Introduction: Navigating the Global Market for irrigation control valve on or off

In the complex landscape of agricultural and landscape irrigation, understanding the nuances of irrigation control valves—specifically their on and off functionalities—can be a pivotal challenge for international B2B buyers. The ability to accurately source and implement these valves is essential for optimizing water usage and ensuring efficient irrigation systems, especially in regions like Africa, South America, the Middle East, and Europe, where water scarcity is a growing concern. This guide delves into the various types of irrigation control valves, their applications, and the critical factors influencing purchasing decisions, such as supplier vetting, cost considerations, and maintenance.

Navigating the global market for irrigation control valves requires a keen understanding of not only the products themselves but also the specific needs of diverse agricultural practices across different geographies. By addressing the intricacies of valve selection, installation, and operational efficiency, this comprehensive guide empowers B2B buyers to make informed decisions. From analyzing the latest technologies in solenoid and manual valves to providing insights into supplier reliability and pricing strategies, our aim is to equip buyers with the knowledge necessary to enhance their irrigation systems. With this guide, you will be well-prepared to tackle the challenges of sourcing effective irrigation control solutions that meet the demands of your unique market environment.

Understanding irrigation control valve on or off Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Solenoid Valve | Electrically operated, remote control | Large-scale agricultural irrigation | Pros: Automated control, precise operation. Cons: Higher initial cost, requires electrical setup. |

| Manual Gate Valve | Hand-operated, simple design | Small farms, residential gardening | Pros: Low cost, easy maintenance. Cons: Labor-intensive, less efficient for large operations. |

| Anti-Siphon Valve | Prevents backflow, typically above ground | Commercial landscaping, urban irrigation | Pros: Protects water supply, easy access. Cons: Can be prone to clogging, limited pressure handling. |

| Pressure Regulating Valve | Maintains consistent pressure across systems | High-value crops, delicate irrigation needs | Pros: Reduces water waste, protects infrastructure. Cons: Can be complex, higher maintenance needs. |

| Zone Control Valve | Manages multiple irrigation zones | Sports fields, golf courses | Pros: Efficient water use, tailored irrigation. Cons: More complex installation, potential for failure in multiple zones. |

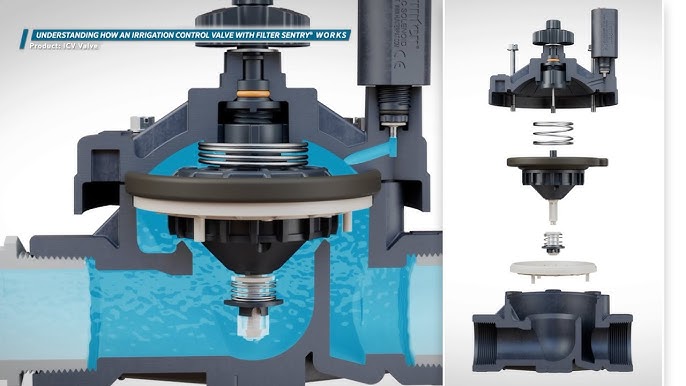

What Are the Characteristics of Solenoid Valves in Irrigation Systems?

Solenoid valves are electrically operated devices that allow for automated control of water flow in irrigation systems. They are commonly used in large-scale agricultural applications where precise timing and water delivery are crucial. B2B buyers should consider the initial investment and the need for electrical infrastructure, but the benefits of automation and efficiency can lead to significant long-term savings.

How Do Manual Gate Valves Function in Irrigation Applications?

Manual gate valves are straightforward, hand-operated mechanisms that control water flow. They are ideal for smaller farms or residential gardens where simplicity and cost-effectiveness are prioritized. While they require manual operation, which can be labor-intensive, their low maintenance and straightforward design make them appealing for certain B2B applications.

What Makes Anti-Siphon Valves Essential for Irrigation?

Anti-siphon valves are designed to prevent backflow, ensuring that contaminated water does not enter the main supply. Typically installed above ground, they are essential in commercial landscaping and urban irrigation systems. While they provide significant protection for water supplies, buyers should be aware of potential clogging issues and the limited pressure handling capabilities.

Why Are Pressure Regulating Valves Important for Irrigation Systems?

Pressure regulating valves are crucial for maintaining consistent water pressure throughout irrigation systems, particularly in areas with varying elevations or in high-value crop cultivation. These valves help reduce water waste and protect irrigation infrastructure from damage due to excessive pressure. However, their complexity and maintenance requirements should be carefully considered by B2B buyers.

How Do Zone Control Valves Optimize Irrigation Efficiency?

Zone control valves allow for the management of multiple irrigation zones, enabling tailored watering strategies for different areas. They are particularly beneficial in environments such as sports fields or golf courses, where varying irrigation needs exist. While they enhance efficiency and water use, B2B buyers must consider the complexity of installation and the potential for failure across multiple zones.

