Introduction: Navigating the Global Market for diesel irrigation pump

In an increasingly competitive agricultural landscape, sourcing reliable diesel irrigation pumps is essential for optimizing water management and ensuring crop productivity. With diverse climatic conditions and varying infrastructure capabilities across regions like Africa, South America, the Middle East, and Europe, navigating the complexities of the global market can be daunting for B2B buyers. This comprehensive guide aims to demystify the procurement process by examining the various types of diesel irrigation pumps available, their applications, and the critical factors for supplier vetting.

Understanding the nuances of diesel irrigation pumps is vital for making informed purchasing decisions. From high-capacity models suitable for large-scale farming operations to portable units designed for smaller plots, the right choice can enhance efficiency and reduce operational costs. Additionally, this guide delves into cost considerations, maintenance requirements, and performance metrics, equipping international buyers with the knowledge needed to evaluate potential suppliers effectively.

By consolidating essential information and actionable insights, this guide empowers B2B buyers to navigate the global market with confidence. Whether you are in Saudi Arabia or Nigeria, the resources provided here will help you identify the most suitable diesel irrigation pump solutions tailored to your specific agricultural needs, ensuring a sustainable and productive farming future.

Understanding diesel irrigation pump Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Portable Diesel Pumps | Compact, mobile units with trailer-mounted options | Agricultural irrigation, construction | Pros: Easy transport; versatile. Cons: Limited power for large-scale operations. |

| High-Volume Diesel Pumps | Large capacity (up to 10,000 GPM) and robust engines | Municipal water supply, large farms | Pros: High output; efficient for vast areas. Cons: Higher initial investment. |

| Centrifugal Diesel Pumps | Multi-stage designs for high efficiency and pressure | Industrial applications, irrigation systems | Pros: Energy-efficient; adaptable. Cons: Requires regular maintenance. |

| Trash Pumps | Designed to handle solids and debris | Flood control, agricultural drainage | Pros: Durable; handles challenging conditions. Cons: Lower efficiency with clean water. |

| Ag Pumps | Turn-key systems with heavy-duty components | Large-scale agriculture, irrigation | Pros: Ready-to-use; reliable performance. Cons: Can be expensive; limited customization. |

What Are Portable Diesel Pumps and Their Applications?

Portable diesel pumps are designed for mobility and ease of use, often mounted on trailers for quick deployment. They are ideal for agricultural irrigation, construction sites, and emergency water removal. Their compact size allows them to be transported easily, making them suitable for temporary projects or areas with limited access. However, while they are versatile, their capacity may be insufficient for larger-scale operations, which is an essential consideration for B2B buyers.

How Do High-Volume Diesel Pumps Serve Large Projects?

High-volume diesel pumps are engineered to deliver substantial water flow rates, often exceeding 10,000 gallons per minute (GPM). These pumps are primarily used in municipal water supply systems and large-scale agricultural operations where extensive irrigation is required. Their robust engines ensure reliability under demanding conditions. However, the higher upfront costs associated with these pumps can be a barrier for some businesses, making careful budgeting a critical factor in purchasing decisions.

What Are the Advantages of Centrifugal Diesel Pumps?

Centrifugal diesel pumps utilize a multi-stage design to achieve high efficiency and pressure, making them suitable for industrial applications and irrigation systems. They are known for their energy efficiency and adaptability to various pumping needs. However, these pumps require regular maintenance to ensure optimal performance, which can add to operational costs. B2B buyers should weigh the long-term savings from efficiency against the maintenance requirements when considering this type of pump.

How Do Trash Pumps Handle Challenging Conditions?

Trash pumps are specifically designed to manage water mixed with solids and debris, making them essential for flood control and agricultural drainage applications. Their durable construction allows them to perform effectively in harsh environments. While they excel in challenging conditions, their efficiency diminishes when pumping clean water, which may limit their versatility. Buyers must assess their specific needs to determine if a trash pump aligns with their operational requirements.

What Makes Ag Pumps a Reliable Choice for Agriculture?

Ag pumps are turn-key systems built with heavy-duty components, offering reliability for large-scale agricultural applications. They are designed for immediate use and can handle various irrigation tasks effectively. However, the cost of these systems can be significant, and they may offer limited customization options. B2B buyers in agriculture should consider the balance between upfront investment and the long-term benefits of operational efficiency when selecting ag pumps for their needs.

Key Industrial Applications of diesel irrigation pump

| Industry/Sector | Specific Application of diesel irrigation pump | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Crop irrigation systems for large-scale farming | Increases crop yield and reduces water wastage | Pump capacity, fuel efficiency, and adaptability to local conditions |

| Construction | Dewatering construction sites to manage groundwater levels | Ensures safety and operational efficiency | Portability, durability, and ease of maintenance |

| Mining | Water supply for mineral processing and dust suppression | Enhances operational productivity and compliance | Flow rate, compatibility with site infrastructure, and fuel type |

| Landscaping and Golf | Watering large green areas and maintaining landscapes | Promotes healthy growth and aesthetic appeal | Pump size, energy consumption, and ease of transport |

| Disaster Relief | Providing water access in emergency situations | Facilitates timely response and resource allocation | Reliability, ease of setup, and availability of parts and service |

How is Diesel Irrigation Pump Used in Agriculture?

In the agriculture sector, diesel irrigation pumps are essential for efficient crop irrigation, particularly in regions with limited water resources. These pumps facilitate the extraction of water from rivers, lakes, or underground sources, ensuring a consistent supply for large-scale farming operations. By utilizing diesel-powered pumps, farmers can significantly increase crop yields while minimizing water wastage. Buyers in this sector should consider pump capacity, fuel efficiency, and adaptability to local climate conditions when sourcing these systems, especially in areas like Nigeria and Saudi Arabia where agricultural demands are high.

