Introduction: Navigating the Global Market for valve locator for irrigation system

In today’s competitive agricultural landscape, sourcing the right valve locator for irrigation systems is crucial for optimizing water management and enhancing crop yields. International B2B buyers face the challenge of navigating a diverse market filled with various products and suppliers, each claiming to offer the best solution. This guide aims to demystify the complexities of valve locators, covering essential topics such as types of locators, their specific applications, supplier vetting processes, and cost considerations.

By providing comprehensive insights into the functionality and features of different valve locators, this guide empowers B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, including countries such as Vietnam and Brazil. Understanding the distinct advantages and limitations of each product will enable businesses to make informed purchasing decisions that align with their operational needs and budget constraints.

Moreover, the guide emphasizes the importance of supplier reliability and product quality, ensuring that buyers can confidently engage with manufacturers and distributors. With actionable strategies and expert recommendations, this resource serves as a valuable tool for enhancing irrigation efficiency and achieving sustainable agricultural practices. Whether you’re an established agricultural firm or a new entrant in the market, equipping yourself with the right knowledge about valve locators is a significant step towards improving your irrigation systems.

Understanding valve locator for irrigation system Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| TEMPO Wire and Valve Locator | High power transmitter, long-nose receiver wand | Irrigation installation and maintenance | Pros: Long-range detection; reliable. Cons: Higher price point. |

| Click-It Valve Locator | Voltage interruption device for solenoid valves | Troubleshooting and diagnostics | Pros: Affordable; easy to use. Cons: Limited to solenoid valves. |

| Armada Pro-700 Locator | Lightweight, sensitive receiver, and beeping signal tracking | Irrigation wiring and valve tracking | Pros: Comprehensive tracking; rugged design. Cons: Requires battery replacement. |

| Rental Valve Locators | Cost-effective rental option, includes transmitter and receiver | Short-term projects or seasonal use | Pros: Low upfront cost; no long-term commitment. Cons: Availability may vary. |

| Handheld Wire Locators | Compact design, suitable for quick checks | Maintenance and quick diagnostics | Pros: Portable; user-friendly. Cons: Less effective for deep detection. |

What are the Key Characteristics of the TEMPO Wire and Valve Locator?

The TEMPO Wire and Valve Locator is recognized for its high power transmitter and long-nose receiver wand, which allows for extensive range detection. This tool is primarily utilized in the installation and maintenance of irrigation systems, making it ideal for B2B buyers in the agricultural sector. Its ability to locate wires and valve breaks enhances operational efficiency, though the investment may be higher compared to other options.

How Does the Click-It Valve Locator Work?