Key Industrial Applications of irrigation control valve on or off

| Industry/Sector | Specific Application of irrigation control valve on or off | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Automated irrigation systems for crop management | Enhances water efficiency and crop yield | Durability, compatibility with existing systems, local regulations |

| Landscaping and Horticulture | Smart irrigation for parks and gardens | Reduces water wastage and maintenance costs | Weather-resistance, ease of installation, adaptability to diverse climates |

| Municipal Water Management | Control of water flow in public parks and green spaces | Improved resource management and sustainability | Compliance with municipal standards, scalability, and reliability |

| Golf Course Management | Precision irrigation for greens and fairways | Optimizes water use and improves turf quality | Precision control capabilities, integration with existing systems, service support |

| Industrial Facilities | Cooling water systems in manufacturing processes | Reduces operational costs and enhances efficiency | Robustness under pressure, ease of maintenance, supplier reliability |

How is ‘Irrigation Control Valve On or Off’ Used in Agriculture?

In agriculture, irrigation control valves are pivotal for managing water distribution efficiently across fields. These valves can be automated to regulate the water flow based on soil moisture levels or weather conditions, significantly enhancing water conservation and crop yield. For international buyers, especially in regions like Africa and South America, sourcing durable and weather-resistant valves that comply with local agricultural practices is essential. Additionally, understanding the compatibility with existing irrigation systems can prevent costly upgrades or replacements.

What Role Do Irrigation Control Valves Play in Landscaping and Horticulture?

In landscaping and horticulture, irrigation control valves are integral to smart irrigation systems designed for parks and gardens. They help in minimizing water wastage by ensuring that water is only supplied when needed, thereby reducing maintenance costs. Buyers in the Middle East, where water scarcity is a concern, should prioritize valves that are weather-resistant and can withstand high temperatures. Furthermore, ease of installation and adaptability to various landscape designs are crucial factors for sourcing.

How Do Municipal Water Management Systems Utilize Irrigation Control Valves?

Municipal water management systems employ irrigation control valves to regulate the water flow in public parks and green spaces. These valves contribute to improved resource management and sustainability by ensuring optimal water usage. For European municipalities, compliance with local environmental regulations is paramount. When sourcing, municipalities should consider the scalability of the valve systems and their reliability to handle varying water pressure levels, ensuring consistent operation.

Why Are Irrigation Control Valves Important for Golf Course Management?

In golf course management, precision irrigation is vital for maintaining the quality of greens and fairways. Irrigation control valves allow for targeted watering, which optimizes water use and enhances turf quality. Buyers from regions with varying climates, like Europe and the Middle East, should look for valves with precision control capabilities that can integrate seamlessly with existing irrigation systems. Service support and the ability to withstand the rigors of commercial use are also key considerations.

How Are Irrigation Control Valves Used in Industrial Facilities?

In industrial facilities, irrigation control valves are critical for managing cooling water systems in manufacturing processes. By controlling water flow efficiently, these valves can help reduce operational costs and enhance overall efficiency. Buyers should focus on sourcing robust valves that can handle high pressure and are easy to maintain, ensuring minimal downtime. Supplier reliability is also essential, particularly for industries that operate under tight production schedules.

3 Common User Pain Points for ‘irrigation control valve on or off’ & Their Solutions

Scenario 1: Stuck Valves Preventing Efficient Operation

The Problem: B2B buyers often encounter irrigation control valves that are difficult to operate, especially in older systems. For example, a buyer may find that the valves are stuck due to corrosion or sediment build-up, making it impossible to switch the system from “off” to “on” or vice versa. This issue can lead to water waste, inefficient irrigation, and ultimately, damage to crops or landscapes, which is particularly concerning in regions where water is scarce or costly.

The Solution: To resolve this issue, it is essential to perform regular maintenance on irrigation control valves. Buyers should consider investing in high-quality, corrosion-resistant valves specifically designed for their environment. In cases of stuck valves, a combination of penetrating oil and gentle mechanical force can help. Apply the oil to the valve stems and allow it to penetrate for a few hours. If manual operation is still not possible, using a valve wrench designed for irrigation systems can provide the necessary leverage without damaging the valve. Additionally, when specifying valves for new installations, look for models with built-in features such as anti-corrosion coatings or self-cleaning mechanisms that reduce the likelihood of future issues.

Scenario 2: Confusion Over Valve Position and System Functionality

The Problem: Many buyers struggle with understanding the correct positions of their irrigation control valves, particularly when trying to troubleshoot or optimize system performance. For instance, a buyer may find that while the control panel indicates the system should be running, the irrigation heads show no water. This confusion can stem from a lack of clarity about whether the valves should be “on” or “off” for the control panel to function correctly, leading to ineffective irrigation strategies and potential crop loss.

