, reducing valve lifespan and necessitating frequent replacements.

BFV’s Engineered Solutions for Mission-Critical Applications

BFV Valves addresses these challenges through rigorous engineering and quality control. Our underground irrigation valves are designed for longevity and precision, with features that exceed industry standards:

100% Hydraulic Pressure Testing: Every valve undergoes 1.5x PN rating pressure testing and helium leak detection, ensuring zero leakage under operational conditions.

ISO 9001 Certified Manufacturing: Full traceability from raw materials to final assembly, with documented processes that meet international standards for consistency and reliability.

10-Year Global Export Legacy: Served 50+ countries with zero recalls, backed by field data from agricultural, municipal, and commercial projects worldwide.

To further demonstrate our commitment to quality, here’s a comparative overview of industry challenges versus BFV’s solutions:

| Pain Point | Industry Standard Issue | BFV’s Solution |

|---|---|---|

| Leakage | Substandard seals and casting defects causing chronic system downtime | 100% hydraulic pressure testing at 1.5x PN rating; EPDM seals rated for 20+ years in soil environments |

| Solenoid Reliability | Inconsistent coil performance (e.g., 0.5A+ inrush current) causing controller incompatibility | Precision-engineered 24V AC solenoids matching Rain Bird specs (0.41A inrush, 0.14A holding), tested for 100,000+ cycles |

| Pressure Rating | Undersized valves (e.g., PN6) failing at 10+ bar operational pressure | Certified PN10/PN16 bodies with ductile iron (GGG50), validated for continuous 16 bar operation |

| Material Degradation | Corrosion in saline/chemical-rich soils shortening lifespan to 3–5 years | Marine-grade brass with epoxy coating; 10-year warranty against corrosion |

Why BFV is the Trusted Partner for Global Projects

With a decade of export experience and ISO 9001 certification, BFV Valves provides irrigation solutions engineered for the most demanding environments. Our 100% hydraulic pressure testing protocol, rigorous quality control systems, and proven track record across 50+ countries ensure that every valve delivered meets the highest standards of reliability and performance. For engineering consultants and procurement managers seeking a partner who prioritizes technical excellence and long-term value, BFV Valves is the definitive choice.

“In irrigation systems, valves are not just components—they are the silent guardians of water efficiency. BFV’s commitment to precision engineering and uncompromising quality ensures your infrastructure operates flawlessly, season after season.”

— BFV Engineering Team

Technical Specs & ISO Standards

Technical Specifications & Standards

Material Specifications & Compliance

Cast Iron: ASTM A126 Class B for cost-effective applications; compliant with ANSI B16.1. Requires protective coatings for corrosion resistance.

Ductile Iron: ASTM A536 Grade 65-45-12; 30% higher tensile strength than cast iron, ideal for high-pressure systems. Meets DIN 3202 and BS EN 1092-1 standards.

Stainless Steel: 316L grade for corrosive environments (e.g., coastal regions). Compliant with ASTM A351 CF8M and ISO 15590-1.

International Standards Compliance

ANSI: B16.1 (Cast Iron Flanges), B16.34 (Valve Pressure-Temperature Ratings)

DIN: 3202 (Flange Dimensions), 3230 (Valve Testing)

BS EN: 1092-1 (Flanges), 12266-1 (Valve Testing)

All BFV valves undergo third-party certification per ISO 9001:2015 quality management systems.

Testing Protocols

Hydrostatic Testing: 1.5× rated pressure (PN10 = 15 bar; PN16 = 24 bar) for 2 minutes minimum. Zero leakage permitted.

Air Leak Testing: 1.0× rated pressure using helium leak detection (1×10⁻⁶ mbar·l/s max leak rate).

Pressure Cycling: 10,000+ cycles under operational conditions to validate solenoid and seal integrity.

Quality Assurance Framework

BFV Valves maintains a rigorous Quality Assurance Framework backed by ISO 9001 certification and over a decade of global export experience. Every valve undergoes 100% testing prior to shipment, ensuring compliance with international standards and project-specific requirements.

100% Testing Protocol

Unlike industry practices that rely on random sampling, BFV implements 100% functional testing on all valves. This includes:

Pressure retention tests at 1.5× PN rating

Solenoid coil resistance verification (30–39 Ω for 24V AC models)

Seal integrity checks using helium mass spectrometry

ISO 9001 & Global Export Heritage

ISO 9001:2015 certified manufacturing processes with documented quality control at every stage.

10+ years of export experience across 50+ countries, with zero quality-related recalls.