What Role Do Diesel Pumps Play in Construction?

In construction, diesel irrigation pumps are vital for dewatering sites, helping to manage groundwater levels effectively. This application is crucial for maintaining safety and operational efficiency during excavation and foundation work. The ability to quickly remove excess water prevents delays and hazards associated with flooding. B2B buyers in the construction industry should prioritize features such as portability, durability, and ease of maintenance when selecting these pumps, particularly in regions prone to heavy rainfall or flooding.

How Are Diesel Pumps Utilized in Mining Operations?

Mining operations rely on diesel irrigation pumps for a variety of water management tasks, including supplying water for mineral processing and dust suppression. These pumps enhance operational productivity by ensuring that water is readily available for essential processes while also complying with environmental regulations. Buyers in the mining sector should focus on flow rate, compatibility with existing site infrastructure, and the type of fuel used, as these factors can significantly impact operational efficiency in remote areas of South America and Africa.

What Benefits Do Diesel Pumps Offer in Landscaping and Golf Course Management?

For landscaping and golf course maintenance, diesel irrigation pumps provide the necessary water supply to maintain lush green spaces. These pumps ensure that large areas receive adequate hydration, promoting healthy plant growth and enhancing the aesthetic appeal of the landscape. When sourcing pumps for these applications, businesses should consider pump size, energy consumption, and ease of transport, as many landscaping projects require mobility and efficiency.

How Do Diesel Pumps Assist in Disaster Relief Efforts?

In disaster relief scenarios, diesel irrigation pumps are crucial for providing immediate water access in affected areas. These pumps can be deployed quickly to supply clean water for drinking and sanitation, facilitating timely responses to emergencies. For international B2B buyers involved in disaster management, reliability, ease of setup, and the availability of parts and service are key factors to consider when sourcing diesel irrigation pumps, ensuring they can effectively support relief efforts in crisis situations.

3 Common User Pain Points for ‘diesel irrigation pump’ & Their Solutions

Scenario 1: Difficulty in Sourcing Reliable Diesel Irrigation Pumps

The Problem: Many B2B buyers in regions such as Africa and South America face challenges in sourcing high-quality diesel irrigation pumps. The issue often stems from a lack of local suppliers and the need for reliable equipment that can withstand harsh environmental conditions. Buyers may encounter products that fail to meet their specifications or have limited service support, leading to operational downtime and increased costs.

The Solution: To effectively source reliable diesel irrigation pumps, buyers should begin by conducting thorough research on manufacturers known for their durable products and good after-sales support. Engage with suppliers who have a strong presence in your region and can provide testimonials or case studies from other buyers. It’s essential to request detailed specifications and performance data for the pumps to ensure they meet the specific needs of your agricultural operations. Additionally, consider forming partnerships with local distributors who can offer not just sales but ongoing maintenance and support, which is crucial in preventing future equipment failures.

Scenario 2: Overcoming High Fuel Consumption and Operational Costs

The Problem: A significant concern for B2B buyers is the high fuel consumption associated with diesel irrigation pumps, particularly in areas where fuel prices are volatile. This can lead to unexpected operational costs that impact the overall profitability of agricultural operations. Many buyers struggle to find a balance between the efficiency of the pump and its operational costs, leading to frustration and financial strain.

The Solution: To address this issue, buyers should focus on selecting diesel irrigation pumps that are designed for fuel efficiency. When evaluating pumps, look for models with advanced engine technology and those equipped with features such as variable speed control, which can optimize fuel use based on the specific pumping needs. Additionally, consider integrating a monitoring system that tracks fuel consumption in real-time, allowing for adjustments in operations to minimize waste. Regular maintenance of the pump is also critical; ensure that filters are clean and components are well-lubricated to maintain optimal efficiency.

Scenario 3: Maintenance Challenges and Downtime Risks

The Problem: Buyers often face challenges related to the maintenance of diesel irrigation pumps, which can lead to prolonged downtime and costly repairs. The complexity of some pump systems can deter operators from performing regular maintenance, resulting in equipment failures during critical irrigation periods. This not only affects crop yields but also strains relationships with stakeholders relying on consistent water supply.

The Solution: To mitigate maintenance challenges, buyers should invest in training programs for their staff that focus on the operation and upkeep of diesel irrigation pumps. Understanding the specific maintenance requirements for each model can empower operators to perform routine checks and minor repairs effectively. Additionally, consider establishing a preventive maintenance schedule that includes regular inspections and servicing by qualified technicians. Investing in pumps that come with comprehensive manuals and support from manufacturers can also facilitate easier maintenance. Furthermore, integrating a digital maintenance tracking system can help keep records of service dates and parts replacements, ensuring that pumps are always in optimal condition.

Strategic Material Selection Guide for diesel irrigation pump

What are the Common Materials Used in Diesel Irrigation Pumps?

When selecting a diesel irrigation pump, the choice of materials is critical to ensure optimal performance, durability, and cost-effectiveness. Below, we analyze four common materials used in diesel irrigation pumps, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Cast Iron Perform in Diesel Irrigation Pumps?

Key Properties: Cast iron is known for its excellent strength and wear resistance, making it suitable for high-pressure applications. It can withstand temperatures up to 300°C and has good corrosion resistance when coated.