The Solution: Buyers need to familiarize themselves with the operational characteristics of their specific irrigation system. A practical step is to create a clear diagram or documentation of the system layout, detailing each valve’s function and its corresponding control panel settings. Additionally, investing in training for staff on how to operate and troubleshoot the system can greatly enhance understanding. When purchasing new systems or components, buyers should ensure that clear operational guidelines are included, possibly even as part of a digital platform that allows for easy reference. For immediate troubleshooting, buyers can manually check each valve’s position and ensure they are set according to the control panel’s instructions, taking care to adjust based on pressure readings if necessary.

Scenario 3: Pressure Build-Up Issues in Irrigation Systems

The Problem: Another common pain point for B2B buyers is experiencing pressure build-up within their irrigation systems, particularly when certain control valves are inadvertently left in the “off” position. This can lead to water hammer, causing noise and potential damage to pipes and fittings. In some cases, buyers might notice that the system operates inefficiently, with irregular water distribution or even bursts in extreme cases.

The Solution: To mitigate pressure build-up, buyers should implement a systematic approach to valve management. First, they should regularly monitor the pressure levels in the system using pressure gauges. When setting up the irrigation system, it is crucial to ensure that all valves are correctly positioned based on the desired irrigation schedule. Buyers can also consider installing pressure relief valves to automatically mitigate excessive pressure. Furthermore, using variable rate irrigation (VRI) systems can help optimize water usage and reduce pressure fluctuations. If buyers frequently encounter pressure issues, consulting with an irrigation specialist can provide tailored solutions and help adjust system components for improved efficiency and reliability.

Strategic Material Selection Guide for irrigation control valve on or off

What are the Common Materials for Irrigation Control Valves?

When selecting materials for irrigation control valves, it is essential to consider their properties, advantages, and limitations. The right choice can significantly impact the efficiency and longevity of the irrigation system, especially in diverse climates and conditions found in regions like Africa, South America, the Middle East, and Europe.

How Does Brass Perform as a Material for Irrigation Control Valves?

Brass is a popular choice for irrigation control valves due to its excellent corrosion resistance and mechanical strength. It can handle high-pressure applications and has a temperature rating that suits various irrigation needs. However, brass can be more expensive than other materials and may require more complex manufacturing processes.

Pros:

– High durability and longevity.

– Good resistance to corrosion, particularly in water-based environments.

Cons:

– Higher cost compared to alternatives like PVC.

– Can be affected by dezincification in certain water conditions.

In applications involving potable water or systems exposed to harsh chemicals, brass valves are often preferred due to their reliability and performance.

Why is PVC a Common Choice for Irrigation Control Valves?

Polyvinyl Chloride (PVC) is widely used in irrigation systems for its lightweight nature and resistance to corrosion. PVC valves are typically rated for lower pressures than brass but are suitable for many agricultural and residential applications. They are also cost-effective and easier to install.

Pros:

– Low cost and lightweight, reducing installation labor.

– Excellent chemical resistance, making them suitable for various irrigation media.

Cons:

– Limited temperature range; can become brittle in extreme cold.

– Lower pressure ratings compared to metals.

International buyers should note that PVC is often compliant with ASTM standards, making it a reliable choice for many regions.

What Role Does Stainless Steel Play in Irrigation Control Valves?

Stainless steel is another robust option, known for its exceptional strength and corrosion resistance. It is particularly effective in environments where valves are exposed to saline or acidic conditions. Stainless steel valves can handle high pressures and temperatures, making them suitable for industrial applications.

Pros:

– Superior corrosion resistance, especially in harsh environments.

– High durability and strength, suitable for high-pressure applications.

Cons:

– Generally more expensive than brass and PVC.

– Heavier, which may complicate installation.

For B2B buyers in regions with aggressive water chemistry, stainless steel valves can be a long-lasting investment.

How Does Ductile Iron Compare for Irrigation Control Valves?

Ductile iron is often used for larger irrigation systems due to its strength and ability to withstand high pressures. It is less common for smaller residential applications but is favored in municipal and agricultural settings. Ductile iron valves are typically coated to enhance corrosion resistance.

Pros:

– High strength and durability, suitable for heavy-duty applications.

– Excellent pressure handling capabilities.

Cons:

– Heavier and more challenging to install than other materials.

– Requires protective coatings to prevent corrosion.

For international buyers, ductile iron valves must comply with local standards, such as DIN or JIS, depending on the region.

Summary Table of Material Selection for Irrigation Control Valves

| Material | Typical Use Case for irrigation control valve on or off | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Residential and commercial irrigation systems | High durability and corrosion resistance | Higher cost and potential dezincification | High |

| PVC | Agricultural and residential irrigation | Lightweight and cost-effective | Limited temperature range and pressure ratings | Low |

| Stainless Steel | Industrial irrigation systems exposed to harsh conditions | Superior corrosion resistance | Higher cost and heavier weight | High |

| Ductile Iron | Municipal and large agricultural applications | High strength and pressure handling capabilities | Heavier and requires protective coatings | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the properties and applications of different materials for irrigation control valves. Understanding these factors can help in making informed purchasing decisions tailored to specific operational needs and environmental conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for irrigation control valve on or off

What Are the Key Stages in the Manufacturing Process of Irrigation Control Valves?