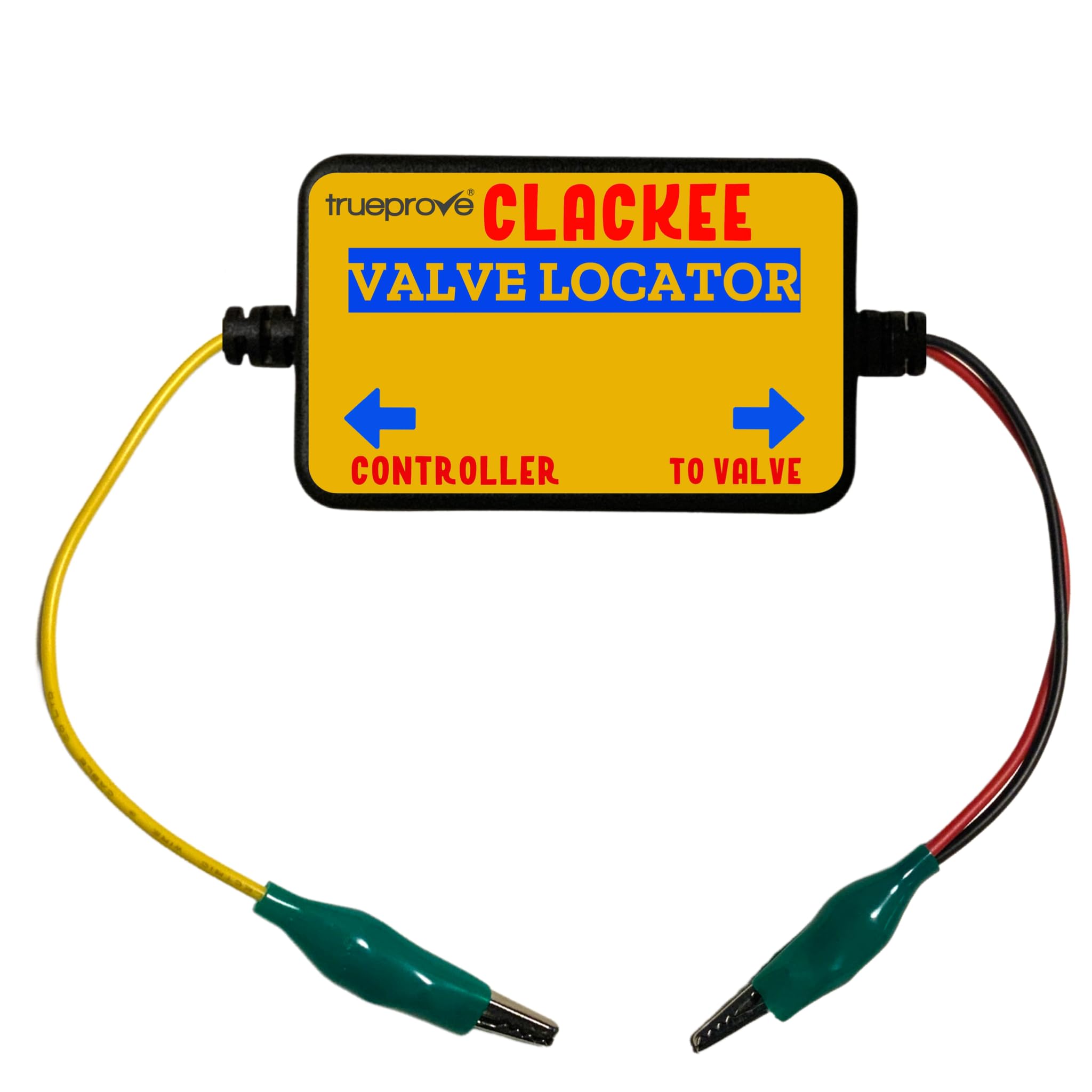

The Click-It Valve Locator operates by interrupting the voltage to solenoid valves, causing them to “chatter,” which helps in pinpointing their location. This makes it particularly suitable for troubleshooting and diagnostics in irrigation systems. Its affordability and ease of use are significant advantages for B2B buyers, especially those managing smaller operations or projects. However, its functionality is limited to solenoid valves, which may not meet all needs.

What Makes the Armada Pro-700 Locator a Popular Choice?

The Armada Pro-700 Wire and Valve Locator is designed for comprehensive tracking of irrigation wiring and valves, featuring a lightweight design and a beeping signal for guidance. This makes it highly effective for irrigation contractors and maintenance personnel. B2B buyers appreciate its rugged construction and detailed tracking capabilities, although it requires battery replacements, which adds to ongoing costs.

Why Consider Rental Valve Locators for Short-Term Projects?

Rental valve locators provide a cost-effective solution for businesses needing equipment for short-term projects or seasonal work. These devices typically include all necessary components, allowing users to avoid the high upfront costs of purchasing. However, availability can be a concern, and buyers must ensure they can secure the necessary equipment when needed.

What are the Benefits of Using Handheld Wire Locators?

Handheld wire locators are compact and designed for quick checks, making them ideal for maintenance tasks and rapid diagnostics. Their portability and user-friendly nature appeal to B2B buyers who require efficiency in their operations. Nonetheless, they may be less effective for deep detection, which could limit their applicability in more complex irrigation systems.

Key Industrial Applications of valve locator for irrigation system

| Industry/Sector | Specific Application of valve locator for irrigation system | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Locating underground irrigation valves for crop management | Enhances efficiency in managing water resources and reduces downtime during maintenance. | Compatibility with existing irrigation systems and ease of use. |

| Landscaping | Identifying valve locations in commercial landscaping projects | Improves project planning and execution, minimizing the risk of damaging existing systems. | Durability and performance in diverse environmental conditions. |

| Municipal Water Supply | Mapping irrigation systems in public parks and green spaces | Ensures effective maintenance and water conservation in public areas, enhancing community services. | Regulatory compliance and reliability of the locator technology. |

| Golf Course Management | Tracking irrigation valves to optimize water usage on courses | Reduces water waste and promotes sustainability, leading to cost savings and improved course quality. | Precision in locating valves and ease of integration with existing systems. |

| Sports Facilities | Managing irrigation for athletic fields, ensuring optimal playing conditions | Ensures consistent turf quality, improving the user experience and facility reputation. | Ability to handle varied soil types and underground conditions. |

How is a Valve Locator Used in Agriculture?

In the agricultural sector, valve locators are essential for locating underground irrigation valves, which are crucial for effective water management. Farmers use these tools to quickly identify valve positions, enabling them to maintain irrigation systems without extensive digging. This not only saves time but also prevents damage to crops and soil structure. For international buyers, especially in regions like Africa and South America, it’s vital to ensure that the valve locator can withstand varying soil conditions and is compatible with local irrigation technologies.

What Role Does a Valve Locator Play in Landscaping Projects?

In landscaping, the valve locator is instrumental in identifying existing irrigation valves during installation or maintenance projects. This is particularly important in commercial landscaping, where precise planning is required to avoid damaging underground utilities. By using a valve locator, landscapers can enhance project efficiency and reduce the risk of costly repairs. Buyers in Europe and the Middle East should consider locators that offer high durability and reliable performance in diverse climates.

Why is a Valve Locator Important for Municipal Water Supply?

Municipalities utilize valve locators to map out irrigation systems in public parks and green spaces. This application is critical for maintaining efficient water supply systems and ensuring compliance with water conservation regulations. By accurately locating valves, municipalities can perform timely maintenance, which helps in reducing water waste and improving service delivery. When sourcing these tools, it’s essential for buyers to prioritize technology that meets local regulatory standards and offers robust support.

How Does a Valve Locator Benefit Golf Course Management?

In golf course management, valve locators help in tracking irrigation systems, which are vital for maintaining optimal playing conditions. By ensuring accurate water distribution, golf courses can enhance turf quality while minimizing water usage. This is especially relevant for facilities aiming for sustainability and cost reduction. International buyers should focus on locators that are designed for precision and can handle diverse environmental challenges, particularly in regions with varying climates like Brazil and Vietnam.

How is a Valve Locator Utilized in Sports Facilities?