Pros & Cons: The durability of cast iron is a significant advantage, as it can handle harsh operating conditions. However, it is relatively heavy, which can complicate transportation and installation. Additionally, the manufacturing process can be more complex and costly compared to other materials.

Impact on Application: Cast iron is compatible with various media, including water and some chemical solutions. However, it may not be suitable for highly corrosive environments without proper coatings.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards such as ASTM or DIN. Additionally, the weight of cast iron pumps may affect shipping costs, so logistics should be planned accordingly.

Why is Stainless Steel a Preferred Material for Diesel Irrigation Pumps?

Key Properties: Stainless steel offers excellent corrosion resistance and can withstand temperatures up to 800°C. Its mechanical properties make it suitable for high-pressure applications.

Pros & Cons: The main advantage of stainless steel is its longevity and resistance to rust, making it ideal for environments with high humidity or corrosive elements. However, it is more expensive than cast iron and may require specialized welding techniques during manufacturing.

Impact on Application: Stainless steel is compatible with a wide range of media, including potable water, making it a versatile choice for irrigation systems.

Considerations for International Buyers: Buyers in the Middle East and Europe often prefer stainless steel due to its compliance with health and safety standards. Understanding local regulations regarding materials used in agricultural applications is crucial.

What Role Does Aluminum Play in Diesel Irrigation Pumps?

Key Properties: Aluminum is lightweight and has good corrosion resistance, with a melting point of around 660°C. It is also a good thermal conductor, which can be beneficial in heat dissipation.

Pros & Cons: The lightweight nature of aluminum makes it easier to transport and install, reducing overall costs. However, it has a lower tensile strength compared to cast iron and stainless steel, which may limit its use in high-pressure applications.

Impact on Application: Aluminum is suitable for non-corrosive media and can be used effectively in less demanding environments. Its compatibility with various fluids makes it a flexible option.

Considerations for International Buyers: In regions like Europe, adherence to specific alloy standards (e.g., EN or ISO) is essential. Buyers should also consider the local availability of aluminum components, as this can affect lead times.

How Does Plastic Material Fit into Diesel Irrigation Pumps?

Key Properties: Plastics, particularly high-density polyethylene (HDPE) and polyvinyl chloride (PVC), offer excellent chemical resistance and can operate at temperatures up to 60°C.

Pros & Cons: The main advantage of plastic is its lightweight and cost-effectiveness, making it an attractive option for budget-conscious projects. However, plastics may not withstand high pressures as effectively as metals, limiting their application scope.

Impact on Application: Plastic pumps are ideal for handling water and some chemicals but may not be suitable for high-pressure irrigation systems.

Considerations for International Buyers: Buyers in Africa and South America should verify that the plastic materials comply with local agricultural standards. The availability of specific types of plastics may also vary by region.

Summary Table of Material Selection for Diesel Irrigation Pumps

| Material | Typical Use Case for diesel irrigation pump | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cast Iron | High-pressure irrigation systems | Excellent durability and wear resistance | Heavy and complex manufacturing | Medium |

| Stainless Steel | Potable water and corrosive environments | Superior corrosion resistance | Higher cost and specialized welding | High |

| Aluminum | Lightweight irrigation applications | Easy transport and installation | Lower tensile strength | Medium |

| Plastic | Budget-friendly, low-pressure systems | Cost-effective and lightweight | Limited high-pressure capability | Low |

This strategic material selection guide provides actionable insights for international B2B buyers, enabling informed decisions when sourcing diesel irrigation pumps tailored to specific agricultural needs.

In-depth Look: Manufacturing Processes and Quality Assurance for diesel irrigation pump

What Are the Main Stages of Manufacturing a Diesel Irrigation Pump?

The manufacturing process of diesel irrigation pumps involves several critical stages that ensure the final product meets performance and durability standards. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: High-quality materials such as cast iron, aluminum, and various steel alloys are selected based on their mechanical properties and resistance to environmental factors. Raw materials undergo rigorous testing to ensure compliance with industry standards. For instance, materials are often subjected to tensile strength tests and chemical composition analysis to confirm their suitability for irrigation applications.

Forming: The forming process typically involves casting and machining. Components like the pump casing, impellers, and engine mounts are produced through sand casting or die-casting methods, which allow for complex shapes and high precision. After casting, parts are machined using CNC (Computer Numerical Control) technology to achieve exact dimensions, enhancing the performance and efficiency of the pump.

Assembly: The assembly stage integrates various components, including the engine, pump body, and drive mechanisms. Skilled technicians employ specific assembly techniques, such as torque specifications and alignment checks, to ensure that all parts fit together seamlessly. This stage may also include the installation of electrical components, such as control panels and sensors, which are crucial for monitoring pump performance.

Finishing: After assembly, pumps undergo a finishing process that includes painting, coating, or galvanizing to protect against corrosion and wear. This step not only enhances the aesthetic appeal of the pump but also extends its lifespan, particularly in harsh environmental conditions common in agricultural settings.

Which Quality Assurance Standards Are Relevant for Diesel Irrigation Pumps?

Quality assurance (QA) is a vital aspect of manufacturing diesel irrigation pumps. Adhering to international and industry-specific standards ensures that products are reliable, safe, and efficient. Key standards include:

ISO 9001: This international standard outlines criteria for a quality management system (QMS). Manufacturers certified under ISO 9001 demonstrate a commitment to consistently providing products that meet customer and regulatory requirements.

CE Marking: In Europe, the CE marking indicates compliance with safety, health, and environmental protection standards for products sold within the European Economic Area (EEA). It assures buyers that the product meets EU safety requirements.