Manufacturing irrigation control valves involves several critical stages, each essential for producing a reliable and durable product. These stages include material preparation, forming, assembly, and finishing.

Material Preparation

The process begins with the selection of high-quality materials, typically brass, stainless steel, or durable plastics. These materials are chosen for their resistance to corrosion and wear. The raw materials are then cut to specific dimensions and inspected for any defects. Suppliers often adhere to international standards to ensure material quality, which is a crucial factor for B2B buyers.Forming Techniques

The forming stage utilizes techniques like casting, machining, and molding. For brass valves, die casting is a common method, allowing for intricate designs and shapes. Machining processes, such as CNC milling, ensure precise dimensions and tolerances. Additionally, plastic components may undergo injection molding to create complex geometries efficiently.Assembly of Components

Once the individual parts are formed, they move to the assembly line. Skilled technicians assemble the valve components, which may include solenoids, diaphragms, and handles. Automated systems are increasingly used in assembly to enhance speed and precision. This stage often involves the installation of seals and gaskets to ensure leak-proof functionality.Finishing Processes

The final stage of manufacturing focuses on surface treatment and finishing. Techniques such as electroplating, powder coating, or anodizing are employed to enhance the valve’s resistance to environmental factors. These treatments not only improve aesthetic appeal but also contribute to the longevity of the product.

What Quality Assurance Measures Are Essential for Irrigation Control Valves?

Quality assurance (QA) is a pivotal aspect of manufacturing irrigation control valves. It ensures that the final products meet both international standards and customer expectations.

International Standards Compliance

Adhering to international quality standards, such as ISO 9001, is essential for manufacturers. This certification indicates that a company has established a robust quality management system. Industry-specific certifications, such as CE marking for European markets and API standards for oil and gas applications, also play a crucial role in ensuring compliance and product safety.Quality Control Checkpoints

Effective quality control involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Raw materials are inspected before production to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Regular inspections during manufacturing help identify any defects early, minimizing waste and rework.

– Final Quality Control (FQC): The finished products undergo rigorous testing to verify functionality, durability, and compliance with specifications.Common Testing Methods for Valves

Various testing methods are employed to ensure quality, including:

– Pressure Testing: Valves are subjected to high-pressure conditions to verify their ability to withstand operational stresses.

– Leak Testing: This involves checking for leaks under pressure to ensure the integrity of the seal.

– Functionality Testing: Each valve is tested to confirm that it operates correctly, both in manual and automated modes.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is crucial.

Conducting Supplier Audits

One effective method is to conduct on-site audits of the manufacturing facility. These audits allow buyers to assess the supplier’s quality management systems, production processes, and adherence to safety standards. Audits can also reveal the supplier’s commitment to continuous improvement.Requesting Quality Reports

Buyers should request quality assurance reports, which should include details on testing methods, inspection results, and compliance with international standards. These documents provide transparency and help buyers make informed decisions.Utilizing Third-Party Inspection Services

Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality control processes. These agencies conduct inspections and testing, ensuring that products meet the required specifications before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers operating in different regions must consider various nuances in quality control.

Regional Standards and Compliance

Understanding the specific quality standards and regulations in the target market is essential. For instance, European buyers might prioritize CE certification, while Middle Eastern buyers may look for compliance with local regulations and standards.Cultural Differences in Quality Perception

Cultural perceptions of quality can vary significantly. Buyers should be aware of these differences when negotiating and establishing quality expectations. Clear communication and mutual understanding are vital to ensure that both parties align on quality standards.Supply Chain Reliability

Evaluating the reliability of the supply chain is crucial for maintaining quality. Buyers should assess the supplier’s ability to deliver consistent quality over time, considering factors such as production capacity, lead times, and responsiveness to quality issues.

By understanding the intricacies of manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing irrigation control valves. This knowledge not only helps in selecting reliable suppliers but also ensures the long-term performance and durability of irrigation systems in diverse environments.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘irrigation control valve on or off’

In the competitive landscape of irrigation management, procuring the right irrigation control valves is crucial for optimizing water usage and ensuring system efficiency. This guide provides a step-by-step checklist tailored for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Establishing your technical specifications is the foundation of a successful procurement process. Consider factors such as flow rate, pressure requirements, and the types of valves needed (manual or solenoid). Clearly defined specifications will help you communicate effectively with suppliers and ensure that the products meet your operational needs.

Step 2: Assess Compatibility with Existing Systems

Before purchasing, evaluate how the new valves will integrate with your current irrigation system. Check for compatibility with existing components, including piping, control systems, and other hardware. This step is essential to avoid costly modifications or system downtimes after installation.

Step 3: Evaluate Potential Suppliers

Conduct a thorough evaluation of potential suppliers to ensure reliability and quality. Request company profiles, product catalogs, and references from similar industries. Look for suppliers with a proven track record in the irrigation sector, particularly those familiar with the specific challenges of your region.