Sports facilities rely on valve locators to manage irrigation for athletic fields effectively. These tools allow facility managers to pinpoint valve locations quickly, ensuring that water is distributed evenly across the field, thus maintaining optimal turf conditions. This not only enhances the playing experience but also helps in preserving the integrity of the field. Buyers from regions with different soil types should ensure that the locators they choose are adaptable and provide accurate readings in various underground conditions.

3 Common User Pain Points for ‘valve locator for irrigation system’ & Their Solutions

Scenario 1: Inefficient Locating of Hidden Valves Leads to Downtime

The Problem: For many irrigation system operators, particularly in regions with extensive underground installations, locating buried valves can be a time-consuming and frustrating task. Traditional methods, such as manual digging or using basic detection tools, often result in unnecessary labor costs and extended downtime, which can significantly impact productivity. This is especially critical in areas where water management is vital for agriculture or landscaping, as delays can lead to crop damage or loss of business opportunities.

The Solution: Investing in a high-quality valve locator specifically designed for irrigation systems can drastically reduce downtime and improve efficiency. For instance, the TEMPO Wire and Valve Locator 521A is a robust tool that not only identifies the location of valves but also assesses the depth and detects any wire breaks. B2B buyers should prioritize sourcing devices that offer long-range detection capabilities and intuitive user interfaces, enabling quick and accurate identification of valve locations. Additionally, training staff on the effective use of these tools can further streamline operations, allowing for more precise and less labor-intensive searches.

Scenario 2: High Repair Costs from Undetected Faults

The Problem: Undetected faults in irrigation systems can lead to significant repair costs and wasted resources. For contractors managing large-scale installations, the inability to accurately trace wires and valves can result in unnecessary excavations and repairs, escalating expenses and project timelines. This pain point is particularly prevalent in regions where labor and materials are costly, making efficient problem-solving essential for maintaining profitability and customer satisfaction.

The Solution: Utilizing advanced valve locators like the Armada Technologies PRO-700 can mitigate these issues by providing detailed tracking of irrigation wiring and valves. This device not only locates valves but also identifies wiring faults, allowing for targeted repairs without extensive digging. B2B buyers should seek out locators that feature advanced signal technology and clear audio-visual indicators, ensuring that operators can quickly diagnose issues. Implementing regular maintenance checks using these tools can help in early detection of faults, significantly reducing overall repair costs and project delays.

Scenario 3: Difficulty in Training Staff on Locating Techniques

The Problem: A common challenge for irrigation system managers is training staff to effectively use valve locators, especially when dealing with newer technologies. In many cases, employees may lack the technical expertise needed to operate advanced locating devices, leading to misidentifications and inefficient use of resources. This can be particularly problematic in regions where skilled labor is scarce, and the training process can become a bottleneck for operations.

The Solution: To address this, companies should invest in comprehensive training programs that not only cover the use of valve locators but also the underlying principles of irrigation systems. Manufacturers often provide training resources, including manuals and video tutorials, which can be invaluable for onboarding new staff. Additionally, B2B buyers should consider tools with user-friendly designs that minimize the learning curve, such as the Click-It Valve Locator, which utilizes a straightforward voltage interruption method. Offering hands-on training sessions and creating a culture of continuous learning can empower employees to use these tools effectively, enhancing both individual and team productivity.

Strategic Material Selection Guide for valve locator for irrigation system

When selecting materials for valve locators in irrigation systems, it is crucial to consider the specific properties and performance characteristics of each material. This analysis focuses on four common materials: plastic, aluminum, stainless steel, and copper. Each material has unique advantages and disadvantages that can significantly impact the product’s performance, durability, and overall cost.

What are the Key Properties of Plastic for Valve Locators in Irrigation Systems?

Plastic is widely used in valve locators due to its lightweight nature and resistance to corrosion. Common types of plastics used include PVC and polycarbonate, which can withstand a range of temperatures and pressures. The key properties of plastic include its low density, good electrical insulation, and resistance to chemical degradation.

Pros: Plastic is generally less expensive than metals, making it an attractive option for cost-sensitive projects. It is also easy to manufacture and mold into complex shapes, which can enhance design flexibility.

Cons: While durable, plastic may not withstand extreme temperatures or heavy mechanical stress as well as metals. Additionally, it can be susceptible to UV degradation if exposed to sunlight over extended periods.

Impact on Application: Plastic valve locators are suitable for environments with moderate temperatures and where chemical exposure is limited. However, they may not be ideal for high-pressure applications.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers should also consider the availability of specific plastic grades that meet local regulations, especially in regions with stringent environmental controls.

How Does Aluminum Perform in Valve Locators for Irrigation Systems?

Aluminum is another popular choice for valve locators, known for its excellent strength-to-weight ratio and corrosion resistance. It can handle a variety of environmental conditions, making it suitable for outdoor applications.

Pros: Aluminum is lightweight, durable, and resistant to corrosion, which extends the lifespan of the locator. It is also relatively easy to machine and can be anodized for additional protection.

Cons: While aluminum is cost-effective, it may not be as strong as stainless steel in high-stress applications. Additionally, it can be more expensive than plastic.

Impact on Application: Aluminum valve locators are ideal for environments where weight is a concern, such as portable irrigation systems. They perform well in moderate to high-pressure applications.

Considerations for International Buyers: Buyers should ensure that the aluminum used complies with local standards and specifications, particularly in regions with specific requirements for metal products.

What are the Benefits of Using Stainless Steel in Valve Locators?

Stainless steel is renowned for its exceptional durability and corrosion resistance, making it a preferred material for valve locators in challenging environments. Its key properties include high tensile strength and resistance to rust and oxidation.