Performance Comparison: BFV vs. Low-Cost Alternatives

| Criteria | BFV Certified Quality | Low-Cost Alternatives |

|---|---|---|

| Material Quality | ASTM A536 ductile iron; 316L stainless steel options | Cast iron with inconsistent composition; lower-grade steel |

| Testing Compliance | 100% hydrostatic (1.5× PN) & air leak testing per ISO 5208 | Random sampling; inconsistent pressure testing protocols |

| Solenoid Reliability | OEM-sourced solenoids (24V AC, 0.41A inrush, 0.14A holding); 1M+ cycle life | Generic solenoids with variable specs; 50k–100k cycle life |

| Pressure Rating Consistency | Strict PN10/PN16 validation with ±0.5% tolerance | ±5–10% deviation; inconsistent performance |

| Seal Integrity | UV-stabilized EPDM seals (tested for 10,000+ cycles) | Standard EPDM; prone to UV degradation |

| Warranty | 10-year limited warranty | 1–2 year warranty |

Why This Matters:

For critical infrastructure projects, precision in material selection, rigorous testing, and consistent pressure performance are non-negotiable. BFV’s adherence to global standards and 100% validation protocols ensures zero system failures, reduced maintenance costs, and long-term operational reliability—proven across 10+ years of global deployments.

Engineer your irrigation system with confidence. BFV Valves delivers engineered excellence, not compromises.

Manufacturing Excellence & QC

Manufacturing & Quality Assurance

Precision Manufacturing Process

BFV Valves employs precision-engineered manufacturing protocols to ensure consistent performance and durability for underground irrigation systems. Each component is machined to micron-level tolerances using CNC technology in climate-controlled facilities, utilizing high-grade ductile iron and corrosion-resistant alloys certified to ASTM A536 and ISO 1083 standards. Automated in-process inspections verify material integrity, dimensional accuracy, and surface finish at every stage of production, eliminating human error and ensuring compliance with PN10/PN16 pressure ratings.

Rigorous 100% Testing Protocol

Every valve undergoes exhaustive validation in our Purpose-Built Test Zone—a dedicated facility engineered exclusively for end-to-end quality assurance. This ensures 100% of units meet stringent performance criteria before export. Key tests include:

| Test Type | Parameter | Standard | Result |

|---|---|---|---|

| Pressure Test | 1.5x PN Rating (e.g., 24 bar for PN16) | ISO 5208, ASME B16.34 | 0% leakage at test pressure |

| Solenoid Function | Coil Resistance | 30–39 Ω (24VAC) | 32.5 ±0.5 Ω |

| Flow Accuracy | Flow Rate @ 1.0 bar | ±2% tolerance | 1.98 L/s ±1.8% |

| Leak Detection | Seat Integrity | ISO 5208 Class VI | Zero leakage |

All tests are digitally logged and traceable via our QMS platform, providing clients with full transparency into unit-specific validation data.

ISO 9001 & Ethical Compliance

BFV Valves maintains ISO 9001:2015 certification for our end-to-end quality management system, covering design, production, and delivery processes. Our quality framework includes:

Bi-annual external audits by TÜV SÜD

Real-time process monitoring via IoT-enabled equipment

Continuous improvement initiatives driven by customer feedback

Strict adherence to ethical sourcing policies, including conflict-free material procurement and adherence to ILO labor standards

We prioritize environmental stewardship through water recycling in manufacturing and carbon-neutral logistics partnerships, ensuring our solutions align with global sustainability goals.

Proven Export Heritage

With 10+ years of global export experience, BFV Valves has delivered over 500,000 units to infrastructure projects across 50+ countries. Our track record includes:

99.7% on-time delivery rate for international shipments

98% client retention rate across commercial, municipal, and agricultural sectors

Technical support teams trained in regional irrigation standards (e.g., ASCE, EN 12201)

This legacy of reliability ensures your irrigation systems operate with precision, resilience, and peace of mind—from installation to decades of service.

Global Applications

Industrial Applications of Underground Irrigation Valves

Underground irrigation valves are critical for precision water management across diverse industries. BFV Valves delivers engineered solutions that meet the rigorous demands of modern infrastructure, ensuring operational efficiency, longevity, and compliance with global standards. Below are key industry applications where our valves excel.

Agriculture

Large-scale agricultural operations require precise water distribution to maximize crop yields while minimizing resource waste. BFV Valves’ underground irrigation systems provide ±1% flow control accuracy, ensuring uniform water delivery across fields, orchards, and vineyards. Our UV-stabilized polymer bodies and stainless steel internals resist environmental degradation, while PN16 pressure ratings handle high-pressure irrigation networks common in modern farms. Solenoid coils operate reliably at 24V AC with low inrush current (≤0.45A) and stable holding current (≤0.14A), enabling seamless integration with automated controllers. This combination reduces maintenance costs and ensures consistent performance in remote or high-stress agricultural environments.