API Standards: The American Petroleum Institute (API) provides standards that are particularly relevant for pumps used in industrial applications, ensuring that products can withstand the rigors of demanding operational environments.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) checkpoints are established throughout the manufacturing process to ensure that any defects are identified and addressed promptly. Typical QC checkpoints include:

Incoming Quality Control (IQC): At this stage, raw materials and components received from suppliers are inspected for quality and compliance with specifications. This may involve visual inspections and mechanical testing.

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor the quality of parts as they are being produced. This includes checking dimensions and tolerances during machining and assembly.

Final Quality Control (FQC): Once the diesel irrigation pump is fully assembled, it undergoes comprehensive testing. This includes performance tests under various conditions, pressure testing for leaks, and operational tests to ensure the pump operates within specified parameters.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure product reliability. Here are several strategies:

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing facilities and QC processes directly. This provides insights into the supplier’s commitment to quality management and compliance with international standards.

Requesting QC Reports: Buyers should request detailed quality control reports that outline testing methods, results, and compliance with relevant standards. This documentation can help buyers understand the level of scrutiny each product undergoes.

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing process and product quality. These inspectors can verify that the supplier adheres to the agreed-upon specifications and standards.

What Are the QC and Certification Nuances for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique challenges regarding quality control and certification. Here are some nuances to consider:

Regional Standards Compliance: Different regions may have specific regulations and standards that manufacturers must comply with. For instance, pumps sold in the Middle East may need to meet specific local environmental regulations. Buyers should ensure that suppliers are familiar with and compliant with these regional standards.

Documentation and Certification: When purchasing from international suppliers, it is crucial to obtain all necessary documentation, including certificates of compliance, test reports, and warranties. This documentation serves as proof of quality and can be essential for customs clearance.

Understanding Lead Times and Logistics: Quality control processes can affect lead times. Buyers should consider the time required for manufacturing, testing, and shipping when placing orders, particularly for large-scale agricultural projects that depend on timely delivery.

Conclusion

Understanding the manufacturing processes and quality assurance measures associated with diesel irrigation pumps is vital for B2B buyers looking to procure reliable and efficient equipment. By focusing on the key stages of production, relevant quality standards, and verification methods, buyers can make informed decisions that align with their agricultural needs and operational requirements. Engaging with reputable suppliers who prioritize quality assurance will ultimately lead to successful irrigation solutions tailored to specific regional demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘diesel irrigation pump’

When sourcing diesel irrigation pumps, particularly for diverse agricultural needs across regions such as Africa, South America, the Middle East, and Europe, it is essential to follow a structured approach. This guide outlines critical steps to ensure you make informed purchasing decisions, balancing performance, cost, and supplier reliability.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is foundational to your procurement process. Identify the required flow rate, pressure, and engine type that aligns with your irrigation needs. Consider factors such as:

– Pump Capacity: Determine the gallons per minute (GPM) required for your operation.

– Power Source: Choose between different diesel engine brands (e.g., Kubota, Perkins) based on reliability and availability of service.

Step 2: Assess Project Requirements

Understand the specific conditions and demands of your project. This includes evaluating the terrain, water source, and potential environmental challenges. Critical considerations include:

– Mobility: Will the pump be stationary or need to be portable?

– Durability: Assess the pump’s construction materials to ensure longevity under local conditions.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough vetting is crucial. Request detailed company profiles, case studies, and references from previous clients in similar markets. Key points to investigate include:

– Certifications: Verify if the supplier meets international standards relevant to your region.

– After-Sales Support: Ensure they provide ongoing support and parts availability.

Step 4: Request Quotes and Compare Pricing

Gather quotes from multiple suppliers to compare pricing and value propositions. Look beyond the initial cost and consider:

– Total Cost of Ownership: Include factors such as maintenance, fuel efficiency, and warranty terms.

– Discounts and Financing Options: Check for potential discounts for bulk orders or financing plans that may ease budget constraints.

Step 5: Verify Product Specifications and Compliance

Ensure that the products offered meet your defined specifications and comply with local regulations. This step is vital to avoid costly issues post-purchase. Consider:

– Technical Documentation: Request product datasheets and compliance certificates.

– Warranty Terms: Understand the warranty coverage and what it entails regarding repairs and replacements.

Step 6: Conduct Site Visits or Virtual Demos

If possible, arrange site visits to see the equipment in action or request virtual demonstrations. Observing the pump’s operation provides insights into:

– Performance in Real Conditions: Evaluate how the pump performs in settings similar to your own.

– Ease of Use: Assess the user interface and operational complexity for your team.

Step 7: Finalize the Purchase and Logistics Planning

Once you have chosen a supplier, finalize the purchase and discuss logistics. Ensure clarity on:

– Delivery Timelines: Confirm when the pump will arrive and any shipping arrangements.

– Installation Support: Discuss whether the supplier offers installation services or training for your team.

By following this practical checklist, you can streamline your sourcing process for diesel irrigation pumps, ensuring that you select the best equipment tailored to your operational needs while minimizing risks associated with procurement.

Comprehensive Cost and Pricing Analysis for diesel irrigation pump Sourcing

What are the Key Cost Components for Diesel Irrigation Pumps?

Understanding the cost structure of diesel irrigation pumps is crucial for international B2B buyers. The main cost components include:

Materials: The quality of materials used in the manufacturing of diesel pumps significantly impacts costs. High-grade components, such as robust engines (e.g., Kubota or Perkins) and durable pump materials, can elevate prices but ensure longevity and efficiency.