Step 4: Verify Certifications and Compliance

Ensure that the products comply with international standards and local regulations. Certifications such as ISO or specific agricultural standards indicate that the supplier adheres to quality and safety benchmarks. This verification is crucial for maintaining operational integrity and avoiding legal issues related to product compliance.

Step 5: Request Samples or Prototypes

Before making a bulk purchase, request samples or prototypes of the irrigation control valves. Testing these samples in real-world conditions allows you to assess their performance and durability. This step minimizes the risk of investing in products that do not meet your expectations or operational demands.

Step 6: Evaluate Pricing and Payment Terms

Consider the total cost of ownership, which includes not only the initial purchase price but also shipping, installation, and maintenance costs. Compare pricing from multiple suppliers and negotiate favorable payment terms. Understanding the financial implications will help you make a more informed decision.

Step 7: Plan for After-Sales Support and Maintenance

Investing in irrigation control valves is not just about the initial purchase; it also involves planning for long-term support. Inquire about after-sales services, warranty terms, and availability of spare parts. A supplier that offers robust support can significantly enhance the longevity and efficiency of your irrigation system.

By following this comprehensive checklist, B2B buyers can navigate the complexities of sourcing irrigation control valves effectively, ensuring a well-functioning irrigation system that meets their specific needs.

Comprehensive Cost and Pricing Analysis for irrigation control valve on or off Sourcing

What Are the Key Cost Components for Sourcing Irrigation Control Valves?

When analyzing the cost structure for irrigation control valves, several components must be considered. These include:

Materials: The primary materials used in irrigation control valves typically include brass, plastic, and rubber. The choice of materials can significantly influence the overall cost. For instance, brass valves are generally more durable but also more expensive compared to plastic options.

Labor: Labor costs encompass the wages paid to workers involved in manufacturing and assembling the valves. This can vary widely based on the geographical location of the manufacturing facility and the skill level of the workforce.

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help lower these costs, impacting the final pricing.

Tooling: The cost of tooling refers to the investment in molds and machinery required for producing the valves. Custom tooling for specialized valves can add significant upfront costs.

Quality Control (QC): Ensuring that the valves meet industry standards requires investment in quality control processes. This may involve testing and inspection, which can further influence pricing.

Logistics: Shipping and handling costs also play a crucial role in the total cost structure. Factors such as distance, mode of transport, and packaging can affect logistics expenses.

Margin: Finally, suppliers will include a profit margin in their pricing. This varies based on market conditions and the competitive landscape.

How Do Price Influencers Affect the Cost of Irrigation Control Valves?

Several factors can influence the pricing of irrigation control valves in the B2B market:

Volume/MOQ: Bulk orders often lead to reduced per-unit pricing. Suppliers may offer discounts for larger volumes, making it advantageous for buyers to consolidate their orders.

Specifications and Customization: Customization can significantly impact pricing. Standard valves will generally be less expensive than those tailored to specific requirements, such as unique sizes or materials.

Materials and Quality Certifications: Higher quality materials and certifications (e.g., ISO, CE) can lead to increased costs. Buyers should assess whether the added expense aligns with their operational needs.

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer competitive rates to gain market share.

Incoterms: Understanding Incoterms is vital for international transactions. The chosen terms dictate responsibility for shipping costs, insurance, and risk, ultimately affecting the total landed cost of the valves.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Irrigation Control Valves?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

Negotiation: Engaging in negotiation can yield better pricing. Buyers should be prepared to discuss volume commitments and long-term partnerships to leverage discounts.

Total Cost of Ownership (TCO): Consider the TCO rather than just the initial purchase price. This includes maintenance, durability, and energy efficiency, which can affect long-term operational costs.

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and import duties that can impact the final cost. Establishing relationships with local distributors may mitigate some of these challenges.

Research and Compare: Conduct thorough research on multiple suppliers and compare their offerings. This includes evaluating product quality, service levels, and delivery timelines.

Leverage Technology: Utilize procurement platforms and software to streamline the sourcing process, helping to identify the best suppliers and pricing options available in the market.

Disclaimer on Indicative Prices

Pricing for irrigation control valves can vary significantly based on the factors discussed. It is advisable for buyers to seek specific quotes from suppliers, taking into account their unique requirements and market conditions to ensure accurate budgeting.

Alternatives Analysis: Comparing irrigation control valve on or off With Other Solutions

Introduction: Exploring Alternatives to Irrigation Control Valves

In the world of irrigation management, the choice of technology can significantly impact both efficiency and cost-effectiveness. While the traditional approach of using irrigation control valves—either in the ‘on’ or ‘off’ position—has been a staple in agricultural practices, alternative solutions are gaining traction. This section evaluates the performance, cost, implementation ease, maintenance requirements, and best use cases for different methods of irrigation control, allowing international B2B buyers to make informed decisions tailored to their unique needs.