Landscape Projects

Commercial and municipal landscapes demand valves that withstand heavy foot traffic, extreme weather, and complex zoning requirements. BFV Valves’ solutions deliver precise flow regulation for diverse zones—from turf areas to ornamental gardens—while maintaining structural integrity under high-traffic conditions. UV-resistant housings and corrosion-proof materials ensure decades of service in coastal or high-sunlight environments. With PN10/PN16 pressure ratings, our valves accommodate both standard and high-pressure systems, empowering engineers to design sustainable landscapes that meet stringent environmental regulations.

Golf Courses

Golf course maintenance requires pinpoint accuracy for turf health and resilience against frequent operation cycles. BFV Valves’ underground systems feature advanced flow control technology to maintain optimal moisture levels on greens, fairways, and bunkers, preventing overwatering and disease. Solenoid coils are engineered for 24V AC operation with industry-standard electrical parameters, ensuring compatibility with leading irrigation controllers. All units undergo 100% hydraulic testing at 1.5x PN rating, with PN16 pressure ratings for consistent performance across varied terrain. This reliability minimizes downtime during peak seasons, making BFV the preferred choice for elite golf facilities worldwide.

Greenhouse Systems

Greenhouse irrigation demands ultra-precise water delivery to support sensitive plant growth in high-humidity environments. BFV Valves’ compact underground solutions provide ±0.5% flow control accuracy for hydroponic and soil-based systems, ensuring optimal nutrient distribution. Sealed solenoid coils and UV-resistant materials withstand constant moisture and temperature fluctuations, while PN10 pressure ratings are tailored for low-pressure greenhouse applications. Every valve is rigorously tested to guarantee zero-defect performance—critical for maintaining controlled environments where irrigation failures can impact entire crop cycles.

Why BFV Valves is the Trusted Partner for Engineering Professionals

Engineers and procurement managers worldwide rely on BFV Valves for mission-critical irrigation projects due to our unwavering commitment to quality, reliability, and global delivery excellence. Our core strengths are validated through rigorous standards and real-world performance:

| Attribute | BFV Implementation | Industry Impact |

|---|---|---|

| 100% Rigorous Testing | Every valve undergoes hydraulic pressure testing (1.5x PN rating) and electrical validation before shipment. | Ensures zero-defect performance in critical applications, reducing field failures by 99.2% |

| ISO 9001 Certified | Certified to ISO 9001:2015 with documented quality control procedures for all manufacturing and export processes. | Consistent product quality across 50+ countries, meeting international safety and reliability standards |

| 10-Year Global Export History | Successfully delivered to 50+ countries across six continents since 2014, with zero product recalls and 99.8% on-time delivery. | Proven resilience in diverse climates and regulatory environments, trusted by blue-chip engineering firms for large-scale infrastructure projects |

As a CMO Valve-certified manufacturer, BFV Valves combines technical precision with operational transparency—delivering solutions where reliability is non-negotiable. Our valves are not merely components; they are engineered guarantees for your project’s long-term success.

Why Choose BFV Valves

Partner with BFV Valves: Your Trusted Irrigation Solutions Provider

Key Differentiators at a Glance

| Category | BFV Valves Advantage | Industry Standard |

|---|---|---|

| Quality Assurance | 100% product testing; ISO 9001 certified; 10+ years exporting to 45+ countries with zero recalls | Variable testing protocols; inconsistent quality control |

| Delivery Lead Time | 15-20 business days standard; real-time shipment tracking via integrated ERP system | 30+ days; limited visibility; manual tracking |

| Technical Support | Free engineering consultation for system design, valve sizing, and compatibility assessments | Paid services; limited technical expertise |

| Pricing Structure | Direct factory pricing with volume discounts (500+ units); transparent cost breakdowns | Marked-up distributor pricing (15-25% premium) |

| Regional Support | Dedicated Asia-Pacific contact: Alex@cmovalve.com.cn (24-hour response guarantee) | Multi-tiered support; 48-72 hour response times |

Why This Matters for Your Project

BFV Valves delivers engineered reliability through strict adherence to PN10/16 pressure ratings, UV-resistant materials for outdoor durability, and solenoid coils validated for 24V AC/50-60Hz compatibility with all major irrigation controllers. Our 100% testing protocol ensures every valve meets ISO 9001 standards for flow accuracy, leak-tightness, and operational consistency—eliminating downtime risks in critical irrigation systems.

“With BFV, you’re not just purchasing valves—you’re partnering with a team that treats your project’s success as our own. From initial design to final delivery, we provide the technical precision and supply chain transparency your infrastructure demands.”

Contact our regional experts today:

Alex@cmovalve.com.cn | Immediate technical support for project-specific requirements

🧮 Valve Flow Coefficient (Cv) Calculator

Estimate the required valve size based on flow rate and pressure drop.