Labor: Labor costs vary by region and manufacturing practices. Skilled labor is essential for assembling complex machinery, which can lead to higher costs in regions with stricter labor regulations or higher wage standards.

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, rent, and equipment maintenance. Efficient factories may have lower overheads, impacting the final pricing positively.

Tooling: Custom tooling for unique pump designs or specifications can add significant costs. Standardized designs typically reduce tooling expenses, while bespoke solutions drive them up.

Quality Control (QC): Rigorous QC processes ensure that pumps meet industry standards, particularly for agricultural applications. Investing in quality assurance can raise upfront costs but is critical for minimizing long-term failure rates.

Logistics: Shipping costs can vary widely based on location, weight, and urgency of delivery. International buyers must account for customs duties and transportation fees, especially when sourcing from different continents.

Margin: Suppliers will typically add a profit margin to cover their costs and ensure profitability. This margin can fluctuate based on market demand and competition.

How Do Price Influencers Affect Diesel Pump Costs?

Several factors influence the pricing of diesel irrigation pumps:

Volume and Minimum Order Quantity (MOQ): Bulk purchases often yield discounts. Understanding the supplier’s MOQ can help buyers negotiate better pricing.

Specifications and Customization: Customized pumps designed for specific applications can command higher prices. Buyers should assess whether standard models meet their needs to avoid unnecessary costs.

Materials and Quality Certifications: Pumps made from superior materials or with recognized certifications (e.g., ISO) often carry a premium. Buyers should weigh the benefits of higher-quality products against budget constraints.

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their experience and the perceived value they offer.

Incoterms: Understanding Incoterms is essential for international transactions. They define responsibilities for shipping, insurance, and tariffs, which can significantly affect the total price.

What Tips Can Help Buyers Optimize Diesel Pump Sourcing Costs?

International B2B buyers can implement several strategies to enhance cost-efficiency:

Negotiation: Always negotiate prices, especially for bulk orders. Suppliers may be willing to adjust prices based on the volume or long-term partnership potential.

Total Cost of Ownership (TCO): Consider not just the purchase price but also operational costs, maintenance, and potential downtime. A lower upfront cost may lead to higher long-term expenses.

Research and Compare Suppliers: Conduct thorough research on multiple suppliers. Compare costs, quality, and service offerings to identify the best fit for your needs.

Leverage Local Market Insights: Buyers from regions like Africa and the Middle East should leverage local market knowledge to understand pricing dynamics and supplier relationships that may offer cost advantages.

Stay Informed on Market Trends: Keep abreast of market trends and technological advancements in pump manufacturing. Innovations can lead to more efficient, cost-effective options.

What Should Buyers Keep in Mind Regarding Indicative Prices?

While indicative prices provide a baseline for budgeting, they can fluctuate due to market conditions, exchange rates, and supplier pricing strategies. Buyers should always request formal quotes that reflect current pricing, including all potential costs associated with delivery and installation. This approach ensures a more accurate financial forecast and helps mitigate unexpected expenses during the procurement process.

Alternatives Analysis: Comparing diesel irrigation pump With Other Solutions

Understanding Alternative Solutions to Diesel Irrigation Pumps

When considering irrigation solutions, diesel-powered pumps are a common choice due to their reliability and high performance. However, various alternatives exist that may better suit specific operational needs, especially for international buyers in diverse regions like Africa, South America, the Middle East, and Europe. This section explores viable alternatives to diesel irrigation pumps, comparing their effectiveness, cost, and ease of use.

Comparison Table

| Comparison Aspect | Diesel Irrigation Pump | Electric Irrigation Pump | Solar-Powered Irrigation Pump |

|---|---|---|---|

| Performance | High flow rates; robust for heavy-duty tasks | Moderate flow; suitable for smaller operations | Variable; dependent on sunlight; ideal for remote areas |

| Cost | Higher initial investment; ongoing fuel costs | Lower initial cost; electricity costs vary | Higher initial cost; low operational costs |

| Ease of Implementation | Requires fuel infrastructure; installation can be complex | Easier to install; plug-and-play design | Installation can be complex; requires adequate sunlight |

| Maintenance | Regular maintenance needed; fuel system care | Low maintenance; mainly electrical checks | Minimal maintenance; battery replacement needed periodically |

| Best Use Case | Large-scale agricultural operations needing consistent power | Small to medium farms with access to electricity | Remote areas with high sunlight exposure and limited access to fuel |

In-Depth Analysis of Alternatives

Electric Irrigation Pumps

Electric irrigation pumps are increasingly popular, especially in regions with stable electricity supply. They offer a lower initial investment compared to diesel pumps and are easier to install, often requiring less technical knowledge. Their maintenance is also straightforward, primarily involving electrical checks. However, their performance may not match that of diesel pumps, particularly in heavy-duty applications, and they may incur higher operational costs in areas with expensive electricity. They are best suited for small to medium-sized farms where consistent electrical supply is available.

Solar-Powered Irrigation Pumps

Solar-powered irrigation pumps represent an innovative alternative, leveraging renewable energy to reduce operational costs significantly. While they come with a higher initial investment, the operational costs are minimal since they harness solar energy. This option is particularly advantageous for remote areas where fuel and electricity infrastructure may be lacking. However, their performance can be variable, heavily reliant on sunlight availability, which may limit their effectiveness during cloudy days or in less sunny regions. They are ideal for agricultural operations that prioritize sustainability and operate in sunny climates.