Comparison Table

| Comparison Aspect | Irrigation Control Valve On or Off | Smart Irrigation Controllers | Drip Irrigation Systems |

|---|---|---|---|

| Performance | Reliable but manual adjustments needed | Automated, precise control | Highly efficient water usage |

| Cost | Low initial cost, potential high long-term costs | Moderate initial investment, lower operational costs | High upfront costs, but significant savings over time |

| Ease of Implementation | Simple setup but requires manual operation | Requires installation and configuration | Requires careful planning and setup |

| Maintenance | Low maintenance, occasional checks needed | Requires software updates and periodic maintenance | Moderate maintenance, regular checks needed |

| Best Use Case | Small to medium-sized farms with basic needs | Large-scale operations needing automation | Water-scarce regions with high-value crops |

Detailed Breakdown of Alternatives

What Are Smart Irrigation Controllers and How Do They Compare?

Smart irrigation controllers utilize advanced technology to automate the watering process based on real-time data, such as weather conditions and soil moisture levels. They can optimize water usage by adjusting schedules and run times, leading to significant water savings. While they require a moderate initial investment, the long-term operational cost savings can be substantial, especially for larger operations. However, they do necessitate a more complex installation and configuration process, which might deter some users.

What Are the Advantages of Drip Irrigation Systems?

Drip irrigation systems deliver water directly to the plant roots, minimizing evaporation and runoff. This method is especially advantageous in arid regions where water conservation is critical. Although the upfront costs can be high, the efficiency gains and reduced water usage often lead to significant savings over time. The installation and planning require careful consideration, and while maintenance is moderate, regular checks ensure optimal performance and longevity of the system.

Conclusion: Choosing the Right Irrigation Solution for Your Needs

For international B2B buyers, the choice between using traditional irrigation control valves and exploring alternatives like smart irrigation controllers or drip systems hinges on specific operational requirements and environmental conditions. Buyers should evaluate factors such as the scale of their operations, initial budget constraints, and long-term water management goals. By considering these alternatives, businesses can enhance their irrigation efficiency, reduce costs, and adapt to the growing demands of sustainable agriculture. Each solution has its unique benefits and challenges, making it essential to align the chosen method with the specific needs of the agricultural context.

Essential Technical Properties and Trade Terminology for irrigation control valve on or off

What Are the Key Technical Properties of Irrigation Control Valves?

When considering irrigation control valves, several technical properties are critical for ensuring optimal performance and reliability in various conditions. Understanding these specifications can significantly influence purchasing decisions for B2B buyers.

What Material Grades Are Common in Irrigation Control Valves?

The material grade of an irrigation control valve is essential for durability and corrosion resistance. Common materials include:

Brass: Known for its strength and resistance to corrosion, brass is often used in solenoid and manual valves. It provides longevity in various environments but may be more expensive.

PVC: Lightweight and resistant to corrosion, PVC valves are popular in low-pressure systems. They are cost-effective but may not withstand extreme temperatures or pressures.

Stainless Steel: For applications requiring high durability, stainless steel valves offer excellent resistance to corrosion and can handle higher pressures and temperatures, making them suitable for diverse climates.

How Does Tolerance Affect Irrigation Control Valve Performance?

Tolerance refers to the permissible limits of variation in a valve’s dimensions. This specification is crucial for ensuring that the valve fits properly within the irrigation system, preventing leaks and ensuring effective operation. High tolerance levels (e.g., ±0.5 mm) are vital for maintaining system integrity and reducing the risk of failure in critical applications.

Why Is Flow Rate Important in Irrigation Control Valves?

Flow rate, measured in gallons per minute (GPM) or liters per minute (LPM), indicates the volume of water that can pass through the valve. Understanding the flow rate is essential for ensuring that the irrigation system meets the requirements of the landscape or agricultural area being serviced. A mismatch can lead to inadequate watering or damage to the system due to excessive pressure.

What Is the Significance of Pressure Rating in Valves?

The pressure rating of a valve indicates the maximum pressure it can handle without failing. This is particularly important in regions with high water pressure or fluctuating conditions. Selecting a valve with an appropriate pressure rating helps prevent leaks and catastrophic failures, ensuring a reliable irrigation system.

What Are Common Trade Terms in the Irrigation Control Valve Industry?

Familiarity with industry jargon can facilitate smoother transactions and communications between buyers and suppliers. Here are some essential terms:

What Does OEM Stand For in the Irrigation Industry?

OEM, or Original Equipment Manufacturer, refers to companies that produce components for other companies to use in their products. Understanding OEM relationships can help B2B buyers identify quality suppliers and ensure compatibility with existing systems.

Why Is MOQ Important for Bulk Purchases?

MOQ stands for Minimum Order Quantity, the smallest amount a supplier is willing to sell. Knowing the MOQ helps buyers plan their purchases effectively, ensuring they meet supplier requirements while managing inventory levels.