Pros: Stainless steel offers superior durability and is capable of withstanding extreme temperatures and pressures. It is also aesthetically pleasing, which can be a consideration for visible installations.

Cons: The primary disadvantage of stainless steel is its higher cost compared to plastic and aluminum. Additionally, it can be heavier, which may not be ideal for all applications.

Impact on Application: Stainless steel valve locators are particularly well-suited for harsh environments, such as those found in agricultural settings with high moisture levels.

Considerations for International Buyers: Buyers should verify that the stainless steel used meets international standards, such as ASTM and JIS, to ensure compatibility with local regulations and practices.

Why is Copper Considered for Valve Locators in Irrigation Systems?

Copper is sometimes used in valve locators due to its excellent conductivity and resistance to corrosion. It is particularly effective in applications requiring electrical connections.

Pros: Copper is highly conductive, making it ideal for applications that require electrical signaling. It also has good corrosion resistance, particularly in non-acidic environments.

Cons: Copper can be more expensive than plastic and aluminum, and it is susceptible to corrosion in acidic conditions. Additionally, it is heavier than plastic and aluminum.

Impact on Application: Copper valve locators are best suited for applications where electrical conductivity is critical, such as in systems that require precise control.

Considerations for International Buyers: Buyers should be aware of the copper standards in their region, as well as any import regulations that may apply.

Summary Table of Material Selection for Valve Locators

| Material | Typical Use Case for valve locator for irrigation system | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Moderate temperature environments | Lightweight and cost-effective | Susceptible to UV degradation | Low |

| Aluminum | Portable irrigation systems | Strong and corrosion-resistant | More expensive than plastic | Medium |

| Stainless Steel | Harsh agricultural environments | Superior durability and strength | Higher cost and weight | High |

| Copper | Applications requiring electrical conductivity | Excellent conductivity | Susceptible to corrosion in acids | Medium |

This analysis provides a comprehensive overview of material selection for valve locators in irrigation systems, enabling B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for valve locator for irrigation system

What Are the Key Stages in the Manufacturing Process of Valve Locators for Irrigation Systems?

Manufacturing a valve locator for irrigation systems involves several critical stages, each ensuring the product meets the required performance and quality standards. Here’s a breakdown of the main stages:

1. Material Preparation

The first stage involves sourcing high-quality materials suitable for the functionality and durability of the valve locator. Common materials include high-grade plastics for housing, copper or aluminum for wiring, and various metals for internal components. Suppliers often provide certifications for raw materials, ensuring compliance with international quality standards. This stage also includes material testing to check for strength, conductivity, and resistance to environmental factors.

2. Forming

Once materials are prepared, the forming stage begins. This typically involves processes such as injection molding for plastic parts and stamping or machining for metal components. Advanced techniques like CNC machining may be employed for precision components, ensuring tight tolerances that are crucial for the accurate operation of the locator. The forming stage also integrates any electronic components, such as sensors and circuit boards, ensuring they are securely fitted and functional.

3. Assembly

The assembly stage is where all components come together. Skilled technicians or automated systems assemble the valve locator, ensuring that each part fits correctly and functions as intended. This stage may include soldering electronic components and testing connections to ensure there are no faults. Quality assurance checks are often incorporated at this stage, including visual inspections and initial performance testing to catch any issues early.

4. Finishing

The final stage is finishing, where the product undergoes surface treatment, painting, or coating to enhance durability and aesthetics. This stage may also include additional testing to verify that the locator meets waterproof or dustproof standards, which are critical for outdoor use in irrigation systems. Finishing touches, such as branding and packaging, are completed to prepare the product for distribution.

How Is Quality Assurance Implemented in the Manufacturing of Valve Locators?

Quality assurance (QA) is essential in the manufacturing of valve locators to ensure they meet industry standards and customer expectations. Here are the key aspects of QA in this context:

Relevant International Standards: What Should Buyers Know?

Manufacturers of valve locators often adhere to international quality standards such as ISO 9001, which focuses on quality management systems. This certification ensures that the manufacturing processes are documented, consistent, and continuously improved. Additionally, industry-specific standards such as CE marking for products sold in Europe and API standards for performance may apply. Buyers should request evidence of these certifications to validate compliance.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are critical throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified quality standards.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify defects early. This can include testing the functionality of electronic components as they are assembled.

- Final Quality Control (FQC): Once assembly is complete, the final product undergoes thorough testing, including performance, safety, and reliability tests, to ensure it operates correctly under expected conditions.

Common Testing Methods: What Are the Best Practices?

Manufacturers employ various testing methods to ensure valve locators function as intended. Common methods include:

- Functional Testing: Verifying the locator’s ability to detect and trace valves accurately.

- Environmental Testing: Assessing performance under extreme conditions, such as high humidity or temperature fluctuations.

- Durability Testing: Simulating long-term use to identify potential failures.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers must ensure their suppliers maintain rigorous quality control to mitigate risks associated with defective products. Here are practical steps buyers can take:

Audits and Reports

Buyers should conduct audits of potential suppliers to assess their manufacturing processes, quality management systems, and compliance with international standards. Requesting detailed quality reports can provide insights into the supplier’s QC procedures and historical performance.

Third-Party Inspections

Engaging third-party inspection services can offer an unbiased assessment of the manufacturing processes and product quality. These inspections can be scheduled at various stages of production, providing transparency and assurance that the products meet specified standards.