Making the Right Choice for Your Irrigation Needs

In selecting the appropriate irrigation solution, B2B buyers should consider several factors, including the scale of their operations, local infrastructure, and environmental conditions. Diesel irrigation pumps remain a strong choice for large-scale agricultural operations that require consistent power and high flow rates. However, for smaller farms or those in areas with reliable electricity, electric pumps may provide a cost-effective solution. Conversely, solar-powered pumps are an excellent option for those looking to minimize operational costs while embracing sustainable practices, particularly in regions with abundant sunlight. By evaluating these aspects, buyers can make informed decisions that align with their operational goals and regional constraints.

Essential Technical Properties and Trade Terminology for diesel irrigation pump

What Are the Key Technical Properties of Diesel Irrigation Pumps?

When selecting a diesel irrigation pump, understanding its technical specifications is crucial for ensuring efficiency and reliability in agricultural applications. Here are some essential properties to consider:

1. Flow Rate (GPM)

The flow rate, measured in gallons per minute (GPM), indicates the volume of water the pump can move in a specified time. This specification is vital for B2B buyers as it directly affects the pump’s ability to meet irrigation demands. A higher flow rate is usually required for larger agricultural fields, making it a key factor in project planning.

2. Horsepower (HP)

Horsepower reflects the engine’s power output, which influences the pump’s performance. For diesel irrigation pumps, HP ratings typically range from 25 to over 200. Selecting the appropriate horsepower ensures the pump can handle the required flow rate and pressure, optimizing operational efficiency.

3. Suction Lift

Suction lift is the vertical distance the pump can draw water from its source. It is critical for applications in regions where water sources are not level with the pump. Understanding this property helps buyers assess the pump’s suitability for specific geographic conditions, ensuring it meets the operational requirements.

4. Discharge Pressure

Discharge pressure, measured in pounds per square inch (PSI), indicates the pressure at which water exits the pump. This property is essential for determining how far water can be pushed through irrigation systems. Buyers need to ensure the discharge pressure aligns with the needs of their irrigation setup to avoid inefficiencies.

5. Fuel Tank Capacity

The fuel tank capacity determines how long the pump can operate before refueling, impacting labor and operational costs. A larger tank can provide extended running times, which is particularly advantageous for large-scale operations that require continuous water supply.

6. Pump Material and Construction

The material and construction quality of a diesel irrigation pump affect its durability and resistance to environmental factors. Common materials include cast iron and aluminum, which offer different strengths and weights. Buyers should consider their operational environment and select pumps designed for longevity to minimize maintenance costs.

What Are Common Trade Terms Related to Diesel Irrigation Pumps?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B space. Here are some commonly used terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is important for buyers seeking specific brands or components for compatibility and quality assurance.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is crucial for buyers, particularly in bulk purchasing scenarios, as it influences inventory levels and cost management.

3. RFQ (Request for Quotation)

An RFQ is a document sent by a buyer to suppliers requesting pricing and other details for specific products or services. Issuing an RFQ allows buyers to compare offers and negotiate terms effectively.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for managing shipping costs, risks, and delivery timelines, ensuring smooth logistics in cross-border purchases.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. Buyers need to consider lead times to plan their projects effectively, especially in agricultural settings where timing can be critical.

6. Warranty

A warranty is a guarantee provided by the manufacturer regarding the product’s performance and quality. Understanding warranty terms helps buyers assess the risk associated with their investment, providing peace of mind regarding repairs and replacements.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when selecting diesel irrigation pumps, ultimately enhancing operational efficiency and effectiveness in agricultural practices.

Navigating Market Dynamics and Sourcing Trends in the diesel irrigation pump Sector

What Are the Key Trends in the Diesel Irrigation Pump Market?

The diesel irrigation pump market is witnessing significant growth, driven by increasing agricultural productivity demands across developing regions, particularly in Africa, South America, and the Middle East. As global food security becomes a pressing issue, the need for reliable and efficient irrigation systems is paramount. Diesel pumps are favored for their robustness and high power output, making them ideal for large-scale agricultural operations.

Emerging technologies are reshaping sourcing strategies within the sector. The integration of IoT (Internet of Things) devices for monitoring and optimizing pump performance is gaining traction, allowing farmers to achieve better water management and reduce operational costs. Additionally, online platforms are facilitating direct purchases from manufacturers, enhancing transparency and competition. As a result, international buyers can benefit from a wider selection of products and potentially lower prices.

Another notable trend is the customization of diesel irrigation systems to cater to specific regional needs, such as varying water sources and crop types. Suppliers are increasingly offering tailored solutions that incorporate local environmental conditions, which is crucial for B2B buyers looking to maximize efficiency and return on investment.

How Is Sustainability Shaping the Sourcing of Diesel Irrigation Pumps?

Sustainability is becoming a critical factor for B2B buyers in the diesel irrigation pump sector. The environmental impact of traditional diesel engines has prompted a shift towards more sustainable practices. Buyers are increasingly interested in suppliers that demonstrate a commitment to reducing carbon footprints through innovations such as biofuels or hybrid systems that combine diesel and electric power.

Ethical sourcing is also gaining importance. Companies are focusing on establishing transparent supply chains that adhere to environmental and labor standards. This includes obtaining certifications for ‘green’ materials and processes, which not only enhance brand reputation but also attract environmentally-conscious consumers. For instance, pumps made from recyclable materials or those manufactured using energy-efficient processes are becoming preferred choices among buyers looking to align with sustainability goals.

Moreover, suppliers that prioritize ethical labor practices and engage in fair trade are more likely to gain trust and loyalty from B2B buyers. As sustainability becomes intertwined with operational efficiency, it is essential for buyers to evaluate suppliers based on their environmental policies and ethical sourcing commitments.