What Is an RFQ and How Does It Benefit Buyers?

An RFQ, or Request for Quotation, is a document sent to suppliers to solicit price quotes for specific products. This process allows buyers to compare prices, negotiate terms, and ensure they receive competitive offers, ultimately leading to more informed purchasing decisions.

How Do Incoterms Affect International Shipping?

Incoterms (International Commercial Terms) are standardized terms used in international trade to define the responsibilities of buyers and sellers. Understanding these terms is crucial for B2B buyers involved in global transactions, as they clarify who is responsible for shipping costs, insurance, and risks during transportation.

By grasping these essential technical properties and trade terminologies, B2B buyers in the irrigation control valve market can make informed decisions that align with their operational needs and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the irrigation control valve on or off Sector

What Are the Current Market Dynamics Affecting the Irrigation Control Valve Sector?

The global irrigation control valve market is experiencing significant transformation driven by technological advancements and environmental imperatives. Key trends include the integration of smart irrigation systems, which utilize IoT (Internet of Things) technology to enhance water efficiency and automate control functions. This shift is particularly relevant for international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, where water scarcity is a pressing issue. Buyers are increasingly seeking valves that not only perform efficiently but also support smart agricultural practices.

Moreover, the demand for durable and reliable valves is growing, especially in areas with extreme weather conditions. In regions like Saudi Arabia and Vietnam, the ability to withstand harsh environments is crucial, prompting buyers to prioritize sourcing from manufacturers known for quality and resilience. Furthermore, the trend towards modular and customizable solutions allows buyers to adapt systems to specific agricultural needs, enhancing operational efficiency.

Emerging sourcing strategies also reflect a shift towards direct relationships with manufacturers, enabling buyers to gain better insights into product capabilities and innovations. Collaborating with suppliers who understand local market conditions and regulatory requirements can provide a competitive edge. Overall, B2B buyers are encouraged to stay informed about technological advancements and to leverage these trends for improved irrigation management.

How Are Sustainability and Ethical Sourcing Impacting the Irrigation Control Valve Market?

As the global focus on sustainability intensifies, B2B buyers in the irrigation control valve sector are increasingly prioritizing environmentally friendly and ethically sourced products. The manufacturing process of control valves often involves materials that can have significant environmental impacts. Therefore, buyers are looking for suppliers who adhere to sustainable practices, such as using recycled materials and minimizing waste.

The demand for ‘green’ certifications is on the rise, with buyers seeking valves that meet recognized environmental standards. Certifications such as ISO 14001 for environmental management systems or LEED (Leadership in Energy and Environmental Design) can serve as indicators of a supplier’s commitment to sustainability. Furthermore, the use of innovative materials, such as bio-based plastics or sustainably sourced metals, is becoming a key consideration in the procurement process.

Ethical supply chains are also gaining importance, with buyers increasingly scrutinizing the labor practices of their suppliers. Transparency in sourcing and manufacturing processes not only enhances brand reputation but also fosters trust with consumers who are increasingly concerned about the origins of the products they use. By prioritizing sustainability and ethical sourcing, B2B buyers can not only comply with regulatory requirements but also contribute to broader environmental goals, aligning their procurement strategies with global sustainability initiatives.

What Is the Historical Context of Irrigation Control Valve Technology?

The evolution of irrigation control valves has been shaped by the need for efficient water management in agriculture and landscaping. Traditionally, these valves were manual, requiring physical adjustments to control water flow. However, as agricultural practices evolved, the introduction of solenoid-operated valves marked a significant advancement. This technology allowed for automated irrigation systems, enabling farmers and landscape managers to optimize water usage without constant manual intervention.

Over the years, innovations in materials and design have improved the durability and functionality of these valves. Modern irrigation control valves now incorporate features such as pressure regulation and flow control, further enhancing their efficiency. The rise of smart irrigation systems represents the latest phase in this evolution, integrating real-time data and automation to meet the growing demands of sustainable agriculture. This historical context underscores the importance of continuous innovation in the sector, as B2B buyers seek solutions that align with modern agricultural practices and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of irrigation control valve on or off

How do I solve issues with stuck irrigation control valves?

If you encounter stuck irrigation control valves, it’s essential first to identify the type of valve you are dealing with—manual or solenoid. For manual valves, carefully apply a penetrating lubricant to the handle and allow it to sit for a few minutes before attempting to turn it. If the valve is a solenoid, ensure the power is off before inspecting for debris or damage. If the valve remains stuck, consider consulting a local irrigation specialist to avoid damaging the system.What is the best type of irrigation control valve for high-pressure systems?

For high-pressure irrigation systems, brass solenoid valves are often the best choice due to their durability and resistance to corrosion. They can handle higher pressure levels and are less likely to fail compared to plastic alternatives. Ensure the valve’s specifications match your system’s pressure requirements. It’s advisable to consult with your supplier about the best options tailored to your specific irrigation needs.How can I verify the credibility of an irrigation control valve supplier?