What Are the Quality Control and Certification Nuances for International Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification:

- Regional Standards Compliance: Different regions may have unique regulatory requirements. For example, CE certification is mandatory for products sold in the European Union, while different standards may apply in Africa and South America.

- Documentation and Traceability: Ensuring that suppliers provide complete documentation for materials and manufacturing processes is crucial for compliance and traceability. This is especially important when products cross international borders.

- Cultural Considerations: Understanding cultural differences in business practices can facilitate smoother communication and negotiations. This can include varying expectations around quality and compliance standards.

Conclusion: Ensuring High-Quality Valve Locators for Irrigation Systems

The manufacturing processes and quality assurance measures for valve locators are integral to delivering reliable products that meet the demands of the irrigation industry. By understanding these processes and actively engaging in quality verification, B2B buyers can make informed decisions, ensuring that they procure high-quality valve locators that will perform effectively in the field.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘valve locator for irrigation system’

To assist B2B buyers in procuring a valve locator for irrigation systems, this guide provides a practical step-by-step checklist. Each step is designed to ensure informed purchasing decisions that align with operational needs and regional considerations.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements of the valve locator needed for your irrigation systems. Consider factors such as the depth of the valves, wire type, and system voltage. This step is crucial as it helps narrow down options that meet specific operational criteria, ensuring compatibility with existing systems.

Step 2: Research Available Products

Investigate various valve locator models available in the market. Look for features such as depth measurement capabilities, signal strength, and battery life. Comparing product specifications and user reviews can provide insights into reliability and performance, enabling you to make an informed choice.

Step 3: Evaluate Potential Suppliers

Before committing, it’s essential to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This ensures that the supplier has a proven track record and can meet your specific needs. Additionally, consider suppliers that offer warranties or after-sales support.

Step 4: Check for Compliance and Certifications

Verify that the products meet international safety and quality standards relevant to your region. Certifications may include ISO, CE, or other local standards, depending on where you operate. Compliance ensures that the equipment is safe to use and built to last, minimizing the risk of operational failures.

Step 5: Assess Pricing and Payment Terms

Compare prices across different suppliers while considering the total cost of ownership, including shipping and potential customs duties. Look for flexible payment terms that can accommodate your budget and cash flow needs. This step is vital to ensure you remain within budget without compromising on quality.

Step 6: Inquire About Training and Support

Determine if the supplier provides training on how to use the valve locators effectively. Additionally, inquire about technical support availability for troubleshooting and maintenance. Adequate training and support can significantly enhance the operational efficiency of your irrigation systems, reducing downtime.

Step 7: Finalize Your Purchase and Review Terms

Once you’ve identified the right product and supplier, review all purchase terms, including return policies and warranty information. Ensure that you understand the terms of the sale to avoid any unforeseen complications post-purchase. This final step is crucial for securing a satisfactory transaction and ensuring long-term value from your investment.

By following this checklist, B2B buyers can systematically approach the procurement of valve locators for irrigation systems, ensuring they make well-informed decisions that meet their operational needs and regional requirements.

Comprehensive Cost and Pricing Analysis for valve locator for irrigation system Sourcing

What Are the Key Cost Components for Valve Locators in Irrigation Systems?

When sourcing valve locators for irrigation systems, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

Materials: The quality and type of materials used directly impact the cost. High-grade metals and durable plastics enhance the longevity and performance of valve locators but also raise production costs.

Labor: Labor costs vary significantly based on the region of production. In countries with higher labor costs, manufacturers may charge more, while those in lower-cost regions might offer competitive pricing.

Manufacturing Overhead: This encompasses expenses related to facility maintenance, utilities, and administrative costs. Efficient manufacturing processes can help mitigate these costs, ultimately affecting the final price.

Tooling: The cost of molds and tools required for manufacturing valve locators can be substantial. Custom tooling for unique specifications will increase costs, while standard tools may help keep expenses lower.

Quality Control (QC): Investing in robust QC processes ensures product reliability and compliance with international standards. However, stringent QC measures can lead to higher manufacturing costs.

Logistics: Shipping and handling costs can vary widely depending on the origin, destination, and transportation method. International shipping often incurs additional tariffs and duties that buyers need to consider.

Margin: Suppliers typically add a margin to cover their operating costs and profit. This margin can fluctuate based on market demand, competition, and the perceived value of the product.

How Do Price Influencers Affect Valve Locator Costs?

Several factors can influence the pricing of valve locators, particularly for international B2B buyers:

Volume/MOQ: Bulk purchases often lead to lower per-unit costs. Suppliers may offer discounts for larger orders, making it advantageous for buyers to consolidate their purchasing.

Specifications/Customization: Custom features or specifications can significantly increase costs. Standard models are generally more affordable, so buyers should assess whether customization is necessary for their application.

Materials: The choice of materials not only affects durability but also impacts pricing. For instance, locators made from advanced materials may command a higher price but offer greater longevity and performance.

Quality/Certifications: Products that meet international quality standards (ISO, CE, etc.) may be priced higher due to the added assurance of reliability. Buyers should weigh the importance of certifications against their budget.

Supplier Factors: The reputation and reliability of the supplier can influence price. Established suppliers with a proven track record may charge more but offer better quality and service.

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for pricing. Different terms can affect shipping costs, insurance, and liability, impacting the total cost of ownership.

What Are Effective Buyer Tips for Sourcing Valve Locators?

For B2B buyers looking to optimize their procurement of valve locators, consider these strategies:

Negotiate Wisely: Always engage in negotiation. Suppliers may have room to adjust pricing based on your order size or payment terms. Building a relationship can also lead to better deals in the future.