What Is the Historical Context of Diesel Irrigation Pumps in B2B Markets?

The evolution of diesel irrigation pumps dates back to the early 20th century when mechanized farming began to replace traditional methods. Initially, these pumps were bulky and less efficient, but advancements in engine technology and materials have led to significant improvements in performance and reliability. The introduction of compact, high-efficiency diesel engines has made it feasible to deploy powerful irrigation systems even in remote areas.

As global agricultural practices evolved, so did the design and functionality of diesel irrigation pumps. The late 20th century saw a surge in demand for portable and versatile pumping solutions, particularly in developing regions where infrastructure was lacking. Today, modern diesel irrigation pumps are engineered for durability, ease of transport, and efficiency, catering to the diverse needs of international buyers. The historical context underscores the continuous innovation within the sector, which remains essential for meeting the challenges of modern agriculture.

Frequently Asked Questions (FAQs) for B2B Buyers of diesel irrigation pump

How do I choose the right diesel irrigation pump for my agricultural needs?

Choosing the right diesel irrigation pump depends on several factors, including the size of your agricultural land, water source availability, and the specific crops you are growing. Assess the required flow rate (measured in gallons per minute) and the total dynamic head (TDH), which indicates the height the water must be lifted. It’s also crucial to consider the pump’s durability, ease of maintenance, and fuel efficiency. Consulting with local experts or suppliers can provide valuable insights tailored to your specific conditions.What is the best type of diesel irrigation pump for large-scale farming?

For large-scale farming, a centrifugal diesel irrigation pump is typically the best option due to its ability to handle high flow rates efficiently. These pumps are designed for continuous operation and can effectively manage the demands of extensive irrigation systems. Look for pumps with high-quality components, such as those equipped with heavy-duty engines like Kubota or Perkins, which are known for their reliability and fuel efficiency.What are the key features to look for in a diesel irrigation pump?

Key features to consider include the pump’s horsepower, flow rate, and durability. A robust construction that can withstand harsh environmental conditions is essential. Additionally, consider the pump’s ease of maintenance, availability of spare parts, and fuel tank capacity for longer operation periods. Features like automatic shutdown systems, pressure gauges, and mobility options (like trailers) can enhance usability and safety.What are the minimum order quantities (MOQ) for diesel irrigation pumps?

Minimum order quantities can vary significantly between suppliers, often depending on the manufacturer and the specific model of the pump. Typically, MOQs range from one unit for smaller suppliers to several units for larger manufacturers. Always clarify MOQs during initial discussions, as some suppliers may offer flexibility for first-time buyers or larger orders.How do I vet suppliers of diesel irrigation pumps for international trade?

To vet suppliers, start by checking their reputation through online reviews, industry certifications, and customer testimonials. Request references from previous clients, particularly those in your region. It’s also beneficial to verify their production capabilities, quality assurance processes, and after-sales support. Engaging in direct communication and possibly conducting a factory visit can provide deeper insights into their operations.What payment terms are typically offered for purchasing diesel irrigation pumps internationally?

Payment terms can vary widely among suppliers but generally include options such as advance payment, letter of credit, or payment on delivery. For international transactions, negotiating terms that provide security for both parties is essential. Be clear about currency, payment methods (like bank transfers or online payment platforms), and timelines to avoid misunderstandings.How can I ensure quality assurance for the diesel irrigation pumps I purchase?

Ensure quality assurance by requesting certifications that verify compliance with international standards, such as ISO certifications. Ask suppliers about their quality control processes, including testing procedures and warranty offerings. Some suppliers may provide product samples or allow third-party inspections before shipment, which can further guarantee that the pumps meet your quality expectations.What logistics considerations should I keep in mind when importing diesel irrigation pumps?

Logistics considerations include shipping methods, lead times, and import regulations specific to your country. Ensure that your supplier can provide details on shipping costs, insurance, and customs clearance processes. It’s advisable to work with a freight forwarder familiar with agricultural equipment to streamline the importation process and avoid potential delays. Additionally, confirm that the pumps are adequately packaged to prevent damage during transit.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Diesel Irrigation Pump Manufacturers & Suppliers List

1. Rainflo – Large Portable Diesel Pump Units

Domain: rainfloirrigation.com

Registered: 2008 (17 years)

Introduction: Large Portable Pumps:

1. **25 HP Diesel Pump Units**

– Engine: Kubota D1105

– Pump: Berkeley B2½ZRLS with 9″ impeller

– Fuel Tank: 22 Gallon steel

– Trailer: Heavy duty

– Features: Hand primer, check valve, safety shutdown

– Price: $11,800.00

2. **37 HP Diesel Pump Units**

– Engine: Kubota D1803CR

– Pump: Berkeley B2EQHH

– Fuel Tank: 50 Gallon

– Trailer: Heavy duty

…

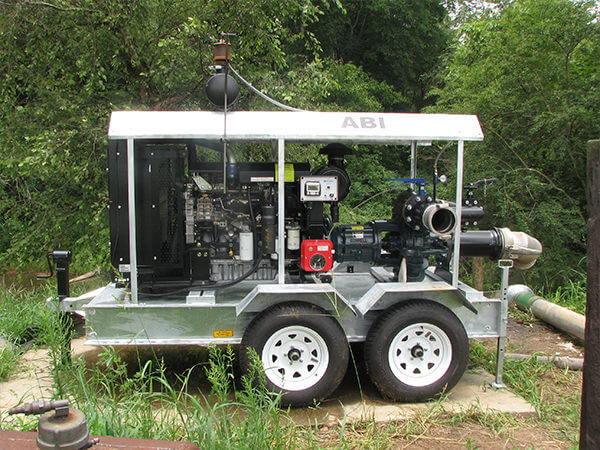

2. ABI Irrigation – Diesel Water Pumps

Domain: abi-irrigation.com

Registered: 2000 (25 years)