To verify a supplier’s credibility, check for industry certifications, customer reviews, and case studies showcasing their products in similar applications. Request references from existing clients and consider visiting their manufacturing facilities if possible. Participation in international trade shows can also be a good indicator of a reputable supplier, as it shows their commitment to quality and innovation in the field.What are the typical minimum order quantities (MOQ) for irrigation control valves?

Minimum order quantities for irrigation control valves can vary significantly between suppliers. Typically, you might encounter MOQs ranging from 50 to 500 units, depending on the type and size of the valve. It’s essential to discuss your requirements with potential suppliers to negotiate favorable terms, especially if you are a smaller buyer or need a custom order.What payment terms should I expect when sourcing irrigation control valves internationally?

Payment terms can vary by supplier and region but commonly include options such as upfront payment, partial payment upon order confirmation, and the balance upon shipment. Letters of credit are often used for larger transactions to protect both parties. Always discuss payment options early in negotiations to ensure they align with your cash flow and risk management strategies.How can I ensure quality assurance for my irrigation control valve orders?

To ensure quality assurance, request detailed product specifications and certifications from your supplier. Implement a third-party inspection process before shipment to verify product standards. Establish clear quality criteria and communicate these to your supplier. Regular audits and building strong relationships can also help maintain consistent quality throughout your orders.What logistics considerations should I keep in mind when importing irrigation control valves?

When importing irrigation control valves, consider shipping methods, customs regulations, and duties applicable to your region. Work with a logistics partner who has experience with agricultural products to navigate the complexities of international shipping. Additionally, factor in lead times for production and delivery to avoid disruptions in your irrigation projects.Can irrigation control valves be customized for specific applications?

Yes, many suppliers offer customization options for irrigation control valves, including size, pressure ratings, and materials. When discussing your needs, provide detailed specifications and application requirements to ensure the product meets your expectations. Customization may impact lead times and costs, so it’s advisable to plan accordingly and confirm these details with your supplier.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Irrigation Control Valve On Or Off Manufacturers & Suppliers List

1. Reddit – Community Insights

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – Community Insights, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Lawn Forum – Irrigation Control Valves

Domain: thelawnforum.com

Registered: 2017 (8 years)

Introduction: Irrigation Control Valves, approximately 20 years old, green in color, featuring two cross handles that are extremely tight and cannot be turned by hand. They may be older brass control valves or manual shut-off valves, potentially used for manual control of an irrigation system that has been replumbed with solenoid valves for automatic operation.

3. Hunter – Pro-C Sprinkler System

Domain: lawnsite.com

Registered: 2000 (25 years)

Introduction: Hunter Pro-C sprinkler system, 5 solenoid valves, main brass valve, 1/4 turn mechanism for solenoid valves.

4. Angi – Irrigation Shut-Off Valve

Domain: angi.com

Registered: 1996 (29 years)

Introduction: The irrigation shut-off valve is typically located near the corners of the house or main building, just downstream of the backflow preventer. It can be found above-ground, inside the home (garage, utility closet, basement), or outside in a protective box near the water source. Below-ground valves are usually buried in a valve box with a green lid. The shut-off valve typically has a ball valve with…

5. JustAnswer – Plumbing & Irrigation Expertise

Domain: justanswer.com

Registered: 2004 (21 years)

Introduction: Expert insights on plumbing and irrigation systems, including advice on running sprinklers with the water supply off. Licensed Master plumber with over 50 years of experience available for consultation. Service provides fast responses to home improvement questions, including sprinkler system maintenance and potential damage risks. Membership offers access to over 12,000 verified experts for variou…

6. Christie’s Landscapes – Sprinkler Valves

Domain: christieslandscapes.com.au

Introduction: Sprinkler valves are a vital part of any irrigation system, translating instructions from the main control box into changes in water flow. The most common type used in sprinkler systems today are electronic solenoid valves, which are ‘normally closed’. This means they remain closed unless a signal is received from the control box or manually operated. To open the valve, a current is sent to the so…

Strategic Sourcing Conclusion and Outlook for irrigation control valve on or off

In summary, strategic sourcing of irrigation control valves—whether they are manual or solenoid-operated—is crucial for optimizing water management in agricultural and landscaping applications. Understanding the functionality of these valves allows buyers to make informed decisions that enhance system efficiency and reduce costs. Key factors to consider include the adaptability of valves to local conditions, ease of operation, and compatibility with existing systems.

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, leveraging strategic sourcing can lead to significant improvements in irrigation practices. By partnering with reliable suppliers who offer high-quality products and support, businesses can ensure sustainable water usage and boost crop yields or landscaping quality.

As the global demand for efficient irrigation systems continues to rise, now is the time to invest in cutting-edge solutions. Engage with suppliers who understand regional challenges and can offer tailored solutions that meet your specific needs. By doing so, you position your business for future growth and success in a competitive market.