Focus on Cost-Efficiency: Look beyond the initial purchase price. Assess the total cost of ownership, including maintenance, operational efficiency, and replacement frequency, to ensure long-term savings.

Understand Pricing Nuances: International buyers must consider currency fluctuations, local tariffs, and shipping costs that can affect final pricing. Always request a detailed breakdown of costs to avoid surprises.

Research Suppliers: Conduct thorough research on potential suppliers. Read reviews, seek references, and compare multiple quotes to ensure you’re making an informed decision.

Conclusion

Sourcing valve locators for irrigation systems involves a complex interplay of cost components and pricing influencers. By understanding these elements and employing effective procurement strategies, international B2B buyers can secure optimal products that meet their operational needs while maximizing cost efficiency. Always keep in mind that prices may vary, and it’s essential to request quotes that reflect the most current market conditions.

Alternatives Analysis: Comparing valve locator for irrigation system With Other Solutions

Exploring Alternatives to Valve Locators for Irrigation Systems

In the irrigation industry, accurately locating valves is crucial for efficient system management and maintenance. While valve locators are designed specifically for this purpose, several alternative solutions exist that can also achieve similar results. Understanding these alternatives helps B2B buyers make informed decisions based on their specific operational needs, budget constraints, and technological preferences.

| Comparison Aspect | Valve Locator For Irrigation System | Click-It Valve Locator | Armada Tech PRO-700 Wire and Valve Locator |

|---|---|---|---|

| Performance | High accuracy in locating valves | Effective for solenoid valve detection | Tracks wiring and locates valves efficiently |

| Cost | Moderate to high ($600 – $1,200) | Low-cost option ($54.75) | Moderate rental cost ($59 for 2 days) |

| Ease of Implementation | Requires training for optimal use | User-friendly, minimal setup | Slightly complex, requires understanding of wiring |

| Maintenance | Low, durable equipment | Minimal, basic care needed | Moderate, batteries need replacement |

| Best Use Case | Large-scale irrigation systems | Small to medium systems | Contractors needing reliable tracking |

What Are the Benefits and Drawbacks of Using a Click-It Valve Locator?

The Click-It Valve Locator is a budget-friendly solution ideal for small to medium irrigation systems. It operates by interrupting power to the solenoid valve, causing it to “chatter,” which helps locate the valve. Its user-friendly design requires minimal setup, making it accessible for users with varying levels of experience. However, its performance might not be as robust for larger systems, and it may lack the depth of features found in more advanced locators.

How Does the Armada Tech PRO-700 Compare in Terms of Functionality?

The Armada Tech PRO-700 offers a more advanced option for contractors who need to track wiring and locate valves with precision. This device combines a powerful transmitter with a sensitive receiver, providing clear audio and visual signals that guide users to the target. It is lightweight and portable, making it suitable for various job sites. However, it may require a deeper understanding of electrical systems, and its rental model means ongoing costs for frequent users, which could be a consideration for budget-conscious buyers.

Conclusion: How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the appropriate valve locator or alternative solution, B2B buyers should assess their specific operational requirements, budget, and the scale of their irrigation systems. For large-scale operations requiring high accuracy and reliability, investing in a dedicated valve locator may be the best choice. Conversely, smaller operations or those with limited budgets may find that simpler options, such as the Click-It or rental solutions like the Armada Tech PRO-700, provide sufficient functionality at a lower cost. Ultimately, understanding the unique needs of your irrigation system and the capabilities of each solution is key to making an informed purchasing decision.

Essential Technical Properties and Trade Terminology for valve locator for irrigation system

What Are the Key Technical Properties of a Valve Locator for Irrigation Systems?

When selecting a valve locator for irrigation systems, understanding the technical specifications is crucial for ensuring operational efficiency and reliability. Below are several critical properties that should be considered:

Frequency Range: The frequency range indicates the operating bandwidth of the valve locator. Most locators operate between 512 Hz and 33 kHz. A wider frequency range allows for better detection of various types of underground wiring and valve configurations, making it essential for users to choose a locator that meets their specific detection needs.

Depth Detection Capability: This specification defines how deep the device can locate underground valves and wiring. High-quality locators can typically detect depths of up to 10 feet or more. Understanding this capability is vital for contractors working in areas with varying soil conditions, as deeper detection ensures that all components are accessible and maintainable.

Power Source and Battery Life: Many valve locators are powered by rechargeable batteries, while others use disposable types. Battery life can vary significantly, with some devices lasting up to 50 hours on a single charge. A longer battery life is crucial for minimizing downtime during field operations, especially in remote areas without easy access to power sources.

Transmitter Power Output: The transmitter’s power output, measured in volts, affects the locator’s range and effectiveness. Higher output (e.g., 750V peak-to-peak) ensures the signal can penetrate deeper into the ground and travel farther distances, which is particularly beneficial in large agricultural fields or complex irrigation systems.

Receiver Sensitivity: The sensitivity of the receiver dictates how well it can pick up signals from the transmitter. A more sensitive receiver can detect weaker signals, making it easier to locate valves and wiring faults. This feature is essential for minimizing the time spent searching for buried components.

Durability and Weather Resistance: Given the outdoor environments in which these tools are typically used, durability is a significant consideration. Many valve locators are designed to be weather-resistant and rugged enough to withstand harsh conditions, ensuring longevity and reliability.

What Common Trade Terminology Should B2B Buyers Understand?