Introduction: Diesel Water Pumps for irrigation; available with diesel, propane, electric, or natural gas engines; matched to Flange-Mount Pumps; multi-stage flanged or bare-shaft centrifugal pumps; designed for specific project needs; standard features include engine hood, battery assembly, control panel with pressure gauge, single or double axle, trailer jack, suction extension and discharge adapters, dischar…

3. Hardy Diesel – Diesel Ag Pumps for Irrigation

Domain: hardydiesel.com

Registered: 1998 (27 years)

Introduction: Diesel Ag Pumps for Irrigation are turn-key ready for various agricultural applications. They feature Cornell Pumps with options for 4″, 5″, and 6″ discharge sizes. The pumps are powered by either Perkins or Volvo Penta engines, providing 110 HP, 150 HP, or 250 HP at 2300 RPM. Standard features include heavy-duty open design, fully automatic continuous priming, large DEF tank, and a 2-year or 2,00…

4. Defu – Diesel Multistage Pump 150TSWA*6

Domain: defupump.com

Registered: 2014 (11 years)

Introduction: Product: Diesel Engine Pump for Irrigation Project

Type: Multistage Centrifugal Pump

Production Year: 2017

Application: Irrigation in plateau area

Altitude: 4100m

Vertical Head: 145m

Pipe Length: 1800m

Model: Diesel Multistage Pump 150TSWA*6

Flow Rate: 150m3/h @ 180m head

Max Capacity: 200m3/h

Max Head: 200m

Max Suction Head: up to 7m

Engine: Chinese Ricardo brand R series engine R6110ZLDP

Engine …

5. Deutz – Diesel Irrigation Pumps

Domain: talk.newagtalk.com

Registered: 2000 (25 years)

Introduction: Diesel irrigation pumps discussed include options from Deutz and Deere, with users sharing experiences on reliability and fuel efficiency. Key points include:

– Deutz engines are noted for being simple, reliable, and fuel-efficient, with some users reporting 25-30 years of service.

– Deere engines, particularly the 4045T, are praised for good fuel economy but can be expensive to repair.

– Users…

6. EUROMAST – Irrigation Pumps

Domain: motopompe-irrigation.com

Registered: 2021 (4 years)

Introduction: Irrigation pumps offered by EUROMAST include various types for agricultural use, such as diesel, electric, and solar motor pumps. Key product details include:

– Types of pumps: Micro-irrigation pumps, Spray Pumps, Roller Cannon Pumps, Pumps for Pivots and Retractable Ramps, Portable Pumps, Network Pumps, and Accessories.

– Engine options: Diesel (15), Gasoline (1).

– Configurations: Fixed (3), Por…

7. Nanshing – Diesel Engine Water Pump

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Diesel Engine Water Pump High Power Vertical Agricultural Irrigation Water Pumps”, “Brand”: “Nanshing”, “Condition”: “New”, “Price”: {“Original Price”: “US $607.49”, “Discounted Price”: “US $577.12”, “Savings”: “US $30.37”}, “Shipping”: {“Cost”: “US $360.00”, “Origin”: “Greater China”, “Estimated Delivery”: “Between Fri, Oct 31 and Fri, Nov 28”}, “Specifications”: {“Speed”: “3000…

8. Rain for Rent – Diesel Pumps

Domain: rainforrent.com

Registered: 1996 (29 years)

Introduction: Diesel pumps from Rain for Rent range in flows from 200 to 24,000 GPM. Trailer or skid mounts enable maximum portability. High head diesel pumps provide pressure up to 950 feet. Product specifications include:

– DV200c SA 12″x8″ Pump: Max Flow 4600 GPM, Max Head 260 ft

– HH225c LD SA 10″x8″ High Head Pump: Max Flow 365 ft, Self-Priming

– DV150B SD SA 6″x6″ Pump: Max Flow 2,157 GPM, Max Head 160…

Strategic Sourcing Conclusion and Outlook for diesel irrigation pump

What Are the Key Insights for B2B Buyers in Diesel Irrigation Pumps?

In summary, strategic sourcing for diesel irrigation pumps is essential for optimizing agricultural productivity and efficiency. Key takeaways include the importance of selecting high-quality, durable pumps that meet specific irrigation needs, as well as the necessity of considering factors such as engine performance, fuel efficiency, and ease of maintenance. Establishing strong relationships with reliable suppliers can lead to favorable pricing, timely delivery, and access to the latest technologies.

How Can Strategic Sourcing Enhance Your Competitive Edge?

Investing in diesel irrigation pumps that align with local conditions and agricultural practices can significantly enhance yield and profitability for B2B buyers in regions like Africa, South America, the Middle East, and Europe. As global demand for efficient irrigation solutions continues to rise, now is the time to evaluate your sourcing strategies and explore innovative options that can lead to long-term success.

What’s Next for International Buyers of Diesel Irrigation Pumps?

We encourage international buyers to actively engage with manufacturers and distributors, leveraging market insights and technological advancements to make informed purchasing decisions. By prioritizing strategic sourcing, you can ensure that your agricultural operations remain competitive and resilient in an ever-evolving landscape. Take action today to secure the right diesel irrigation pump solutions for your needs and drive sustainable growth in your business.