In the B2B landscape, understanding industry jargon can facilitate better communication and decision-making. Here are several key terms relevant to valve locators:

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is vital for ensuring compatibility and quality when sourcing valve locators.

MOQ (Minimum Order Quantity): MOQ indicates the smallest number of units a supplier is willing to sell. This is an important consideration for buyers who need to manage inventory costs effectively while ensuring they meet project demands.

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting pricing information for specific quantities of products. This process helps buyers compare prices and terms, enabling informed purchasing decisions.

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help mitigate risks related to shipping and delivery, ensuring clarity on who bears the cost and responsibility at various stages of transport.

Lead Time: This term refers to the amount of time from placing an order to its delivery. Understanding lead times is crucial for project planning, particularly in industries where timely irrigation system installations are critical.

Calibration: Calibration refers to the process of adjusting the precision of the locator to ensure accurate readings. Regular calibration is essential for maintaining the reliability of the locator’s performance, directly impacting the efficiency of irrigation system maintenance.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring they select the right valve locators for their irrigation systems while navigating the complexities of international procurement.

Navigating Market Dynamics and Sourcing Trends in the valve locator for irrigation system Sector

What Are the Current Market Dynamics and Key Trends in the Valve Locator for Irrigation Systems?

The global market for valve locators in irrigation systems is experiencing significant growth, driven by increasing agricultural demands, efficient water management practices, and advancements in technology. Key trends include the adoption of smart irrigation solutions that integrate IoT technology, enabling remote monitoring and management of irrigation systems. This shift is particularly evident among international B2B buyers from regions like Africa, South America, the Middle East, and Europe, where water scarcity is a pressing issue. The need for efficient irrigation systems is prompting buyers to seek out advanced solutions that enhance operational efficiency and reduce water wastage.

Moreover, the trend toward rental services for specialized equipment, such as valve locators, is gaining traction. This model allows companies to access high-quality tools without the capital expenditure associated with outright purchases. As a result, many suppliers are expanding their rental offerings to cater to budget-conscious buyers in developing markets. Additionally, the rise of e-commerce platforms is making it easier for international buyers to source valve locators directly from manufacturers and suppliers, fostering a more competitive landscape.

In terms of market dynamics, fluctuating raw material prices and supply chain disruptions remain challenges for B2B buyers. However, the growing emphasis on local sourcing and manufacturing is helping to mitigate these risks, particularly in emerging markets. By leveraging local suppliers, businesses can enhance their responsiveness to market changes while supporting regional economies.

How Are Sustainability and Ethical Sourcing Influencing the Valve Locator Market?

Sustainability is becoming a cornerstone of purchasing decisions in the valve locator sector. B2B buyers are increasingly aware of the environmental impact of their supply chains, prompting them to seek out products made from sustainable materials. For valve locators, this means sourcing components that are recyclable or made from biodegradable materials. Suppliers are responding by obtaining green certifications that demonstrate their commitment to sustainable practices, which can enhance their appeal to environmentally-conscious buyers.

Additionally, ethical sourcing is gaining importance as companies strive to ensure transparency and fairness in their supply chains. Buyers are looking for suppliers who adhere to strict labor standards and environmentally friendly practices. This focus on ethical sourcing not only helps to build trust with customers but also aligns with the growing demand for corporate social responsibility (CSR) initiatives across various sectors.

As a result, suppliers of valve locators are increasingly adopting sustainable practices, such as reducing carbon footprints in manufacturing and logistics. This trend is particularly relevant in regions like Africa and South America, where environmental regulations are evolving. By prioritizing sustainability and ethical sourcing, B2B buyers can not only meet regulatory requirements but also appeal to a broader customer base that values corporate responsibility.

What Is the Historical Context of Valve Locators in Irrigation Systems?

The evolution of valve locators for irrigation systems can be traced back to the increasing complexity of agricultural irrigation networks. Initially, these tools were rudimentary, relying on basic electromagnetic principles to locate buried valves. However, as irrigation technology advanced, so did the sophistication of valve locators.

In the late 20th century, innovations such as digital signal processing and enhanced frequency detection were introduced, leading to more accurate and efficient locating capabilities. This evolution was driven by the growing need for precision in irrigation management, particularly in regions facing water scarcity.

Today, valve locators are equipped with advanced features, including smart technology that allows for real-time tracking and integration with irrigation management systems. This historical progression reflects the broader trends in agriculture toward efficiency and sustainability, setting the stage for continued innovation in the sector. For international B2B buyers, understanding this evolution can inform purchasing decisions and highlight the importance of investing in cutting-edge technology that meets modern agricultural demands.

Frequently Asked Questions (FAQs) for B2B Buyers of valve locator for irrigation system

How do I solve issues with locating buried irrigation valves?

To effectively locate buried irrigation valves, consider using advanced valve locators that employ both visual and auditory signals to identify valve positions. Devices such as the TEMPO Wire and Valve Locator or the Armada Tech Pro series are designed to trace wiring paths and detect faults. Ensure the locator is compatible with your irrigation system’s voltage levels. For best results, follow the manufacturer’s instructions for setup and operation, and conduct a thorough test in a controlled environment before deploying it in the field.What is the best valve locator for irrigation systems?

The best valve locator for irrigation systems depends on your specific needs, including the size of the area and the complexity of the irrigation setup. Popular models like the TEMPO 521A and Armada Tech Pro-700 offer robust features such as long-range detection and depth tracking. For smaller systems, a simpler device like the Click-It Valve Locator may suffice. Assess your operational requirements, including ease of use, battery life, and range, to determine the most suitable option.What are the key features to look for in a valve locator?

When selecting a valve locator, key features to consider include detection range, depth measurement capabilities, battery life, and user interface. Look for devices that provide both audible and visual signals for ease of tracking. Additionally, assess the durability and weight of the equipment, especially if it will be used in rugged environments. Compatibility with various irrigation systems is also crucial to ensure seamless integration.What are common payment terms when sourcing valve locators internationally?

Payment terms for international sourcing of valve locators typically include options such as advance payment, letter of credit, or payment upon delivery. Many suppliers may require a deposit upfront, especially for large orders or customized products. It’s essential to clarify terms like currency, payment method, and any potential fees associated with international transactions. Engaging with a reputable supplier can help mitigate risks and facilitate smoother financial dealings.How can I vet suppliers for valve locators?

To vet suppliers for valve locators, start by researching their reputation in the industry. Check for customer reviews, case studies, and testimonials to gauge reliability. Request references and inquire about their experience with international buyers. Verify their certifications and compliance with industry standards. Additionally, consider visiting their manufacturing facilities or arranging virtual meetings to discuss product quality and support services.What is the minimum order quantity (MOQ) for valve locators?

Minimum order quantities (MOQ) for valve locators can vary significantly by supplier and product type. Many manufacturers set MOQs to ensure cost-effectiveness in production and shipping. Common MOQs may range from 10 to 50 units, depending on the complexity and customization of the product. Always confirm the MOQ with your supplier, as some may offer flexibility or tiered pricing based on order size.Can I customize valve locators for specific irrigation systems?

Yes, many suppliers offer customization options for valve locators to ensure compatibility with specific irrigation systems. Customization may include adjusting voltage settings, adding unique features, or branding with your company logo. Discuss your requirements with the supplier early in the process to understand the feasibility and any additional costs associated with custom designs.What logistics considerations should I keep in mind when importing valve locators?

When importing valve locators, logistics considerations include shipping methods, customs duties, and delivery timelines. Choose a reliable freight forwarder familiar with your destination country’s regulations. Calculate total landed costs, including shipping, insurance, and taxes, to avoid unexpected expenses. Additionally, ensure that your supplier provides proper documentation to facilitate smooth customs clearance, which can help prevent delays in receiving your order.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Valve Locator For Irrigation System Manufacturers & Suppliers List

1. Reddit – Best Valve Locator

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Best valve locator. No AC interference (unlike the pro800). 1 of many tools needed to troubleshoot wire problems.

2. Irrigation Outlet – Voltage Interruption Device

Domain: irrigationoutlet.com

Registered: 2012 (13 years)

Introduction: This company, Irrigation Outlet – Voltage Interruption Device, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Facebook – Best Sprinkler Valve Locator

4. Armada – Pro800D Wire and Irrigation Valve Locator

Domain: testersandtools.com

Registered: 2004 (21 years)

Introduction: Armada Pro800D is a wire and irrigation valve locator designed to track irrigation wires, find missing valves, and detect damage to underground cabling. Key features include: 20% more transmitter power than its predecessor Pro700, Peak tracing mode, wireless Broadcast mode, excellent AC hum blocking, audio and visual signal indicators, powered by 8 “D” cell batteries. It can find and trace buried …

5. Sprinkler Supply Store – Sprinkler Valves

Domain: sprinklersupplystore.com

Registered: 2010 (15 years)

Introduction: Sprinkler valves are typically made of plastic for residential and most commercial applications, while metal is used for heavy-duty sites like golf courses and municipal pumping stations. They can be grouped in manifolds or installed individually and should always be buried inside a plastic irrigation valve box, with a minimum size of 10-inch round recommended for single valves. Valves operate ele…

6. Armada – Pro700 TechTracker

Domain: school.sprinklerwarehouse.com

Registered: 1999 (26 years)

Introduction: Armada Pro700 TechTracker Wire and Valve locator; consists of a transmitter, a receiver, two lead wires, and a grounding stake; accurately locates irrigation valves by tracing wires from the controller to the valve location; transmits a beeping signal along the wire to find lost valves without damaging the lawn or garden.

Strategic Sourcing Conclusion and Outlook for valve locator for irrigation system

What Are the Key Takeaways for B2B Buyers of Valve Locators in Irrigation Systems?

In conclusion, strategic sourcing of valve locators for irrigation systems presents significant advantages for B2B buyers across diverse markets, including Africa, South America, the Middle East, and Europe. Understanding the product range—from sophisticated wire locators like the Armada Pro-700 to simpler devices like the Click-It Valve Locator—enables buyers to make informed decisions tailored to their operational needs. The ability to locate and manage irrigation valves efficiently not only enhances system reliability but also promotes sustainability by optimizing water usage.

How Can Strategic Sourcing Enhance Your Irrigation Operations?

Investing in the right valve locator technology streamlines maintenance processes, reduces downtime, and ultimately leads to cost savings. By fostering relationships with reputable suppliers and leveraging competitive pricing strategies, businesses can ensure they are equipped with the best tools for efficient irrigation management.

What Does the Future Hold for Valve Locator Technologies?

Looking ahead, the demand for advanced irrigation solutions will continue to grow, driven by increasing agricultural needs and environmental considerations. International B2B buyers are encouraged to embrace innovative sourcing strategies and explore partnerships that enhance their operational capabilities. By staying ahead of technological advancements and market trends, businesses can position themselves for success in an evolving landscape.